Escolar Documentos

Profissional Documentos

Cultura Documentos

USP Dissolution Apparatus 5, 6, 7

Enviado por

Rezaul RazibDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

USP Dissolution Apparatus 5, 6, 7

Enviado por

Rezaul RazibDireitos autorais:

Formatos disponíveis

Accessed from 10.6.1.

1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

600 721 Distilling Range / Physical Tests USP 40

Procedure

Assemble the apparatus, and place in the flask 100 mL of the liquid to be tested, taking care not to allow any of the liquid to

enter the side-arm. Insert the thermometer, shield the entire burner and flask assembly from external air currents, and apply

heat, regulating it so that between 5 and 10 minutes elapse before the first drop of distillate falls from the condenser. Contin-

ue the distillation at a rate of 4 to 5 mL of distillate per minute, collecting the distillate in the receiver. Note the temperature

when the first drop of distillate falls from the condenser, and again when the last drop of liquid evaporates from the bottom of

the flask or when the specified percentage has distilled over. Unless otherwise specified in the individual monograph, apply

when necessary the emergent stem correction and report the temperatures adjusting the barometric pressure by the following

formula:

t = t0 + [(t0104 + 0.033)(760 p)]

in which t is the corrected boiling temperature, in Celsius scale; t0 is the measured boiling temperature, in Celsius scale; and p

is the barometric pressure at the time of measurement, in mm Hg.

724 DRUG RELEASE

General Chapters

SCOPE

This test is provided to determine compliance with drug release or dissolution requirements where stated in the individual

monographs for transdermal systems (TDS) and other dosage forms. From the types of apparatus described herein, use the

one specified in the individual monograph.

GENERAL DRUG RELEASE STANDARDS

Apparatus 5 (Paddle over Disk)

APPARATUS

Use the paddle and vessel assembly from Apparatus 2 as described in Dissolution 711, with the addition of a disk assembly

designed to hold the TDS at the bottom of the vessel. This disk assembly is designed to minimize any dead volume between

the assembly and the bottom of the vessel. The disk assembly holds the TDS flat and is positioned such that the release surface

is parallel with the bottom of the paddle blade (see Figure 1a, Figure 1b, and Figure 1c). A distance of 25 2 mm between the

paddle blade and the surface of the disk assembly is maintained during the test. Other appropriate devices may be used (see

Figure 2), provided they do not sorb, react with, or interfere with the specimen being tested.

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

USP 40 Physical Tests / 724 Drug Release 601

General Chapters

Figure 1a. Paddle over disk.

(All measurements are expressed in mm unless noted otherwise.)

Figure 1b. Paddle over disk (screen and watchglass).

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

602 724 Drug Release / Physical Tests USP 40

General Chapters

Figure 1c. Clip to hold screen and watchglass.

Figure 2. Holding wire screen.

APPARATUS SUITABILITY

Proceed as directed for Apparatus 2 in Dissolution 711, Apparatus Suitability, Performance Verification Test, Apparatus 1 and 2.

MEDIUM

Proceed as directed for Dissolution Medium in Dissolution 711, Procedure, Apparatus 1 and Apparatus 2, Immediate-Release

Dosage Forms.

PROCEDURE

Place the stated volume of Medium in the vessel, and equilibrate to 32 0.5.

Apply the TDS to the disk assembly, assuring that the release surface is as smooth as possible and the TDS is completely and

firmly attached to the disk. The TDS, with release surface side up, may be attached to the disk by an appropriate and validated

procedure such as use of an adhesive, double-face adhesive tape, screen, or membrane. Care must be taken to avoid the pres-

ence of air bubbles between the membrane, if used, and the TDS, or the presence of wrinkles on the surface of the TDS. Care-

fully remove the protective liner from the TDS without causing damage to the surface of the TDS.

Place the disk assembly flat at the bottom of the vessel with the release surface facing up and parallel to the edge of the

paddle blade and surface of the Medium. Ensure that the surface of the TDS is devoid of air bubbles. The bottom edge of the

paddle is 25 2 mm from the surface of the disk assembly. The vessel may be covered during the test to minimize evapora-

tion.

