Escolar Documentos

Profissional Documentos

Cultura Documentos

000 Indice API

Enviado por

Joel Pacheco Diaz0 notas0% acharam este documento útil (0 voto)

114 visualizações6 páginasTodos los API

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

XLS, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoTodos los API

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

114 visualizações6 páginas000 Indice API

Enviado por

Joel Pacheco DiazTodos los API

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato XLS, PDF, TXT ou leia online no Scribd

Você está na página 1de 6

NORMAS API American Petroleum Institute

Item Designacin Ttulo Alcance Hipervnculo

API RECOMMENDED PRACTICE 5A3 Recommended Practice on 1 Scope

1 FIRST EDITION, JUNE 1996 Thread Compounds for Casing, 1.1 PURPOSE API 5A3-1996

EFFECTIVE DATE: OCTOBER 1, 1996 Tubing, and Line Pipe The purpose of this recommended

API SPECIFICATION STANDARD 5B practice is to provide

Specification for Threading, 1 Scopefor2.2

means REQUIREMENTS

evaluating the suitability of

FOURTEENTH EDITION, AUGUST Gauging, and Thread Inspection 1.1 COVERAGE

2 1996 thread compounds, regardless API 5B-1996

of Casing, Tubing, and Line Pipe This specification

of composition, for usecovers on API dimensioannsd

round

EFFECTIVE DATE: DECEMBER Threads (U.S. Customary Units) marking requirements

1,1996 thread and buttress

for API Master thread gauges. Additional

casing,

Recommended Practice for 1 Scopetubing and line pipe connections

API RECOMMENDED PRACTICE 5L1 product

in

3 Railroad Transportation of 1.1 GENERAL API 5L1-2002

SIXTH EDITION, JULY 2002 threads

high-pressure and thread service.gauges The tests asoutlined

well as

Line Pipe The recommendations provided herein

instruments

herein are usedand to methods

apply to the transportation

Recommended Practice for for

1 the inspection

Scope

evaluate the ofperformance

threads for line pipe,

Exploration and Production Department on railcars ofcritical

API Specification 5L steel

Conducting Drop-Weight round

1.1 These

properties thread procedures describe a

API RECOMMENDED PRACTICE 5L3 line pipe inof thread compounds

Tear Tests on Line Pipe casing,

recommended buttressmethod casing, andWhen extreme line

4

THIRD EDITION, FEBRUARY 1996

under

sizes 23/8 laboratory and larger conditions.inforlengths longer API 5L3-1996

casing

conducting

evaluating connectionsdrop-weight tear tests to

EFFECTIVE DATE: APRIL 1,1996 that single the random.

are

measure included.

suitability the

of afracture It is applicable

thread appearancewhen

compound, so

The recommendations of Sectionthe 4 user

stipulated

or fracture

should considerinductility

the APIof tine pipe as

Specification for concerned

Scope with load

standard

referenced governing

API testthe product. The

5

API SPECIFICATION 5L Line Pipe

full size connection

stresses

1.1 This areinexclusively

specification

results

covers applicable and to

seamless

field

API API 5L-1995

FORTY-FIRST EDITION, APRIL 1, 1995 inspection procedures

Specification

experience in 5L, Specification

addition fur Line

line

and pipe

welded having steel of taper, lead, height,

for

Pipe.

to themeasurements

results of reduced scale (bench top)

diameter

fine pipe. to thickness

Itconversions

includes (D/t) ratios of 50and or

Specification for and

1.2

test

1 Scopeangle

Metric

methods of thread standard-weight of US customary

more.

extra-strong However,

API SPECIFICATION 5L Line Pipe are

units

ike

1.1 applicable

are shown

those

PURPOSE described to

AND threads

herein.

COVERAGE having 1 11/2 or

pipe

threaded with D/t ratios well below 50 may

FORTY-SECOND EDITION, JANUARY less

in

The turnsLine

parenthesis

purpose perofinch. pipe;

in the

this

and

test, standard-weight

specificationfigures, isand

to

6 suffer fatigue

plain-end, in transit

regularweight API 5L-2000

2000 Requirements

tables.

provide See

standards Appendixof other

for standards included

under

plain-end, some circumstances, as noted in

EFFECTIVE DATE: JULY 1, 2000 byfor

B

pipe metricspecial

reference

suitable in

conversion

for use

plain-end,

in factors.

conveying

extra-strong

gas,

the foreword.

plain-end,

this

water,specification

and oil in both are essential to the

These

and recommendations

double-extra-strong cover coated

plain-end pipe;or

API RECOMMENDED PRACTICE 5LW Recommended Practice for safety

1

theSCOPE and

oil andpipe, interchangeability

natural gas industries.

uncoated

as well as but

bell andproduced.

Transportation of Line Pipe on of

The thee quipment

7 SECOND EDITION, DECEMBER 1996 they recommendations

This

spigot specification

doand notthrough-the-flowline

encompass covers inloading

this document

seamless and

practices API 5LW-1996

EFFECTIVE DATE, MARCH 1, 1997 Barges and Marine Vessels 2.3

apply

welded EQUIVALENT

tosteeltransportation

line STANDARDS4TFL)

designed

pipe. to protect

Other

of API

pipe. nationally

ItSpecification

includes 5Lor

plain-end, internationally

steelthreaded-end,

fine pipe by

Standard on pipe

1

TheScope coating

purpose from

of this damage.

specification is to

API STANDARD 5T1 recognized

ship

and or barge

belled-end standards pipe,

8 Imperfection Terminology 1.2 BASIC

The

provide purpose RULES

standards of thisAND standard is to provide API 5T1-1996

TENTH EDITION, NOVEMBER 1996 shall

on

as both

well beas submitted

inland and marine

through-the-flowline to andwaterways approved

(TFL) pipe by

REQUIREMENTS

definitions

for pipe of

suitable for use in conveying gas,

API for

unless

and pipe inclusion

the withspecific in

Certain

water,

imperfections andminimum oilofin and mandatory

defects rules

API SPECIFICATION 6D Specification for Pipeline Valves this

1.1

ends specification

requirement

Coverage.

prepared a

This prior

forparagraph

use tothat

specification

with special

occur

intheir

this use

covers

in as

governing

steel

both pipe;

the oil the

noand loading

criteria

natural gas industries.

