Escolar Documentos

Profissional Documentos

Cultura Documentos

Aig Tower 3/F To 5/F Transfer Truss Type A Joint Connection Calculation

Enviado por

Nasrul Adli0 notas0% acharam este documento útil (0 voto)

20 visualizações1 páginaweld

Título original

03B TYPE A

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoweld

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

20 visualizações1 páginaAig Tower 3/F To 5/F Transfer Truss Type A Joint Connection Calculation

Enviado por

Nasrul Adliweld

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

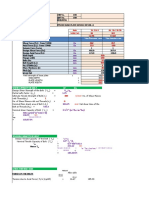

AIG TOWER

3/F TO 5/F TRANSFER TRUSS

TYPE A JOINT CONNECTION CALCULATION

WELD TYPE a3

JOINT MARK D205

MEMBER SIZE AND FORCE DATA

Top/Bottom Chord Data

Axial force(Design Force) from T/B Chord Nu(kN) 300

Shear force(Design Force) from T/B Chord Vu(kN) 400

Size Designation W360x990

Height of Chord Ha(mm) 550

Width of Chord Ba(mm) 448

Thickness of Chord web twa(mm) 72

Thickness of Chord flange tfa(mm) 115

Brace no. 1 Data

Axial force(Design Force) from Brace Nb1(kN) 600

Size Designation W360x509

Height of Brace H1(mm) 446

Width of Brace B1(mm) 416

Thickness of Brace web tw1(mm) 39

Thickness of Brace flange tf1(mm) 63

X component of slope h(mm) 3,060

Y component of slope v(mm) 5,550

Column Data

Size Designation W360x990

Height of Column Hc(mm) 550

Width of Column Bc(mm) 448

Thickness of Column web twc(mm) 72

Thickness of Column flange tfc(mm) 115

Plate Data

Gusset Plate Thickness (mm) type a2, a3 tg = max { H1-[min(Bc, Ba)]/2,tf1 } 63

Stiffener Plate Thickness at Chord (mm) ta=twa/2, if twa<20 ts=twa 36

WELD DESIGN CHECK OF BRACE TO GUSSET PLT CON.

Weld no. 1 Full Pen. Check

Design Axial Force per flange (kN) Fa1=Nb1/2 300

max thickness of joining plate (mm) max (tg, tf1) 63

Weld Design Strength (BS5950:2000) (MPa) pw=py 335

2

Effective Weld Area (Area of Flange) (mm ) Af1=tf1*B1 26,083

Allowalbe Axial Force,fa1 (kN) fa1=pw1*Af1/1000 8,738

Stress Ratio SR1=Fa1/fa1 0.03

WELD DESIGN CAL. OF GUSSET PLT TO TOP/BOT. CHORD

Weld no. 2

Partial Penetration weld

Design Shear shear (kN) Vu 400

calculate eccentricity:

y1, mm h (B1+80)/ [2*sqrt(v^2+h^2)] 120

y, mm y1+40+Ha/2 435

x, mm y*h/v 240

x1, mm y1*v/h 217

eccentricity,e mm x+x1 457

Induced Moment, M (kN-m) M (Vu*e) 183

Flange axial force due to moment, Fa2 Fa2 = M/ (Ha-tfa) 420

Design Axial Force per flange (kN) Fa1 = Nu/2 150

Total Flange forces, Fat (kN) Fat1 = Fa1+ Fa2 570

Fat2 = Fa1-Fa2 -270

Critical Design force, Fat (kN) max abs( Fa1,Fa2 ) 570

Note: Direct shear force is assumed carried by web

Length of weld, lw (mm) lw = Ba 448

Design strength of thicker plate (MPa) py = BS5950 295

Weld Design Strength pw = py 295

Req'd effective weld detph (mm) se = fat*1000/ (pw * lw) 5.0

Req'd Design weld depth (mm) s = se+3mm 8

Minimum depth req'd by BS5950 smin1 = 2*sqrt tfa + 3mm 24

Minimum depth req'd by dwg. no. C230 smin2 = smin+3mm 16

Used weld depth (mm) s2 = max(s,smin1,smin2) 24

Check of plate thickness if s2 > tfa, check plate thk. OK

Critical Design force/ unit length of weld (N/mm) fat = Fat/ lw 1,273

Actual weld capacity (N/mm) pw1 =(s2-3) *pw 6,327

Stress Ratio SR2 = fa1/Pw1 0.20

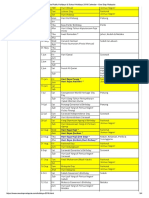

Você também pode gostar

- Calculation of Beam/Column Splice: HB-300x300x10x15Documento5 páginasCalculation of Beam/Column Splice: HB-300x300x10x15mustika05Ainda não há avaliações

