Escolar Documentos

Profissional Documentos

Cultura Documentos

Turbine Efficiency

Enviado por

Dipti Bhanja0 notas0% acharam este documento útil (0 voto)

28 visualizações10 páginasEff

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoEff

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

28 visualizações10 páginasTurbine Efficiency

Enviado por

Dipti BhanjaEff

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 10

srano17 Steam Turbine Etfclancy - Turbines Info

Turbines info

All about turbines

Steam Turbine Efficiency

© August 7, 2011 & Posted by Turbinesinfo 221

Me

14Cos? ar, Reaction Turbine

__> Impulse Turbine

Cosa, Cos a,

Tweet 6H

The efficiency of any turbine or engine can be defined as its ability to convert the input energy into

useful output energy which is expressed in the form of the following equation.

Efficiency (n) = Output / Input

‘An ideal turbine with 100% efficiency is the one which converts all its input energ)

without dissipating energy in the form of heat or any other form. But in the real world, itis not

possible to build a turbine with 100% efficiency because of friction in the parts of turbines, heat loss,

and other such losses. In the case of steam turbines following factors decides the overall efficiency f

the turbine.

= Velocity of input steam (which in turn depends on the temperature and pressure of

steam)

hpi turinesinfo\comisteam-turine-eficiency! a0

somo ‘Steam Turbine Etfcency - Turbines ro

= Angle of guiding vanes

= Blade angle on the rotor

= Radius of rotor

The electrical generating efficiency of standard steam turbine power plants varies from a high of

37% HHV4 for large, electric utility plants designed for the highest practical annual capacity factor, to

under 10% HHV for small, simple plants which make electricity as a byproduct of delivering steam to

processes or district heating systems.

There are two types of steam turbines; impulse turbine and reaction turbine. Both types of steam

turbines have different efficiency due to their different working principles but the efficiency of both

types of steam turbines is expressed by the following equation

Efficiency (n) = Work Done / Input Kinetic Energy

Here input kinetic energy totally depends on the absolute velocity of the steam at the inlet of steam

turbine but work done depends on lots of factors including drop in heat content of steam within the

turbine, the angle of guide vanes especially at the inlet of turbines, blade angles, relative velocity of

steam in the turbine, etc. Itis fairly difficult to calculate work done by turbine because of all these

factors and in some cases itis not possible to accurately calculate certain factors like velocity,

temperature, or pressure of steam. There are two ways of calculating steam efficiency. These methods

referred as blade efficiency (nb) and stage efficiency (ns). Blade efficiency is calculated using the

velocity of the steam while stage efficiency is calculated by measuring changes in the enthalpy of the

steam. Enthalpy is referred to the heat content of the steam. In both cases the angle of guide vanes at

the inlet plays an important role which is represented by al. The cosine of this angle plays the central

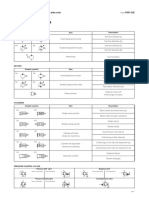

role in defining the efficiency of both impulse and reaction steam turbine. The following figure 1s

showing the graph of blade efficiency for both types of steam turbines. This figure is indicating that

reaction turbine is more efficient than impulse turbine.

hpi turinesinfo\comisteam-turine-eficiency! 20

sora Steam Turbine Etfclancy - Turbines Info

Ab

Reaction Turbine

> Impulse Turbine

Cosa, Cosa, psu

2 Mi

Figure 1: Blade efficiency of impulse and reaction steam turbine

The maximum efficiency of impulse steam turbine is achieved at zero degrees angle of inlet blades

because this angle keeps the friction at the minimum by reducing the surface area of the blade. It is

also possible to Link several turbines in series to utilize maximum energy from steam before sending

it back to the condenser. In this type of arrangement stage efficiency calculation method works best.

‘An important point to note here is that all this discussion did not include the energy loss in heating

water and condensing steam. Commercial industries also calculate efficiencies of these operations to

find out the overall efficiency of the entire setup.

Different Efficiencies of Steam Turbines

Isentropic Efficiency: This is the efficiency which compares the actual output with the ideal isentropic

‘output to measure the effectiveness of extracted work.

CHP Electrical Efficiency. Combined Heat and Power (CHP) electrical efficiency measures the amount

of boiler fuel converted into electrical energy or electricity. It can be calculated by following equation

CHP electrical efficiency = Net electricity generated/Total fvel into boiler

Total CHP Efficiency: This efficiency measures total output including electricity and steam energy by

the boiler fuel. It is calculated by following formula.

