Escolar Documentos

Profissional Documentos

Cultura Documentos

Review Questions To Attempt

Enviado por

Fish de Paie0 notas0% acharam este documento útil (0 voto)

105 visualizações2 páginasOperations management

Título original

Review Questions to Attempt

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoOperations management

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

105 visualizações2 páginasReview Questions To Attempt

Enviado por

Fish de PaieOperations management

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

CHAPTER 10: REVIEW QUESTIONS QUALITY CONTROL

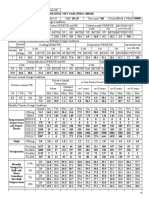

1. What are the key concepts that underlie the construction and interpretation of control charts?

2. What is the purpose of a control chart?

3. Checkout time at a supermarket is monitored using a mean and a range chart. Six samples of

n = 20 observations have been obtained and the sample means

and ranges computed:

Sample Mean Range Sample Mean Range

1 3.06 .42 4 3.13 .46

2 3.15 .50 5 3.06 .46

3 3.11 .41 6 3.09 .45

a. Using the factors in Table 10.3, determine upper and lower limits for mean and range

charts.

b. Is the process in control?

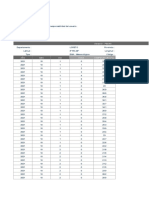

QUESTION 4

The table below shows the fillweights of toothpaste tubes on a filling machine. The time between samples is

20 minutes; 24 samples are taken during the 8-hour production shift. The samples are of size n=4.

Table: Data on fillweight of Toothpaste Tubes

Sample Fillweight (gms)

1 22.1 21.9 21.7 22.0

2 22.0 22.2 21.7 21.6

3 22.2 21.9 22.0 22.0

4 21.6 22.2 22.3 22.0

5 22.2 21.9 22.1 22.4

6 22.2 22.2 21.9 22.3

7 22.2 22.2 22.1 21.8

8 22.0 22.0 22.0 22.1

9 21.9 22.2 21.7 21.5

10 22.2 21.8 21.8 22.2

11 21.9 21.7 22.5 22.0

12 22.3 22.0 21.9 21.8

13 21.8 22.2 22.2 21.7

14 22.0 21.9 22.1 22.1

15 22.2 21.9 22.1 22.2

16 22.2 21.9 22.1 22.1

17 22.2 21.9 21.9 22.0

18 21.9 22.0 22.0 21.8

19 22.2 22.2 21.8 21.8

20 22.1 22.1 22.0 21.7

21 21.5 21.7 21.9 21.9

22 21.8 21.8 21.7 21.5

23 21.5 21.9 21.7 21.8

24 21.5 21.6 21.7 21.7

a. Calculate both the X-bar chart and R-chart control limits.

b. Draw both charts and plot the above data.

c. Comment on the process variability.

Você também pode gostar

- Government Publications: Key PapersNo EverandGovernment Publications: Key PapersBernard M. FryAinda não há avaliações

- CompatibilityMatrix Current LetterDocumento249 páginasCompatibilityMatrix Current LettermopachameAinda não há avaliações

- Assignments Ise October 2020Documento4 páginasAssignments Ise October 2020kelvinAinda não há avaliações

- Toshiba Smms Capacity TablesDocumento3 páginasToshiba Smms Capacity Tablesnassar_aymanAinda não há avaliações

- Estación: PEBASDocumento28 páginasEstación: PEBASLinda Tierra CanasAinda não há avaliações

- Zainul Fahmi TABEL Perhitungaan DAC 1 Dan DAC 2Documento1 páginaZainul Fahmi TABEL Perhitungaan DAC 1 Dan DAC 2Starla HemaAinda não há avaliações

- List of FiguresDocumento98 páginasList of FiguresSeanAinda não há avaliações

- Wetted Wall ColumnDocumento8 páginasWetted Wall ColumnSameer NasirAinda não há avaliações

- UnitTest - D17 Sept 2023Documento26 páginasUnitTest - D17 Sept 2023boss.siddhi007Ainda não há avaliações

- SimulationDocumento8 páginasSimulationalokAinda não há avaliações

- Assignments GD BlogsDocumento11 páginasAssignments GD BlogsSonu KushwahaAinda não há avaliações

- MS14E Chapter 21 FinalDocumento12 páginasMS14E Chapter 21 FinalHilea Jane GalesAinda não há avaliações

- Teaching Assistant Evaluation Data SetDocumento5 páginasTeaching Assistant Evaluation Data SetRani AyundaAinda não há avaliações