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

USP 40 Physical Tests / 724 Drug Release 603

Immediately operate the apparatus at the rate specified in the monograph.

At each sampling time interval, withdraw a specimen from a zone midway between the surface of the Medium and the top

of the blade, not less than 1 cm from the vessel wall.

Perform the analysis on each sample aliquot as directed in the individual monograph, correcting for any volume losses, as

necessary. Repeat the test with additional TDS as needed.

TIME

The test time points, at least three, are expressed in hours. Specimens are to be withdrawn within a tolerance of 15 min or

2% of the stated time, selecting the tolerance that results in the narrowest time interval.

INTERPRETATION

Unless otherwise specified in the individual monograph, the requirements are met if the quantities of active ingredient re-

leased from the system conform to Acceptance Table 1 below. Continue testing through the three levels unless the results con-

form at either L1 or L2.

Acceptance Table 1

Level Number Tested Criteria

L1 6 No individual value lies outside the stated range.

General Chapters

The average value of the 12 units (L1 + L2) lies within the stated range. No individual val-

L2 6 ue is outside the stated range by more than 10% of the average of the stated range.

The average value of the 24 units (L1 + L2 + L3) lies within the stated range. Not more

than 2 of the 24 units are outside the stated range by more than 10% of the average of

the stated range; and none of the units is outside the stated range by more than 20% of

L3 12 the average of the stated range.

Apparatus 6 (Cylinder)

APPARATUS

Use the vessel assembly as described in Dissolution 711, Apparatus, Apparatus 1 (Basket Apparatus), except replace the bas-

ket and shaft with a stainless steel cylinder stirring element with the specifications shown in Figure 3. This cylinder stirring ele-

ment is composed of two parts, one comprising the shaft and the upper cylinder, and the other being the extension cylinder.

Since both parts are serially numbered, it is recommended that they be kept paired because the friction fitting is done individ-

ually for each cylinder, allowing a very tight fit. The distance between the inside bottom of the vessel and the cylinder is main-

tained at 25 2 mm during the test.

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

604 724 Drug Release / Physical Tests USP 40

General Chapters

Figure 3. Cylinder stirring element.

(All measurements are expressed in cm unless noted otherwise.)

MEDIUM

See Dissolution Medium in Dissolution 711, Procedure, Apparatus 1 and Apparatus 2, Immediate-Release Dosage Forms.

PROCEDURE

Place the stated volume of Medium in the vessel, and equilibrate to 32 0.5.

Apply the TDS to the cylinder, assuring that the release surface is as smooth as possible and the TDS is completely and firmly

attached to the cylinder. The TDS, with release side facing the Medium, may be attached to the cylinder by an appropriate and

validated procedure such as use of an adhesive, double-face adhesive tape, membrane, or nylon net. Care must be taken to

avoid the presence of air bubbles between the membrane, if used, and the TDS, or the presence of wrinkles on the surface of

the TDS. Carefully remove the protective liner from the TDS without causing damage to the surface. If additional reinforce-

ment of the TDS to the cylinder is needed, inert metal wire or a polymer ring may be used.

Place the cylinder in the apparatus, and immediately rotate at the rate specified in the individual monograph. The vessel

may be covered during the test to minimize evaporation.

At each sampling time interval, withdraw a specimen from a zone midway between the surface of the Medium and the top

of the rotating cylinder, not less than 1 cm from the vessel wall.

Perform the analysis on each sample aliquot as directed in the individual monograph, correcting for any volume losses, as

necessary. Repeat the test with additional TDS, as needed.

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

USP 40 Physical Tests / 724 Drug Release 605

TIME

The test time points, at least three, are expressed in hours. Specimens are to be withdrawn within a tolerance of 15 min or

2% of the stated time, selecting the tolerance that results in the narrowest time interval.

INTERPRETATION

Unless otherwise specified in the individual monograph, the requirements are met if the quantities of active ingredient re-

leased from the system conform to Acceptance Table 1 above. Continue testing through the three levels unless the results con-

form at either L1 or L2.

