Escolar Documentos

Profissional Documentos

Cultura Documentos

Ma PDF

Enviado por

Oscar VillaseñorTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ma PDF

Enviado por

Oscar VillaseñorDireitos autorais:

Formatos disponíveis

MAINTENANCE

SECTION

MAINTENANCE

MA B

E

CONTENTS

SERVICE INFORMATION ............................ 2 Removal and Installation .........................................31 F

Air Bleeding .............................................................32

PRECAUTIONS ................................................... 2 Draining Water from Sedimentor .............................32

Precaution for Supplemental Restraint System Changing Engine Air Cleaner Filter .........................33 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN- Removal and Installation .........................................33

SIONER" ................................................................... 2 Changing Engine Oil ................................................34

Changing Engine Oil Filter .......................................35

PREPARATION ................................................... 3 H

Special Service Tool ................................................. 3 CHASSIS AND BODY MAINTENANCE ........... 37

Commercial Service Tool .......................................... 3 Checking Exhaust System .......................................37

Checking Clutch Fluid Level and Leaks ..................37 I

GENERAL MAINTENANCE ................................ 4 Inspection and Adjustment ......................................37

General Maintenance ................................................ 4 Checking Clutch System .........................................38

PERIODIC MAINTENANCE ................................ 5 Checking M/T Oil - FS5W71C .................................38 J

Changing M/T Oil - FS5W71C .................................39

For Mexico ................................................................ 5

Checking M/T Oil - FS5R30A ..................................39

EXCEPT FOR MEXICO ............................................ 9

Changing M/T Oil - FS5R30A ..................................39

Checking Transfer Fluid ..........................................40 K

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................14 Changing Transfer Fluid ..........................................40

Fluids and Lubricants .............................................. 14 Checking Propeller Shaft .........................................41

SAE Viscosity Number ............................................ 15 Checking Front Final Drive Oil (Front Differential MA

Engine Coolant Mixture Ratio ................................. 16 Gear Oil) ..................................................................41

Changing Front Final Drive Oil (Front Differential

ENGINE MAINTENANCE (KA24DE) .................17 Gear Oil) ..................................................................41 M

Checking Drive Belts ............................................... 17 Checking Rear Final Drive Oil - C200 (Rear Differ-

Changing Engine Coolant ....................................... 18 ential Gear Oil) ........................................................42

System Inspection ................................................... 19 Changing Rear Final Drive Oil - C200 (Rear Differ-

Checking Fuel Line ................................................. 21 ential Gear Oil) ........................................................42 N

Component .............................................................. 21 Inspection ................................................................43

Changing Engine Air Filter ...................................... 21 Adjustment ...............................................................44

Changing Engine Oil ............................................... 22 Checking Brake Fluid Level .....................................46 O

Changing Engine Oil Filter ...................................... 23 Checking Brake Line ...............................................46

Changing Spark Plugs ............................................ 23 Changing Brake Fluid ..............................................46

Checking EVAP Vapor Line .................................... 25 Checking Disc Brake ...............................................46 P

Checking Drum Brake .............................................47

ENGINE MAINTENANCE (YD25DDTi) ..............26 Checking Steering Gear and Linkage ......................48

Checking Drive Belts ............................................... 26 Checking Power Steering Fluid and Line ................48

Changing Engine Coolant ....................................... 27 Checking Axle and Suspension Parts .....................49

System Inspection ................................................... 28 Lubricating Locks, Hinges and Hood Latches .........50

Checking Fuel Line ................................................. 30 Checking Seat Belts, Buckles, Retractors, An-

Changing Fuel Filter ................................................ 30 chors and Adjusters .................................................50

Revision: September 2009 MA-1 2010 D22 LCV

PRECAUTIONS

< SERVICE INFORMATION >

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005783035

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: September 2009 MA-2 2010 D22 LCV

PREPARATION

< SERVICE INFORMATION >

PREPARATION

A

Special Service Tool INFOID:0000000005473098

B

Tool number

Description

Tool name

KV10115801 Removing oil filter

C

Oil filter wrench (KA24DE engine models)

a: 64.3 mm (2.531 in)

S-NT375

E

EG17650301 Adapting radiator cap tester to radiator cap

(J-33984-A) and radiator filler neck.

Radiator cap tester adapter a: 28 (1.10) dia.

b: 31.4 (1.236) dia. F

c: 41.3 (1.626) dia.

Unit: mm (in)

G

S-NT564

Commercial Service Tool INFOID:0000000005473099

H

Tool name Description

Spark plug wrench Removing and installing spark plug I

(KA24DE engine models)

S-NT047

K

Radiator cap tester Checking radiator and reservoir tank cap

MA

M

PBIC1982E

Revision: September 2009 MA-3 2010 D22 LCV

GENERAL MAINTENANCE

< SERVICE INFORMATION >

GENERAL MAINTENANCE

General Maintenance INFOID:0000000005473100

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified. WT-7, "Tire"

Check carefully for damage, cuts or excessive wear.

Windshield wiper

Check for cracks or wear if not functioning correctly.

blades

Doors and engine Check that all doors and the engine hood operate smoothly. Also make sure that

hood all latches lock securely. Lubricate if necessary. Make sure that the secondary BL-10, "Fitting Adjust-

latch keeps the hood from opening when the primary latch is released. ment", BL-56, "Align-

When driving in areas using road salt or other corrosive materials, check for lu- ment"

brication frequently.

Tire rotation Tires should be rotated every 10,000 km (6,000 miles) for 2WD models and every

WT-5, "Adjustment"

5,000 km (3,000 miles) for 4WD models.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim.

Warning lamps and

Make sure that all warning lamps and chimes are operating properly.

chimes

Steering wheel PS-6, "Checking Steer-

Check that it has the specified play. ing Wheel Play" (Power

Check for changes in the steering conditions, such as excessive free play, hard Steering)

steering or strange noises. MS-6, "Checking Steer-

Free play: Less than 35 mm (1.38 in) ing Wheel Play" (Manual

steering)

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

SB-10, "Seat Belt Inspec-

retractors) operate properly and smoothly, and are installed securely. Check the

tion"

belt webbing for cuts, fraying, wear or damage.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

Check that there is adequate fluid in the tank.

fluid

CO-9 (KA24DE)

Engine coolant level Check the coolant level when the engine is cold.

CO-32 (YD25DDTi)

Check the level after parking the vehicle (on a level ground) and turning off the LU-6 (KA24DE)

Engine oil level

engine. LU-18 (YD25DDTi)

Brake and clutch fluid Make sure that the brake and clutch fluid levels are between the MAX and MIN

BR-7, CL-5

levels lines on the reservoir(s).

Battery Check the fluid level in each cell. It should be between the MAX and MIN lines.

Revision: September 2009 MA-4 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

A

For Mexico INFOID:0000000005473101

FOR MEXICO: Explanation of Periodic Maintenance B

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required. C

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

EMISSION CONTROL SYSTEM MAINTENANCE

D

Abbreviations: I = Inspect and correct or replacee as necessary, R = Replace, E = Check and correct the engine coolant mixture ratio.

MAINTENANCE OPERA-

MAINTENANCE SCHEDULE

TION E

km x Refer-

Perform at a ki- 10 20 30 40 50 60 70 80 90 100 110 120 130 140

1,000 ence

lometer (mile)

or month inter- Miles x page

6.0 12.0 18.0 24.0 30.0 36.0 42.0 48.0 54.0 60.0 66.0 72.0 78.0 84.0 F

val, whichever 1,000

comes first.

Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84

EMISSION CONTROL SYSTEM MAINTENANCE G

Engine oil and

R R R R R R R R R R R R R R LU-7

engine oil filter

See H

Engine coolant E R R CO-10

(NOTE 1)

See

Drive belts I I I EM-15

(NOTE 2) I

Spark plugs

(For unleaded R R R MA-23

fuel)

J

Ignition wires I I I

Air cleaner fil-

ter (Viscous R R R MA-21 K

paper type)

Intake and ex-

See

haust valve EM-68 MA

(NOTE 3)

clearance

Fuel lines I I I FL-3

EVAP vapor M

lines (With car- I I I MA-25

bon canister)

Fuel filter (In- See

tank type) NOTE (4)

FL-4 N

Cooling sys-

I I I CO-9

tem

O

NOTE:

(1) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant. After first replacement, replace every 40,000

km (24,000 miles) or 24 months.

P

(2) Replace the drive belts if found damaged.

(3) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(4) Fuel filter is maintenance-free.

ENGINE AND EMISSION CONTROL MAINTENANCE (YD25DDTi DIESEL ENGINE)

Revision: September 2009 MA-5 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Check filter and drain water, E = Check and correct the

engine coolant mixture ratio C = Clean.

MAINTENANCE

MAINTENANCE SCHEDULE

OPERATION

Per- km x

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

form at 1,000

a kilo-

Miles Refer-

meter

x 3.0 6.0 9.0 12.0 15.0 18.0 21.0 24.0 27.0 30.0 33.0 36.0 39.0 42.0 45.0 48.0 ence

(mile) or

1,000 page

month

interval,

which-

Month

ever 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48

s

comes

first.

EMISSION CONTROL SYSTEM MAINTENANCE

Engine

See

oil and

NOTE I I R I I R I I R I I R I I R I LU-18

engine

(1)

oil filter

See

Engine

NOTE E R R CO-33

coolant

(2)

See

Drive

NOTE I I I I EM-88

belts

(3)

Air

cleaner

filter

C C C C C C C R C C C C C C C R MA-33

(Dry pa-

per

type)

Intake

and ex-

See

haust EM-

NOTE

valve 202

(4)

clear-

ance

Fuel

I I FL-11

lines

Fuel fil-

D R D R D R D R D R D FL-14

ter

See

Fuel in- EM-

NOTE

jector 117

(5)

NOTE:

(1) Never use API CG-4 grade oil. Oil filter element assembly and O-ring seal are replacement parts.

(2) Use NISSAN Genuine Engine Coolant, or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system.

(3) Replace the belt if found damage or if the auto belt tensioner reading reaches the maximum limit.

(4) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(5) If engine power decreases, black exhaust smoke is emitted or engine noise increases, perform this maintenance item.

CHASSIS AND BODY MAINTENANCE

Revision: September 2009 MA-6 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate, T = Tighten.

MAINTENANCE OP-

MAINTENANCE SCHEDULE

A

ERATION

Perform at a km x

10 20 30 40 50 60 70 80 90 100 110 120 130 140

kilometer 1,000 Reference B

(mile) or page

(Miles x

month inter- 6.0 12.0 18.0 24.0 30.0 36.0 42.0 48.0 54.0 60.0 66.0 72.0 78.0 84.0

1,000)

val, whichev-

er comes C

Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84

first.

Power steer-

ing fluid &

I I I I I I I MA-48 D

lines (For

level & leaks)

Manual MA-38

transmission (FS5W71C) E

I I I I R I I

oil (For level MA-39

& leaks) (FS5R30A)

Transfer fluid F

(For level & I R I R I R I TF-9

leaks)

Differential

G

gear oil (For I R I R I R I MA-42

level & leaks)

Propeller

I R I R I R I MA-41 H

shaft

Brake pads,

MA-46,

rotors, drums I I I I I I I

MA-47

& linings I

Brake fluid

(for level and I I I I I I I BR-7

leaks) J

Brake fluid

(Replace- R R R MA-46,

ment)

K

Brake lines BR-10,

I I I I I I I

and cables PB-3, PB-7

Clutch fluid

MA

(for level and I I I I I I I CL-5

leaks)

Drive shafts I I I I I I I PR-6

M

Free-run-

ning hub I I I I I I I FSU-7

grease

Front wheel N

bearing I I I FSU-7

grease (4x2)

Front wheel O

bearing I R I R I R I FSU-29

grease (4x4)

Steering P

gear & link-

MA-48

age, axle & I I I

, MA-49

suspension

parts

Body mount-

T T T T T T T

ing

Revision: September 2009 MA-7 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

MAINTENANCE OP-

MAINTENANCE SCHEDULE

ERATION

Perform at a km x

10 20 30 40 50 60 70 80 90 100 110 120 130 140

kilometer 1,000 Reference

(mile) or page

(Miles x

month inter- 6.0 12.0 18.0 24.0 30.0 36.0 42.0 48.0 54.0 60.0 66.0 72.0 78.0 84.0

1,000)

val, whichev-

er comes

Months 6 12 18 24 30 36 42 48 54 60 66 72 78 84

first.

Wheel align-

ment (If nec-

essary rotate I I I I I I I WT-5

& balance

wheels)

Foot brake,

parking

brake & BR-5,

clutch (For I I I I I I I PB-3,

free play, PB-7

stroke & op-

eration)

Clutch sys-

I I I I I I I CL-5

tem

Exhaust sys-

I I I MA-37

tem

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A Driving under dusty conditions

B Repeatedly driving short distances

C Towing a trailer or caravan

D Extensive idling

E Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Driving in high humidity or mountainous areas

G Driving in areas using salt or other corrosive materials

H Driving on rough and/or muddy roads or in the desert

I Driving with frequent use of braking or in mountainous areas

J Frequent driving in water

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

Mainte-

Reference

Driving condition Maintenance item nance Maintenance interval

page

operation

A . . . . . . . . . Air cleaner filter Viscous paper type Replace More frequently MA-33

Engine oil & engine oil filter Every 5,000 km (3,000 LU-7,

A B C D . . . . . . Replace

(Gasoline engine) miles) or 3 months MA-23

Engine oil & engine oil filter Every 7,500 km (4,500 LU-7,

A B C D . . . . . . Replace

(Diesel engine) miles) or 6 months MA-35

Every 10,000 km (6,000

A . . . E . . . . . Fuel filter Diesel engine Replace MA-30

miles)

Every 20,000 km (12,000

. . . . E F . . . . Brake fluid Replace BR-7

miles) or 12 months

Front wheel bearing grease (4WD) & Every 5,000 km (3,000

. . . . . . . . . J Inspect FAX-5

Free-running hub grease miles) or 3 months

Revision: September 2009 MA-8 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

MA-48,

Steering gear box & linkage, axle & sus- Every 20,000 km (12,000 MA-49, A

. . . . . . G H . . Inspect

pension parts miles) or 12 months MA-41,

MA-48

Every 10,000 km (6,000 B

. . . . . . G H . . Propeller shaft & drive shafts Inspect MA-47

miles) or 6 months

Maintenance for off-road driving (4WD only) C

Whenever you drive off-road through sand, mud or water, more frequent maintenance may be required of the

following items:

Brake pads and rotors

Brake lining and drums D

Brake lines and hoses

Differential gear oil, transfer fluid

Steering linkage E

Propeller shafts and front drive shafts

Air cleaner filter

Clutch housing

F

EXCEPT FOR MEXICO INFOID:0000000005783154

EXCEPT FOR MEXICO: Explanation of Periodic Maintenance G

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required. H

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE (KA24DE ENGINE)

I

Abbreviations: I = Inspect and correct or replacee as necessary, R = Replace, E = Check and correct the engine coolant mixture ratio.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

km x Refer- J

1,000 10 20 30 40 50 60 70 80 ence

Perform at a kilometer (mile) or month interval,

(Miles x (6) (12) (18) (24) (30) (36) (42) (48) page

whichever comes first.