9 TWENTY-FIRST EDITION, MARCH (Gate, Ball, and Check Valves) equivalent

document

couplings.

flanged and standards.

references only API 6D-1994

practices

as

1.2 toDimensional

severity are prescribed

arerequirements

addressed. by the The word

on threads

1994 3 Definitions

marine

butt-welding

Although orthe only gate, inland

plain-end plug, waterway

ball,

line andtransport.

pipe check

meeting

Association

impegection

and thread of

as American

used Railroads

All

Inland

valves.

this threadwaterways

specification dimensions shown without

Specification for (AAR)

gauges,

herein

1 Scope as

refers referenced

stipulations

tothose in the

metallurgical

on gauging nextandsection.

practice,

other

tolerances

are

1.2

is defined

Codes,

primarily areas

Specifications,

intended waterways

for field and with

Standards.

makeup by

The

featuresrecommendations

of this given herein to are

API SPECIFICATION 6FA Fire Test for Valves gauge

It is the

related

various

circumferential

Each to steel

specifications

purpose

degrees the of pipe

of basifso document

protection, r connection

10 supplementary

products,

and certification,

establish, which

theare tomay

as the

requirements or

well may

as not be

instruments API 6FA-1999

THIRD EDITION, APRIL 1999 designa

such

code,

welding, as nd

rivers,

specification,

the notorsubject

canals,

manufacturer will 3.1

intracoastal

standard Shall is

not assume

AAR

injurious

and

for loading

methods

testing toand the practices.

use of

evaluating theIf any

the pressure- is

used

waterways,

referenced

responsibilityto indicate

and

hereinfor that

shall a provision

recommendations

for

product.

inspection

containing Definition ofThese

performance are

threads in are

conflict

of injuriousness givencan in

is API

mandatory.

sheltered

be the latest bays. edition or waterways

supplement be

field

with

outside

Standard

of API

welding.

AAR 6A the loading

5B

and scope

and 6Dto practices,

of

valves when those exposedofinAAR to

to

1.2 measurement

fresh

effect or

PRODUCT

at salt

the water

time determine

SPECIFICATION acceptance

LEVEL

shall

this

are

fire. govern.

document.

applicable

Theusuallyofto Defects

products arecovered

defined byin the

this

or

but

of rejection

are

manufacture

(PSL) 3.2

traversed

of the Should by

product. is used

barges. to

Note:

respective If thepipe

specification.

performance AAR loading rules

requirements of are not

this

indicate

Marine

1.3

This that

waterways

Definitions.

specification a provision

are

establishes is not

applicable

Grades

standards. coveredto the railroad

by thisover specification

document

product.

defined

Bidirectional

requirements

transportation as are

mandatory,

waterwaysintended

Valve:

for

of two

fine Abut valve

to

product

pipe

recommendeda

open

designed

indefinitions seasare

the country for ofs

It should

A25,

establish

good A, B,

practice.be X42,noted

standard that

limits the of acceptability are

with

origin, limited

specification

sealing in or no

levels protection

(PSL 1 and PSL 2).

Pgina 1 de 6 X52,

listed

X46, inthe basic

English,

X56, X60, loading X65, X70, and X80

NORMAS API American Petroleum Institute

Item Designacin Ttulo Alcance Hipervnculo

API SPECIFICATION 6FB API Specification for Fire Test for

1 Scope

THIRD EDITION, MAY 1998 End Connections 1.1 PURPOSE

11 This specification was formulated to API 6FB-1998

EFFECTIVE DATE: NOVEMBER 30,

1998 establish procedures

for testing and evaluating the pressure-

Specification for Fire Test for 1 Scope performance

containing

SPECIFICATION 6FC Valves With Automatic Backseats It

ofisAPItheend purpose connections of this document

when exposed to to

12 establish the requirements API 6FC-1999

THIRD EDITION, APRIL 1999 fire. Valves,

for testingseals,

wellhead and evaluating

or other related the pressure-

containing

equipment, performance

are not included

Specification for 1

of Scope

API scopeSpec 6A anddocument.

Spec 6D Automatic

Fire Test for Check Valves in

It the

is the purpose of this of this document The

13

API SPECIFICATION 6FD Backseating

procedures valves

are when

presented exposedtoto fire. API 6FD-1995

FIRST EDITION, FEBRUARY 15, 1995 establish

The performance the requirements

in

for two

testingparts. andofevaluating the pressure

requirements

Part I represents this document

conditions in an areonshore

containing

intended to establish standard

API SPECIFICATION 6H Specification on End Closures, 1

or Scope

open

performance offshore of API Spec 6A andof6D

Connectors and Swivels limits

This of acceptability

specication regardless size or

14

SECOND EDITION, MAY 1,1998 location.

check

pressure valves rating. whencovers exposed the following:

API 6H-1998

EFFECTIVE DATE: NOVEMBER 1, a.

Part

to Pipeline

II

fire. represents closures.

The performance conditions in an

requirements of

1998 This

b. document

Connectors.

offshore platform establishes

well bay. acceptable

this

levels document

for leakage

c.

are Couplings.

Background

intended information

to establish on fire-resistance

standard limits

Recommended Practice 1

d. General

through

Misalignmenttheconnections

test valve

devices and also external

(swivels).

of

of API end

acceptability

API RECOMMENDED PRACTICE 17B for Flexible Pipe 1.1

is

SCOPE

leakage

e. Split

contained afterinexposure

mechanical ttings.

APIorBulletin 6F1. Further

15 regardless

This recommended of size pressure

practice rating.

provides API 17B-2002

THIRD EDITION, MARCH 2002 to

Thisa fire for

specication

background a 30-minute does timeapply

not period, to both

This

before document

guidelines and for

after establishes

the or acceptable

welded,

on

levels anged,

fire-resistance

ofanalysis,

leakage improvements of API

design,

reworking

threaded the stuffing

ttings manufacture,

that box.specied

are testing,in

Sizing, Selection, and Installation flanges

1.1 Scope

through is

the test operation

valve and established

also external

installation,

The burn and

period has been

Of Pressure- Relieving Devices in other

contained

This

leakage recognized

recommended

afterin API exposure standards.

Bulletin

practice 6F2.applies to on the

of

the flexible

basis that

Appendices pipes itandand

A30-minute B flexible

provide pipe systems

API RECOMMENDED PRACTICE 520 Refi neries 1.2

sizing

to a APPLICATIONS

fire and for selection

a time period.

