Escolar Documentos

Profissional Documentos

Cultura Documentos

2008-09 Sem-II Paper-4 Instrumentation For Agriculture, Food & Pharmaceutical Industry

Enviado por

gurusaravana0 notas0% acharam este documento útil (0 voto)

86 visualizações2 páginasAgri Instrumentation

Título original

2008-09 Sem-II Paper-4 Instrumentation for Agriculture, Food & Pharmaceutical Industry

Direitos autorais

© Attribution Non-Commercial (BY-NC)

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoAgri Instrumentation

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

86 visualizações2 páginas2008-09 Sem-II Paper-4 Instrumentation For Agriculture, Food & Pharmaceutical Industry

Enviado por

gurusaravanaAgri Instrumentation

Direitos autorais:

Attribution Non-Commercial (BY-NC)

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

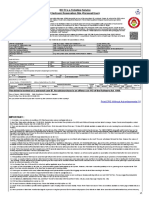

Semester-II, Paper-4

INSTRUMENTATION FOR AGRICULTURE, FOOD &

PHARMACEUTICAL INDUSTRY

Teaching scheme Examination scheme

Lectures: 4 Hrs / Week Theory: 100 Marks

Practical: 2 Hrs/ week Term work: 25 Marks

Unit 1. (10 Hrs, 20 Marks)

Introduction: necessity of Instrumentation and control for agriculture, food processing

and pharmaceutical industries, Sensor requirement remote sensing biosensors in

agriculture standards for food quality.

Soil science and sensor: pH conductivity resistively temp. Soil moisture and salinity

ion concentration measurement, methods of soil analysis.

Instruments for environments conditioning of seed germination and growth.

Unit 2. (10 Hrs, 20 Marks)

Flow Diagram of sugar plant sensors and Instrumentation set up for it. Flow diagram

of fermenter and control (batch process), Oil extraction plant and instrumentation set

up, Pesticides Manufacturing Process and control, a) Flow diagram of dairy and

confectionery industry and instrumentation set up, Juice Extraction control set up.

Unit 3. (10 Hrs, 20 Marks)

Application of SCADA for dam parameters and control, Water distributions and

management control auto drip irrigation systems, Irrigation Canal Management

upstream and downstream control systems

Green houses and Instrumentation: Ventilation cooling and heating wind speed temp.

and humidity rain gauge carbon dioxide enrichment measurement and control.

Unit 4. (10 Hrs, 20 Marks)

Automation in earth moving equipment and farm implements pneumatic hydraulic

and electronic control circuits in harvesters cotton pickers tractors etc. Application of

SCADA and PLC in Packing industry.

Leaf area length evapotranspiration temp, Wetness and respiration measurement and

data logging electromagnetic radiations photosynthesis infrared and UV Bio sensor

methods in agriculture, Agrometeorological Instrumentation weather stations.

Unit 5. (10 Hrs, 20 Marks)

Speciality bioproducts for agricultural, food and pharmaceutical industries:

Biopesticides, biofertilizers and plant growth factors. Natural biopreservatives

(nisin), biopolymers (xanthan gum pi single cell protein.

Enzymatic bioconversion processes: Production of synthetic penicillins and cephalos

racemically pure drug intermediates. Steroid bioconversion. High-fructose corn syrp.

Bioconversion of vegetable

Biological waste treatment processes: Objectives of biological waste treatment

processes. A brief overview of various aerobic and anaerobic processes for removal

of organic waste.

References:

1. Industrial Instrumentation, “Patranabis” , TMH.

2. Instrumentation handbook-Process Control, “B.G.Liptak”, Chilton.

3. Process Control and Instrumentation technology, “C.D.Johnson”,PHI.

4. Wills B.A., "Mineral Processing Technology", 4th Ed., Pergamon Press.

List of Experiments:

Term work shall consist of at least eight experiments based on above topics.

