Escolar Documentos

Profissional Documentos

Cultura Documentos

Report Print Libre

Enviado por

HHTDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Report Print Libre

Enviado por

HHTDireitos autorais:

Formatos disponíveis

Retrofitting of Existing RCC Buildings by Method of Jacketing

CHAPTER 1

INTRODUCTION

1.1 SEISMIC STRENGTHENING

Seismic strengthening is defined as the actions taken to upgrade the seismic resistance of an

existing building so that it becomes safe under earthquakes. This can be in the form of providing

seismic bands, eliminating source of weakness or concentrations of large mass and opening in

walls, adding shear walls or strong column points in walls, bracing roofs and floors to be able to

act as horizontal diaphragms adequately connecting roofs to walls and columns and also

connecting between walls and foundations.

1.2 CONCEPT OF RETROFITTING

Retrofitting is technical interventions in structural system of a building that improve the

resistance to earthquake by optimizing the strength, ductility and earthquake loads. Strength of

the building is generated from the structural dimensions, materials, shape and number of

structural elements. Ductility of the building is generated from good detailing, materials used,

degree of seismic resistant etc. Earthquake load is generated from the site seismicity, mass of the

structures, important of buildings, degree of seismic resistant etc.

Due to variety of structural condition of building, it is hard to develop typical rules for

retrofitting. Each building has different approaches depending upon the structural deficiencies.

Hence engineers are needed to prepare and design the retrofitting approaches. In the design of

retrofitting approach, the engineers must comply with the building codes. The results generated

by adopting retrofitting techniques must fulfill the minimum requirements on the building codes

such as deformation, detailing strength etc.

1.3 CAUSES OF FAILURE

Damage of buildings was caused by a combination of affects:

Old decaying buildings predating modern construction practices.

New buildings not being designed to Indian Earthquake codes.

MLMCE 1 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

CHAPTER 2

STRENGTHENING OF RCC STRUCTURES

2.1 INTRODUCTION

Structure repair and rehabilitating is a process whereby an existing structure is enhanced to

increase the probability that the structure will survive for a long period of time and also against

earthquake forces. This can be accomplished through the addition of new structural elements, the

strengthening of existing structural elements and/or the addition of base isolators. Deterioration

of concrete and corrosion of embedded reinforcement structure might make the R.C.C structure

structurally deficient. Corrosion can be controlled to some extent by fixing of chloride or

protective coating

Before any repair work is put in hand, the cause of damage must be identified as clearly

as possible. This principle may seem self-evident but it is surprising how often it is disregarded,

with the result that further repairs have to be carried out within a short time. Sometimes the cause

is obvious as, for example, in many cases of accidental damage but, more often than not, careful

investigation is required. The next step must be to consider the objective of the repair, which will

generally be to restore or enhance one or more of the following:

Durability

Structural strength

Function

Appearance.

Of these four requirements, restoration of durability is by far the most common in repair

work. One must also consider whether the repair is to be permanent or temporary. Only after

deciding on the most likely cause of damage, whether it is likely to occur, and the purpose of the

work, should the method of repair be chosen.

2.2 CONVENTIONAL STRENGTHENING METHODS

These are the conventional strengthening methods adopted to rehabilitate RCC

Grouting process

Guniting Process

MLMCE 2 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Application of Epoxy Resins

Section Enlargement or Jacketing

Post Tensioning

Bonded Steel Plates

Carbon Fiber Reinforced Plastics(CFRP) for Repair & Strengthening

2.2.1 Grouting

It is the process of placing a material into cavities in concrete for the purpose of increasing the

load bearing capacity of the structure, grouting restores the monolithic nature of the structure.

Primary grouting materials and their common uses are:

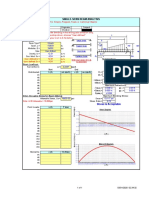

Table 2.1 Primary grouting materials

CHEMICAL CEMENTITIOUS

Control Seepage Mass Placement

Shut-off Seepage Structural (high strength)

EPOXY POLYURETHANES

Seal Cracks Building Envelope Insulation

Acidic Environments Acoustical Sealant

POLYSTERS SILICONES

Bolt Anchoring Smoke Seals

MLMCE 3 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

2.2.2 Guniting Process

Guniting is an effective method, which has been extensively used in the rehabilitation of

structurally distressed RC members. There have been cases of heavy rusting of the mesh in the

form of powder or in the form of sheets coming out. The Guniting process suffers from

drawbacks like dust and noise nuisance.

2.2.3 Application of Epoxy Resins

In this method of strengthening, an epoxy adhesive normally consisting of two components a

resin and a hardener is used to bond steel plates to overstressed regions of RC members.

Normally, the steel plates are located tension zone of concrete to enhance the flexural capacity.

The plates can also be placed at the compression and shear regions to enhance the axial and shear

capacities of the RC structural elements

2.2.4 Section Enlargement or Jacketing

In this method the entire height of the column section is increased and a cage of additional main

reinforcement bars with shear stirrups is provided right from the foundation as per the

requirement of additional load, etc. However, there are many instances where the column section

is increased with additional reinforcement bars only on one face, and that too starting from the

floor slab level of a particular floor and only up to the height of deterioration of the column .The

enlargement should be bonded to the existing concrete to produce a monolithic member .Cement

mortar is used for these enlargements.