16 for onshore,

represents

recommended the purchaser

maximum timeSpec required to API 520-1993

SIXTH EDITION, MARCH 1993 API RP*520 PT*I 93 - 0732290 This

of

The specification

pressure

burn relief

period covers

beenAPI

devices

has used in This

established 6A end

on

subsea,

extinguish

guidelines and most

to marine

assist applications.

the purchaser in

0511140 916 connections,

refineries

the basis and itrelated

that

recommended

fires.

decisions Fires practice

of greater

which are duration are

Part 1-Sizing and Selection which

industries

represents include: for

the equipment

maximum that

timehas a [i] and

required to

supplements

considered

optional to to

the API

be Specification

of

purchasera major 175

a. API Flanged

maximum

extinguish allowable

most End and Outlet assuring

and in

API

that Specification

magnitude

adequate with consequences

information greater

Flanged Steel Pressure Connections

1.1

fires.Scope

working Fires pressureof (6B,

greater 6BX,

of 15 and are

pounds

duration per

17K

than

is [2],

those

communicatedwhich specifies

anticipated to the minimum

manufacturer.

API STANDARD 526 Relief Valves Segmented).

This

square standard

considered inch is

gauge

to be aofpurchase

or

a major specification

requirements

in for the

17

FOURTH EDITION, JUNE 1995 b. this

for API

flanged

greater.

magnitude

test.

Threaded

Thewith steel

pressure End and

consequencesreliefOutlet

devicesgreater

API 526-1995

design, material selection, manufacture,

Connections.

pressure

covered

than those inrelief

this valves.

recommended

anticipated Basic requirements

testing, marking, and

c. this

are Other

given

practice

in test.End

are forintended

Connections to and (OECs).

protect unfired

Seat Tightness of Pressure packaging

This standard of unbonded

describes methodsbonded

direct

pressure spring-loaded

vessels pressure reliefofvalves

API STANDARD 527 Relief Valves flexible pipesthe

determining respectively

seat

18 and pilot-operated

related equipment against API 527-1991

THIRD EDITION, JULY 1991 [3].

tightness of metal- andassoft-seated

pressure relieffrom

overpressure valves follows:

In general,

pressure flexible

relief valves, pipeincluding

is a custom-built

a. Orifice

operating designation

and fire and area.

contingencies.

product

those of that can

conventional, bellows, and pilot-

User Acceptance of b.

This

1 Valve

Scope size

recommended and pressure practicerating,includes inlet

be designed

operated designs.and manufactured in a

API RECOMMENDED PRACTICE 591 Refinery Valves and outlet.

basic

This definitions

recommended andItpractice describes

19 variety

The of methods.

maximum acceptable is leakage rates API 591-1998

SECOND EDITION, FEBRUARY 1998 c. Materials.

information

actions a about

purchaser the operational

not the

are defined intent for ofpressure

this document to

d.

can Pressure-temperature

characteristics

take to novel

procure andorapplications

new limits. that are

valves

discourage

relief valves with set new

pressures fromand 15

e. various

of Center-to-face

required to pressure

be in dimensions,

relief devices. inlet It also

developments

pounds per square in flexible pipe. On the

outlet.

includes

accordance sizing with the standards listedtoin

contrary,

inch gauge it is(103recognized

kilopascals gauge)

For the

procedures

Section convenience

2, but and the methods of the

purchaser purchaser,

based on a of a

that a pounds

6,000 variety ofper designs

square and methods

sample

steady

may find specification

statethat ofthe flowsuggested actions also

analysis

inch gauge are(41,379 kilopascals gauge). If

sheet

and

apply

Pgina 2 de is given

6 Newtonian

to influids.

Appendix A.

possible. For this reason, some topics are

NORMAS API American Petroleum Institute

Item Designacin Ttulo Alcance Hipervnculo

Check Valves: 1 General

API STANDARD 594 Wafer, Wafer-Lug, and 1.1 SCOPE

20 Double Flanged Type This standard covers design, material, API 594-1997

FIFTH EDITION, NOVEMBER 1997

face-to-face dimensions,

pressure-temperature ratings, and

Metal Plug Valves-Flanged 1.1 Scope inspection,

examination,

API STANDARD 599 and Welding Ends 1.1.1

and test This standard covers

requirements for graymetal iron,plug

21 valves with flanged API 599-1994

FOURTH EDITION, NOVEMBER 1994 ductile iron, steel,

or

and butt-welding

alloy singleends and dual and ductile

plate check iron plug

valves

valves. with

Valve configurations

Steel Gate Valves Flanged and 1.1

flanged Scope ends inwafer-lug,sizes NPS 1 through NPS

API STANDARD 600 Butt-Welding Ends, Bolted and include

1.1.1 Thiswafer,

standard covers and double

steel gate

22 24,

flanged which typecorrespond

with API 600-1997

TENTH EDITION, FEBRUARY 1997 Pressure Seal Bonnets valves

to nominal withpipe flanged sizes orin ASME B36.10M.

facings

butt-welding that will ends permit

in installation

sizes NPS 1 through

Valve

between ASME and MSS

NPS

bodies 24. These

conforming to ASME B 16.34 may

API Standard 600, Eleventh Edition Bolted Bonnet Steel Gate Valves 1

sizesScope

flanges that conform

correspond to the standards

to nominal pipe sizesand in

October 2001 for Petroleum and Natural Gas have

This one flanged

International

specifications listed Standard specifies the

23 ASME

end and B36.1OM.

one butt-welding end. API 600-2001

ISO 10434: 1998 Industries requirements

in

1.1.2section

This 2. for a heavy

standard covers duty

valvesseries in of

ANSI/API Std 600-2001 1.1.2

bolted This

bonnet standardsteel covers

gate additional

valves for

Classes

requirements 150 throughfor and related

petroleum

2500 refinery

as specified in otherwise

ASME B 16.34.

Compact Steel Gate Valves 1

plug Scope

valves

applications that

where are corrosion, in full and

erosion

API STANDARD 602 Flanged, Threaded, Welding, and 1.1.3

1.1

conformanceThis standard

to the covers requirements

24 other

for service conditions indicate a need

a standard

heavy-duty API 602-1998

SEVENTH EDITION, OCTOBER 1998 Extended-Body Ends This

requirements

for fullofport covers

of

openings, ASMEflanged-end,

B16.34

heavy wall forsections

style

threaded-end,

Standard bolted

Class bonnet

150 gate valves for

and

petroleumextra large

refinery stem and diameters.

socket-welding-end,

through 2500 or ASME andB16.42

butt-welding-end

for Class

Corrosion-Resistant, Bolted 1 Scope steel gate where corrosion,

related

150 andapplications

compact 300.