- Beam - Column Steel SpliceDocumento20 páginasBeam - Column Steel SpliceAnsh SharmaAinda não há avaliações

- Beam - Column Steel SpliceDocumento22 páginasBeam - Column Steel Splicerelu59Ainda não há avaliações

- Doubly BeamDocumento4 páginasDoubly Beamsrinivasa raoAinda não há avaliações

- Perhitungan Perkuatan FRP Balok PrategangDocumento15 páginasPerhitungan Perkuatan FRP Balok PrategangAditya Bayu NugrahaAinda não há avaliações

- One Way Slab SAPDocumento3 páginasOne Way Slab SAPMANJUNATh EAinda não há avaliações

- Roof Beam Design CalculationDocumento5 páginasRoof Beam Design CalculationArnold VercelesAinda não há avaliações

- From RCC Col To Steel ColDocumento9 páginasFrom RCC Col To Steel ColJanya AssociatesAinda não há avaliações

- Base Plate Design (From RCC ColDocumento9 páginasBase Plate Design (From RCC ColJanya AssociatesAinda não há avaliações

- Cleat Angle ConnectionDocumento3 páginasCleat Angle ConnectionSrishti Project ConsultantsAinda não há avaliações

- Secondfloor Beam Design CalculationDocumento7 páginasSecondfloor Beam Design CalculationArnold VercelesAinda não há avaliações

- Normal Case: ProvidedDocumento3 páginasNormal Case: ProvidedDanish AhmadAinda não há avaliações

- Channel Steel Beam Torsion Design (EN1993)Documento5 páginasChannel Steel Beam Torsion Design (EN1993)Anupam AjayanAinda não há avaliações

- DESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Documento4 páginasDESIGN OF PILE CAP (For Four Piles Only) : Depth of Slab (MM) 700Mahananda RKAinda não há avaliações

- Shear Wall Design (IS 13920-2016)Documento8 páginasShear Wall Design (IS 13920-2016)Sahil OzaAinda não há avaliações

- Moment Connection DesignDocumento2 páginasMoment Connection DesignmaheshbandhamAinda não há avaliações

- Second Floor Beam Design CalculationDocumento5 páginasSecond Floor Beam Design CalculationArnold VercelesAinda não há avaliações

- Design of Singly Reinforced Beam SectionDocumento6 páginasDesign of Singly Reinforced Beam SectionREVATHY GOPALAinda não há avaliações

- B-1 - Canopy Base PlateDocumento2 páginasB-1 - Canopy Base PlateSaurabh GuptaAinda não há avaliações

- Roof Beam Design CalculationDocumento7 páginasRoof Beam Design CalculationArnold VercelesAinda não há avaliações

- WSD Connection MasterDocumento5 páginasWSD Connection MasterSteelfab Structural AssociatesAinda não há avaliações

- DGN - SGL - GayatriDocumento2 páginasDGN - SGL - GayatriSaurav KumarAinda não há avaliações

- Thiet Ke Cot Composite - EC4. V1.0 (MS03)Documento5 páginasThiet Ke Cot Composite - EC4. V1.0 (MS03)luuvandong48xf396Ainda não há avaliações

- Strut Waler Connection Design TemplateDocumento1 páginaStrut Waler Connection Design TemplateArjun Raja100% (1)

- Pinned Base Plate (Rs Shear Key)Documento7 páginasPinned Base Plate (Rs Shear Key)winlugue3059100% (2)

- BS code-Base-Plate-DesignDocumento38 páginasBS code-Base-Plate-Designrajasekhar.cheruvu8635Ainda não há avaliações

- Base Plate DesignDocumento38 páginasBase Plate DesignRitwick MishraAinda não há avaliações

- Reinforced Masonry Pier 1Documento4 páginasReinforced Masonry Pier 1John SmithAinda não há avaliações