The section enlargement method is relatively easy to construct and economically

effective. The disadvantages of this method are a high risk of corrosion of embedded reinforcing

steel and concrete deterioration. These problems are associated with relative dimensional

incompatibility between existing and new concrete. The restrained volume changes of new

material are inducing tensile stresses that may lead to cracking and delaminating when the

induced tensile stresses are greater than tensile strain capacity of tile new material

The way to make this strengthening technique effective in the future is to use materials

with higher tensile strain capacity, with low shrinkage properties

MLMCE 4 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Figure 2.1 Additional Reinforcement & Micro concreting

2.2.5 Post Tensioning

External prestressing is now widely developed for concrete strengthening in the United States,

Japan &Switzerland. External prestressing techniques have been employed with great success to

correct excessive and undesirable deflections in existing structure. They have also been used to

strengthen existing concrete structures to carry additional loads

It can be used on tile inside of box girders or the outside of I girders to increase the

capacity of existing bridges and to provide improved resistance to fatigue and cracking.

2.2.6 Bonded Steel Plates

In this method of strengthening steel plates or other steel elements are glued to the concrete

surface by a two component epoxy adhesive creating a three-phase concrete glue steel composite

system. The wide acceptance and at the same time attractiveness is due to negligible changes to

overall dimensions of the structure and minimum disruption to its use. At the same time,

adequate design, specification and execution of the job will ensure the necessary composite

action for the designed loading range. It was demonstrated that steel plates bonded to the tension

MLMCE 5 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

face of the concrete beams can lead to increase in flexural capacity, along with increase in

flexural stiffness and associated decreases in deflection and cracking.

2.2.7 Carbon Fiber Reinforced Plastics (CFRP) for Repair & Strengthening

CFRP has high strength, lightweight, excellent strength to weight ratio, resistant to chemicals

(acids and bases), good fatigue strength, and nonmagnetic, non-corrosive and nonconductive

properties. As with any composite system, bond of the strengthening plate the existing concrete

is very critical. Therefore, the surface preparation of both phases of tile system, concrete and

CFRP plates is very important .The plates should be ground on tile bonding side, immediately

before bonding, the surface should be cleaned with acetone. After mixing the epoxy glue

component should be placed oil tile plate without delay, after assembling the plate in the design

position, a slight pressure is applied to squeeze out excessive adhesive

MLMCE 6 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

CHAPTER 3

JACKETING

3.1 INTRODUCTION

Jacketing is one of the most frequently & popularly used techniques to strengthen reinforced

concrete (RC) columns. With this method, axial strength, bending strength, and stiffness of the

original column are increased. It is well known that the success of this procedure is dependent on

the monolithic behavior of the composite element. To achieve this purpose, the treatment of the

interface must be carefully chosen. The common practice consists of increasing the roughness of

the interface surface and applying a bonding agent, normally an epoxy resin. Steel connectors are

also occasionally applied. These steps involve specialized workmanship, time, and cost.

Concerning the added concrete mixture and due to the reduced thickness of the jacket, the option

is usually a grout with characteristics of self-compacting concrete (SCC) and high strength

concrete (HSC).

The most common types of jackets are steel jacket, reinforced concrete jacket, fiber

reinforced polymer composite jacket, jacket with high tension materials like carbon fiber, glass

fiber etc. The main purposes of jacketing are:

1. To increase concrete confinement by transverse fiber reinforcement, especially for

circular cross-sectional columns

2. To increase shear strength by transverse fiber reinforcement

3. To increase flexural strength by longitudinal fiber reinforcement provided.

3.2 TECHNICAL CONSIDERATIONS

The main objective of jacketing is to increase the seismic capacity of the moment resisting

framed structures. In almost every case, the columns as well .as beams of the existing structure

have been jacketed. In comparison to the jacketing of reinforced concrete columns, jacketing of

reinforced concrete beams with slabs is difficult yielding good confinement because slab causes

hindrance in the jacket. In structures with waffle slab, the increase in stiffness obtained by

jacketing columns and some of the ribs, have improved the efficiency of structures. In some

cases, foundation grids are strengthened and stiffened by jacketing their beams. An increase in

strength, stiffness and ductility or a combination of them can be obtained. Jacketing serves to

MLMCE 7 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

improve the lateral strength and ductility by confinement of compression concrete. It should be

noted that retrofitting of a few members with jacketing or some other enclosing techniques

might not be effective enough to improve the overall behavior of the structure, if the remaining

members are not ductile.

3.3 JACKETING OF COLUMNS

Jacketing of columns consists of added concrete with longitudinal and transverse reinforcement

around the existing columns. This type of strengthening improves the axial and shear strength of

columns while the flexural strength of column and strength of the beam-column joints remain the

same. It is also observed that the jacketing of columns is not successful for improving the

ductility. A major advantage of column jacketing is that it improves the lateral load capacity of

the building in a reasonably uniform and distributed way and hence avoiding the concentration of

stiffness as in the case of shear walls. This is how major strengthening of foundations may be

avoided. In addition the original function of the building can be maintained, as there are no major

changes in the original geometry of the building with this technique. The jacketing of columns is

generally carried out by two methods:

(i) Reinforced concrete jacketing

(ii) Steel jacketing.

3.3.1 Reinforced Concrete Jacketing

Reinforced concrete jacketing can be employed as a repair or strengthening scheme. Damaged

regions of the existing members should be repaired prior to their jacketing. There are two main

purposes of jacketing of columns:

Increase in the shear capacity of columns in order to accomplish a strong column-weak

beam design

To improve the column's flexural strength by the longitudinal steel of the jacket made

continuous through the slab system are anchored with the foundation. It is achieved by

passing the new longitudinal reinforcement through holes drilled in the slab and by

placing new concrete in the beam column joints as illustrated in figure 3.1. Rehabilitated

sections are designed in this way so that the flexural strength of columns should be

greater than that of the beams. Transverse steel above and below the joint has been

provided with details, which consists of two L-shaped ties that overlap diagonally in

MLMCE 8 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

opposite corners. The longitudinal reinforcement usually is concentrated in the column

corners because of the existence of the beams where bar bundles have been used as

shown in figure 3.1

Figure 3.1 Construction Techniques for Column Jacketing

MLMCE 9 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Table 3.1 Details of Reinforced Concrete Jacketing

Match with the concrete of the existing structure.