API STANDARD 603 Bonnet Gate ValvesFlanged and 1.1

erosion, and otherextended-body

valves, including Service type,

25 Butt-Welding Ends This standard covers corrosion-resistant API 603-2001

SIXTH EDITION, MAY 2001 conditions

corresponding indicate a need

to nominal for fui] port

bolted

openings,

pipe sizes bonnet heavy

in ASME B36.10M or ASME

gate

body

B36.19M valves

wall aswith

sections,

follows:anged

and large or butt-weld

stem

Fire Test for Soft-Seated 1.1

ends Scope

in sizes NPS

diameters.

a) flanged-end Covered and are

butt-welding-end in

API STANDARD 607 Quarter-Turn Valves 1.1.1

1 This standard covers the

26 requirements

sizes NPS 4 for outside screw-and-yoke

and API 607-1993

FOURTH EDITION, MAY 1993 requirements

/(OS&Y) for testing and

smaller, b) valves

threaded-end andofsocket-

evaluating

2 the performance

with rising stems,

welding-end in sizes nonrising handwheels,

straightway,

through soft-seated quarter-

Metal Ball Valves-Flanged, and

turn 2 24, when

NPSvarious

valves

corresponding

types of to nominal

they are exposed to

API STANDARD 608 Threaded, and Welding Ends pipe

gate sizes in ASME

configurations. In addition, Appendix

1

certain fireand conditions

27 SECOND EDITION, SEPTEMBER B36.10M,

A of this standard Classes 150, 300, and, API 608-1995

/defined in this standard. The procedures

1995 600,

covers as specied

requirements in specifically for

2

described in

ASME

pressure

and B16.34.

smaller, sea]and bonnet

c) gate seal bonnet

bellows

Butterfly Valves: this standard apply to all classes and

1 Scope

1.2

valves

types for both a heavy-duty style and a

in

API STANDARD 609 Double Flanged, Lug- and siozfe

1.1

This This ssstandard

standarduch valves covers coversthat design, for

requirements

general

sizes NPS purpose

2 materials

and style

smaller. The

28

FIFTH EDITION, MAY 1997 Wafer-Type are made

materials,

corrosion of

face-to-face

resistant listed in following

ASME B API 609-1997

for applications

valves are specifically where less arduous

16.34.

dimensions;

gate valves pressure-temperature

for use in process

corrosion

covered byand this erosion

standard: Service piping

Note:

ratings; Throughout

applications.andare this standard the term

examination,

Covered

conditions

a. Class confronted

800 capitalized

valve with threaded, or materials are

class (either

inspection, or not) socket-

are soand

requirements

selected

welding, or as test

buttwelding forrequirements

outside-screw-and- for gray

means

iron,

yoke pressure

ductile

(OS&Y) iron, class as defined in

to ameliorate

ends; an these conditions.

inside screw with rising stem

ASME

bronze, B 16.34.

steel,

valves with

1.1.4 Figure

(ISRS) 1 nickel-base

rising

andperformance

alloy,

boltedorbonnet

stems, anon-rising

illustrates special

hand-

1.1.2

alloy

wheels, The

butterfly

bolted bonnets, requirements

gate

threadedvalve for

packing the nut or an outside screw

presented

valves

and thatinestablishing

this document

provide oftight shutoffi n the

and various

purposeyokeof

establish (OS&Y)types

standard

gate

limits

congurations.

standard

of acceptability.

Pgina 3 declosed

1.3

nomenclatureposition

6 rising stem and

forandvalveare parts.

with bolted packing-gland

NORMAS API American Petroleum Institute

Item Designacin Ttulo Alcance Hipervnculo

Centrifugal Pumps for Petroleum, 1.1 Scope

API STANDARD 61O Heavy Duty Chemical, and 1.1.1 This standard covers the minimum

29 Gas Industry Services requirements for API 610-1995

EIGHTH EDITION, AUGUST 1995

centrifugal pumps, including pumps

running in reverse as

Design and Construction of Large, hydraulic power recovery turbines, for use

Welded, Low-Pressure Storage Tanks in petroleum,

30 API STANDARD 620 API 620-2002

heavy duty chemical, and gas industry

services.

Welded Steel Tanks for Note: A bullet (o) at the beginning of a

1.1 General

API STANDARD 650 Oil Storage paragraph

1.1.1 indicates covers

This standard that either a

material,

NINTH EDITION, JULY 1993 decision or further information is required.

design, fabrication,

31 ADDENDUM 1, DECEMBER 1994 Further

erection,information

and testingshould be

requirements for API 650-1996

ADDENDUM 2, DECEMBER 1995 shown on

vertical, the data sheet(ss ee Appendix

cylindrical,

ADDENDUM 3, DECEMBER 1996 B) or stated in closed-

aboveground, the quotation request

and open-top,

and purchase

welded order.

steel storage

Welded Steel Tanks for 1 Scope

tanks in various sizes and capacities for

API STANDARD 650 oil Storage 1.1 GENERAL

internal pressures

32 1.1.1 This standard covers material, API 650-1998

TENTH EDITION, NOVEMBER 1998 approximating atmospheric pressure

design,

(internalfabrication,

pressures not

erection,

exceedingand thetesting

weightrequirements for

of the roof plates),

Welded Steel Tanks for 1 Scope cylindrical,

vertical,

API STANDARD 650 but a higher internal

Oil Storage 1.1 GENERALclosed- and open-top,

aboveground,

33 TENTH EDITION, NOVEMBER 1998 pressure is permitted when additional API 650-2000

1.1.1

welded This

steelstandard

storage covers material,

ADDENDUM 1, MARCH 2000 requirements are met

design,

tanks in fabrication,

various

(see 1.1.8). Thissizes and applies

standard capacities

onlyforto

erection,

internal and testing requirements for

pressures

API STANDARD 650 Welded Steel Tanks for tanks

1 Scope whose entire

vertical,

approximatingcylindrical,

atmospheric pressure

TENTH EDITION, NOVEMBER 1998 Oil Storage bottom

1.1 is uniformly

GENERAL supported and to

34 aboveground,

(internal closed-

pressures notand open-top, API 650-2001

ADDENDUM 1, JANUARY 2000 tanks in nonrefrigerated

1.1.1

welded

exceeding steel storage

service

This thatthe

standard haveweight of the roof

a maximum

covers plates),

operating

ADDENDUM 2, NOVEMBER 2001 tanks

but a in various

higher sizes material,

internal

design,

and capacities for

temperature

fabrication, of

Welded Steel Tanks for internal

1 Scope

pressure pressures

is permitted when additional

200F (see

erection, and1.1.15).