- 05 Erection ChecklistDocumento8 páginas05 Erection ChecklistAnonymous cG5MyHMAinda não há avaliações

- MiLA Structure Pile Cap Moment Design For One PileDocumento3 páginasMiLA Structure Pile Cap Moment Design For One PileLim Wee BengAinda não há avaliações

- Design of Column SpliceDocumento2 páginasDesign of Column SpliceAndro Rebuyas100% (1)

- Provided: XT XB YT YBDocumento2 páginasProvided: XT XB YT YBDanish AhmadAinda não há avaliações

- Combined Footing DesDocumento7 páginasCombined Footing Desansar700Ainda não há avaliações

- Footing DesignDocumento4 páginasFooting DesignMainali IshuAinda não há avaliações

- Stud Calculations C16 B3 LevelDocumento1 páginaStud Calculations C16 B3 LevelRonakShahAinda não há avaliações

- Footing DesignDocumento5 páginasFooting DesignMainali IshuAinda não há avaliações

- Designing of Square Pad FootingDocumento6 páginasDesigning of Square Pad FootingShamitha KanchanaAinda não há avaliações

- Jb1220 Colum SpliceDocumento3 páginasJb1220 Colum SpliceadihindAinda não há avaliações

- Analisa Balok 400Documento3 páginasAnalisa Balok 400Rifki SaputraAinda não há avaliações

- Doubly Reinforced BeamWITH SHEAR 1-21-12-2018Documento17 páginasDoubly Reinforced BeamWITH SHEAR 1-21-12-2018Mariappan .PAinda não há avaliações

- Roof Beam Design CalculationDocumento11 páginasRoof Beam Design CalculationArnold VercelesAinda não há avaliações

- Longitudinal BearingDocumento6 páginasLongitudinal BearingDPJAIN INFRASTRUCTUREAinda não há avaliações

- Base Plate DesignDocumento21 páginasBase Plate Designtitir bagchi100% (1)

- DesignDocumento6 páginasDesignAbhay SuwalAinda não há avaliações

- Bolt Design Based On BS Code:: Input DataDocumento14 páginasBolt Design Based On BS Code:: Input DataSURIYAAinda não há avaliações

- Beam and CorbelDocumento14 páginasBeam and CorbelAkshay DuggalAinda não há avaliações

- Analysis and Design of Base Plate and Anchor Bolt For Pinned BaseDocumento4 páginasAnalysis and Design of Base Plate and Anchor Bolt For Pinned BaseSunil PulikkalAinda não há avaliações

- DesignDocumento34 páginasDesignAbhay SuwalAinda não há avaliações

- Design Calculation For Splice & Bottom Plate of Vertical Column MembersDocumento4 páginasDesign Calculation For Splice & Bottom Plate of Vertical Column Membersinnovativekarthi100% (1)

- Fixed Base Plate Design-ECPLUS Design-ExampleDocumento4 páginasFixed Base Plate Design-ECPLUS Design-ExampleNivarAinda não há avaliações

- Design of Base Plate & Anchor BoltDocumento2 páginasDesign of Base Plate & Anchor Boltrameshdorage12100% (8)

- Design of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)Documento13 páginasDesign of Shear Connection Between Beam To Beam:: As Per AISC 13 Edition (ASD)rohitnrg0% (1)

- Design of Beam To Column SpliceDocumento1 páginaDesign of Beam To Column SpliceAndro RebuyasAinda não há avaliações

- Second Floor Beam Design CalculationDocumento3 páginasSecond Floor Beam Design CalculationArnold VercelesAinda não há avaliações

- G1: Beam 1Documento24 páginasG1: Beam 1Jan DaveAinda não há avaliações

- Base Plate - Anchor Bolt Design-FinalDocumento22 páginasBase Plate - Anchor Bolt Design-FinalEmil Parangue100% (1)

- Piping Engineering - Tank Nozzle Loads 1Documento1 páginaPiping Engineering - Tank Nozzle Loads 1Nasrul AdliAinda não há avaliações

- Cost Renovation RumahDocumento3 páginasCost Renovation RumahNasrul AdliAinda não há avaliações