1,000) 6 12 18 24 30 36 42 48

Months K

Engine compartment and under vehicle

See

Intake and exhaust valve clearance MA

NOTE EM-68

(1)

See

Drive belts NOTE I I EM-15 M

(2)

Engine oil (Use recommended oil) R R R R R R R R LU-7

Engine oil filter (Use genuine NISSAN engine N

R R R R R R R R LU-9

oil filter or equivalent)

See

Engine coolant (Use Genuine NISSAN Engine O

NOTE E R CO-10

Coolant or equivalent in its quality)

(3)

Cooling system I I I I CO-9

Fuel lines I I FL-3 P

Air cleaner filter (Viscous paper type) R R EM-17

See

Fuel filter (In-tank type) NOTE FL-4

(4)

Spark plugs (For unleaded fuel) R R EM-19

Revision: September 2009 MA-9 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

MAINTENANCE OPERATION MAINTENANCE INTERVAL

km x Refer-

1,000 10 20 30 40 50 60 70 80 ence

Perform at a kilometer (mile) or month interval,

(Miles x (6) (12) (18) (24) (30) (36) (42) (48) page

whichever comes first.

1,000) 6 12 18 24 30 36 42 48

Months

Ignition wires I I

EVAP vapor lines (With carbon canister) I I MA-25

See EC-

Heated oxygen sensor 1 NOTE I I 407,

(5) EC-417

NOTE:

Maintenance items with should be performed more frequently according to Maintenance Under Severe Driving Condi-

tions.

(1) If valve noise increases, check valve clearance.

(2) Replace the drive belts if found damaged.

(3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant. After first replacement, replace every 40,000

km (24,000 miles) or 24 months.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) For OBD equipped modules, periodic maintenance is not required.

ENGINE AND EMISSION CONTROL MAINTENANCE (YD25DDTi DIESEL ENGINE)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, D = Check filter and drain water, E = Check and correct the

engine coolant mixture ratio.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

km x Refer-

Perform at a kilometer (mile) or 1,000 10 20 30 40 50 60 70 80 ence

month interval, whichever comes (Miles x (6) (12) (18) (24) (30) (36) (42) (48) page

first. 1,000) 6 12 18 24 30 36 42 48

Months

Engine compartment and under vehicle

See

Intake & exhaust valve clearance EM-202

NOTE(1)

Drive belts I I I I EM-88

See

Engine oil (Use recommended oil.) Replace every 15,000Km (9,000 miles) or 12 months LU-19

NOTE(2)

Engine oil filter (Use genuine NIS- See

Replace every 15,000Km (9,000 miles) or 12 months LU-21

SAN engine oil filter or equivalent) NOTE(3)

Engine coolant (Use Genuine NIS-

See

SAN Engine Coolant or equivalent in E R CO-32

NOTE(4)

its quality)

Cooling system I I I I CO-32

Fuel lines I I MA-30

Clean air cleaner filter every 5,000km (3,000 miles)

Air cleaner filter (Dry paper type) EM-90

R R

Fuel filter - Water drain D D D D D D D D FL-14

Fuel filter - Replacement Replace every 15,000Km (9,000 miles) FL-12

See

Fuel injector EM-117

NOTE(5)

NOTE:

Maintenance items with should be performed more frequently according to Maintenance Under Severe Driving Condi-

tions.

Revision: September 2009 MA-10 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Never use API CG-4 grade oil. A

(3) Oil filter element assembly and O-ring seal are replacement parts.

(4) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine engine coolant. After first replacement, replace every 40,000 B

km (24,000 miles) or 24 months.

(5) If engine power decreases, black exhaust smoke is emitted or engine noise increases, perform this maintenance item.

CHASSIS AND BODY MAINTENANCE C

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate, T = Tighten.

MAINTENANCE OPERATION MAINTENANCE INTERVAL D

km x 1,000 10 20 30 40 50 60 70 80 Reference

Perform at a kilometer (mile) or month page

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48)

interval, whichever comes first.

Months 6 12 18 24 30 36 42 48

E

Underhood and under vehicle

BR-7,

Brake, clutch & manual steering gear

I I I I I I I I CL-5,

fluid (For level & leaks)

MS-15

F

Brake fluid R R BR-7

Brake booster vacuum hoses, connec-

I I BR-19

G

tions & check valve

Power steering fluid & lines (For level &

I I I I PS-7

leaks) H

BR-7,

Brake, clutch & exhaust system I I I I I I I I MA-37,

MA-37

I

MT-10

Manual transmission gear oil (For level (FS5W71C)

See NOTE(1) I I I I

& leaks) MT-49

(FS5R30A) J

Transfer fluid (For level & leaks) I I I R I I I R TF-9

Differential gear oil (For level & leaks) I I I R I I I R RFD-7

K

Limited-slip differential (LSD) gear oil

I I I R I I I R RFD-7

(For level & leaks or replace)

Steering gear & linkage, axle & sus- MA-48,

pension parts, propeller shaft,& drive MA

I I I I I I I I MA-49,

shafts MA-41,

Body mountings*1 T T T T -

M

Outside and inside

FSU-23,

(2WD)

N

Wheel alignment (If necessary, rotate WT-5,

I I I I

& balance wheels) (4WD)

FSU-44,

WT-5 O

Brake pads, rotors & other brake com-

I I I I I I I I BR-32

ponents

Free-running hub grease I I I I FAX-15 P

Front wheel bearing grease (2WD) I I FAX-5

Front wheel bearing grease (4WD) I* R I* R FAX-5

Brake linings, drums & other brake

I I I I MA-47

components&

Locks, hinges & hood latch L L L L L L L L MA-50

Revision: September 2009 MA-11 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

MAINTENANCE OPERATION MAINTENANCE INTERVAL

km x 1,000 10 20 30 40 50 60 70 80 Reference

Perform at a kilometer (mile) or month page

(Miles x 1,000) (6) (12) (18) (24) (30) (36) (42) (48)

interval, whichever comes first.

Months 6 12 18 24 30 36 42 48

Seat belts, buckles, retractors, anchors

I I I I MA-50

& adjusters

PB-3,

Foot brake, parking brake & clutch (For

I I I I I I I I PB-7,

free play, stroke & operation)

CL-5

*1: It is applicable, when the vehicle is in use of commercial vehicle.

NOTE:

Maintenance items with should be performed more frequently according to Maintenance Under Severe Driving Condi-

tions.

(1) Replace manual transmission gear oil every 100,000 km (60,000 miles).