testing requirements for

API STANDARD 650 Oil Storage approximating

1.1 GENERAL

requirements atmospheric

are met pressure

vertical,

(internal cylindrical,

TENTH EDITION, NOVEMBER 1998 1.1.1

(see Thispressures

1.1.10).

aboveground, standard

This not

covers

standard

closed- and material,

applies only to

35 ADDENDUM 1, JANUARY 2000 exceeding

design,

tanks whose the weighotf

fabrication,

entire theopen-top,

roof plates), API 650-2003

ADDENDUM 2, NOVEMBER 2001 welded

but steel

a higher storage

internal

erection,

bottom

tanks and

inisvarioustesting

uniformly requirements

supported

sizes and to

and capacities for

ADDENDUM 3, SEPTEMBER 2003 pressure

vertical, is permitted

cylindrical,

tanks in pressures

nonrefrigerated when additionalfor

internal

requirements are met

aboveground,

service that have

approximating closed- and open-top,

a maximum

atmospheric operating

pressure

Tank Inspection, Repair, Alteration, (see

1 1.1.10).

Scope

welded

temperaturesteel This

storage

of standard applies

90C only

(internal

ttaon ks pressures

whose not

entire

API STANDARD 653 and Reconstruction 1.1

tanks INTRODUCTION

in

(200F) (see

exceeding various sizes

the1.1.17).

weight and capacities

of the roof for

plates),

36 bottom

1.1.1

internal is uniformly

pressures supported and t aton API 653-2001

THIRD EDITION, DECEMBER 2001 but

ks

Thisinastandard

higher internal

nonrefrigerated

approximating covers carbon

atmospheric and low alloy

pressure

service is permitted

that have a not when pressure

maximum additional

operating

steel tanks

(internal

requirements pressures

are met

temperature

built to

exceeding API theofweight

90C 650

Standard of and

the its plates),

roof

(see

(200F)1.1.10). This standard applies

(seeinternal

1.1.17). only to

predecessor

but a higher

tanks whose entire API 12C. This

standard

pressure

bottom is is provides

permitted

uniformly minimum requirements

when additional

supported and to

for maintaining

requirements arethe

tanks in nonrefrigerated met

integrity

(see

service of welded

1.1.10).

that have or riveted,

This astandard

maximum applies only to

operating

nonrefrigerated,

tanks

Pgina 4 de 6 whose

temperature atmospheric

entire

of 90C

NORMAS API American Petroleum Institute

Item Designacin Ttulo Alcance Hipervnculo

Quality Improvement Manual for 1.1 Scope

API RECOMMENDED PRACTICE 683 Mechanical Equipment in This recommended practice provides

37 Petroleum, Chemical, and Gas guidelines for improving API 683-1993

FIRST EDITION, SEPTEMBER 1993

Industries the quality of mechanical equipment. It is

intended

Welding of Pipelines and 1

toGeneral

mutually benefit users, contractors, and

API STANDARD 1104 Related Facilities 1.1 SCOPE

38 NINETEENTH EDITION, SEPTEMBER suppliers and facilitate API 1104-1999

This standard

improved covers the

relationships gas andthem

between arc by

1999 welding of butt, fillet,

promoting

and

trust, socket

teamwork, weldsand in carbon

communication. and low-alloy It is

Pipeline Maintenance 1.1

steel Scope

piping 1.3used Equipment

in

API RECOMMENDED PRACTICE 1107 Welding Practices not intended

This recommended to determine practice covers

39 the compression,

certification to or pumping, and

compliance with a API 1107-1991

THIRD EDITION, APRIL 1991 recommended

transmission of maintenance

crude petroleum.

particular

welding quality

practices thatfuel may be used when

petroleum products,

system specification. gases, carbon

making

dioxide, repairs

and

Pressure Testingo f Liquid 1

A

to Scope

three-part

or installing approach

appurtenances for improving oncovers

pipingthe

API RECOMMENDED PRACTICE 11 nitrogen

Petroleum Pipelines This

quality

systems ofand,

recommended

mechanical

which

where applicable,

practice covers the

40 10 welding

pressure on distribution

testing ofin service API 1110-1997

equipment

are or have isbeendescribed in this in the

FOURTH EDITION, MARCH 1997 systems.

new and It applies

existing to both

liquid new

petroleum

recommended

compression, practice,

pumping, and

construction

pipelines.

consisting Itofrecommendsand

(a) in-service

the traditional methods

Installation of Underground transmission

1.1 General

welding.The of crude

welding maypetroleum,

minimum

used

petroleumto helpprocedures

products, andto bebefollowed,done by a

API RECOMMENDED PRACTICE 1615 Petroleum Storage Systems 1.1.1

shielded

suggests Petroleum

metal-arc

equipment product releases from

toapplicable,

41 assure

fuel gases quality;

and, (b)

where techniques that whencan be API 1615-1996

FIFTH EDITION, MARCH 1996 underground

welding,

be used, submerged

and storage

points arc

out welding,

factors togas

be

used to repairs

making identify to

systems

tungsten-arc

considered areduringawelding,

problem the that can affect

those suppliers

distribution piping who have quality

systems for these systems

safety,

gas

pressure health,

metal-arc testing and

welding,

of liquid flux-cored

petroleum arc

API SPECIFICATION Q1 Specification for Quality Programs so

1 effective

Scope

products. that

The welding intense

the environment.

welding,

pipelines. plasma

This Releases may be

arc

recommended

SIXTH EDITION, MARCH 1, 1999 for the Petroleum and Natural Gas user international

This

may involvement

be done is unnecessary:

standard

by shielded species

metal-arc and (c)

42 caused

welding,

practice by

does improper

oxyacetylenenot address installation

welding, or flash

low pressure API Q1-1999

EFFECTIVE DATE: SEPTEMBER 1, Industry suggestions

quality

welding, system

gas tungsten-arc

and

butt maintenance

welding

pneumatic process of a storage system,

1999 on how

requirements

welding, users,

gas metal-arccontractors,

for use where welding,and suppliers

a suppliers

flux-cored

among

or a other

bywork combination

testing.

can

capability

arc welding, together

to design

or toof these processes

Technical Report on Temperature factors.

using

1 Scope

This Successsemiautomatic,

a manual,

recommended in preventing

practice releases

improve

and

depends

or

supply

oxyacetylene

automatic

quality.