Total CHP efficiency = (Net electricity generated + Net steam to process)/Total fuel into boiler

Effective Electrical Efficiency: This efficiency is calculated by the formula

hpi turinesinfo\comisteam-turine-eficiency! a0

sora Steam Turbine Etfclancy - Turbines Info

(Steam turbine electric power output) / (Total fuel into boiler - (steam to process/boiler efficiency)

Ieis equivalent to 3,412 Btu/KWh/Net Heat Rate and

Net Heat Rate = (total fuel input to the boiler — the fuel that would required to generate the steam to

process assuming the same boiler efficiency/steam turbine electric output (kW)

Heat or power ratio is also an important factor in this discussion and it can be calculated by the

formula

Power/Heat Ratio = CHP electrical power output (Btu)/ useful heat output (Btu)

Following table 1 is showing the list of different performance characteristics f various commercial

steam turbines. This table is for classic steamn/boiler CHP system with the capacities of SOOKW, 3MW,

and 1SMW.

Cost & Performance Characteristios ‘System 1 System 2 Systems

Steam Turbine Parameters

[_ Nominal: ¢ Capacity (EW) 500 3,000 15,000

Turbine Type Back Presswe | Back Presswe | Back Pressime

Equipment Cost SAW)” S40 208

Total Installed Cost SW) 318 349

‘Turbine Isentropic Efficiency (%s)* 50% 70% 30%

"Generator/Gearbox Efficiency (0) 34% 24% 97%

Steam Flow. (Ihs/ir) il 126.000. 450.000,

“Inlet Pressure (psig) 700

t re ~ 650

2 —————————— 150

Outlet Temperature (° Falirenlieit) 366

CHP System Parameters

Boiler Efficiency 0), HHV. 30% 809

CHP Electric Efficiency (°0). Hiv 65% 9.3%

Fuel Input (MMBtwhr)? 74 $49.0

1070 386.6

Steam to Process (kW) 31.352

“Total CHP Efiiciency (0), HH 79.5%

‘Powei/Heat Ratio 0.10

‘Net Heat Rate (Bru/k Wh) 4568

75.180

Boiler Steam Turbine CHP System Cost and Performance Characteristics

Performance characteristics of typical steam/boiler CHP system

OD steam Turbines

(1 boiler, CHP, CHP systems, Efficiency, gearbox, generator, Steam Turbine, thermodynamic efficiency,

Turbine

« Innovative Wind Turbines Introduction of Gas Turbines »

hpi turinesinfo\comisteam-turine-eficiency! ano

sora Steam Turbine Etfclancy - Turbines Info

21 thoughts on “Steam Turbine Efficiency”

mahesh babu says:

December 30, 2012 at 7:36 pm

turbine efficiency methods and bland efficiency

Reply

ALLG says!

May 8, 2013 at 5:45 pm.

isentropic method

Reply

Jyotirmaya Nayak says:

January 5, 2013 at 6:18 pm.

|am a young promoter and entrepreneur of biomass to energy plants.

| want to build 2 500Kw of biomass gasification based steam power plant.

| want to know steam conditions / boiler specifications for 500Kw turbine.

| would be waiting for your reply.

Thanking you

Regards

Reply

Pravinkumar Wankhade says:

February 13, 2013 at 1:09 pm

| have worked considerable experimentation on biomass gasification and would like to be

associated with you and share technical knowhow

Reply

Ravishankar says:

January 17, 2013 at 10:40 am

Dear Mr. Nayak,

Assuming you are able to generate your biogas on a continuous basis, a steam condition of 10 bar

and 150 deg C should be adequate to generate the 500 kW of power you are Looking for.

Normally the biogas generation poses difficulty in terms of

1. Source of raw material

2. Consistent quality of fuel

3. Your ability to remove Carbondi Oxide and sulphur compounds

hpi turinesinfo\comisteam-turine-eficiency! 510

szreoi7 ‘Steam Turbine Etfcency - Turbines ro

There is a company by name Mizun Consultants and Engineers, India who claim they have both

boilers and steam turbines for a wide range particularly in the lower range.

Hope that helps.

Regards,

Ravi

Reply

bhesania ramesh says:

April 6, 2013 at 2:41 pm.