Properties of jackets

Compressive strength greater than that of the existing structures

by 5 N/mm2or at least equal to that of the existing structure.

10 cm for concrete cast-in-place and 4 cm for shotcrete.

If possible, four-sided jacket should be used.

A monolithic behavior of the composite column should be

Minimum width of

assured.

jacket

Narrow gap should be provided to prevent any possible increase

in flexural capacity.

Designed and spaced as per earthquake design practice.

Minimum area of

Minimum bar diameter used for ties is not less than 10 mm or 1/3

transverse

of the diameter of the biggest longitudinal bar.

reinforcement

The ties should have 135-degree hooks with 10bar diameter

anchorage

3Afy, where, A is the area of contact in cm2 and fy is in kg/cm2

Spacing should not exceed six times of the width of the new

Minimum area of

longitudinal elements (the jacket in the case) up to the limit of 60 cm.

reinforcement Percentage of steel in the jacket with respect to the jacket area

should be limited between 0.015and 0.04.

At least, 12 mm bar should be used at every corner for a four

sided jacket

Provide adequate shear transfer mechanism to assured monolithic

behavior.

A relative movement between both concrete interfaces (between

Shear stress in the the jacket and the existing element) should be prevented.

interface Chipping the concrete cover of the original member and

roughening its surface may improve the bond between the old and

the new concrete.

For four-sided jacket, the ties should be used to confine and for

MLMCE 10 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

shear reinforcement to the composite element

Connectors should be anchored in both the concrete such that it

may develop at least

80% of their yielding stress.

Distributed uniformly around the interface, avoiding concentration

Connectors in specific locations.

It is better to use reinforced bars (rebar) anchored with epoxy

resins of grouts.

3.3.2 Steel Jacketing

Local strengthening of columns has been frequently accomplished by jacketing with steel plates.

A general feature of steel jacketing is mentioned in Table 3.2

Figure 3.2 Construction Techniques for Steel Jacketing

MLMCE 11 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Table 3.2 Details Of Steel Jacketing.

Steel plate thickness At least 6 mm

1.2 to 1.5 times splice length in case of flexural

Height of jacket columns.

Full height of column in case of shear columns

Rectangular jacketing, prefabricated two L-shaped

panels The use of rectangular jackets has proved to

be successful in case of small size columns upto 36

inch width that have been successfully retrofitted

Shape of jackets with %" thick steel jackets combined with adhesive

anchor bolt, but has been less successful on larger

rectangular columns. On larger columns, rectangular

jackets appear to be incapable to provide adequate

confinement

Welded throughout the height of jacket, size of weld

38 mm (1.5 inch), steel jacket may be terminated

Free ends of jackets bottom above the top of footing to avoid any possible

clearance. bearing of the steel jacket against the footing, to

avoid local damage to the jacket and/or an

undesirable or unintended increase in flexural

capacity.

25 mm fill with cementations grout.

25 mm in diameter and 300 mm long embedded in

Gap between steel jacket and

200 mm into concrete column.

concrete column Size of anchor

Bolts were installed through pre-drilled holes on the

Number of anchor bolts

steel jacket using an epoxy adhesive.

Two anchor bolts are intended to stiffen the steel

jacket and improve confinement of the splice.

3.4 BEAM JACKETING

Jacketing of beams is recommended for several purposes as it gives continuity to the columns

and increases the strength and stiffness of the structure. While jacketing a beam, its flexural

resistance must be carefully computed to avoid the creation of a strong beam-weak column

system. In the retrofitted structure, there is a strong possibility of change of mode of failure and

redistribution of forces as a result of jacketing of column, which may consequently causes beam

MLMCE 12 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

hinging. The location of the beam critical section and the participation of the existing

reinforcement should be taken into consideration. Jacketing of beam may be carried out under

different ways, the most common are one-sided jackets or 3- and 4-sided jackets. At several

occasions, the slab has been perforated to allow the ties to go through and to enable the casting

of concrete. The beam should be jacketed through its whole length. The reinforcement has also

been added to increase beam flexural capacity moderately and to produce high joint shear

stresses. Top bars crossing the orthogonal beams are put through holes and the bottom bars have

been placed under the soffit of the existing beams, at each side of the existing column. Beam

transverse steel consists of sets of U-shaped ties fixed to the top jacket bars and of inverted U-

shaped ties placed through perforations in the slab, closely spaced ties have been placed near the

joint region where beam hinging is expected to occur (figure no. 3.3). The main features of

reinforcement details of beam jacketing are given in table 3.3 although those guidelines can give

a rational basis for practical design; research still needs to address critical aspects in the behavior

of jacketed elements. The change in behavior in jacketed elements, whose shear span/depth

ratios are significantly reduced, due to their jacketing, needs to be clarified.

Fig 3.3 Construction Technique for Beam Jacketing

MLMCE 13 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Table 3.3 Reinforcement of beam jacketing.

8 cm if concrete cast in place or 4 cm for

shotcrete

Minimum width for jacket

Longitudinal reinforcement Percentage of steel on the jacket should be

limited to 50 of the total area of the composite

section

Ignore the effect of existing shear

reinforcement

New reinforcement should have 135 hooks and

at each corner of the tie there must be at least

one longitudinal bar.