Você também pode gostar

- Appraisal of New and Emerging Food Processing Technologies and Their Potential Risks To Food SafetyDocumento45 páginasAppraisal of New and Emerging Food Processing Technologies and Their Potential Risks To Food Safetysheela bethapudiAinda não há avaliações

- Consumer Driven Cereal Innovation: Where Science Meets IndustryNo EverandConsumer Driven Cereal Innovation: Where Science Meets IndustryAinda não há avaliações

- Sugarcane: Agricultural Production, Bioenergy and EthanolNo EverandSugarcane: Agricultural Production, Bioenergy and EthanolFernando SantosNota: 5 de 5 estrelas5/5 (2)

- Food Safety Management: A Practical Guide for the Food IndustryNo EverandFood Safety Management: A Practical Guide for the Food IndustryHuub L. M. LelieveldNota: 5 de 5 estrelas5/5 (12)

- Gujarat Technological University: Instrumentation For Agriculture and Food Processing - Department Elective - IIIDocumento3 páginasGujarat Technological University: Instrumentation For Agriculture and Food Processing - Department Elective - IIIHarsal PatelAinda não há avaliações

- ISSN: 1692-7257 - Volumen 2 - Número 8 - Año 2006 Revista Colombiana de Tecnologías de AvanzadaDocumento7 páginasISSN: 1692-7257 - Volumen 2 - Número 8 - Año 2006 Revista Colombiana de Tecnologías de AvanzadaCrist VillarAinda não há avaliações

- Analysis of Food Toxins and ToxicantsNo EverandAnalysis of Food Toxins and ToxicantsYiu-Chung WongAinda não há avaliações

- Hygiene Monitoring in Support of Food Safety - A Review of Methods and Industry TrendsDocumento6 páginasHygiene Monitoring in Support of Food Safety - A Review of Methods and Industry TrendsIvone DominguezAinda não há avaliações

- Kissan AssistantDocumento15 páginasKissan AssistantSujit GangurdeAinda não há avaliações

- Sensors 18 01333 CompressedDocumento16 páginasSensors 18 01333 CompressedJorge Ivan Soto SernaAinda não há avaliações

- Novel Thermal and Non-Thermal Technologies for Fluid FoodsNo EverandNovel Thermal and Non-Thermal Technologies for Fluid FoodsPJ CullenAinda não há avaliações

- 5.1 Computer Applications in Food TechnologyDocumento15 páginas5.1 Computer Applications in Food TechnologyAbu RaihanAinda não há avaliações

- The Computerized Greenhouse: Automatic Control Application in Plant ProductionNo EverandThe Computerized Greenhouse: Automatic Control Application in Plant ProductionAinda não há avaliações

- RUSA - Food Processing ProposalDocumento3 páginasRUSA - Food Processing Proposalhomescience123Ainda não há avaliações

- Design and Process Control System Performance Test in Microferm FermentorDocumento9 páginasDesign and Process Control System Performance Test in Microferm Fermentorhasna nadhifahAinda não há avaliações

- Bioprocessing & Microbial TechnologyDocumento14 páginasBioprocessing & Microbial TechnologyKavisa GhoshAinda não há avaliações

- The Canadian Society For Bioengineering La Société Canadienne de Génie Agroalimentaire Et de BioingénierieDocumento8 páginasThe Canadian Society For Bioengineering La Société Canadienne de Génie Agroalimentaire Et de BioingénierieHumphrey IbifubaraAinda não há avaliações

- Intelligent Data Mining and Fusion Systems in AgricultureNo EverandIntelligent Data Mining and Fusion Systems in AgricultureAinda não há avaliações

- Day3 Symp AIASDocumento34 páginasDay3 Symp AIASHanaw MohammadAinda não há avaliações

- Assessment of Ultra Filtration and Vacuum Evaporation On Whey Protein ConcentrationDocumento9 páginasAssessment of Ultra Filtration and Vacuum Evaporation On Whey Protein ConcentrationAndre CharlesAinda não há avaliações