500kw cost is 989usd is a lowest prise to get our owen power need to get heat energy from

agricalture waste

Reply

Sofia says:

December 30, 2014 at 3:25 pm

Hi. I'ma final year student, majoring in electrical power. I'm doing a final year project on generating

electricity using biomass in palm oil mill and | am required to calculate the like how much steam will

produce how much kW.. It’s a bit complicated as at first | wanted to ignore the mechanical side such

8 calculating the steam and the calorific value and so on as I should be completing the electrical

side. But my supervisor is asking me to find the calculation on the steam turbine which makes me a

bit confused. Can you please help me and reply this message soon ? Thanks

Reply

Mahesh Khot says:

February 11, 2015 at 9:03 am

Hil am a PG student. Will you please help me in optimizing the turbine blade parameters for

obtaining the maximum efficiency.? Please reply. Thanks

Reply

Nithya R Menon says:

June 19, 2015 at 12:57 am

Ifthe size of turbine directly proportional to its speed?

Reply

ee Carlos Barrera says:

~ July 25, 2015 at 2:01 am

State of the Art — Novel InFlow Tech ~ Featured Project Development; / 1; Rotary-Turbo-InFlow Tech /

— GEARTURBINE PROJECT Have the similar basic system of the Aeolipilie Heron Steam Turbine device

from Alexandria 10-70 AD * With Retrodynamic = DextroRPM VS LevoinFlow = Ying Yang Way Power

Type - Non Waste Looses *8X/Y Thermodynamic CYCLE Way Steps. Higher efficient percent. No

hpi curinesnfo.comisteam turbine eicieney! ero

szreo7 ‘Steam Turbine Etfcency - Turbines ro

blade erosion by sand & very low heat target signature Pat:197187IMPI MX Dicl991 Atypical Motor

Engine Type /-2; Imploturbocompressor; One Moving Part System Excellence Design - The InFlow

Interaction comes from Macro-Flow and goes to Micro-Flow by Implossion - Only One Compression

Step; Inflow, Compression and outflow at one simple circular dynamic motion / New Concept. To see

a Imploturbocompressor animation, is possible on a simple way, just to check an Hurricane Satellite

view, and is the same implo inflow way nature.

Reply

shahaji wathare says

October 12, 2015 at 9:00 am

how back pressure is decided in steam turbine 727?

Reply

Ugur says:

December 22, 2015 at 6:33 am

When you need to produce electricty as well as steam for some process, backpressure

turbine is a choice because you can use the same steam at low pressure after turbine which

requires high pressure of steam to produce shaft work.

Reply

maqbool says:

December 16, 2015 at 10:52 am

very nice

Reply

gary says:

April, 2016 at 4:27 am

Hi guys, can anyone provide potential causes for reduced efficiency in smaller turbines? I understand

that often small turbines operate at a lower pressure and temperature which inherently affects the

thermal efficiency. However, if hypothetically, one was to develop a turbine with capacity of say

5MWe with the same steam operating conditions as a 200MWe turbine. Why would it experience a

lower efficiency? Is there specific loss mechanisms that do not scale linearly with turbine size?

Reply

Pingback: Wind Turbine Efficiency Comparison | New Energy Nexus

Pingback: Wind Turbine Efficiency Rate

unblocked games vevo run says:

August 12, 2016 at 1:39 am

Ithas been found that youngsters although playing such games try different

tricks to clear the level that aid them with mind development as

nicely as with problem solving (clearing Levels).

hpi turinesinfo\comisteam-turine-eficiency! mo

somo Seam Turbine Effceney - Turbines fo

Reply

Jaydeep says:

October 15, 2016 at 1:54 am

pl help me to explain impulse turbine efficiency in analytical methods.

Reply

praveen sharma says:

October 20, 2016 at 10:59 am

what is overall efficiency of a steam turbine which includes high pressure turbine, intermediate

pressure turbine and low pressure turbine.

Reply

Ravi B Tallikeri says:

October 22, 2016 at 1:46 am

Hi

| want to know steam turbine efficiency formula

Reply

titi says:

November 22, 2016 at 12:47 am

Hello,

May | know the typical conversion efficiency of steam enthalpy in to electricity? How much energy is

lost in the mechanical transmission and the electric generators?

Reply

Leave a reply

Default Comments (21) Facebook Comments (0)

Your email address will not be published. Required fields are marked *

Comment.

hpi turinesinfo\comisteam-turine-eficiency! ano

srano17 Steam Turbine Etfclancy - Turbines Info

Name *

Email *

Website

x seven =14

POST COMMENT

Search Q

Daily Popular

Steam Turbine Efficiency

Types of Steam Turbines

Horizontal Axis Wind Turbines ~ HAWT

What is a Turbine?