onis conforming

welding

awelding

number product

using

technique asuggests

needs or

manual

or arepon

to

API TR 6AF1 Derating on API Flanges Under This repon

procedures

Section

be that a continuation

are

2 describes methods by

demonstrated. to thewhich

43 semiautomatic

of factors,

combination including

of engineering the following: API TR 6AF1-1998

SECOND EDITION, NOVEMBER 1998 Combination of Loading on

based

users

The the capabilities

on sound

prequalify

requirements specied judgment,

are aimed

welding

a. Sound

these technique

design

techniques. of or

The a welds

combination

installations. may beof the

of

but flanges

certain

suppliers,

primarily at under

governmental

prepare

achieving combined

comprehensive loadings

techniques.

b. Proper

produced selection

by position of materials

or from the for

(PRAC

requirements 86-21)2

specifications,

customer may

conduct

satisfaction differ by preventing

Technical Report on Capabilities of This

1 recommended

Introduction

specific

roll welding locations.

or by practice

a combination does of not

which

procedures resulted

communication

nonconformity set in the

forth

atmeetings,

all publication

audit of of API

designs,

API TR 6AF2 API Integral Flanges Under preclude

1.1

c. The

Installation

position using

original in other

and roll welding.design

accordance criteria, with which

sound

44 Bulletin

in

institute

stages 6AF.4

this recommended

manufacturing

from design practice.

through Such

servicing. API TR 6AF2-1999

SECOND EDITION, APRIL 1999 Com binat ion of Loading- methods

all present

engineering

This standard besides

API welding

specifications,

also covers to

theinstall

procedures

Included

requirements

quality

This herein

surveillance,

standard is

should

does an in-depth

be

sponsor

not look

intensive into

Phase Il appurtenances

flanges

practices,

for

the dimensions

radiographic,

effect and

of

or make are address

manufacturer's

elevated based,instructions.

was

fulfilled

factory

competitive

The weldingbecause

testing, or this

commercial

equipment, recommended

whether gas or

developed

d. Capable,

magnetic

temperatures back

particle,onin

adequate API theflanges.

liquid late

supervision

penetrant, and

and

WIRELINE OPERATIONS AND practicies

and

matters

arc, conduct

should suchnot be intended

equipment

as ofprice, toinspections

warranties, at the

1920s

quality

ultrasonic

The and

results 1930s

assurance

testing

inoroverride

this by

during

asrepon Waters prior

are analytical to the

PROCEDURES supersede

site

a prior

guarantees,

type and to or

size clauses

suitable them.for the work and

advent

installation.

well

and as the

assumeof the recent

acceptance

a temperature standards to be

THIRD EDITION Please

start-up.

intended

should betoadequately

be advised

sustain that this document

commercial

45 API VT5-1994 powerful,

e. Thorough

applied

gradient to computer

testing

production

across the technology

at appropriate

flange as andstages

stated in API VT5-1994

BOOK 5 OF THE VOCATIONAL does

Section not

objectives.

maintained preclude

3 (alongtotoensure with Appendix

acceptable A)welds,

associated

during

welds

this tested

repon. finite-element

installation destruction or inspected

TRAINING SERIES requalifying

contains

This

continuity a

guidelines

international

of line for for

standardliquid service

is applicable under in

analysis

and

by

When theprograms.

operation.

radiographic, flange The original

s insulated on analyses

the and

the provisions

evaluating

situations

operation, the of

and type

safety of of quality

personnel. system Arc-

methods

f. Appropriate

magnetic were

particle, used

monitoringliquid and

outside

ASME

effectiveness

when:

welding

surface,

31.8,

equipmentAppendix the

ofdefining

the Npenetrant,

allowable (as provided for

successfully

maintenance

ultrasonic,

loads will beand inprograms.

visualby

higher. the flange design

testing

49

a.

must Code

quality

Design of

system

is

be operated Federal used

required within and a supplier.

theamperage

the product

and

g. pressure

Compliance

methods.

Additional finite rating

with

element appropriate models

Regulations

Emphasis

requirements

and voltage is 195.5

placed

are

ranges (a)

statedon (1)

the (I.)). of five

but

The

new did

regulations.

valuesnot address

flanges stated

in inexternal

either inch-poundloading

commitment

principally of management to theor quality

given

h.

API Use

units inofSI

capabilities.

or

6A, ain

the performance

qualified

The

qualified

units

Sixteenth flange

are welding

contractor:

Edition,

terms,

1989,

procedure;

which

they

system,

need to

gas-welding

designs the

be structure

wereequipment

Pgina 5 de 6

experienced inbased on surface stress

the installation

NORMAS API American Petroleum Institute

Item Designacin Ttulo Alcance Hipervnculo

46

47

48

49

50

Pgina 6 de 6

Você também pode gostar

- Steel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesDocumento28 páginasSteel Wedge Gate Valves (Flanged and Butt-Welding Ends) For The Petroleum, Petrochemical and Allied IndustriesImed BenAinda não há avaliações

- Bottom & Annular Plate Design: We Will Use Bottom Witout AnularDocumento25 páginasBottom & Annular Plate Design: We Will Use Bottom Witout AnularhgagAinda não há avaliações

- API STANDARD For PipingDocumento28 páginasAPI STANDARD For PipingsahaAinda não há avaliações

- Specification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness TestingDocumento4 páginasSpecification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness Testingstephen lewellenAinda não há avaliações

- Wps MainlineDocumento5 páginasWps MainlineAlfian FebriansyahAinda não há avaliações

- Welding Consumable Storage ProcedureDocumento8 páginasWelding Consumable Storage ProcedureMahesh PanditAinda não há avaliações

- Trimec: Chemical Compatibility ChartDocumento12 páginasTrimec: Chemical Compatibility ChartMandiriAinda não há avaliações

- Proposed Welding Procedure Specification (PWPS) : REV:A3Documento1 páginaProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakAinda não há avaliações

- API AARsDocumento2 páginasAPI AARsDhaval ChitreAinda não há avaliações

- API 5L-2007 Specification For Line PipeDocumento153 páginasAPI 5L-2007 Specification For Line Pipetom787485100% (1)

- ASME pressure vessel manual coil heating procedureDocumento8 páginasASME pressure vessel manual coil heating procedurehgagAinda não há avaliações

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocumento15 páginasQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarAinda não há avaliações

- Requirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc NoDocumento1 páginaRequirement For Wn/Blind Flanges Astm A182 F316L/316L: INQ - 610 Rev.: A Page: 1 of 1 Doc Nonaveen_86Ainda não há avaliações

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Documento15 páginasFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaAinda não há avaliações

- CV Ram Deo Yadav Quality EngineerDocumento7 páginasCV Ram Deo Yadav Quality Engineerkbpatel123Ainda não há avaliações