Shear reinforcement

The bar used for the tie should have at least 8

mm diameter

Multiple piece ties can be used, as discussed

before for columns

Span/depth ratio

Depth of jacketed beam Storey height

Ductile behavior

MLMCE 14 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

CHAPTER 4

RETROFITTING OF HEALTH BUILDING AT NASIK A CASE STUDY

4.1 GENERAL

In order to overcome the future disorders that may have occurred due to unwanted and no

predicted disasters it was decided to strengthen the existing Health building located in the central

part of Nasik city. This building was proposed in 1984 and accordingly was designed for B + G

+ 4 stories. The building during its life span at the end in 2008 found completely deteriorated and

was not capable to sustain further loads and was predicted that it may fail due to the following

reasons.

a) Higher ground water table in the locality.

b) Faulty workmanship during the stage of execution at initial stage.

c) The columns were not centered properly in their position.

d) Improper methods of compaction to the concrete.

e) Insufficient cover to the steel reinforcement.

In addition to this it may also have caused failure due to the non predicted disasters as was

caused too many buildings in the past which are listed in the next bit.

4.2 CAUSES OF FAILURE AND DAMAGES TO THE BUILDING IN PAST FEW

EARTHQUAKES

Following were the main causes of failure and damages to the buildings in Gujarat &

Maharashtra; causes to buildings same in rest part India.

Damages to buildings were caused by a combination of affects:

Old decaying buildings predating modern construction practices

New Buildings not being designed to Indian earthquake codes

Lack of knowledge, understanding or training in the use of these codes by local engineers

Unawareness that Gujarat and some part of Maharashtra is a highly seismic region

Buildings erected without owners seeking proper engineering advice

MLMCE 15 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Improper detailing of masonry and reinforced structures

Poor materials, construction and workmanship used, particularly in commercial buildings

Alterations and extensions being carried out without proper regard for effects on structure

during an earthquake.

Buildings having poor quality foundations or foundations built on poor soils.

Little or no regularity authority administering or policing the codes.

Its necessary to every civil engineer to have knowledge of proper repairs and strengthening of

earthquake damaged buildings. Indian standards exist but are not used by local engineers or

builders in urban or rural areas, mainly due to lack of knowledge and training. As a result, many

of the owner-occupiers have unknowingly been carrying out bad repairs in Gujarat. Many

buildings have been severely weakened, and the experts are concerned to that there could be

another disaster in waiting from a future earthquake. Good repairs, using well-recognized

seismic standards may reduce this vulnerability.

This project aims in simple terms to explain to the engineers why earthquakes happen in

India, which regions are seismically active, how buildings respond in an earthquake; and how to

safely carry out good repair and strengthening techniques to damaged and low strength buildings.

Fig.4.1 Some damages those were occurred after earth quake at Gujarat in non engineered R.C.C building

construction

The inset shows large deformations were concentrated at column heads, which caused many soft

storey failures, as per picture. Buildings if designed with uniform deflections of insert would

have survived without collapse.

MLMCE 16 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

4.3 RETROFITTING OF R.C.C BUILDING BY METHOD OF JACKETING

As its shown in above part of chapter no five, that Nasik and some part of Maharashtra is along

the border part of Gujarat, Gujarat has suffered from severe earth quake in last two decades,

nobody knows which would be the next time of future earth quake & its intensity. Like Gujarat

many constructions in Maharashtra and at Nasik are found as non engineered unsafe & quality

compromised constructions, this would be future risk for coming days. So it is necessary to carry

out the non destructive tests of all construction in Nasik and rest part of India, to save valuable

lives and properties, nowadays many advance retrofitting techniques are available in the world,

those can be used to repair & strengthen the unsafe and damaged buildings. Here the paper has

its focus on a Health building which is under execution (for re modification and strengthening of

existing structure).

4.4 HISTORY OF HEALTH BUILDING

A group proposed to start a hospital in Nasik in 1984. And as per the decision the detail plan

& the structural details for the same were prepared. It was proposed to construct a Basement + G

+ 4 storey structure and the designs were prepared so. The site for the hospital was near Dwarka

circle. Nasik: 11. Though it was planned to construct 6 storey in all, only 2 storey ( i. e.

Basement + G) structure was constructed in actual when structural details were for 6 storey. The

built up area for basement is 1236 sq.mt. And that of the ground floor is 1178 sq. mt. This group

had a smooth functioning up to 2004. Then in 2005 the administration of the hospital was

changed. New administrative body utilized the same infrastructure up to 2008. Then in 2009

was decided to extend the building as per the initial plan and structural details and for the same

had the structural audit in that respect. From the audit it was found that all the defects were at the

execution stage. The faults that were concluded were as below.

a) The high ground water table in the region.

b) Eccentricity of all the columns was a serious problem observed.

c) Improper techniques that were followed during mixing, placing & compacting the concrete.

d) There were many loose pockets found in the concrete.

e) Sufficient concrete cover at different stages to the steel reinforcement was not maintained.

f) The terrace slabs are provided with unwanted thickness of IPS flooring at the top.

MLMCE 17 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

From the NDT test results it was suggested that the management should demolish the

entire existing structure instead of extending it and go for complete new structure. The

management refused to do so and asked to suggest such a measure so that the existing

infrastructure at least can withstand and be utilized for 5 7 years more. As the final conclusion

and the requirement of the management it was decided to go for Retrofitting of the Structure.

4.5 THE STEPS THAT WERE SUGGESTED AND ARE ADOPTED

The entire flooring at the basement to be removed & to be provided again with a raft

below it. To overcome the uplift pressure that could be generated due to the higher

ground water table it was suggested to provide a raft below the basement floor.

All the columns should be jacketed. In the existing structure it was found that the

columns were not centered properly in their position, due to which they were

subjected to unwanted eccentric loads. Also the concrete in columns, beams, slabs

was not compacted properly which created loose pockets & honey combs in the

components. Suitable cover for the reinforcement was not maintained.

To overcome the above difficulties it was decided to jacket all the columns such that the

eccentricity of loading will be reduced, the loose pockets of concrete will be capable to sustain

the load to which the column is subjected & all the steel get the required concrete covering.

The loose pockets in the concrete in the beams are also removed and recasted in M25

grade.