Apparatus 7 (Reciprocating Holder)

APPARATUS

The assembly consists of (1) a set of volumetrically calibrated or tared solution containers made of glass or other suitable

inert material that should not sorb, react with, or interfere with the specimen being tested; (2) a motor and drive assembly to

reciprocate the system vertically and to index the system horizontally to a different row of vessels, automatically if desired; and

(3) a set of suitable sample holders (see Figure 4 and Figures 5a, 5b, 5c, and 5d).

General Chapters

Figure 4. Reciprocating disk sample holder.

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

606 724 Drug Release / Physical Tests USP 40

Figure 5a. Transdermal system holderangled disk.

General Chapters

Figure 5b. Transdermal system holdercylinder.

Figure 5c. Oral extended-release tablet holderrod, pointed for gluing.

Figure 5d. Oral extended-release tablet holderspring holder.

During the test, the solution containers are partially immersed in a suitable water bath of any convenient size that permits

maintaining the temperature inside the containers at 32 0.5 for TDS or at 37 0.5 for other dosage forms during the test.

No part of the assembly, including the environment in which the assembly is placed, contributes significant motion, agita-

tion, or vibration beyond that due to the smooth, vertically reciprocating sample holder.

Apparatus that permits observation of the system and holder during the test is preferable.

Use the size container and sample holder as specified in the individual monograph.

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Accessed from 10.6.1.1 by spen3tkzy on Mon Jul 24 06:20:56 EDT 2017

USP 40 Physical Tests / 729 Globule Size Distribution 607

MEDIUM

See Dissolution Medium in Dissolution 711, Procedure, Apparatus 1 and Apparatus 2, Immediate-Release Dosage Forms.

SAMPLE PREPARATION A (FOR OSMOTIC PUMP TABLETS)

Attach each unit to be tested to a suitable holder by an appropriate and validated procedure such as use of an adhesive to

adhere the edge of the tablet to a holder (e.g., Figure 5c), the spring holder (Figure 5d), a small nylon net bag, or a membrane.

SAMPLE PREPARATION B (FOR TDS)

Apply the TDS to the appropriate holder, assuring that the release surface is as smooth as possible and the TDS is completely

and firmly attached to the holder. The TDS, with release side facing the Medium, may be attached to the holder by an appro-

priate and validated procedure such as use of an adhesive, double-face adhesive tape, membrane, or nylon net. Care must be

taken to avoid the presence of air bubbles between the membrane, if used, and the TDS, or the presence of wrinkles on the

surface of the TDS. Carefully remove the protective liner from the TDS without causing damage to the surface of the TDS. If

additional reinforcement of the TDS to the holder is needed, inert metal wire or a polymer ring may be used.

SAMPLE PREPARATION C (FOR OTHER DOSAGE FORMS)

General Chapters

Attach each dosage form to be tested to a suitable holder.

PROCEDURE

Place the stated volume of Medium in the solution containers, and equilibrate to the test temperature.

Suspend each prepared sample holder from a vertically reciprocating shaker such that each system is continuously immersed

in Medium during the entire test.

Reciprocate at a frequency of about 30 cycles/min with an amplitude of about 2 cm, or as specified in the individual mono-

graph, for the specified time.

At each sampling time interval, remove the solution containers from the bath, cool to room temperature, and add sufficient

solvent (i.e., water in most cases) to correct for evaporative losses.

Perform the analysis on each sample as directed in the individual monograph. Repeat the test with additional transdermal

systems, as needed.

TIME

The test time points, at least three, are expressed in hours. Specimens are to be withdrawn within a tolerance of 15 min or

2% of the stated time, selecting the tolerance that results in the narrowest time interval.

INTERPRETATION

Unless otherwise specified in the individual monograph, the requirements are met if the quantities of active ingredient re-

leased from the TDS conform to Acceptance Table 1 above, or the appropriate acceptance table in Dissolution 711 for other

dosage forms. Continue testing through the three levels unless the results conform at either L1 or L2.

729 GLOBULE SIZE DISTRIBUTION IN LIPID INJECTABLE EMULSIONS

INTRODUCTION

Lipid injectable emulsions for intravenous administration are sterile oil-in-water emulsions of soybean oil, used to provide an

ample supply of essential fatty acids, linoleic and linolenic, dispersed with the aid of an emulsifying agent in Water for Injection.