- Autonomous Infrared Micronutrients Monitoring Farming Robot in AgricultureDocumento8 páginasAutonomous Infrared Micronutrients Monitoring Farming Robot in AgricultureZoe Althea SantelicesAinda não há avaliações

- III Intro and MethodsDocumento8 páginasIII Intro and Methodsrovic.esprelaAinda não há avaliações

- Adapting High Hydrostatic Pressure (HPP) for Food Processing OperationsNo EverandAdapting High Hydrostatic Pressure (HPP) for Food Processing OperationsAinda não há avaliações

- The Study of The Decontamination Efficiency in Meat Processing UnitsDocumento8 páginasThe Study of The Decontamination Efficiency in Meat Processing UnitsMihaelaHorgaAinda não há avaliações

- Microbiological Sampling Plans HACCPDocumento62 páginasMicrobiological Sampling Plans HACCPRoxana Sifuentes VasquezAinda não há avaliações

- Observatorynano Briefing No 28 SensorDocumento4 páginasObservatorynano Briefing No 28 SensorShobhit GuptaAinda não há avaliações

- Good Manufacturing PracticesDocumento40 páginasGood Manufacturing Practicessandeep singh gaurAinda não há avaliações

- Low-Cost IoT Based Monitoring and Control System For Aeroponic Vertical FarmingDocumento14 páginasLow-Cost IoT Based Monitoring and Control System For Aeroponic Vertical FarmingDinesh BhoyarAinda não há avaliações

- Sensors: Monitoring Plant Status and Fertilization Strategy Through Multispectral ImagesDocumento21 páginasSensors: Monitoring Plant Status and Fertilization Strategy Through Multispectral ImagesMatheus CardimAinda não há avaliações

- Foods 09 01294 v3Documento12 páginasFoods 09 01294 v3Jorge RuizAinda não há avaliações

- Nanobiotechnology, Bioproducts and Sustainability: Where Is Agriculture Going??Documento28 páginasNanobiotechnology, Bioproducts and Sustainability: Where Is Agriculture Going??anirbanmanna88320Ainda não há avaliações

- Safety and Quality of Water Use and Reuse in the Production and Processing of Dairy Products: Meeting ReportNo EverandSafety and Quality of Water Use and Reuse in the Production and Processing of Dairy Products: Meeting ReportAinda não há avaliações

- Gujarat Technological University: W.E.F. AY 2018-19Documento3 páginasGujarat Technological University: W.E.F. AY 2018-19Saumya LutadeAinda não há avaliações

- Ehedg Doc 07 e 2004Documento10 páginasEhedg Doc 07 e 2004riza ayu putri100% (1)

- Food Safety and Produce Operations: What Is The Future?Documento7 páginasFood Safety and Produce Operations: What Is The Future?. .Ainda não há avaliações

- Sist Nac Cert Prod OrganicosDocumento130 páginasSist Nac Cert Prod OrganicosingeclaudioAinda não há avaliações

- Ece305 - Project ProposalDocumento7 páginasEce305 - Project ProposalEDUARD VI DANDAAinda não há avaliações

- Food Safety and QMDocumento9 páginasFood Safety and QMmohanpbisAinda não há avaliações

- Microbiological Analysis of Rice Cake Processing in KoreaDocumento6 páginasMicrobiological Analysis of Rice Cake Processing in Koreannhoangmai797Ainda não há avaliações

- Ayurvedic Pharmacy: Current Concepts and GMP NormsDocumento22 páginasAyurvedic Pharmacy: Current Concepts and GMP NormsbrahmapulseAinda não há avaliações

- Piretrinas Prestes2012Documento8 páginasPiretrinas Prestes2012Adrian Rojas AvilaAinda não há avaliações

- Long-Term Farming Systems Research: Ensuring Food Security in Changing ScenariosNo EverandLong-Term Farming Systems Research: Ensuring Food Security in Changing ScenariosGurbir BhullarAinda não há avaliações