- FINAL EXAM STATISTICS - Dr. Gloria O. GomezDocumento2 páginasFINAL EXAM STATISTICS - Dr. Gloria O. GomezPRINCE ONTIVEROS ESTRELLAAinda não há avaliações

- Coa HS0009310 06114Documento4 páginasCoa HS0009310 06114Sob Note AinyAinda não há avaliações

- Kunci Baja Kelas 4Documento1 páginaKunci Baja Kelas 4Sus BiantoroAinda não há avaliações

- Exercise 2 - MinitabDocumento7 páginasExercise 2 - MinitabLawrence BelloAinda não há avaliações

- Tugas PPM 3 RusdiDocumento3 páginasTugas PPM 3 RusdiRusdi PratiwoAinda não há avaliações

- Gauge Capability (R & R) StudiesDocumento4 páginasGauge Capability (R & R) StudiesmakrygiaAinda não há avaliações

- Graficas de Control (1) Sanchez SerranoDocumento13 páginasGraficas de Control (1) Sanchez SerranoHéctor Reydavid GallardoAinda não há avaliações

- Wind Speed and Generator Output Data For Calculating A Power Curve For A Wind TurbineDocumento1 páginaWind Speed and Generator Output Data For Calculating A Power Curve For A Wind TurbineDennis Dale FanogaAinda não há avaliações

- 08 11 2023 02 00 To 3 30 PM B Tech Y22 Batch Lateral Entry SeatingDocumento11 páginas08 11 2023 02 00 To 3 30 PM B Tech Y22 Batch Lateral Entry Seatingsripallavid1214Ainda não há avaliações

- Report 22m 1 PDFDocumento44 páginasReport 22m 1 PDFNabin MaharjanAinda não há avaliações

- Tadano Gr600ex Load ChartDocumento1 páginaTadano Gr600ex Load Chartasdasd asdasdAinda não há avaliações

- Compressive and Flexural Test of Mortar PDFDocumento9 páginasCompressive and Flexural Test of Mortar PDFHusam RjoubAinda não há avaliações

- Curah Hujan Tahunan (CM) Suatu Daerah Dalam 90 TahunDocumento8 páginasCurah Hujan Tahunan (CM) Suatu Daerah Dalam 90 Tahunimron hanif aminAinda não há avaliações

- Data Analysis Photosynthesis BiologyDocumento12 páginasData Analysis Photosynthesis BiologyLionqueenAinda não há avaliações

- 2018 Fluid Mechanics Workbook Key: (By:-Manoj Kumar Gour)Documento2 páginas2018 Fluid Mechanics Workbook Key: (By:-Manoj Kumar Gour)Shiraz KhanAinda não há avaliações

- Form AnchorDocumento2 páginasForm AnchoradityaAinda não há avaliações

- R9.1.41 Grama Sachivalayam Building Works Status Report (Agriculture Staff)Documento2 páginasR9.1.41 Grama Sachivalayam Building Works Status Report (Agriculture Staff)Aepr pentapaduAinda não há avaliações

- Vorticity - Phase 1 ReportDocumento7 páginasVorticity - Phase 1 Reportjulian55555Ainda não há avaliações

- Tsako PosterDocumento1 páginaTsako PosterTsako ManganyeAinda não há avaliações

- 12th + ICS Class Pairing Scheme 2024 All BoardsDocumento36 páginas12th + ICS Class Pairing Scheme 2024 All BoardsnoumanwaqarAinda não há avaliações

- Down Time Machine Coarse Grinding Andritz Optimil 900 Year 2016Documento101 páginasDown Time Machine Coarse Grinding Andritz Optimil 900 Year 2016hr.setiawanAinda não há avaliações

- Cairo WeatherDocumento2 páginasCairo Weatheralsayed miesalamAinda não há avaliações

- TANAHDocumento3 páginasTANAHDoniIskandarAinda não há avaliações

- Project ScheduleDocumento3 páginasProject Schedulelamthunguyen001Ainda não há avaliações

- Ujian Biostatistik NoveliaDocumento11 páginasUjian Biostatistik NoveliaOcsiana OxciAinda não há avaliações

- Table 7: Solar Radiation and Sunshine Duration in Sudan (: Create PDF in Your Applications With The PdfcrowdDocumento1 páginaTable 7: Solar Radiation and Sunshine Duration in Sudan (: Create PDF in Your Applications With The PdfcrowdElwasilaAinda não há avaliações