Alternatively, soybean oil can be mixed with other suitable oils (neutral triglycerides), such as safflower oil, medium-chain tri-

glycerides (MCT) derived from coconut or palm kernel oils, olive oil, or a marine oil, such as menhaden oil. The size of the lipid

droplets is critical: because of mechanical filtration, larger-size fat globules (>5 mm) can be trapped in the lungs. The essential

size characteristics of a lipid injectable emulsion for intravenous use include the mean diameter of the lipid droplets and the

range of the various droplet diameters distributed around the mean diameter, expressed as the standard deviation. In particu-

Official from May 1, 2017

Copyright (c) 2017 The United States Pharmacopeial Convention. All rights reserved.

Você também pode gostar

- L-2200 Autosampler PDFDocumento157 páginasL-2200 Autosampler PDFCarlos Andrés MarroquinAinda não há avaliações

- BACPACDocumento50 páginasBACPACkavya nainitaAinda não há avaliações

- WHO Certificate E120 2019Documento4 páginasWHO Certificate E120 2019Risen ChemicalsAinda não há avaliações

- Supplement 16Documento18 páginasSupplement 16Su NguyenAinda não há avaliações

- Acute & Chronic Toxicity TestingDocumento33 páginasAcute & Chronic Toxicity Testingaziskf0% (1)

- 09931250D Lambda 365 8-Position Multi-Cell Holder Installation InstructionsDocumento11 páginas09931250D Lambda 365 8-Position Multi-Cell Holder Installation InstructionsAndronikus SitumorangAinda não há avaliações

- D 1387 - 89 R02 - Rdezodc - PDFDocumento2 páginasD 1387 - 89 R02 - Rdezodc - PDFJail MartinezAinda não há avaliações

- Using Stability Tools and Analytical Methods to Support a Global Clinical ProgramDocumento15 páginasUsing Stability Tools and Analytical Methods to Support a Global Clinical ProgramIsabelLópezAinda não há avaliações

- Satorius A210P Balance Users ManualDocumento18 páginasSatorius A210P Balance Users ManualJim McMicanAinda não há avaliações

- AS510 Differential Pressure ManometerDocumento2 páginasAS510 Differential Pressure ManometerEnriqueAinda não há avaliações

- PHR1030 - LRAB3630 (Tocoferol Acetato)Documento8 páginasPHR1030 - LRAB3630 (Tocoferol Acetato)Otit Yarag SenrofAinda não há avaliações

- Dissolution MethodsDocumento74 páginasDissolution MethodsDilawar Bakht0% (2)

- Milliq Manual PDFDocumento153 páginasMilliq Manual PDFbannerAinda não há avaliações

- Dissolution MethodsDocumento59 páginasDissolution MethodsShiraz KhanAinda não há avaliações

- Supplement 4 TS Security Fire Protection ECSPP ECBSDocumento30 páginasSupplement 4 TS Security Fire Protection ECSPP ECBSJelena PopovicAinda não há avaliações

- Operational Manual: DGYF-S500 Type Electromagnet Induction Sealing MachineDocumento8 páginasOperational Manual: DGYF-S500 Type Electromagnet Induction Sealing MachineHaroldAinda não há avaliações

- Water-Id CatalogueDocumento63 páginasWater-Id CatalogueHanna NainggolanAinda não há avaliações

- LAMBDA 265, 365, 465: UV/Visible SpectrosDocumento2 páginasLAMBDA 265, 365, 465: UV/Visible SpectrosUswatul Hasanah100% (1)

- Metronidazol 500 MGDocumento12 páginasMetronidazol 500 MGAbou Tebba SamAinda não há avaliações

- PRESERVATIVESDocumento25 páginasPRESERVATIVESimran aliAinda não há avaliações

- Making Sense of Trueness, Precision, Accuracy, and UncertaintyDocumento5 páginasMaking Sense of Trueness, Precision, Accuracy, and UncertaintyJoe Luis Villa MedinaAinda não há avaliações