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A Driving under dusty conditions

B Repeatedly driving short distances

C Towing a trailer or caravan

D Extensive idling

E Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F Driving in high humidity or mountainous areas

G Driving in areas using salt or other corrosive materials

H Driving on rough and/or muddy roads or in the desert

I Driving with frequent use of braking or in mountainous areas

J Frequent driving in water

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

Mainte-

Reference

Driving condition Maintenance item nance Maintenance interval

page

operation

EM-17

(KA24DE),

A . . . . . . . . . Air cleaner filter Viscous paper type Replace More frequently EM-90

(YD25DDT

i)

Engine oil & engine oil filter Every 5,000 km (3,000 LU-7,

A B C D . . . . . . Replace

(Gasoline engine) miles) or 3 months LU-9

Engine oil & engine oil filter Every 7,500 km (4,500 LU-19,

A B C D . . . . . . Replace

(Diesel engine) miles) or 6 months LU-21

FL-4

(KA24DE),

Every 10,000 km (6,000

A . . . E . . . . . Fuel filter Diesel engine Replace FL-12

miles)

(YD25DDT

i)

Every 20,000 km (12,000

. . . . . F . . . . Brake fluid Replace BR-7

miles) or 12 months

Front wheel bearing grease (4WD) & Every 5,000 km (3,000

. . . . . . . . . J Inspect FSU-44

Free-running hub grease miles) or 3 months

MA-48,

Steering gear box & linkage, axle & sus-

Every 5,000 km (3,000 MA-49,

. . . . . . G H . . pension parts, propeller shaft, & drive Inspect

miles) or 3 months MA-41,

shafts

FFD-30

Revision: September 2009 MA-12 2010 D22 LCV

PERIODIC MAINTENANCE

< SERVICE INFORMATION >

Brake pads, rotors & other brake compo- Every 5,000 km (3,000

A . C . . . G H I . Inspect BR-32

nents miles) or 3 months A

Brake linings, drums & other brake com- Every 10,000 km (6,000

A . C . . . G H I . Inspect BR-32

ponents miles) or 6 months

Every 5,000 km (3,000 B

. . . . . . G . . . Locks, hinges & hood latch Lubricate MA-50

miles) or 3 months

Maintenance for off-road driving (4WD only) C

Whenever you drive off-road through sand, mud or water, more frequent maintenance may be required of the

following items:

Brake pads and rotors D

Brake lining and drums

Brake lines and hoses

Differential gear oil, transfer fluid

Steering linkage E

Propeller shafts and front drive shafts

Air cleaner filter

Clutch housing F

MA

Revision: September 2009 MA-13 2010 D22 LCV

RECOMMENDED FLUIDS AND LUBRICANTS

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants INFOID:0000000005473102

Capacity (Approximate)

Imp mea- Recommended Fluids/Lubricants

Liter

sure

KA24DE 3.5 3-1/8 qt Gasoline engine

With oil filter Except for Mexico and Brazil

2WD 5.6 4-7/8 qt

change YD25DDTi Genuine NISSAN engine oil*1

Engine oil 4WD 4.3 3-3/4 qt

API grade SJ, SL or SM*1

Drain and refill KA24DE 3.3 2-7/8 qt ILSAC grade GF-2, GF-3 or GF-4*1

Without oil

2WD 5.3 4-5/8 qt Viscosity SAE 5W-30*1

filter change YD25DDTi For Mexico

4WD 4.0 3-1/2 qt

Genuine NISSAN engine oil*1

API grade SL or SM*1

KA24DE 4.1 3-5/8 qt ILSAC grade GF-2, GF-3 or GF-4*1

Viscosity SAE 10W-30*1

For Brazil

2WD 6.3 1-3/8 gal Genuine NISSAN engine oil*1

API grade SL or SM*1

Dry engine (engine overhaul) ILSAC grade GF-3 or GF-4*1

Viscosity SAE 15W-50*1

Diesel engine

YD25DDTi

4WD 5.0 4-3/8 qt Genuine NISSAN engine oil*1

API grade CF-4*1*2

JASO DH-1*1

ACEA B1, B3, B4, or B5

Viscosity SAE 5W-30 *1

KA24DE 7.7 6-3/4 qt

Cooling system (with reservoir) Genuine NISSAN Engine Coolant or equiva-

YD25DDTi 9.4 8-1/4 qt

lent in its quality*3

Reservoir tank 0.8 3/4 qt

KA24DE 2.0 1-3/4 qt

Genuine NISSAN Manual Transmission Fluid

Manual transmission gear oil 2WD 3.05 2-5/8 qt (MTF) HQ Multi 75W-85 or API GL-4, Viscos-

YD25DDTi ity SAE 75W-85

4WD 5.1 4-1/2 qt

Genuine NISSAN Matic C ATF, or equivalent

Transfer fluid TX15B 2.2 2 pt

*4 or API GL-4, Viscosity SAE75W-90

Genuine NISSAN Differential Oil Hypoid Su-

Front 1.3 2-1/4 pt per GL-5 80W-90 or API GL-5, Viscosity SAE

80W-90

C200 with-

out LSD

1.3 2-1/4 qt API GL-5, Viscosity SAE 90 or equivalent*1

Differential gear oil

Rear

C200 with Genuine NISSAN Differential Oil Hypoid LSD

1.3 2-1/4 pt

LSD GL-5 80W-90LS or equivalent

M216

35.2 - 38.7

Power steering fluid 1.0 - 1.1

oz Genuine NISSAN PSF or equivalent*5

Brake and clutch fluid DOT 3 (US FMVSS No. 116)

Multi-purpose grease NLGI No. 2 (Lithium soap base)

*1: For further details, see SAE Viscosity Number.

*2: Never use API CG-4.

Revision: September 2009 MA-14 2010 D22 LCV

RECOMMENDED FLUIDS AND LUBRICANTS

< SERVICE INFORMATION >

*3: Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within the engine

cooling system caused by the use of non-genuine engine coolant. A

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Genuine NISSAN Matic D or equivalent (if available).

B

*5: DEXRONTM VI type ATF may be used.

SAE Viscosity Number INFOID:0000000005473103

C

GASOLINE ENGINE

For Mexico:

10W-30 is preferable. D

5W-30 is also preferable and will improve fuel economy.

For Brazil: E

15W-50 is preferable.

5W-30 is also preferable and will improve fuel economy.

If 15W-50 or 5W-30 is not available, select the viscosity, from the

chart, that is suitable for outside temperature range. F

Except for Mexico and Brazil:

5W-30 is preferable. G

If 5W-30 is not available, select the viscosity, from the chart, that is

suitable for outside temperature range.

H

J

JPPIA0003GB

DIESEL ENGINE

5W-30 is preferable. K

If 5W-30 is not available, select the viscosity, from the chart, that is

suitable for outside temperature range.

MA

AWPIA0003GB

Revision: September 2009 MA-15 2010 D22 LCV

RECOMMENDED FLUIDS AND LUBRICANTS

< SERVICE INFORMATION >

DIFFERENTIAL GEAR OIL

For warm and cold areas: 90 for the rear differential gear is prefer-

able.

For hot areas: 90 for the rear differential gear is suitable for ambi-

ent temperatures below 40 C (104F).

AWPIA0004GB

Engine Coolant Mixture Ratio INFOID:0000000005473104

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genu-

ine NISSAN Engine Coolant or equivalent in its quality with

the proper mixture ratio. See the examples shown right.

The use of other types of engine coolant may damage your

cooling system.

SMA089D

When checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer reading (specific gravity) according to coolant

temperature.

Mixed coolant specific gravity

Unit: specific gravity

Engine coolant mixture Coolant temperature C (F)

ratio 15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

Revision: September 2009 MA-16 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

ENGINE MAINTENANCE (KA24DE)

A

Checking Drive Belts INFOID:0000000005783161

AMA150

J

1. Inspect belt for cracks, fraying, wear and oil. If necessary, replace.

2. Inspect drive belt deflection or tension at a point on the belt midway between pulleys using Tool.

K

Tool number : BT-3373-F

NOTE:

Inspect drive belt deflection or tension when engine is cold. MA

Adjust if belt deflections exceed the limit or if belt tension is not within specifications.