The unwanted heavy loading of water proofing (IPS flooring) damaged the slab to

greater extent.

Therefore, five slabs are entirely opened, strengthened with additional reinforcement and

are casted with 150 mm thick M25 grade concrete layer.

The estimated cost of retrofitting the existing structure is 4.5 crore. To meet the further

requirement of infrastructure the management now is constructing additional new building

with G + 2 storey, instead of razing the existing building.

MLMCE 18 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Fig 4.2 Column jacketing at basement stage

Fig 4.3 Beam column junction strengthening in basement

MLMCE 19 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

4.4 finished Column after jacketing work

Fig 4.5 Rusting condition of existing slabs reinforcement

MLMCE 20 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Fig 4.6 Replaced slab reinforcement for existing rusted steel reinforcement

Fig 4.7 Application of chemical admixtures at the joint of new and old concrete

MLMCE 21 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

Fig 4.8 Compaction of concrete by needle vibrator and placement of cover blocks

Fig 4.9 Finished slabs - ready to cure

MLMCE 22 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

As discussed above all works those were carried out on strengthening of the Health building at

Nasik, will definitely increases the strength of existing building, this practice would be necessary

for many buildings at Nasik and rest of India, it will save the many lives, when any natural

disasters will occur.

MLMCE 23 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

CHAPTER 5

CONCLUSIONS

The analysis of results of this experimental study led to the following statements:

1) All models behaved monolithically independent of the adopted interface

preparation method,

2) Whether the strengthening operation was carried out with or without an axial load

applied had no significant influence for the adopted conditions;

3) The resistance of the strengthened models was considerably higher than that of

the original column and slightly higher than that of the monolithic model;

4) The stiffness of the strengthened models was considerably higher than that of the

original column;

5) The transverse reinforcement strain of the original column was significantly

higher in the no strengthened model than in the strengthened models, although the

horizontal force applied in the first case was less than half the corresponding

value in the other cases; and

6) The contribution of the adherent jacket to the horizontal force resistance varied

between 86 and 90%.

Thus it was also confirmed that RC jacketing is a very effective strengthening technique, leading

to values of resistance and stiffness of the strengthened column considerably higher than those of

the original column.

JOURNAL

MLMCE 24 Civil Engineering

Retrofitting of Existing RCC Buildings by Method of Jacketing

REFERENCE

1. Bhavar Dadasaheb, Retrofitting of existing RCC buildings by method of jacketing

IJRMEET-Volume 1,Issue 5 (June 2013)

2. E S Julio, Structural rehabilitation of columns with reinforced concrete jacketing Prog

Structural Engineering Mater, Volume 5 (2010)

3. Eduardo N B, Reinforced concrete jacketing interface influence on monolithic loading

response ACI Structural Journal (2007)

4. Gnanasekaran Kaliyaperumal, Seismic retrofit of columns in buildings for flexure using

concrete jacket SET Journal of Earthquake Technology, Volume 46 (June 2009)

5. Hamidreza Nasersaeed, Evaluation of behavior and seismic retrofitting of RC structures

by concrete jacket Asian Journal Of Applied Sciences, Volume 4(2011)

6. Pravin B Waghmare, Materials and jacketing techniques for retrofitting of structures

IJAERS(2012)

7. Ramirez Ortiz J L & Barcena Diaz J M, Strengthening effectiveness of low quality

reinforced concrete columns strengthened by two different procedures Informes De La

Construction, Volume 272(July 2008)

MLMCE 25 Civil Engineering

Você também pode gostar

- Chapter 2 Incompressible Flow Through PipesDocumento38 páginasChapter 2 Incompressible Flow Through Pipesطريخم المشتاق100% (1)

- 10 5 13 Surveying Refresher Module 1Documento2 páginas10 5 13 Surveying Refresher Module 1Walter CatapangAinda não há avaliações

- 10 5 13 SURVEYING Refresher Module 1Documento2 páginas10 5 13 SURVEYING Refresher Module 1Jan Chris VillanuevaAinda não há avaliações

- Some Past Paper Answers CIVL2103Documento7 páginasSome Past Paper Answers CIVL2103Chan Yui HinAinda não há avaliações

- Sunday Problems - Week 1 Refresher Course For May 2020 Ce Board ExamDocumento4 páginasSunday Problems - Week 1 Refresher Course For May 2020 Ce Board ExamJerome YangaAinda não há avaliações

- Module 1 StaticsDocumento2 páginasModule 1 StaticsAl Jay CruzadoAinda não há avaliações

- Review Module-Reinforced Concrete Design (RCD Columns-USD Part 2)Documento3 páginasReview Module-Reinforced Concrete Design (RCD Columns-USD Part 2)Dream CatcherAinda não há avaliações

- Review Module 1 Algebra 1 Combined Part 1 and Part 2Documento2 páginasReview Module 1 Algebra 1 Combined Part 1 and Part 2Esmeralda RapingAinda não há avaliações

- Compression MembersDocumento172 páginasCompression Membersbsitler100% (1)

- EG1109 Lectures On Composite BeamsDocumento8 páginasEG1109 Lectures On Composite BeamsSteven KuaAinda não há avaliações

- Required RC Jacket Thickness and Reinforcement Ratio For Repairing RC Tied Rectangular and Circular Concrete ColumnsDocumento17 páginasRequired RC Jacket Thickness and Reinforcement Ratio For Repairing RC Tied Rectangular and Circular Concrete ColumnsMagdy Bakry100% (1)

- Refresher Module 36 Nov 2021Documento2 páginasRefresher Module 36 Nov 2021Joshua Lacaña SaltivanAinda não há avaliações

- Deep Beam PPT SeminarDocumento30 páginasDeep Beam PPT SeminarKrishan Dutt YadavAinda não há avaliações