- Dissolution - DisintegrationDocumento10 páginasDissolution - DisintegrationKathryn Faith Malabag100% (1)

- Supplement 10 TS Calibration ECSPP ECBSDocumento16 páginasSupplement 10 TS Calibration ECSPP ECBSKingston Rivington100% (1)

- Sterility Testing: B. K. SajeebDocumento23 páginasSterility Testing: B. K. SajeebSadia AfrinAinda não há avaliações

- General Chapters USP 38 - 905 - UNIFORMITY OF DOSAGE UNITSDocumento5 páginasGeneral Chapters USP 38 - 905 - UNIFORMITY OF DOSAGE UNITSFitri WahyuningsihAinda não há avaliações

- Data Sheet: Elcometer 8721 Analytical BalanceDocumento2 páginasData Sheet: Elcometer 8721 Analytical BalancenfngkoueAinda não há avaliações

- Magnehelic Gauge CalibrationDocumento7 páginasMagnehelic Gauge CalibrationgrajukankayyaAinda não há avaliações

- 1228 5 PDFDocumento5 páginas1228 5 PDFdeepanmb007Ainda não há avaliações

- Meclizine HCLDocumento10 páginasMeclizine HCLChEng_Ainda não há avaliações

- Guia para CromatografiaDocumento98 páginasGuia para Cromatografiasaidvaret100% (1)

- Fuji Neusilin BrosurDocumento24 páginasFuji Neusilin BrosurEcHie ChoiAinda não há avaliações

- Usp 771 - Ophthalmic Products-Quality TestsDocumento7 páginasUsp 771 - Ophthalmic Products-Quality TestsAdrianaAinda não há avaliações

- Spec-Shilajit Extract-50%Documento1 páginaSpec-Shilajit Extract-50%marketing splsgroupAinda não há avaliações

- Omcl Management of Environmental Conditions Paphomcl1686r6Documento8 páginasOmcl Management of Environmental Conditions Paphomcl1686r6Hans LeupoldAinda não há avaliações

- ICH Guideline Q11 On Development and Manufacture of Drug Substances (Chemical Entities and Biotechnological/biological Entities)Documento27 páginasICH Guideline Q11 On Development and Manufacture of Drug Substances (Chemical Entities and Biotechnological/biological Entities)rodcam1Ainda não há avaliações

- Internal Pressurization Failure Resistance of Unrestrained PackagesDocumento5 páginasInternal Pressurization Failure Resistance of Unrestrained PackagesraulAinda não há avaliações

- High Efficiency Poly Electrolytes For Solid-Liquid SeparationDocumento1 páginaHigh Efficiency Poly Electrolytes For Solid-Liquid SeparationSIVAPATHASEKARANAinda não há avaliações

- Salom Pharmacy LTD: Quality Control Laboratory SPL-SOP-QC-DISS-001 Operation of Dissolution Rate ApparatusDocumento2 páginasSalom Pharmacy LTD: Quality Control Laboratory SPL-SOP-QC-DISS-001 Operation of Dissolution Rate ApparatusPaolo Peps100% (1)

- Labsolutions Ir: Instruction ManualDocumento262 páginasLabsolutions Ir: Instruction ManualEmerson J MesaAinda não há avaliações

- Glutaraldehyde PDFDocumento83 páginasGlutaraldehyde PDFPariseerAinda não há avaliações

- MAN0011430 Pierce BCA Protein Asy UGDocumento8 páginasMAN0011430 Pierce BCA Protein Asy UGIvie João GabrielAinda não há avaliações

- SOP For HPLC Shimadzu LabSolutionsDocumento6 páginasSOP For HPLC Shimadzu LabSolutionsfawaz khalilAinda não há avaliações

- Observation 1: Department of Health A!'Id Hu Ian ServicesDocumento3 páginasObservation 1: Department of Health A!'Id Hu Ian ServicesNevin SmithAinda não há avaliações

- Specification Eudragit L 30 D 55Documento6 páginasSpecification Eudragit L 30 D 55Jivan Battu100% (1)

- ag-METTLER TOLEODocumento84 páginasag-METTLER TOLEOMohammed S.GoudaAinda não há avaliações