- TMPPHP 9 IahycDocumento164 páginasTMPPHP 9 IahycAgung TriyonoAinda não há avaliações

- MistosDocumento1 páginaMistosRobert GomesAinda não há avaliações

- Mien Bac - Nam Dinh Weather ClimateDocumento2 páginasMien Bac - Nam Dinh Weather ClimateNguyễn Thành NamAinda não há avaliações

- ASHRAE - Design Conditions - 2013 - 2Documento2 páginasASHRAE - Design Conditions - 2013 - 2Ing Peter CucchiAinda não há avaliações

- Project PlanDocumento1 páginaProject Planاسعد الماوريAinda não há avaliações

- User S Guide: CZ de en FR Hu PL Ro RuDocumento171 páginasUser S Guide: CZ de en FR Hu PL Ro RuGhinet MariusAinda não há avaliações

- Internal Marks VerificationDocumento2 páginasInternal Marks Verificationrajeshkumar123456Ainda não há avaliações

- Chapter 7, Problem 11PDocumento2 páginasChapter 7, Problem 11Pmahdi najafzadehAinda não há avaliações

- Spreadsheet Conversion TableDocumento82 páginasSpreadsheet Conversion TableHector GuerreroAinda não há avaliações

- Ashrae Dodoma 2017Documento2 páginasAshrae Dodoma 2017FrankAinda não há avaliações

- Ashrae Dodoma 2017Documento2 páginasAshrae Dodoma 2017FrankAinda não há avaliações

- THERMODYNAMICSDocumento11 páginasTHERMODYNAMICSPeter NdisoAinda não há avaliações

- Workbook Answer Key UpdatedDocumento3 páginasWorkbook Answer Key Updatedharshita guptaAinda não há avaliações

- Narrative Report: 1. Site ClearingDocumento2 páginasNarrative Report: 1. Site ClearingMatthew DalisayAinda não há avaliações

- About BlankDocumento2 páginasAbout BlankAbdo aliAinda não há avaliações

- BBE 4301 Activity 1 9-1-21Documento5 páginasBBE 4301 Activity 1 9-1-21DeniseAinda não há avaliações

- Risk Discipline TM v1Documento6 páginasRisk Discipline TM v1Free Latest MoviesAinda não há avaliações

- Mechanical Properties of Metric FastenersDocumento10 páginasMechanical Properties of Metric FastenersadventmanurungAinda não há avaliações

- Demand ForecastingBSABSMA 1Documento14 páginasDemand ForecastingBSABSMA 1Eldia DanaoAinda não há avaliações

- FM Workbook Answer KeyDocumento3 páginasFM Workbook Answer Keyharshita guptaAinda não há avaliações

- Mathematics Module Volume 2 - FINAL4WEBDocumento380 páginasMathematics Module Volume 2 - FINAL4WEBKupa100% (1)

- Retailing StrategyDocumento28 páginasRetailing StrategyFish de PaieAinda não há avaliações

- Sony Max (1-2 August)Documento2 páginasSony Max (1-2 August)Fish de PaieAinda não há avaliações

- Audit and ControlDocumento42 páginasAudit and ControlFish de PaieAinda não há avaliações

- Unbox Your PhoneDocumento9 páginasUnbox Your PhoneFish de PaieAinda não há avaliações

- Operations Management Model AnswersDocumento28 páginasOperations Management Model AnswersFish de PaieAinda não há avaliações

- Kabab-Ji Grill Case StudyDocumento11 páginasKabab-Ji Grill Case StudyFish de Paie0% (1)

- Questions Retail and ServicesDocumento3 páginasQuestions Retail and ServicesFish de PaieAinda não há avaliações

- Chapter 3Documento3 páginasChapter 3Fish de PaieAinda não há avaliações

- MisDocumento13 páginasMisFish de Paie0% (1)

- Importance of Teams & Team Building in Current Day Work ContextDocumento9 páginasImportance of Teams & Team Building in Current Day Work ContextFish de PaieAinda não há avaliações

- Assignment 12 Case Study-Home Style CookiesDocumento3 páginasAssignment 12 Case Study-Home Style CookiesFish de Paie100% (2)

- Ecommerce in Developing Countries BrazilDocumento14 páginasEcommerce in Developing Countries BrazilFish de PaieAinda não há avaliações

- PBL - Chapter 1Documento5 páginasPBL - Chapter 1Fish de PaieAinda não há avaliações