- Assignment 6 1386142Documento4 páginasAssignment 6 1386142DuncanAinda não há avaliações

- Pier Jacketing ReportDocumento5 páginasPier Jacketing Reportsamirbendre1100% (1)

- Review Module: - Analytic GeometryDocumento2 páginasReview Module: - Analytic GeometryChristian Dela VegaAinda não há avaliações

- Tall Buildings Chap 3 ADocumento7 páginasTall Buildings Chap 3 ATharangi MunaweeraAinda não há avaliações

- Refresher MODULE - Geotechnical Engineering and HydraulicsDocumento1 páginaRefresher MODULE - Geotechnical Engineering and HydraulicsMacatangay MhorienAinda não há avaliações

- Unit-I Thin Plate Theory, Structural InstabilityDocumento78 páginasUnit-I Thin Plate Theory, Structural InstabilityNirav LakhaniAinda não há avaliações

- Member resistance under combined bi-axial bending and axial compressionDocumento12 páginasMember resistance under combined bi-axial bending and axial compressionrd radenAinda não há avaliações

- Comparative Response Assessment of Steel Frames With Different Bracing PDFDocumento14 páginasComparative Response Assessment of Steel Frames With Different Bracing PDFaxl_calin82Ainda não há avaliações

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeDocumento9 páginasAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSAinda não há avaliações

- Civil Engineering May 2022 Review Analyzes Hyperbolas and Conic SectionsDocumento2 páginasCivil Engineering May 2022 Review Analyzes Hyperbolas and Conic SectionsEd Vincent PabloAinda não há avaliações

- Pre Stressed Concrete 18Cv641: Topic: Magnels MethodDocumento14 páginasPre Stressed Concrete 18Cv641: Topic: Magnels MethodShobhaAinda não há avaliações

- Beam Deflection Problems and SolutionsDocumento2 páginasBeam Deflection Problems and SolutionsKrisia MartinezAinda não há avaliações

- Ce2404-Prestressed Concrete StructuresDocumento1 páginaCe2404-Prestressed Concrete StructuresDhivya RamachandranAinda não há avaliações

- Department of Mechanical Engineering Instructor: Dr. Nirmal Baran HuiDocumento3 páginasDepartment of Mechanical Engineering Instructor: Dr. Nirmal Baran HuiSatyajit SahuAinda não há avaliações

- TSTRUC1 Notes - Beam Deflections - Area-MomentDocumento8 páginasTSTRUC1 Notes - Beam Deflections - Area-MomentAndy OretaAinda não há avaliações

- Retrofitting Guideline Final 25 8 19Documento86 páginasRetrofitting Guideline Final 25 8 19indranigogoiAinda não há avaliações

- Notching On BeamsDocumento5 páginasNotching On BeamsRRussel CastroAinda não há avaliações

- Minimum Thickness For Ductile RC Structural Walls: Y.H. Chai, S.K. KunnathDocumento12 páginasMinimum Thickness For Ductile RC Structural Walls: Y.H. Chai, S.K. KunnathDavid FloresAinda não há avaliações

- Quiz Assignment No.6Documento4 páginasQuiz Assignment No.6CHA CHAAinda não há avaliações

- Earthquake Analysis of Linear SystemsDocumento67 páginasEarthquake Analysis of Linear SystemsPrantik Adhar Samanta67% (3)

- ThesisDocumento151 páginasThesisRajeshwari NarayanamoorthyAinda não há avaliações

- CE 579 Lecture 6 Stability - Differential Equations-TorsionDocumento16 páginasCE 579 Lecture 6 Stability - Differential Equations-TorsionbsitlerAinda não há avaliações

- DESIGN OF CORNER FLAT-PLATE PANELDocumento20 páginasDESIGN OF CORNER FLAT-PLATE PANELAhsan Khan100% (2)

- Analysis and Design of Slender Columns: Lecture # 4ADocumento33 páginasAnalysis and Design of Slender Columns: Lecture # 4Apk khanAinda não há avaliações

- Review - Mathematics, Surveying and Transportation EngineeringDocumento11 páginasReview - Mathematics, Surveying and Transportation EngineeringPaulyne TuganoAinda não há avaliações

- 15a - Tabla de Deflexion para Vigas PDFDocumento4 páginas15a - Tabla de Deflexion para Vigas PDFKarla BonillaAinda não há avaliações

- 05 04 Chap GereDocumento12 páginas05 04 Chap GereDipNdra SharmaAinda não há avaliações

- 1001 Solved Problems in Engineering Mathematics by Excel Academic CouncilDocumento10 páginas1001 Solved Problems in Engineering Mathematics by Excel Academic CouncilJohn govanAinda não há avaliações

- C1-Analytical Methods Assignment 1Documento2 páginasC1-Analytical Methods Assignment 1JP de AzevedoAinda não há avaliações

- Advanced Retrofitting Techniques For Reinforced Concrete Structures: A State of An Art Technical ReviewDocumento24 páginasAdvanced Retrofitting Techniques For Reinforced Concrete Structures: A State of An Art Technical ReviewHARSHALAinda não há avaliações

- Piling Practices Under Eurocode 7 (Contractor Point of View) PDFDocumento42 páginasPiling Practices Under Eurocode 7 (Contractor Point of View) PDFBatu GajahAinda não há avaliações

- Example-Simply Supported Laterally Unrestrained BeamDocumento9 páginasExample-Simply Supported Laterally Unrestrained BeamBejan Claudiu100% (2)

- Kloeckner Westok A5 Pocket GuideDocumento36 páginasKloeckner Westok A5 Pocket GuidekyleAinda não há avaliações

- Week 5 Assignment SolutionDocumento2 páginasWeek 5 Assignment Solutionamin alzuraikiAinda não há avaliações