- Laboratory Safety Chemical Fume HoodsDocumento2 páginasLaboratory Safety Chemical Fume Hoodsacanis1016Ainda não há avaliações

- Manual Detector FluorescenciaDocumento198 páginasManual Detector FluorescenciaEdgar Nina Velasquez100% (1)

- 71 Sterility Test Usp41Documento8 páginas71 Sterility Test Usp41hh_543Ainda não há avaliações

- Sanfuliq PVP RegistrasiDocumento25 páginasSanfuliq PVP RegistrasiFajarRachmadiAinda não há avaliações

- Rovamycin 3868 DR 1256036243912Documento6 páginasRovamycin 3868 DR 1256036243912Ahmed El AlfyAinda não há avaliações

- SMFDocumento39 páginasSMFMohd AkmalAinda não há avaliações

- GLP ManualDocumento109 páginasGLP Manualangel_machacaAinda não há avaliações

- Handling & Maintenance of DesiccatorsDocumento2 páginasHandling & Maintenance of Desiccatorssaadi387100% (1)

- Bracket Matrix StabilityDocumento15 páginasBracket Matrix StabilityRamchandra KenyAinda não há avaliações

- QC Tests For Tablet Dosage FormsDocumento8 páginasQC Tests For Tablet Dosage FormsSai Krishna ManchikantiAinda não há avaliações

- MFY-01 Leak Tester Instruction ManualDocumento20 páginasMFY-01 Leak Tester Instruction ManualRajan GangarAinda não há avaliações

- 711 USP Dissolution PDFDocumento11 páginas711 USP Dissolution PDFAnnisaIndahPAinda não há avaliações

- General Chapters - 711 - DISSOLUTIONDocumento11 páginasGeneral Chapters - 711 - DISSOLUTIONFitri WahyuningsihAinda não há avaliações

- 0295-0301 (711) DissolutionDocumento7 páginas0295-0301 (711) DissolutionsudermanfitoAinda não há avaliações

- Dissolution Apparatus - USPDocumento6 páginasDissolution Apparatus - USPkakak zeaAinda não há avaliações

- Functions of Growth HormoneDocumento19 páginasFunctions of Growth HormoneRezaul RazibAinda não há avaliações

- Endocrinology: Differences Between Nervous and Endocrine SystemDocumento34 páginasEndocrinology: Differences Between Nervous and Endocrine SystemRezaul RazibAinda não há avaliações

- 200 Special Topics For 42 BCSDocumento187 páginas200 Special Topics For 42 BCSRezaul RazibAinda não há avaliações

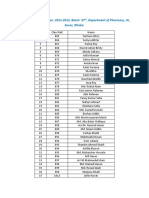

- Class: M.Pharm, Session: 2011-2012, Batch: 37, Department of Pharmacy, JU, Savar, DhakaDocumento2 páginasClass: M.Pharm, Session: 2011-2012, Batch: 37, Department of Pharmacy, JU, Savar, DhakaRezaul RazibAinda não há avaliações

- Methylphenidate HydrochlorideDocumento3 páginasMethylphenidate HydrochlorideRezaul RazibAinda não há avaliações

- ( ) .PDF Version 1Documento21 páginas( ) .PDF Version 1Jamshedul Islam100% (1)

- MV Ú WZK I PJGVB Nubvcöevn (Evsjv 'K)Documento16 páginasMV Ú WZK I PJGVB Nubvcöevn (Evsjv 'K)shakhawat remonAinda não há avaliações

- Apex Discount MailDocumento1 páginaApex Discount MailRezaul RazibAinda não há avaliações

- EXCLUSIVE EDUCATION AID MOCK TEST ANSWERDocumento39 páginasEXCLUSIVE EDUCATION AID MOCK TEST ANSWERRezaul RazibAinda não há avaliações

- Exclusive 42 BCS Solve SheetDocumento272 páginasExclusive 42 BCS Solve SheetRezaul RazibAinda não há avaliações

- It 11 GaDocumento8 páginasIt 11 GaSadav ImtiazAinda não há avaliações

- Rmxg DwÏb iv‡mj ‡ckv: PvU©vW© A ̈vKvD›U ̈v›UDocumento3 páginasRmxg DwÏb iv‡mj ‡ckv: PvU©vW© A ̈vKvD›U ̈v›URezaul RazibAinda não há avaliações