- 3B Dr. T. Okayasu ICT Application For Typical Small - and Medium-Scale Farmers in Japan Agriculture PDFDocumento48 páginas3B Dr. T. Okayasu ICT Application For Typical Small - and Medium-Scale Farmers in Japan Agriculture PDFDavaatseren NarmandakhAinda não há avaliações

- Records To Be Manitained For KayakalpDocumento5 páginasRecords To Be Manitained For KayakalpMarcelina RossAinda não há avaliações

- Technologies to Recover Polyphenols from AgroFood By-products and WastesNo EverandTechnologies to Recover Polyphenols from AgroFood By-products and WastesElisabete M.C. AlexandreAinda não há avaliações

- Evaluation of A Real Time PCR Assay Method For The Detection of Genetically Modified Organisms in Food ProductsDocumento6 páginasEvaluation of A Real Time PCR Assay Method For The Detection of Genetically Modified Organisms in Food ProductsAswad ZEllzAinda não há avaliações

- Bragliaetal 2021acquaponicaDocumento7 páginasBragliaetal 2021acquaponicalorenaAinda não há avaliações

- Full Paper MPalelaDocumento8 páginasFull Paper MPalelaGSBYGALATIAinda não há avaliações

- The Interaction of Food Industry and EnvironmentNo EverandThe Interaction of Food Industry and EnvironmentNota: 5 de 5 estrelas5/5 (1)

- Agricola 2Documento5 páginasAgricola 2Mary BolañosAinda não há avaliações

- Extended Summaries Pesticides in Food and DrinkDocumento5 páginasExtended Summaries Pesticides in Food and DrinkNisha RehmanAinda não há avaliações

- 348 38 Application of The HACCP System During TDocumento13 páginas348 38 Application of The HACCP System During TJayashri chitteAinda não há avaliações

- Syl La Bibs Chort DegreeDocumento41 páginasSyl La Bibs Chort DegreeurkabitaAinda não há avaliações

- Eceg5187 Final PDFDocumento2 páginasEceg5187 Final PDFgurusaravanaAinda não há avaliações

- Introduction To Fuzzy Logic Control: Andrew L. NelsonDocumento34 páginasIntroduction To Fuzzy Logic Control: Andrew L. NelsonClara Jerina IIAinda não há avaliações

- Chapter 5 Dcacbridges 2 0Documento24 páginasChapter 5 Dcacbridges 2 0gurusaravanaAinda não há avaliações

- UOG Wireless ConfigurationDocumento14 páginasUOG Wireless ConfigurationgurusaravanaAinda não há avaliações

- EIE410 Digital Control SystemDocumento3 páginasEIE410 Digital Control SystemgurusaravanaAinda não há avaliações

- EIE306 Process Dynamics and Control Course PlanDocumento4 páginasEIE306 Process Dynamics and Control Course PlangurusaravanaAinda não há avaliações

- MyLahore Cafe-Menu 2020Documento9 páginasMyLahore Cafe-Menu 2020Muhammad Hadi AkbarAinda não há avaliações

- Radisson - JatinDocumento84 páginasRadisson - JatinshlokAinda não há avaliações

- Karakteristik Lactobacillus Spesies Yang Diisolasi Dari Daging SapiDocumento5 páginasKarakteristik Lactobacillus Spesies Yang Diisolasi Dari Daging SapiSyahrul HidayatAinda não há avaliações

- District of Carmona Milagrosa West Elementary 2 Periodical Test Mathematics Vi Name: Date: Grade/Section: TeacherDocumento3 páginasDistrict of Carmona Milagrosa West Elementary 2 Periodical Test Mathematics Vi Name: Date: Grade/Section: TeacherMicah VideosAinda não há avaliações

- Catfish Farming Information Guide - AgrifarmingDocumento5 páginasCatfish Farming Information Guide - AgrifarmingamolkajaleAinda não há avaliações