Drive belt tension can be checked at other points on the belt, if necessary.

DRIVE BELT DEFLECTION AND TENSION M

Deflection adjustment Unit: mm (in) Tension adjustment *1 Unit: N (kg, lb)

Used belt Used belt N

New belt New belt

Limit After adjustment Limit After adjustment

355.8 - 444.8

10 - 12 (0.39 - 8 - 10 (0.31 - 222.4 (22.7, 489.3 - 578.2 (49.9 O

Generator 17 (0.67) (36.3 - 45.4, 80 -

0.47) 0.39) 50) - 59.0, 110 - 130)

100)

355.8 - 444.8

Air conditioner 10 - 12 (0.39 - 8 - 10 (0.31 - 200.2 (20.4, 489.3 - 578.2 (49.9

16 (0.63) (36.3 - 45.4, 80 - P

compressor 0.47) 0.39) 45) - 59.0, 110 - 130)

100)

355.8 - 444.8

Power steering 10 - 13 (0.39 - 8 - 10 (0.31 - 222.4 (22.7, 489.3 - 578.2 (49.9

17 (0.67) (36.3 - 45.4, 80 -

oil pump 0.51) 0.39) 50) - 59.0, 110 - 130)

100)

Applied pushing

98 N (10 kg, 22 lb)

force

*1: If belt tension gauge cannot be installed at check point shown, check belt tension at a different location on the belt.

Revision: September 2009 MA-17 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

Changing Engine Coolant INFOID:0000000005783162

WARNING:

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to release

built-up pressure. Then turn cap all the way.

Be careful not to allow engine coolant to contact drive belts.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove radiator cap.

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

When draining all engine coolant in the system, also perform the following steps.

2. Open cylinder block drain plug. Refer to EM-53, "Component".

3. Remove reservoir tank, drain engine coolant, then clean reservoir tank.

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system.

REFILLING ENGINE COOLANT

1. Install reservoir tank.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-53,

"Component".

2. Install the radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring.

Radiator drain plug: : 1.2 Nm (0.12 kg-m, 11 in-lb)

3. Make sure that each hose clamp has been firmly tightened.

4. Fill radiator and reservoir tank to the specified level.

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2-1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use Genuine Nissan Engine Coolant or equivalent mixed

with water (distilled or demineralized). Refer to MA-16,

"Engine Coolant Mixture Ratio".

Engine coolant capacity : Approx. 7.7 (8-1/8 US qt,

(with reservoir tank at 6-3/4 lmp qt)

MAX level) SMA182B

Reservoir tank capacity : 0.8 (7/8 US qt, 3/4 lmp qt)

(at MAX level)

When engine coolant overflows air relief hole, install air relief

plug and install the radiator cap.

SMA412B

5. Start engine and warm it up until it reaches normal operating temperature (10 minutes maximum).

If engine coolant overflows radiator filler hole, install radiator cap.

Revision: September 2009 MA-18 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

6. Keep racing at 2000-2500 rpm and refill through reservoir tank filler until engine coolant level stabilizes on

MAX. Close reservoir tank cap and continue warm up until thermostat is opened (check the radiator A

hose).

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine. B

7. Stop the engine. After it has completely cooled down (using a fan to reduce the time), start engine and

keep it at idling.

8. Check the engine coolant level and refill engine coolant only through reservoir tank filler. C

9. If the engine coolant level lowered, repeat steps 4 through 7 checking that engine coolant level on reser-

voir tank is stabilized on MAX.

10. Check cooling system for leaks with engine running. D

11. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

Sound may be noticeable at heater unit. E

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating steps 4 through 7 until engine coolant level

no longer drops. F

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap. G

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

H

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer to MA-18.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator. I

System Inspection INFOID:0000000005473107

WARNING: J

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pres-

sure coolant escaping from the radiator.

Wrap a thick cloth around the radiator cap. Slowly turn it a quarter turn to allow built-up pressure to K

escape. Carefully remove the radiator cap by turning it all the way.

LEVEL CHECK

Check if the reservoir tank engine coolant level is within MIN to MA

MAX when engine is cool.

Refill engine coolant if necessary. Refer to CO-10, "Changing

Engine Coolant".

M

SMA412B O

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, chafing and deterioration.

P

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows:

CAUTION:

Be careful not to bend or damage the radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radia-

tor shroud and horns.

Tape the harness connectors to prevent water from entering.

Revision: September 2009 MA-19 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing when water flows clear coming out of the radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (5 kg/cm2, 71 psi) and keep the air hose end more than 30 cm

(11.8 in) away from the core.

5. Blow air again into all the radiator core surfaces once per minute until no water blows out and the core is

dry.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with a

suitable tool and Tool.

CAUTION:

Higher test pressure than specified may cause cooling sys-

tem damage.

Testing pressure : 157 kPa (1.6 kg/cm2, 23 psi)

Tool number : EG17650301 (J-33984-A)

If anything is found, repair or replace damaged parts. SLC756A

CHECKING RADIATOR CAP

To check radiator cap, apply pressure to radiator cap with a suit-

able tool and Tool.

Radiator cap relief pressure

Standard : 78 - 98 kPa (0.8 - 1.0 kg/cm2, 11 - 14 psi)

Limit : 59 kPa (0.6 kg/cm2, 9 psi)

Tool number : EG17650301 (J-33984-A)

SLC755A

Pull the negative pressure valve to open it.

Check that it closes completely when released.

SMA967B

Revision: September 2009 MA-20 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

Checking Fuel Line INFOID:0000000005783163

A

Inspect the fuel lines, filler cap and tank for improper attachment,

leaks, cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts. B

D

SMA803A

Component INFOID:0000000005473109

E

MA

ALBIA0588GB

M

1. Air cleaner assembly support 2. Drain tube 3. Air cleaner case (upper)

4. Wing nut 5. PCV valve 6. Air cleaner filter

7. Air duct bolts 8. Air duct 9. Intake air temperature sensor N

10. Air cleaner case (lower) 11. Clip 12. Air cleaner case bolt (lower)

Front

O

Changing Engine Air Filter INFOID:0000000005473110

REMOVAL P

1. Disconnect intake air temperature sensor harness connector.

2. Disconnect vacuum hoses from air duct.

3. Remove air duct bolts and air duct.

4. Remove air cleaner case bolt (lower).

5. Disconnect PCV hose from air cleaner case (lower).

Revision: September 2009 MA-21 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

6. Remove wing nuts and air cleaner assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

If intake air temperature sensor is dropped, do not reuse it.

CHANGING AIR CLEANER FILTER

Removal

1. Remove wing nuts.

2. Disconnect air duct from air cleaner case (upper).

3. Disconnect clips from air cleaner case (upper) and remove air

cleaner case (upper).

4. Remove air cleaner filter.

SMA243C

Installation

Installation is in the reverse order of removal.

Changing Engine Oil INFOID:0000000005783164

WARNING:

Be careful not to burn yourself, as the engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-6, "Inspection".