‘Types of Wind Turbines

Recent Comments

‘© J Cross-Flow Turbine How Does It Work? - Turbines Info on Pelton Turbines

‘© Jhannah on Horizontal Axis Wind Turbines ~ HAWT

‘© Size of Wind Turbines -Turbines Info on Wind Turbines

‘© yash sagoi on Types of Steam Turbines

DJAKhil on Types of Steam Turbines

Useful Links

> Info Curiosity

> Web Design

hpi turinesinfo\comisteam-turine-eficiency! eno

srano17 Steam Turbine Etfclancy - Turbines Info

Stats

Traffic Rank

tintin

1,192,215

ry Alexa

Ind Turbines Steam Turbines Gas Turbines Turbines Tesla Turbine Contact

hpi turinesinfo\comisteam-turine-eficiency! so10

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Heat Rate PDFDocumento9 páginasHeat Rate PDFDipti BhanjaAinda não há avaliações

- APC EEC WorkshopDocumento35 páginasAPC EEC WorkshopLalatendu PattanayakAinda não há avaliações

- Heat RateDocumento9 páginasHeat RateDipti BhanjaAinda não há avaliações

- Quickstart Tutorial V70 PDFDocumento75 páginasQuickstart Tutorial V70 PDFDipti BhanjaAinda não há avaliações

- Ci Fex300 Fex500 en eDocumento80 páginasCi Fex300 Fex500 en eDipti BhanjaAinda não há avaliações

- TG Building Equipment Unit 4Documento3 páginasTG Building Equipment Unit 4Dipti BhanjaAinda não há avaliações

- ./administrator P@$sw0rd&Documento1 página./administrator P@$sw0rd&Dipti BhanjaAinda não há avaliações

- Ci Fex300 Fex500 en eDocumento80 páginasCi Fex300 Fex500 en eDipti BhanjaAinda não há avaliações

- GFK 1779MDocumento124 páginasGFK 1779MDipti BhanjaAinda não há avaliações

- Annexure To Income Tax CircularDocumento6 páginasAnnexure To Income Tax CircularDipti BhanjaAinda não há avaliações

- Unity Pro Language PDFDocumento722 páginasUnity Pro Language PDFDipti BhanjaAinda não há avaliações

- Bee Code - CogenerationDocumento56 páginasBee Code - Cogenerationszumny0% (1)

- Directional Change ValveDocumento93 páginasDirectional Change ValveDipti BhanjaAinda não há avaliações

- Servalve OperationDocumento4 páginasServalve OperationDipti BhanjaAinda não há avaliações

- Pilot Operated Check ValveDocumento1 páginaPilot Operated Check ValveDipti BhanjaAinda não há avaliações

- DOCUMENTCMYK Pilot Operated Pressure Relief ValveDocumento10 páginasDOCUMENTCMYK Pilot Operated Pressure Relief ValveDipti BhanjaAinda não há avaliações

- Mole Ratio AirDocumento1 páginaMole Ratio AirDipti BhanjaAinda não há avaliações

- Symbols PDFDocumento2 páginasSymbols PDFKuttappa I GAinda não há avaliações

- TG Building Equipment Unit 4Documento3 páginasTG Building Equipment Unit 4Dipti BhanjaAinda não há avaliações

- Aux Steam SystemDocumento14 páginasAux Steam SystemDipti BhanjaAinda não há avaliações

- SCAPHDocumento2 páginasSCAPHDipti BhanjaAinda não há avaliações

- APHDocumento17 páginasAPHDipti BhanjaAinda não há avaliações

- Paper-4 REG - Set A - 20.04.2017Documento17 páginasPaper-4 REG - Set A - 20.04.2017Dipti BhanjaAinda não há avaliações

- Refrigeration and Air Conditioning StudDocumento16 páginasRefrigeration and Air Conditioning StudDipti BhanjaAinda não há avaliações

- Paper-4 SUP - Set A20.04.2017Documento16 páginasPaper-4 SUP - Set A20.04.2017Dipti BhanjaAinda não há avaliações

- Heat RateDocumento9 páginasHeat RateDipti BhanjaAinda não há avaliações

- Auxiliary Power Cosumption PDFDocumento44 páginasAuxiliary Power Cosumption PDFDipti BhanjaAinda não há avaliações

- Bee Code - CogenerationDocumento56 páginasBee Code - Cogenerationszumny0% (1)

- HeatEnginesVol 1 Chapter 11 RS PDFDocumento48 páginasHeatEnginesVol 1 Chapter 11 RS PDFDipti BhanjaAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)