- Antacid - PonbaraniDocumento11 páginasAntacid - PonbaranifmdazharAinda não há avaliações

- Fairprice+AR2020 FinalDocumento38 páginasFairprice+AR2020 FinalCAAinda não há avaliações

- Silverson Bottom Entry MixerDocumento5 páginasSilverson Bottom Entry MixerDiego ArroyaveAinda não há avaliações

- Train Ticket PDFDocumento2 páginasTrain Ticket PDFVarun Kumar Akula100% (1)

- Epidemiology of Trace Elements Deficiencies in Belgian Beef and Dairy Cattle HerdsDocumento8 páginasEpidemiology of Trace Elements Deficiencies in Belgian Beef and Dairy Cattle HerdsHuber RizzoAinda não há avaliações

- Vocabulary Idioms and Discussio Discussion Questio Conversation Topics Dialogs 134177Documento46 páginasVocabulary Idioms and Discussio Discussion Questio Conversation Topics Dialogs 134177Alinfa1100% (1)

- Aloe Vera For Human Nutrition Health and Cosmetic Usea ReviewDocumento9 páginasAloe Vera For Human Nutrition Health and Cosmetic Usea Reviewmihaela_bondocAinda não há avaliações

- Galette Des Rois - Chocolate Academy X Isigny Ste-MèreDocumento18 páginasGalette Des Rois - Chocolate Academy X Isigny Ste-MèreCwt ChanAinda não há avaliações

- Ohi Case Study Powerpoint Presentation 220a - Savanna BeddoesDocumento18 páginasOhi Case Study Powerpoint Presentation 220a - Savanna Beddoesapi-307780636Ainda não há avaliações

- Deb Scott 50 Board Games Sample PagesDocumento22 páginasDeb Scott 50 Board Games Sample PagesThane1020100% (1)

- Best Bet Dinner Menu July 2023Documento2 páginasBest Bet Dinner Menu July 2023MatthewKangAinda não há avaliações

- Bananasap FinalDocumento20 páginasBananasap FinalKarina Lingan100% (1)

- All India 6th ClassDocumento126 páginasAll India 6th ClassAryan DubeyAinda não há avaliações

- Fact UrasDocumento26 páginasFact UrasEdwin JimenezAinda não há avaliações

- Prepare and Cook Meat and SeafoodDocumento6 páginasPrepare and Cook Meat and SeafoodKemathi McnishAinda não há avaliações

- 3m Petrifilm Rapid Yeast Mold Count PlateDocumento2 páginas3m Petrifilm Rapid Yeast Mold Count PlateLugher VaqueroAinda não há avaliações

- Addicted1 - The Inquietude of YouthDocumento867 páginasAddicted1 - The Inquietude of YouthIlsa Krisdwiyani100% (1)

- Poultry Premix ManufacturerDocumento11 páginasPoultry Premix ManufacturerSAHS LifesciencesAinda não há avaliações

- Mcdonald PPT by RakeshDocumento11 páginasMcdonald PPT by RakeshRakesh Chitra100% (1)

- Speakout Elementary, Worksheets.Documento14 páginasSpeakout Elementary, Worksheets.Solang Mgear100% (1)

- 6 Week Fat Crusher Plan PDFDocumento39 páginas6 Week Fat Crusher Plan PDFȘtefania Camelia HorvathAinda não há avaliações

- Gaia - Lingerie Spring Summer Collection Catalog 2020Documento47 páginasGaia - Lingerie Spring Summer Collection Catalog 2020Oleg PloskonisAinda não há avaliações

- Freebase CloudDocumento34 páginasFreebase CloudMiguel CarracedoAinda não há avaliações

- Pocket Guide To Managing High Potassium (Hyperkalemia)Documento12 páginasPocket Guide To Managing High Potassium (Hyperkalemia)Adesh MirashiAinda não há avaliações

- White Fang PRL2Documento9 páginasWhite Fang PRL2Mercedes ManavellaAinda não há avaliações