2. Stop engine and wait for 10 minutes.

3. Loosen oil filler cap and then remove drain plug.

4. Drain engine oil.

5. Install drain plug with new washer. Refer to EM-21, "Component".

CAUTION:

Be sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 34.3 Nm (3.5 kg-m, 25 ft-lb)

6. Refill with new engine oil. Refer to MA-14, "Fluids and Lubricants".

Engine oil capacity (Approximate):

Unit: (US qt, lmp qt)

With oil filter change 3.5 (3-3/4, 3-1/8)

Drain and refill

Without oil filter change 3.3 (3-1/2, 2-7/8)

Dry engine (Overhaul) 4.1 (4-3/8, 3-5/8)

CAUTION:

When filling engine oil, never pull out oil level gauge.

The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

Always use the oil level gauge to determine when the proper amount of engine oil is in the

engine.

7. Warm up engine and check area around drain plug and oil filter for oil leakage.

8. Stop engine and wait for 10 minutes.

Revision: September 2009 MA-22 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

9. Check the engine oil level. Refer to LU-6, "Inspection".

A

Changing Engine Oil Filter INFOID:0000000005473112

REMOVAL

B

1. Remove engine undercover.

2. Place a pan to catch the engine oil under the oil filter before removing.

3. Use a suitable tool to remove oil filter. C

CAUTION:

Be careful not to get burned when engine and engine oil are hot.

When removing, prepare a shop cloth to absorb any engine oil leakage or spillage. D

Do not allow engine oil to spill on drive belts.

Completely wipe off any engine oil that spills on engine and vehicle.

Oil filter is provided with a relief valve. Use Genuine Nissan Oil Filter or equivalent.

E

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal circumference of new oil fil- F

ter.

Use Genuine Nissan Oil Filter or equivalent.

G

SMA010 I

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification. J

Oil filter:

: 18 Nm (1.8 Kg-m, 13 ft-lb) K

MA

SMA229B

INSPECTION AFTER INSTALLATION M

1. Check the engine oil level. Refer to LU-6, "Inspection".

2. Start engine, and check there is no leakage of engine oil.

N

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as necessary. Refer to LU-6, "Inspection".

Changing Spark Plugs INFOID:0000000005473113

O

REMOVAL

P

Revision: September 2009 MA-23 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

1. Disconnect ignition wires from spark plugs at boot.

CAUTION:

Do not pull on the wire.

SMA356CA

2. Remove spark plugs with spark plug wrench.

SMA581C

Spark Plug

Make NGK

Standard type BKR5E-11

Use standard type spark plug under normal conditions.

Do not use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Cleaner air pressure : Less than 588 kPa (6 kg/cm2, 85

psi)

Cleaning time : Less than 20 seconds

SMA673B

Checking and adjusting plug gap is not required between

change intervals.

Spark plug gap (nominal) : 1.1 mm (0.043 in)

SMA806C

INSTALLATION

Installation is in the reverse order of removal.

Revision: September 2009 MA-24 2010 D22 LCV

ENGINE MAINTENANCE (KA24DE)

< SERVICE INFORMATION >

Checking EVAP Vapor Line INFOID:0000000005473114

A

1. Visually inspect EVAP vapor lines for improper attachment and for cracks, damage, loose connections,

chafing and deterioration.

2. Inspect fuel tank filler cap vacuum relief valve for clogging, sticking, etc. B

MA

Revision: September 2009 MA-25 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

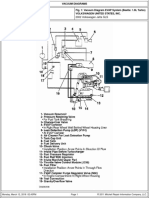

ENGINE MAINTENANCE (YD25DDTI)

Checking Drive Belts INFOID:0000000005783166

INSPECTION

AWBIA0629ZZ

1. Generator pulley 2. Water pump pulley 3. Generator and water pump belt

4. Crankshaft pulley 5. Idler pulley 6. Power steering pump pulley

7. Power steering pump belt 8. A/C compressor belt 9. Idler pulley

10. A/C compressor pulley 11. Idler pulley

Before inspecting engine, make sure engine has cooled down; wait approximately 30 minutes after engine

has been stopped.

Visually inspect all belts for wear, damage or cracks on contacting surfaces and edge areas.

Measure deflection at the marked point ( ).

CAUTION:

When checking belt deflection immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust to the specified value to avoid variation

in deflection between pulleys.

Tighten idler pulley lock nut by hand and measure deflection without looseness.

Belt Deflection:

Belt deflection with 98 N (10 kg, 22 lb) force applied* mm (in)

Applied belt

New Adjusted Limit for re-adjusting

7.0 - 8.0 9.5 - 10.5

A/C compressor belt 12.0 (0.472)

(0.276 - 0.315) (0.374 - 0.413)

6.5 - 7.5 8.0 - 9.5

Generator and water pump belt 12.5 (0.492)

(0.256 - 0.295) (0.315 - 0.374)

6.5 - 7.5 8.0 - 10.0

Power steering pump belt 11.5 (0.453)

(0.256 - 0.295) (0.315 - 0.394)

*: When engine is cold.

ADJUSTMENT

CAUTION:

When a new belt is installed as a replacement, adjust it to the value specified under "New" accom-

modations because of insufficient adaptability with pulley grooves.

If the belt deflection of the current belt is out of the "Limit for re-tightening", adjust to the "Adjusted"

value.

When checking belt deflection immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust it to the specified value to avoid variation

in deflection between pulleys.

Make sure the belts are fully positioned into the pulley grooves during installation.

Revision: September 2009 MA-26 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

Handle with care to avoid spilling engine oil or engine coolant on belts.

Do not twist or bend the belts with excessive force. A

A/C compressor belt (3) and power steering pump belt (2)

1. Loosen idler pulley lock nut (A).

2. Turn adjusting bolt (B) to adjust.

B

3. Tighten lock nut (A).

Lock nut (A) : 54 Nm (5.5 kg-m, 40 ft-lb)

C

Generator and water pump belt (1)

1. Loosen adjuster lock nut (C).

2. Loosen generator nut (D) (rear).

3. Turn adjusting bolt (E) to adjust. D

4. Tighten lock nut (C) and (D) in this order.

Lock nut (C) : 18.1 Nm (1.8 kg-m, 13 ft-lb) E

Lock nut (D) : 50.5 Nm (5.2 kg-m, 37 ft-lb)

AWBIA0630ZZ

H

Changing Engine Coolant INFOID:0000000005783168

WARNING: I

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around cap and carefully remove cap. First, turn cap a quarter of a turn to release

built-up pressure. Then turn cap all the way.

Be careful not to allow engine coolant to contact drive belts. J

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove radiator cap. K

CAUTION:

Be careful not to allow engine coolant to contact drive belts.

MA

When draining all engine coolant in the system, also perform the following steps.

2. Open cylinder block drain plug. Refer to EM-179, "Component".

3. Remove reservoir tank, drain engine coolant, then clean reservoir tank. M

4. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush engine cooling system.

REFILLING ENGINE COOLANT N

1. Install reservoir tank.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to EM-179,

"Component". O

2. Install the radiator drain plug.

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. P

Radiator drain plug: : 1.2 Nm (0.12 kg-m, 11 in-lb)

3. Make sure that each hose clamp has been firmly tightened.

Revision: September 2009 MA-27 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

4. Fill radiator and reservoir tank to the specified level.

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2-1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use Genuine Nissan Engine Coolant or equivalent mixed

with water (distilled or demineralized). Refer to MA-16,

"Engine Coolant Mixture Ratio".

Engine coolant capacity : Approx. 9.4 (10.0 US qt, 8-

(with reservoir tank at 1/4 lmp qt)

MAX level) SMA182B

Reservoir tank capacity : 0.8 (7/8 US qt, 3/4 lmp qt)

(at MAX level)

When engine coolant overflows air relief hole, install air relief

plug and install the radiator cap.