- Long Term Deflection in Concrete BeamsDocumento6 páginasLong Term Deflection in Concrete BeamsRenganayagi BalajiAinda não há avaliações

- Column Design As Per BS 8110-1:1997: PHK/JSNDocumento16 páginasColumn Design As Per BS 8110-1:1997: PHK/JSNShabana ferozAinda não há avaliações

- Review Innovations Measures of Central Tendency FRACTILES: Percentiles, Deciles, and QuartilesDocumento1 páginaReview Innovations Measures of Central Tendency FRACTILES: Percentiles, Deciles, and QuartilesLemuel TeopeAinda não há avaliações

- Lecture 3 - Influence LinesDocumento87 páginasLecture 3 - Influence LinesMary Dominique OnateAinda não há avaliações

- Design of Steel and Timber StructuresDocumento6 páginasDesign of Steel and Timber StructuresYi MokAinda não há avaliações

- Poisson'S Ratio Biaxial and Triaxial DeformationDocumento8 páginasPoisson'S Ratio Biaxial and Triaxial DeformationRyan Jhay YangAinda não há avaliações

- Retrofitting of Existing RCC Buildings B PDFDocumento25 páginasRetrofitting of Existing RCC Buildings B PDFmojeebmashalAinda não há avaliações

- Retrofitting of Existing RCC Buildings BDocumento25 páginasRetrofitting of Existing RCC Buildings BAhetesham Uddin Ahmed TipuAinda não há avaliações

- Rebuild-Vol 10Documento20 páginasRebuild-Vol 10ahtin618100% (1)

- Homework 3Documento3 páginasHomework 3QiieyAinda não há avaliações

- Causes of Deterioration of StructuresDocumento5 páginasCauses of Deterioration of StructuresDhruv PatelAinda não há avaliações

- Seismic Retrofitting Techniques of RCC BuiidingsDocumento29 páginasSeismic Retrofitting Techniques of RCC BuiidingschbaskerAinda não há avaliações

- Seismic Retrofitting Techniques For Concrete StructuresDocumento6 páginasSeismic Retrofitting Techniques For Concrete StructuresSaadat MughalAinda não há avaliações

- Beams GWDocumento10 páginasBeams GWGreatAinda não há avaliações

- Beam With StressDocumento1 páginaBeam With StressHHTAinda não há avaliações

- Beam With StressDocumento1 páginaBeam With StressAmit Kumar PaulAinda não há avaliações

- BEAMANAL - Single & Continuous Beam AnalysisDocumento6 páginasBEAMANAL - Single & Continuous Beam AnalysistambokAinda não há avaliações

- Aci318-08 RC BeamDocumento1 páginaAci318-08 RC BeamHHTAinda não há avaliações

- Beam Allowable End Reaction and End Moment AnalysisDocumento3 páginasBeam Allowable End Reaction and End Moment AnalysisEFECANAinda não há avaliações

- Beam Design FunctionsDocumento18 páginasBeam Design FunctionsAmit Kumar PaulAinda não há avaliações

- Beamanal (Metric)Documento1 páginaBeamanal (Metric)Tri TruongAinda não há avaliações

- Elastic Analysis of Reinforced SectionsDocumento2 páginasElastic Analysis of Reinforced SectionsGreatAinda não há avaliações

- Beam Design FunctionsDocumento18 páginasBeam Design FunctionsAmit Kumar PaulAinda não há avaliações

- BEAMANAL - Single & Continuous Beam AnalysisDocumento6 páginasBEAMANAL - Single & Continuous Beam AnalysistambokAinda não há avaliações

- Aluminum TubeDocumento748 páginasAluminum TubeGreatAinda não há avaliações

- Beam On Elastic FoundationDocumento8 páginasBeam On Elastic FoundationBoonme ChinnaboonAinda não há avaliações

- Aashto LRFD SlabDocumento2 páginasAashto LRFD Slabmichel92748Ainda não há avaliações

- The Design Is Adequate.: 6 OD × 0.375 WALLDocumento3 páginasThe Design Is Adequate.: 6 OD × 0.375 WALLGreatAinda não há avaliações

- (Bulletin 9) - Guidance For Good Bridge Design. Parts 1 and 2-FIB (2000) PDFDocumento185 páginas(Bulletin 9) - Guidance For Good Bridge Design. Parts 1 and 2-FIB (2000) PDFHHTAinda não há avaliações

- RC Beam Analysis and DesignDocumento3 páginasRC Beam Analysis and DesignTarek Abulail0% (1)

- Aashto LRFD SlabDocumento1 páginaAashto LRFD SlabHHTAinda não há avaliações

- Esteem 8 Technical Documentation PDFDocumento860 páginasEsteem 8 Technical Documentation PDFLau Kim Hwa80% (5)

- Beam On Elastic Foundation-Finite ElementDocumento29 páginasBeam On Elastic Foundation-Finite ElementHHTAinda não há avaliações

- Beam On Elastic FoundationDocumento1 páginaBeam On Elastic FoundationHHTAinda não há avaliações

- Elastic Foundation of Beams AnalysisDocumento5 páginasElastic Foundation of Beams AnalysisEFECANAinda não há avaliações

- CALCULATION BEAM ELASTIC FOUNDATIONDocumento7 páginasCALCULATION BEAM ELASTIC FOUNDATIONmotiur basumAinda não há avaliações

- Cyril Stapely Chettoe - Haddon Clifford Adams - Reinforced Concrete Bridge Design-Chapman & Hall (1938)Documento493 páginasCyril Stapely Chettoe - Haddon Clifford Adams - Reinforced Concrete Bridge Design-Chapman & Hall (1938)HHTAinda não há avaliações

- Torsional AnalysisDocumento18 páginasTorsional AnalysisZaki SiddiquiAinda não há avaliações