- Passport MRPOnline Instruction 2013 - Techtunes - COm.BDDocumento14 páginasPassport MRPOnline Instruction 2013 - Techtunes - COm.BDTechtunesAinda não há avaliações

- Ropinirole HydrochlorideDocumento4 páginasRopinirole HydrochlorideRezaul RazibAinda não há avaliações

- Azithromycin USPDocumento5 páginasAzithromycin USPRezaul RazibAinda não há avaliações

- FDA Stability Guidance Questions and AnswersDocumento17 páginasFDA Stability Guidance Questions and AnswersdpakindianAinda não há avaliações

- Ropinirole Extended-Release TabletsDocumento4 páginasRopinirole Extended-Release TabletsRezaul RazibAinda não há avaliações

- CONCERTA Extended-Release Tablets PILDocumento37 páginasCONCERTA Extended-Release Tablets PILRezaul RazibAinda não há avaliações

- Labeling For Biosimilar ProductsDocumento15 páginasLabeling For Biosimilar ProductsRezaul RazibAinda não há avaliações

- Racecadotril Tablet FormulationDocumento14 páginasRacecadotril Tablet FormulationRezaul RazibAinda não há avaliações

- MRP Information Alteration Correction PDFDocumento2 páginasMRP Information Alteration Correction PDFRezaul RazibAinda não há avaliações

- Requip XL PilDocumento39 páginasRequip XL PilRezaul RazibAinda não há avaliações

- Joining Letter TemplateDocumento1 páginaJoining Letter TemplateRezaul RazibAinda não há avaliações

- Comprehensive List of GuidancesDocumento54 páginasComprehensive List of GuidancesRezaul RazibAinda não há avaliações

- PAT - A Framework For Innovative Pharmaceutical Development, Manufacturing, and Quality AssuranceDocumento19 páginasPAT - A Framework For Innovative Pharmaceutical Development, Manufacturing, and Quality AssuranceHeba El-TayebAinda não há avaliações

- Tablet Scoring - Nomenclature, Labeling, and Data For EvaluationDocumento8 páginasTablet Scoring - Nomenclature, Labeling, and Data For EvaluationRezaul RazibAinda não há avaliações

- Naming of Drug Products Containing Salt Drug SubstancesDocumento12 páginasNaming of Drug Products Containing Salt Drug SubstancesRezaul RazibAinda não há avaliações

- Content Uniformity (CU) Testing For The 21st Century CDER PerspectiveDocumento36 páginasContent Uniformity (CU) Testing For The 21st Century CDER PerspectiveRezaul Razib100% (1)

- Guidelines Packaging Pharmaceutical Products TRS902 Annex 9Documento38 páginasGuidelines Packaging Pharmaceutical Products TRS902 Annex 9Shuhash100% (1)

- Site Master FileDocumento51 páginasSite Master FileMilonhg100% (2)

- 10 01 Breather Filters GBDocumento8 páginas10 01 Breather Filters GBosuengAinda não há avaliações

- January 2010 QP - Unit 1 Edexcel Physics A-LevelDocumento23 páginasJanuary 2010 QP - Unit 1 Edexcel Physics A-Levelpraveen alwisAinda não há avaliações

- Geotechnical Elements and Models in OpenSeesDocumento21 páginasGeotechnical Elements and Models in OpenSeesUmut AkınAinda não há avaliações

- 2nd - Science-Second-Quarter-Week-1Documento37 páginas2nd - Science-Second-Quarter-Week-1Arlene AranzasoAinda não há avaliações

- Manual of Curatorship: A Guide To Museum PracticeDocumento7 páginasManual of Curatorship: A Guide To Museum PracticeLuísa MenezesAinda não há avaliações

- Guide to Conducting SAFOP StudiesDocumento52 páginasGuide to Conducting SAFOP Studiesokemma79% (14)

- Inakyd 3623-X-70Documento2 páginasInakyd 3623-X-70roybombomAinda não há avaliações