- Himansu Sekhar Mohapatra: Professional SummaryDocumento5 páginasHimansu Sekhar Mohapatra: Professional SummaryHimansu MohapatraAinda não há avaliações

- Thread GageDocumento30 páginasThread GageRosendo RizoAinda não há avaliações

- Soft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesDocumento4 páginasSoft Magnetic Iron Parts Fabricated by Powder Metallurgy (P/M) TechniquesEduardoAinda não há avaliações

- WELDING PROCEDURES FOR TUG VESSELDocumento11 páginasWELDING PROCEDURES FOR TUG VESSELCostin RotaruAinda não há avaliações

- VSP NDT Cross Check SummaryDocumento2 páginasVSP NDT Cross Check SummaryTHI SEN NGUYENAinda não há avaliações

- Work Instruction FOR: Charpy Impact TestDocumento4 páginasWork Instruction FOR: Charpy Impact TestmahendraAinda não há avaliações

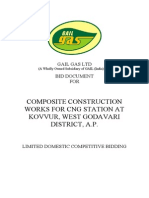

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocumento209 páginasComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999Ainda não há avaliações

- TDC 004 CS Fittings r0Documento1 páginaTDC 004 CS Fittings r0samkarthik47Ainda não há avaliações

- Inspection and Test Paln For LSAWDocumento4 páginasInspection and Test Paln For LSAWkbpatel123Ainda não há avaliações

- Technical Bid Evaluation for Manual ValvesDocumento4 páginasTechnical Bid Evaluation for Manual Valveseko123Ainda não há avaliações

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Documento31 páginasStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaAinda não há avaliações

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverDocumento8 páginasBakhrabad Siddhirganj Pipeline Project Piping / Equipment Specifications For Launcher and ReceiverIbad AlamAinda não há avaliações

- Qap Gate ValveDocumento1 páginaQap Gate ValveAjit PatilAinda não há avaliações

- 23 Astm A790 A790m-2018Documento10 páginas23 Astm A790 A790m-2018FYAinda não há avaliações

- Hidden Defects in FittingsDocumento3 páginasHidden Defects in FittingsFerlie IndrapatiAinda não há avaliações

- SLB Check List-1Documento2 páginasSLB Check List-1Jitendra BhosaleAinda não há avaliações

- Mechanical Engineer Cover LetterDocumento1 páginaMechanical Engineer Cover LetterPravin NairAinda não há avaliações

- E1 Technical Data Sheet - ShortDocumento2 páginasE1 Technical Data Sheet - ShortOmaiyio M. SaginiAinda não há avaliações

- Itp For All MaterialsDocumento59 páginasItp For All MaterialsTauqueerAhmad100% (1)

- Qualification Review Report for Unimit EngineeringDocumento9 páginasQualification Review Report for Unimit EngineeringKeiti Filbrich100% (1)

- 01-SAMSS-035 2018 API Line PipeDocumento29 páginas01-SAMSS-035 2018 API Line PipeWHWENAinda não há avaliações

- (0209) 031801Documento12 páginas(0209) 031801Sixto Gerardo Oña AnaguanoAinda não há avaliações

- Inspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Documento6 páginasInspection and Test Plan - LR Bends For Onshore Pipelines VCS-PL-ITP-004Vidyut UjalaAinda não há avaliações

- A545-736-11-42-DS-0034 - A - Flow TeeDocumento2 páginasA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranAinda não há avaliações

- 00 PR SP 00002 - 2 Positive Material Identification (PMI) of AlloysDocumento14 páginas00 PR SP 00002 - 2 Positive Material Identification (PMI) of AlloysStevanNikolicAinda não há avaliações

- API 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Documento16 páginasAPI 607 Fire Test Report - Copeland - 2 Inch Class 900 Ball Valve - June 9 2017.22172258Nilesh SargaraAinda não há avaliações

- Acceptance Criteria For Weld of All Code and Standard Prepared by SadamDocumento30 páginasAcceptance Criteria For Weld of All Code and Standard Prepared by Sadamananth rajanAinda não há avaliações

- 03EPDocumento38 páginas03EPAndhie OsloAinda não há avaliações

- Qap Hot Induction BendsDocumento6 páginasQap Hot Induction BendsVidyut UjalaAinda não há avaliações

- DCN 47 51570605Documento5 páginasDCN 47 51570605Shilpa GanganAinda não há avaliações

- TDC 003 - SS Pipes - r0Documento1 páginaTDC 003 - SS Pipes - r0samkarthik47Ainda não há avaliações

- KHI Pipe Marking ProcedureDocumento12 páginasKHI Pipe Marking ProcedureAlfian ImaduddinAinda não há avaliações

- Free Span Design According To The DNV-RP-F105 For Free Spanning PipelinesDocumento24 páginasFree Span Design According To The DNV-RP-F105 For Free Spanning PipelinesconanbhAinda não há avaliações

- NDE-Penetrant TestDocumento2 páginasNDE-Penetrant TestCandy KendeeAinda não há avaliações

- Method of Statement PDFDocumento7 páginasMethod of Statement PDFSakib AyubAinda não há avaliações

- QAP for Flange InspectionDocumento2 páginasQAP for Flange InspectionGOPINATH KRISHNAN NAIRAinda não há avaliações

- Hardness Pro Form1Documento2 páginasHardness Pro Form1gst ajah100% (1)

- Ultrasonic Examination of Critical Heat Exchanger WeldsDocumento6 páginasUltrasonic Examination of Critical Heat Exchanger WeldsDARSHIL RAJPURAAinda não há avaliações

- 4d48f0f5e09b8 Plant Piping and Pipeline Systems 2010 Maurice For SiskaDocumento7 páginas4d48f0f5e09b8 Plant Piping and Pipeline Systems 2010 Maurice For Siskau04ajf3Ainda não há avaliações

- 2596 (Asme)Documento1 página2596 (Asme)fracevAinda não há avaliações

- API602 Forged Steel Gate & Globe ValvesDocumento4 páginasAPI602 Forged Steel Gate & Globe ValvesThomasFrenchAinda não há avaliações

- Ip 287Documento5 páginasIp 287Maíra Amaral100% (5)

- Conveyors - Scraper (Flight) - Generalrequirements (: Indian StandardDocumento12 páginasConveyors - Scraper (Flight) - Generalrequirements (: Indian StandardAbinashBeheraAinda não há avaliações

- Marsh Funnel Viscosity of Clay Construction Slurries: Standard Test Method ForDocumento3 páginasMarsh Funnel Viscosity of Clay Construction Slurries: Standard Test Method ForRahul Bhardwaj100% (1)