- Piping Engineering - Tank Nozzle Loads 3Documento1 páginaPiping Engineering - Tank Nozzle Loads 3Nasrul AdliAinda não há avaliações

- Piping Engineering - Tank Nozzle Loads 9Documento1 páginaPiping Engineering - Tank Nozzle Loads 9Nasrul AdliAinda não há avaliações

- Sow A2 Mopu Sepat2Documento1 páginaSow A2 Mopu Sepat2Nasrul Adli0% (1)

- Job Information: Engineer Checked Approved Name: Date: Structure TypeDocumento2 páginasJob Information: Engineer Checked Approved Name: Date: Structure TypeNasrul AdliAinda não há avaliações

- Class1 Div2 PDFDocumento1 páginaClass1 Div2 PDFNasrul AdliAinda não há avaliações

- Malaysia Public Holidays & School Holidays 2018 CalendaR-ALL 3Documento1 páginaMalaysia Public Holidays & School Holidays 2018 CalendaR-ALL 3Nasrul AdliAinda não há avaliações

- PDMS 2Documento1 páginaPDMS 2Nasrul AdliAinda não há avaliações

- Exhibit II Compliance To Technical RequirementsDocumento1 páginaExhibit II Compliance To Technical RequirementsNasrul AdliAinda não há avaliações

- PDMS 3Documento1 páginaPDMS 3Nasrul AdliAinda não há avaliações

- Pipes. Maxi 8 PDFDocumento1 páginaPipes. Maxi 8 PDFNasrul AdliAinda não há avaliações

- PDMS 4Documento1 páginaPDMS 4Nasrul AdliAinda não há avaliações

- Malaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFDocumento4 páginasMalaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFNasrul AdliAinda não há avaliações

- Edes Clip 2016 ModelDocumento1 páginaEdes Clip 2016 ModelNasrul AdliAinda não há avaliações

- B31 3 (Mygaz) - 1Documento1 páginaB31 3 (Mygaz) - 1Nasrul AdliAinda não há avaliações

- Asme Sect8 Div1 - SAMPLE Calculation-COVERDocumento1 páginaAsme Sect8 Div1 - SAMPLE Calculation-COVERNasrul AdliAinda não há avaliações

- Aig Tower 3/F To 5/F Transfer Truss Type A Joint Connection CalculationDocumento1 páginaAig Tower 3/F To 5/F Transfer Truss Type A Joint Connection CalculationNasrul AdliAinda não há avaliações

- PDMS 2Documento1 páginaPDMS 2Nasrul AdliAinda não há avaliações

- Wind LoadDocumento2 páginasWind LoadNasrul AdliAinda não há avaliações

- What Is Piping 2Documento1 páginaWhat Is Piping 2Nasrul AdliAinda não há avaliações

- Pipes. Maxi 8 PDFDocumento1 páginaPipes. Maxi 8 PDFNasrul AdliAinda não há avaliações

- Shear Lug Verification Example 11Documento1 páginaShear Lug Verification Example 11Nasrul AdliAinda não há avaliações

- Solved - Stress Analysis - AutocCeasar II - Autodesk Community 3Documento1 páginaSolved - Stress Analysis - AutocCeasar II - Autodesk Community 3Nasrul AdliAinda não há avaliações

- Table 1: bottom Range a/b 0.9500 btmwl αDocumento1 páginaTable 1: bottom Range a/b 0.9500 btmwl αNasrul AdliAinda não há avaliações

- Shear Lug Verification Example 12Documento1 páginaShear Lug Verification Example 12Nasrul AdliAinda não há avaliações

- 40S Gives A Thickness: NG Thickness Less Than RequiredDocumento1 página40S Gives A Thickness: NG Thickness Less Than RequiredNasrul AdliAinda não há avaliações

- TC 1.59 MM The Schedule Is To Be Determined Thread Depth TD 0 MM Mill Tolerance MT 12.5 %Documento1 páginaTC 1.59 MM The Schedule Is To Be Determined Thread Depth TD 0 MM Mill Tolerance MT 12.5 %Nasrul AdliAinda não há avaliações

- Pipes. Maxi 6 PDFDocumento1 páginaPipes. Maxi 6 PDFNasrul AdliAinda não há avaliações

- Pipes. Maxi 4 PDFDocumento1 páginaPipes. Maxi 4 PDFNasrul AdliAinda não há avaliações