- ASSEMBLING COMPUTER: HOW TO BUILD A PCDocumento48 páginasASSEMBLING COMPUTER: HOW TO BUILD A PCCeejaay PelinaAinda não há avaliações

- Reference Design Hardware Guide for EVM CE-2Documento7 páginasReference Design Hardware Guide for EVM CE-2Angie FoleyAinda não há avaliações

- NTE56004 Thru NTE56010 TRIAC, 15 Amp: FeaturesDocumento2 páginasNTE56004 Thru NTE56010 TRIAC, 15 Amp: FeaturesFreddy SarabiaAinda não há avaliações

- 7H17-28 Clearances and Wear Limits PDFDocumento3 páginas7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- Variants of NormalDocumento9 páginasVariants of NormalFaizah HannyAinda não há avaliações

- Arihant 40 Days Crash Course For JEE Main Physics (Crackjee - Xyz)Documento464 páginasArihant 40 Days Crash Course For JEE Main Physics (Crackjee - Xyz)Milan Dai50% (4)

- Instrument To Be CalibratedDocumento3 páginasInstrument To Be Calibratedsumit chauhanAinda não há avaliações

- M. Valerio Assignment 6.1Documento1 páginaM. Valerio Assignment 6.1Mark Kristian ValerioAinda não há avaliações

- CORRELATION AND LINEAR REGRESSIONDocumento9 páginasCORRELATION AND LINEAR REGRESSIONSANKET GANDHIAinda não há avaliações

- Pick The Gender of Your Baby - Free EditionDocumento26 páginasPick The Gender of Your Baby - Free EditionAlicia Adrianti0% (1)

- AAA Variable Spring Hangers CatalogDocumento31 páginasAAA Variable Spring Hangers CatalogNopparut0% (1)

- Ch1 PDFDocumento54 páginasCh1 PDFChristian Jegues100% (2)

- (Computing 14) A. Aguilera, D. Ayala (Auth.), Professor Dr. Guido Brunnett, Dr. Hanspeter Bieri, Professor Dr. Gerald Farin (Eds.) - Geometric Modelling-Springer-Verlag Wien (2001)Documento356 páginas(Computing 14) A. Aguilera, D. Ayala (Auth.), Professor Dr. Guido Brunnett, Dr. Hanspeter Bieri, Professor Dr. Gerald Farin (Eds.) - Geometric Modelling-Springer-Verlag Wien (2001)ANDRES Fernando Mosquera DIAZAinda não há avaliações

- (Teubner Studienbücher Chemie) Brian R. Eggins (Auth.) - Biosensors - An Introduction (1996, Vieweg+Teubner Verlag) PDFDocumento221 páginas(Teubner Studienbücher Chemie) Brian R. Eggins (Auth.) - Biosensors - An Introduction (1996, Vieweg+Teubner Verlag) PDFRicardo PatrickAinda não há avaliações

- Data Biostataplus Sbi2014-EDocumento4 páginasData Biostataplus Sbi2014-ELucila Milagros PinillosAinda não há avaliações

- Why Check Valves SlamDocumento2 páginasWhy Check Valves SlamBramJanssen76Ainda não há avaliações

- Customer Part Exchange Program: Product InformationDocumento8 páginasCustomer Part Exchange Program: Product InformationAdrian GarciaAinda não há avaliações

- VGHV NBV GH fc7fvbn BN NGCJHGDocumento16 páginasVGHV NBV GH fc7fvbn BN NGCJHGRahul GAinda não há avaliações

- Soal ReadingDocumento3 páginasSoal ReadingSendi PuspaAinda não há avaliações

- Finite Element Simplified Fatigue AnalysisDocumento4 páginasFinite Element Simplified Fatigue AnalysisJin Hwan KimAinda não há avaliações

- Fundamentals of VolleyballDocumento2 páginasFundamentals of VolleyballLawrence CezarAinda não há avaliações

- Consumer preference towards branded milk: A comparative analysis of Verka milk and Amul milkDocumento12 páginasConsumer preference towards branded milk: A comparative analysis of Verka milk and Amul milkBhawna RehanAinda não há avaliações