- Sfa-5.7Documento10 páginasSfa-5.7vannie_yundaAinda não há avaliações

- AISC Shapes Database v14.1Documento20 páginasAISC Shapes Database v14.1Joel Pacheco DiazAinda não há avaliações

- Angulo CoronamientoDocumento1 páginaAngulo CoronamientoJoel Pacheco DiazAinda não há avaliações

- Aisc PerfilesDocumento26 páginasAisc Perfilesapi-2672311278% (9)

- 110P0320427 ADocumento1 página110P0320427 AJoel Pacheco DiazAinda não há avaliações

- Angulo CoronamientoDocumento1 páginaAngulo CoronamientoJoel Pacheco DiazAinda não há avaliações

- Guía de Ventilación de TanquesDocumento31 páginasGuía de Ventilación de TanquesMulkururAinda não há avaliações

- Sistema Hidraulico de La PrimariaDocumento1 páginaSistema Hidraulico de La PrimariaJoel Pacheco DiazAinda não há avaliações

- Optimize crusher performance with the right liner selectionDocumento42 páginasOptimize crusher performance with the right liner selectionJoel Pacheco Diaz100% (1)

- Quality Cost AnalysisDocumento5 páginasQuality Cost Analysisapi-3805571Ainda não há avaliações

- Dimensions in Millimeters: 5-68 Api S 650Documento1 páginaDimensions in Millimeters: 5-68 Api S 650Joel Pacheco DiazAinda não há avaliações

- Radiografia 3Documento1 páginaRadiografia 3Joel Pacheco DiazAinda não há avaliações

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Documento3 páginasSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)mulong83Ainda não há avaliações

- Reviewed For Information OnlyDocumento1 páginaReviewed For Information OnlyJoel Pacheco DiazAinda não há avaliações

- A240Documento11 páginasA240Joel Pacheco DiazAinda não há avaliações

- Dimensions in Millimeters: 5-68 Api S 650Documento1 páginaDimensions in Millimeters: 5-68 Api S 650Joel Pacheco DiazAinda não há avaliações

- Nozzles Anexo S Api 650Documento1 páginaNozzles Anexo S Api 650Joel Pacheco DiazAinda não há avaliações

- D006Documento3 páginasD006Ruddy EspejoAinda não há avaliações

- A002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDocumento3 páginasA002 Carbon Steel Girder Rails of Plain, Grooved, and Guard TypesDaniel Alonso Flores MezaAinda não há avaliações

- Diffraction of Laser Beam Using Wire Mesh, Cross Wire and GratingDocumento2 páginasDiffraction of Laser Beam Using Wire Mesh, Cross Wire and GratingPriyesh PandeyAinda não há avaliações

- List of Linkages2016Documento74 páginasList of Linkages2016engrwho0% (1)

- Parts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: BrakeDocumento2 páginasParts List 09 636 02 02: AC Brake Motors BMG05-BMG1 Additional List: Brakeali morisyAinda não há avaliações

- Fosroc Conbextra EP10: Constructive SolutionsDocumento2 páginasFosroc Conbextra EP10: Constructive SolutionsVincent JavateAinda não há avaliações

- Chapter-6 IscaDocumento1 páginaChapter-6 IscakishorejiAinda não há avaliações

- Airflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideDocumento2 páginasAirflex 728 Vinyl Acetate-Ethylene Copolymer Modified With Vinyl ChlorideNissim Hazar CasanovaAinda não há avaliações

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocumento7 páginasPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4Ainda não há avaliações

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurDocumento8 páginasNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETAinda não há avaliações

- Stationary Concrete Pumps en G 16345-0 PDFDocumento20 páginasStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PAROAinda não há avaliações

- J 1 B 1211 CCDDocumento3 páginasJ 1 B 1211 CCDRegion 51Ainda não há avaliações

- Ea80 Series PDFDocumento82 páginasEa80 Series PDFAnca MunteanuAinda não há avaliações

- Osha 1926.452Documento14 páginasOsha 1926.452Binoy GopinathanAinda não há avaliações

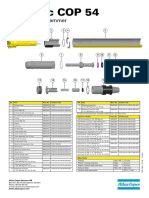

- 9853 1239 01 - COP 54 Service Poster - LOWDocumento1 página9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasAinda não há avaliações

- Application of PLC and SCADA in Auto-Control Systems For Silo Grain HandlingDocumento4 páginasApplication of PLC and SCADA in Auto-Control Systems For Silo Grain Handlingshahid_scribdAinda não há avaliações

- Que Dice Ese Gesto Descargar GratisDocumento2 páginasQue Dice Ese Gesto Descargar GratisjavierAinda não há avaliações

- Lec 958975Documento19 páginasLec 958975Rajasekar PichaimuthuAinda não há avaliações

- Sad Thesis Guidelines FinalsDocumento13 páginasSad Thesis Guidelines FinalsJes RamosAinda não há avaliações

- Bottom Ash HopperDocumento8 páginasBottom Ash HopperBhargav ChaudhariAinda não há avaliações

- Central GeothermalDocumento48 páginasCentral GeothermalНиколай ШипочкиAinda não há avaliações

- Ford Essex V6 EngineDocumento8 páginasFord Essex V6 EngineJoakamaster 16Ainda não há avaliações

- ReleDocumento3 páginasRelevitor4santos_6Ainda não há avaliações

- Minor Project Report On Efficiency Improvement of A Combined Cycle Power PlantDocumento40 páginasMinor Project Report On Efficiency Improvement of A Combined Cycle Power PlantArpit Garg100% (1)

- Caterpillar 914GDocumento28 páginasCaterpillar 914GForomaquinas100% (3)

- The Causes and Prevention of Crowd DisastersDocumento10 páginasThe Causes and Prevention of Crowd DisastersVarun SwaminathanAinda não há avaliações

- Crompton Greaves LimitedDocumento3 páginasCrompton Greaves LimitedNitish SinghAinda não há avaliações

- How rock layers are formedDocumento3 páginasHow rock layers are formedAlemar AllecerAinda não há avaliações

- Achievements Under EpiraDocumento6 páginasAchievements Under EpiraLyn Dela Cruz DumoAinda não há avaliações

- Stressman Engineering - Brochure Norway 2018-6Documento8 páginasStressman Engineering - Brochure Norway 2018-6FelipeAinda não há avaliações

- Artificial LiftDocumento18 páginasArtificial LiftRasya RefanAinda não há avaliações