- Acoustics in Religious BuildingsDocumento31 páginasAcoustics in Religious Buildingsrusydi.dpikAinda não há avaliações

- Relationship of EN 954-1 and IEC 61508 Standards PDFDocumento2 páginasRelationship of EN 954-1 and IEC 61508 Standards PDFfitasmounirAinda não há avaliações

- Series 3501 & 3503Documento4 páginasSeries 3501 & 3503Tim Stubbs100% (2)

- Urethane UB-7 Catalog 2013Documento32 páginasUrethane UB-7 Catalog 2013yfontalvAinda não há avaliações

- K 1020189523hfjfjDocumento3 páginasK 1020189523hfjfjCarlos Angel Vilcapaza CaceresAinda não há avaliações

- Netapp Cabling and Hardware BasicsDocumento14 páginasNetapp Cabling and Hardware BasicsAnup AbhishekAinda não há avaliações

- Engine Test CellDocumento44 páginasEngine Test Cellgrhvg_mct8224Ainda não há avaliações

- Pre Accion PDFDocumento8 páginasPre Accion PDFjhoger2012Ainda não há avaliações

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocumento23 páginasInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamAinda não há avaliações

- C Ds Unit - II NotesDocumento50 páginasC Ds Unit - II NotesAshish ThirunagariAinda não há avaliações

- CPP Exceptions Handling PDFDocumento4 páginasCPP Exceptions Handling PDFRakib Uddin ChowdhuryAinda não há avaliações

- Expansion Joint PDFDocumento7 páginasExpansion Joint PDFPramit RajKarnikarAinda não há avaliações

- Torre Sauter 0 - 5 - 320 - 025 - 4 PDFDocumento27 páginasTorre Sauter 0 - 5 - 320 - 025 - 4 PDFGuiAinda não há avaliações

- Grasshopper Optimization Algorithm Based Design of StructuresDocumento1 páginaGrasshopper Optimization Algorithm Based Design of Structuresinvisible25Ainda não há avaliações

- P45-69Z V3.0 Schematic DiagramDocumento10 páginasP45-69Z V3.0 Schematic DiagramAhmed El SharkawyAinda não há avaliações

- Pulse Emitter EM345Documento1 páginaPulse Emitter EM345wahid.hamraoui.2019Ainda não há avaliações

- Databook Continental Agri 2006 PDFDocumento0 páginaDatabook Continental Agri 2006 PDFdanilo3073Ainda não há avaliações

- Trouble Shooting Dewatering PumpDocumento136 páginasTrouble Shooting Dewatering PumpMuhammad NoorAinda não há avaliações

- NIC Components NTC-T SeriesDocumento10 páginasNIC Components NTC-T SeriesNICCompAinda não há avaliações

- ITC Guide For Thesis PreparationDocumento26 páginasITC Guide For Thesis PreparationPanha MenhAinda não há avaliações

- FORM Inspection Test Plan MMPDocumento8 páginasFORM Inspection Test Plan MMPRicky Stormbringer ChristianAinda não há avaliações

- Important RCC Questions-Short and LongDocumento15 páginasImportant RCC Questions-Short and LongmailjoelsamuelAinda não há avaliações

- LockingDocumento8 páginasLockingDaniel ManoAinda não há avaliações

- Building A Model Steam Engine From Scratch Chapter 1, 150 121Documento19 páginasBuilding A Model Steam Engine From Scratch Chapter 1, 150 121Liam Clink100% (2)

- Powershell Import Update Users Groups From CSV FileDocumento2 páginasPowershell Import Update Users Groups From CSV FilecrakchakibAinda não há avaliações

- Precast Capping Beam Formers DatasheetDocumento2 páginasPrecast Capping Beam Formers Datasheetsantoshgpr100% (1)

- TransformerDocumento14 páginasTransformerNegrea Cristian0% (3)

- Toyota Diesel Piston MedidasDocumento31 páginasToyota Diesel Piston MedidasCarlosArataAinda não há avaliações

- AEC UPS Catalogue 2020Documento46 páginasAEC UPS Catalogue 2020Алексей БабинAinda não há avaliações

- MeshMolder HelpDocumento2 páginasMeshMolder HelpKarlay SouzaAinda não há avaliações