SMA412B

5. Start engine and warm it up until it reaches normal operating temperature (10 minutes maximum).

If engine coolant overflows radiator filler hole, install radiator cap.

6. Keep racing at 2000-2500 rpm and refill through reservoir tank filler until engine coolant level stabilizes on

MAX. Close reservoir tank cap and continue warm up until thermostat is opened (check the radiator

hose).

CAUTION:

Watch engine coolant temperature gauge so as not to overheat the engine.

7. Stop the engine. After it has completely cooled down (using a fan to reduce the time), start engine and

keep it at idling.

8. Check the engine coolant level and refill engine coolant only through reservoir tank filler.

9. If the engine coolant level lowered, repeat steps 4 through 7 checking that engine coolant level on reser-

voir tank is stabilized on MAX.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

Sound may be noticeable at heater unit.

12. Repeat step 11 three times.

13. If sound is heard, bleed air from cooling system by repeating steps 4 through 7 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief plug. Fill radiator and

reservoir tank with water and reinstall radiator cap and reservoir tank cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water from the system. Refer to MA-27.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

System Inspection INFOID:0000000005473117

WARNING:

Revision: September 2009 MA-28 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pres-

sure coolant escaping from the radiator. A

Wrap a thick cloth around the radiator cap. Slowly turn it a quarter turn to allow built-up pressure to

escape. Carefully remove the radiator cap by turning it all the way.

LEVEL CHECK B

Check if the reservoir tank engine coolant level is within MIN to

MAX when engine is cool.

Refill engine coolant if necessary. Refer to CO-10, "Changing C

Engine Coolant".

E

SMA412B

CHECKING COOLING SYSTEM HOSES

Check hoses for improper attachment, leaks, cracks, damage, chafing and deterioration. F

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows: G

CAUTION:

Be careful not to bend or damage the radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radia-

tor shroud and horns. H

Tape the harness connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute. I

3. Stop washing when water flows clear coming out of the radiator.

4. Blow air into the back side of radiator core vertically downward.

J

Use compressed air lower than 490 kPa (5 kg/cm2, 71 psi) and keep the air hose end more than 30 cm

(11.8 in) away from the core.

5. Blow air again into all the radiator core surfaces once per minute until no water blows out and the core is

K

dry.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leakage, apply pressure to the cooling system with a MA

suitable tool and Tool.

CAUTION:

Higher test pressure than specified may cause cooling sys-

tem damage. M

Testing pressure : 157 kPa (1.57 bar, 1.6 kg/cm2,

23 psi) N

Tool number : EG17650301 (J-33984-A)

SLC756A O

If anything is found, repair or replace damaged parts.

CHECKING RADIATOR CAP

P

Revision: September 2009 MA-29 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

To check radiator cap, apply pressure to radiator cap with a suit-

able tool and Tool.

Radiator cap relief pressure

Standard : 98 - 118 kPa (0.98 - 1.18 bar, 1.0 - 1.2 kg/

cm2, 14 - 17 psi)

Limit : 78 kPa (0.78 bar, 0.8 kg/cm2, 11 psi)

Tool number : EG17650301 (J-33984-A)

SLC755A

Pull the negative pressure valve to open it.

Check that it closes completely when released.

SMA967B

Checking Fuel Line INFOID:0000000005783169

Inspect the fuel lines, filler cap and tank for improper attachment,

leaks, cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace faulty parts.

SMA803A

Changing Fuel Filter INFOID:0000000005473119

AWBIA0623GB

Revision: September 2009 MA-30 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

1. Fuel filter bracket 2. Fuel filter A. Refer to MA-31 A

Removal and Installation INFOID:0000000005473120

B

REMOVAL

1. Disconnect fuel hoses at fuel filter bracket.

C

1 : Fuel filter bracket

2 : Fuel hose (to engine)

3 : Fuel hose (from sedimentor)

D

CAUTION:

Plug the pipe to prevent fuel from draining.

E

ALBIA0595ZZ

2. Loosen mounting bolts (2) and remove fuel filter bracket (1) and F

fuel filter.

: Vehicle front G

CAUTION:

Do not splash fuel during removal. If fuel is splashed,

immediately wipe it off. H

I

ALBIA0596ZZ

3. Using band-type fuel filter wrench (A) (commercial service tool),

remove fuel filter (1). J

4. Turn fuel filter (1) upside down to drain fuel.

MA

AWBIA0624ZZ

M

INSTALLATION

Note the following, and install in the reverse order of removal.

Screw the fuel filter by hand until packing contacts sealing surface of fuel filter bracket. Then tighten it by

turning approximately 2/3 turn. N

Fuel filter (reference value)

O

: 13.5 Nm (1.4 kg-m, 10 ft-lb)

Revision: September 2009 MA-31 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

Install fuel filter bracket (1), and tighten mounting nuts (2) to the

specified torque.

: Vehicle front

Fuel filter bracket bolts

: 13.5 Nm (1.4 kg-m, 10 ft-lb)

ALBIA0596ZZ

After installation, bleed air from fuel line. Refer to MA-32, "Air Bleeding".

INSPECTION AFTER INSTALLATION

Use the following procedure to check for leaks.

- 1) Turn ignition switch ON (do not start engine). Then check connections for leaks by applying fuel pressure

to fuel piping.

- 2) Start the engine and let it idle, then check that there are no fuel leaks at the fuel piping connections.

Air Bleeding INFOID:0000000005783171

After fuel filter is replaced and after fuel system components are removed/installed, bleed air from fuel line as

follows:

Move priming pump (1) up and down to bleed air from fuel path.

When air is bled, pumping of priming pump becomes heavy, stop

operation at that time.

ALBIA0598ZZ

Crank engine until it starts. Do not crank engine for more than 30 seconds.

If engine does not start, stop cranking and repeat step 1 above.

If engine does not operate smoothly after it has started, rav it two or three times.

If air cannot be bled easily (pumping of priming pump does not become heavy), disconnect feed-side of hose

between fuel filter and electronically controlled fuel pump. After that, operate priming pump and confirm that

fuel comes out.

CAUTION:

Prepare a tray to collect fuel. Prevent fuel from adhering to rubber parts, especially the engine

mounting insulator.

Draining Water from Sedimentor INFOID:0000000005783170

CAUTION:

Drain water from sedimentor when fuel filter warning lamp

turns on as follows:

PBIC2664E

Revision: September 2009 MA-32 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

1. Prepare a tray under the drain plug. A

2. Loosen air bleeder screw of the sedimentor.

3. Loosen drain cock and drain water.

CAUTION: B

Loosening drain cock four to five turns causes water to

start draining. Do not remove drain cock by loosening it

excessively.

Water in filter is drained with fuel. Prepare larger capacity C

pan than fuel filter volume.

Drained water is mixed with fuel. Prevent fuel from adher-

ing to rubber parts such as engine mounting insulator. SMA281C

D

4. After draining, close drain cock by hand.

CAUTION:

If drain cock is tightened excessively, it may be damaged and fuel will leak. Do not use tools to E

tighten drain cock.