- Ba 1985Documento26 páginasBa 1985Bharath Reddy ChinthiReddyAinda não há avaliações

- Brick Foundation & Brick Wall Defects & FailuresDocumento9 páginasBrick Foundation & Brick Wall Defects & FailuresHHTAinda não há avaliações

- Other - LECTURE 2d BRIDGE LOADINGDocumento62 páginasOther - LECTURE 2d BRIDGE LOADINGAmalina Ng100% (1)

- Try M5 Beam-2Documento21 páginasTry M5 Beam-2HHTAinda não há avaliações

- Designers' Guide To EN 1992-2 Concrete Bridges (2007)Documento381 páginasDesigners' Guide To EN 1992-2 Concrete Bridges (2007)Ialomiteanu Dan100% (7)

- Technician Manual for Tuttnauer AutoclavesDocumento134 páginasTechnician Manual for Tuttnauer AutoclavesIngenieria NemoconAinda não há avaliações

- KJELDSEN 2002 - Present and Long Term Composition of MSW Landfill Leachate A ReviewDocumento41 páginasKJELDSEN 2002 - Present and Long Term Composition of MSW Landfill Leachate A ReviewfernandexrjAinda não há avaliações

- P H100Documento3 páginasP H100nixneusAinda não há avaliações

- Types of Polymer BlendsDocumento7 páginasTypes of Polymer BlendsPramod WattegedaraAinda não há avaliações

- Wastewater Treatment OverviewDocumento55 páginasWastewater Treatment OverviewShorOuq Mohammed Malkawi100% (1)

- Essential Oils in Nepal - A Practical Guide To Essential Oils and AromatherapyDocumento6 páginasEssential Oils in Nepal - A Practical Guide To Essential Oils and Aromatherapykhilendragurung4859Ainda não há avaliações

- 9f Summary SheetsDocumento3 páginas9f Summary SheetsbanaliaAinda não há avaliações

- EDiffusion of AcetoneDocumento4 páginasEDiffusion of AcetoneSourav SutradharAinda não há avaliações

- Jresv107n6p681 A1bDocumento5 páginasJresv107n6p681 A1bMadheswaran Sparkle QE1Ainda não há avaliações

- Feeding and NutritionDocumento4 páginasFeeding and NutritiongennoxydAinda não há avaliações

- Palazzoli Disconnect SwitchDocumento8 páginasPalazzoli Disconnect Switchshar2atAinda não há avaliações

- Cmos Process FlowDocumento29 páginasCmos Process FlowPushparaj Karu100% (1)

- ICP-MS Chapter 1 TheoryDocumento41 páginasICP-MS Chapter 1 TheoryBayu Aji PrasetyoAinda não há avaliações

- Waste Disposal ManagementDocumento24 páginasWaste Disposal Managementmex smashAinda não há avaliações

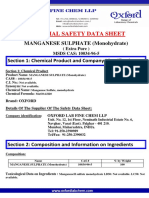

- MANGANESE SULPHATE (Monohydrate) (Extra Pure)Documento8 páginasMANGANESE SULPHATE (Monohydrate) (Extra Pure)Bima KurniawanAinda não há avaliações

- WELL SERVICE AND WORKOVERDocumento52 páginasWELL SERVICE AND WORKOVERAndre YudhistiraAinda não há avaliações

- Lesson 2: Methods and Types of Food PreservationDocumento63 páginasLesson 2: Methods and Types of Food PreservationReymond G. Balilu100% (1)

- The Health of The St. Croix Estuary - Vol. 1 Executive SummaryDocumento19 páginasThe Health of The St. Croix Estuary - Vol. 1 Executive SummaryART'S PLACEAinda não há avaliações

- Synthesis of Tramadol and Related AnalgeticsDocumento4 páginasSynthesis of Tramadol and Related AnalgeticsHeroine2Ainda não há avaliações

- Us4018815 PDFDocumento4 páginasUs4018815 PDFFatih AkmanAinda não há avaliações

- Chemical Composition and Profile Characteristics of Osage Orange Maclura Pomifera (Rafin.) Schneider Seed and Seed OilDocumento8 páginasChemical Composition and Profile Characteristics of Osage Orange Maclura Pomifera (Rafin.) Schneider Seed and Seed OilrajrudrapaaAinda não há avaliações

- IGCSE Chemistry Energy ChangesDocumento11 páginasIGCSE Chemistry Energy ChangesahmedAinda não há avaliações

- Conbextra EP150: Constructive SolutionsDocumento4 páginasConbextra EP150: Constructive SolutionsSHAIK ASIMUDDINAinda não há avaliações

- Gas Properties Chemistry Clicker and Discussion QuestionsDocumento26 páginasGas Properties Chemistry Clicker and Discussion QuestionsShallaw AbdulkaderAinda não há avaliações

- Concrete-Filled Steel Tubular (CFST) Columns: Mayank Vyas and Ghanishth AgrawalDocumento4 páginasConcrete-Filled Steel Tubular (CFST) Columns: Mayank Vyas and Ghanishth AgrawalK RaghuAinda não há avaliações

- Directed Writing Clean EnvironmentDocumento2 páginasDirected Writing Clean Environmentyudrea88Ainda não há avaliações

- 2VBT - Hybridisation 49 58Documento10 páginas2VBT - Hybridisation 49 58Raj Kishore100% (1)

- Lab Report Batch ReactorDocumento21 páginasLab Report Batch Reactornaneesa_190% (30)

- FDK - BBCV2.MH13421 - Lithium Batteries - ComponentDocumento7 páginasFDK - BBCV2.MH13421 - Lithium Batteries - ComponentMedSparkAinda não há avaliações

- Api 510 Exam: Api576 Questions - 01Documento3 páginasApi 510 Exam: Api576 Questions - 01korichiAinda não há avaliações