- Importance of Team BuildingDocumento3 páginasImportance of Team BuildingFish de PaieAinda não há avaliações

- Updated MQC ManualDocumento29 páginasUpdated MQC ManualssselvaAinda não há avaliações

- What Is MSA?Documento4 páginasWhat Is MSA?Adrian FinichiuAinda não há avaliações

- Wasserman 1994Documento4 páginasWasserman 1994Pedro SilvaAinda não há avaliações

- Ge8077 TQM QBDocumento36 páginasGe8077 TQM QBECE113 - SURESH KUMAR MAinda não há avaliações

- QI Macros User GuideDocumento22 páginasQI Macros User GuideJose ArmazaAinda não há avaliações

- Hock Questions 2017 P1D11. Business Process Improvement 22QDocumento15 páginasHock Questions 2017 P1D11. Business Process Improvement 22QSBAinda não há avaliações

- Software Certification CABADocumento63 páginasSoftware Certification CABAMbaStudent56Ainda não há avaliações

- Hotelling T2 For BatchDocumento14 páginasHotelling T2 For Batchapi-3701058Ainda não há avaliações

- EV06 - Design and DrawingsDocumento35 páginasEV06 - Design and DrawingsSivaji KotipalliAinda não há avaliações

- Statistical Control of Measures and Processes: 2009 Elsevier B.V. All Rights ReservedDocumento30 páginasStatistical Control of Measures and Processes: 2009 Elsevier B.V. All Rights ReservedCalidad LassAinda não há avaliações

- Statistical Process Adjustment Methods For Quality Control in Short-Run ManufacturingDocumento250 páginasStatistical Process Adjustment Methods For Quality Control in Short-Run Manufacturingkalite gurusuAinda não há avaliações

- SPCDocumento49 páginasSPCJosephi_abbasAinda não há avaliações

- Internal Quality Controll Handbook For Chemical LaboratoriesDocumento52 páginasInternal Quality Controll Handbook For Chemical LaboratoriesVu HungAinda não há avaliações

- Quality Assurance and Statistical Process Control McDonaldsDocumento3 páginasQuality Assurance and Statistical Process Control McDonaldsOvelia KayuzakiAinda não há avaliações

- Stat Graphic Plus 5Documento8 páginasStat Graphic Plus 5Khin Khin ThanAinda não há avaliações

- 16 Chapter 10Documento16 páginas16 Chapter 10Harshi AggarwalAinda não há avaliações

- Project Quality Management PMPDocumento47 páginasProject Quality Management PMPnguyen728100% (2)

- StatisticalMethods June2019Bazargan PDFDocumento448 páginasStatisticalMethods June2019Bazargan PDFIver SanchezAinda não há avaliações

- The 1.5 Sigma Shift ExplainedDocumento4 páginasThe 1.5 Sigma Shift ExplainedBruno SaturnAinda não há avaliações

- Statistical Process Control: True/False QuestionsDocumento23 páginasStatistical Process Control: True/False QuestionsBo RaeAinda não há avaliações

- ORA-LAB.5.9 Ensuring The Quality of Test Results (v02)Documento17 páginasORA-LAB.5.9 Ensuring The Quality of Test Results (v02)ahmed alghrably100% (1)

- The Book of SPCDocumento208 páginasThe Book of SPCmititicu100% (8)

- Problems From Chapter SPC TutorialDocumento2 páginasProblems From Chapter SPC TutorialNishanth LokanathAinda não há avaliações

- Statistical Quality ControlDocumento91 páginasStatistical Quality ControlJabir Aghadi100% (3)

- Fuzzy Applications in Industrial Engineering - Cengiz Kahraman PDFDocumento608 páginasFuzzy Applications in Industrial Engineering - Cengiz Kahraman PDFpongerkeAinda não há avaliações

- Lesson Plan TQM-NewDocumento7 páginasLesson Plan TQM-Newtmuthu123Ainda não há avaliações

- Chap 8Documento10 páginasChap 8Tú B Mai100% (1)

- Asq Decision Rules FinalDocumento30 páginasAsq Decision Rules FinalSudhagar PAinda não há avaliações

- ENGG 4050 Quality Control: University of Guelph, Winter 2020Documento19 páginasENGG 4050 Quality Control: University of Guelph, Winter 2020Amir HossainAinda não há avaliações

- GE2022 2 Marks PDFDocumento23 páginasGE2022 2 Marks PDFsudharsonkumarAinda não há avaliações