5. Bleed air in fuel piping. Refer to MA-32, "Air Bleeding".

6. Start engine and make sure there is no fuel leakage. F

Changing Engine Air Cleaner Filter INFOID:0000000005473123

MA

N

ALBIA0589GB

1. Air duct 2. Mass air flow sensor 3. Air cleaner case cover O

4. Air cleaner filter 5. Clip 6. Air cleaner case

7. Air cleaner assembly bracket 8. Clamp Front

A. To turbocharger P

Removal and Installation INFOID:0000000005473124

REMOVAL

1. Disconnect harness connector from mass air flow sensor.

2. Loosen clamps and remove air duct.

Revision: September 2009 MA-33 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

Add marks as necessary for easier installation.

3. Remove air cleaner assembly bolts and remove air cleaner assembly.

4. Remove mass air flow sensor from air cleaner case cover, if necessary.

CAUTION:

Do not shock it.

Do not disassemble it.

Do not touch its sensor.

5. Remove air cleaner assembly bracket bolts and air cleaner assembly bracket, if necessary.

INSTALLATION

Installation is in the reverse order of removal.

Align marks. Attach each joint. Tighten clamps firmly.

CHANGING AIR CLEANER FILTER

Removal

1. Disconnect harness connector from mass air flow sensor.

2. Loosen clamps and remove air duct.

Add marks as necessary for easier installation.

3. Release clips and remove air cleaner case cover.

4. Remove air cleaner filter.

Installation

Installation is in the reverse order of removal.

Changing Engine Oil INFOID:0000000005783167

WARNING:

Be careful not to burn yourself, as the engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up engine, put vehicle horizontally and check for engine oil leakage from engine components. Refer

to LU-18, "Inspection".

2. Stop engine and wait for 10 minutes.

3. Loosen oil filler cap (1) and then remove drain plug (3).

2 : Oil filter

: Engine front

PBIC3335E

4. Drain engine oil.

5. Install drain plug with new washer. Refer to EM-108, "Component".

CAUTION:

Be sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 34.3 Nm (3.5 kg-m, 25 ft-lb)

6. Refill with new engine oil. Refer to MA-14, "Fluids and Lubricants".

Engine oil capacity (Approximate):

Revision: September 2009 MA-34 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

Unit: (US qt, lmp qt)

With oil filter change (2WD) 5.6 (5-7/8, 4-7/8)

A

With oil filter change (4WD) 4.3 (4-1/2, 3-3/4)

Drain and refill

Without oil filter change (2WD) 5.3 (5-5/8, 4-5/8)

B

Without oil filter change (4WD) 4.0 (4-1/4, 3-1/2)

Overhaul (2WD) 6.3 (6-5/8, 5-1/2)

Dry engine

Overhaul (4WD) 5.0 (5-1/4, 4-3/8) C

CAUTION:

When filling engine oil, do not pull out oil level gauge.

The refill capacity depends on the engine oil temperature and drain time. Use these specifica- D

tions for reference only.

Always use the oil level gauge to determine when the proper amount of engine oil is in the

engine. E

7. Warm up engine and check area around drain plug and oil filter for oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to LU-18, "Inspection". F

Changing Engine Oil Filter INFOID:0000000005473126

G

REMOVAL

1. Remove engine undercover.

2. Place a pan to catch the engine oil under the oil filter removing. H

3. Use a suitable tool to remove oil filter.

CAUTION:

Be careful not to get burned when engine and engine oil are hot. I

When removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

Do not allow engine oil to spill on drive belts.

Completely wipe off any engine oil that spills on engine and vehicle.

J

Oil filter is provided with a relief valve. Use Genuine Nissan Oil Filter or equivalent.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface. K

2. Apply new engine oil to the oil seal circumference of new oil fil-

ter.

Use Genuine Nissan Oil Filter or equivalent. MA

N

SMA010

3. Screw oil filter manually until it touches the installation surface, O

then tighten it by 2/3 turn. Or tighten to specification.

Oil filter: P

: 18 Nm (1.8 Kg-m, 13 ft-lb)

SMA229B

Revision: September 2009 MA-35 2010 D22 LCV

ENGINE MAINTENANCE (YD25DDTI)

< SERVICE INFORMATION >

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-18, "Inspection".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer to LU-18, "Inspection".

Revision: September 2009 MA-36 2010 D22 LCV

CHASSIS AND BODY MAINTENANCE

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

A

Checking Exhaust System INFOID:0000000005783172

Check the exhaust pipes, muffler, and mounting components for B

incorrect attachment, leaks, cracks, damage, or deterioration.

SMA211A E

Checking Clutch Fluid Level and Leaks INFOID:0000000005473128

If fluid level is extremely low, check clutch system for leaks. F

SMA956C I

Inspection and Adjustment INFOID:0000000005473129

J

CLUTCH PEDAL INSPECTION AND ADJUSTMENT

1. Check to see if the clutch pedal clevis pin (1) floats freely in the

bore of the clutch pedal (2). It should not be bound by the clevis

K

(3) or clutch pedal.

a. If the clevis pin is not free, check that the pedal stopper bolt (A)

is not applying pressure to the clutch pedal causing the clevis

pin to bind. To adjust, loosen the pedal stopper bolt lock nut (B) MA

and turn the pedal stopper bolt.

b. Tighten the lock nut.

c. Verify that the clutch pedal clevis pin floats freely in the bore of M

the clutch pedal. It should not be bound by the clevis or clutch

pedal.

d. If the clevis pin is still not free, remove the clevis pin and check N

for deformation or damage. Replace the pin if necessary. Leave

the pin removed for step 2.

2. Check the clutch pedal stroke for free range of movement. O

a. With the clutch pedal clevis pin removed, manually move the

pedal up and down to determine if it moves freely.

b. If any sticking is noted, replace the related parts (clutch pedal, P

pedal bracket, assist spring, bushing, etc.). Reassemble the

pedal and re-verify that the clevis pin floats freely in the bore of

the pedal.

AWDIA0513GB

3. Check the clutch hydraulic system components (clutch master

cylinder, clutch operating cylinder, Clutch withdrawal lever, clutch release bearing, etc.) for sticking or

binding.

a. If any sticking or binding is noted, repair or replace the related parts as necessary.

Revision: September 2009 MA-37 2010 D22 LCV

CHASSIS AND BODY MAINTENANCE

< SERVICE INFORMATION >

b. If any hydraulic system repair was necessary, bleed the clutch hydraulic system by following the bleeding

procedure.

BLEEDING PROCEDURE

CAUTION:

Carefully monitor the fluid level at the clutch master cylinder during the bleeding operation.

Do not splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

NOTE:

Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or

power bleeder will not purge all of the air from the system.

1. Top off the clutch master cylinder reservoir with the recommended brake fluid "DOT 3".

2. Connect a transparent vinyl tube to the air bleeder valve on the

clutch operating cylinder as shown.

3. Slowly depress the clutch pedal to its full stroke and release it

completely. Repeat this operation several times at 2 to 3 sec-

onds intervals.

4. With the clutch pedal fully depressed, open the air bleeder valve

to release the air.

5. Close the air bleeder valve.

6. Release the clutch pedal and wait at least 5 seconds.

7. Repeat steps 3 through 6 above until no more air bubbles are in SCL203-A

the brake fluid coming out of the vinyl tube attached to the air

bleeder valve.

8. Close the air bleeder valve and tighten to specification.

Air bleeder valve : Refer to CL-10, "Component".

Checking Clutch System INFOID:0000000005473130

Check fluid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, chafing and deterioration.

SMA859

Checking M/T Oil - FS5W71C INFOID:0000000005473131

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from the transmission or around it.

2. Check oil level from the filler plug hole as shown.

CAUTION:

Do not start engine while checking oil level.

3. Apply sealant to the filler plug and install it to the transmission.