Escolar Documentos

Profissional Documentos

Cultura Documentos

SH750 Cross Hatch Cutter 2017 v1

Enviado por

abualamalDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

SH750 Cross Hatch Cutter 2017 v1

Enviado por

abualamalDireitos autorais:

Formatos disponíveis

Physical Testing: Adhesion

Cross Hatch Cutter (SH750)

The Cross Hatch test has been used

widely in various forms in order to

assess the adhesion of paint coatings.

The Cross Hatch Cutter is used for

assessing the resistance of paint

coatings to separation from substrates

when a right angled lattice pattern is cut

into the coating, penetrating through to the

substrate. It can also be viewed for

adhesion between coating layers.

The test method specifies suitable cutting

tools with either single or multiple cutting

edges.

Features

8 cuttings edges for long tool life

Comfortable hard wood handle

5 tool sizes available

Description

The cutting tool consists of a hardened steel cylinder ground to

a high standard of precision so that six or eleven cutting edges

are formed between outer guide edges. A lightweight,

comfortable handle is fitted to provide a firm hold. Four

segments of the circumference are in part removed, a hold pin

is fitted so that the tool can be assembled in eight ways with the

use of a retaining thumb screw. The design enables the

operator to use a substantial part of the total cutting edges.

Method of use

Reference should be made to the relevant National Standard

for the detailed test method. The tool should be held with

forefinger along the handle, fingertip over and above the cutting

edge. The cutter is then carefully and firmly drawn under

pressure over the section of coating to be tested to form, by two

cross cuts, a square or diamond shaped lattice. The sample

area is either given a stiff brushing or (alternatively) adhesive

tape is applied, After this, the pattern inscribed is examined in

order to define the classification of test results.

Sheen Instruments Limited T: +44 (0)208 783 4321

29 Central Avenue, West Molesey, Surrey. KT8 2RF, UK info@sheeninstruments.com

www.sheeninstruments.com

A subsidiary of Elektron Technology UK Limited

SH750 2017v1

Physical Testing: Adhesion: Cross Hatch Cutter (SH750)

Standards

ASTM D3002 ASTM D3359-B AS 1580.408.4

AS 3894.9 BS EN ISO 2409 ECCA T6

ISO 2409 ISO 16276-2 JIS 5600-5.6

NF T30-038

Standard supply includes:

Cross Hatch Cutter, Handle, Case, Instructions

SH750/CK Kit for SH750 includes: Pressure sensitive adhesive, Tape (25 mm wide), Brush, Magnifier Glass, X 2

magnification, Instructions, Hard plastic carry case

Cross Hatch Cutter Range

Product Ref Blade Spacing Blades Coating Thickness ISO ASTM Notes

SH750/1 1 mm 6 0-60 m Yes Up to 50 m For Hard Substrates

SH750/2 1 mm 11 0-60 m Yes Up to 50 m Makes 100 squares for %

evaluation

SH750/3 1.5 mm 6 0-60 m For Hard & soft substrates

SH750/4 2 mm 6 61-120 m 50-125 m For soft / hard substrates

SH750/5 3 mm 6 121-250 m Yes For Hard & Soft substrates

Ordering information

Product Ref Description

SH750/1 Cross Hatch Cutter 1 mm x 6 teeth

SH750/2 Cross Hatch Cutter 1 mm x 11 teeth

SH750/3 Cross Hatch Cutter 1.5 mm x 6 teeth

SH750/4 Cross Hatch Cutter 2 mm x 6 teeth

SH750/5 Cross Hatch Cutter 3 mm x 6 teeth

SH750/CK Kit for Ref SH750 Brush, Magnifier, Tape & Carry Case

SH750/SP Cross hatch cutter (any model) supplied with accessory kit

Consumables

SH750/501/P Reel Pressure Sensitive Adhesive Tape (25mm wide)

SH751/1 Replacement Cutter Head 1 mm x 6 teeth

SH751/2 Replacement Cutter Head 1 mm x 11 teeth

SH751/3 Replacement Cutter Head 1.5 mm x 6 teeth

SH751/4 Replacement Cutter Head 2 mm x 6 teeth

SH751/5 Replacement Cutter Head 3 mm x 6 teeth

Owing to continuous development, we reserve the right to introduce improvements and modify specifications without prior notice.

Our sales team can be contacted on:

info@sheeninstruments.com or +44 (0)208 783 4321

Sheen Instruments Limited T: +44 (0)208 783 4321

29 Central Avenue, West Molesey, Surrey. KT8 2RF, UK info@sheeninstruments.com

www.sheeninstruments.com

A subsidiary of Elektron Technology UK Limited

Você também pode gostar

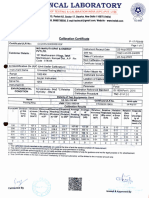

- Force Calibration Results of Force Tranducers According ISO 376Documento64 páginasForce Calibration Results of Force Tranducers According ISO 376Hi Tech Calibration ServicesAinda não há avaliações

- Thermocouple Cable CatalogueDocumento12 páginasThermocouple Cable CatalogueIrfan AshrafAinda não há avaliações

- NABL 122-05 W.E.F. 01.01.16-Specific Criteria For Calibration Laboratories in Mechanical Discipline - Density and Viscosity Measurement PDFDocumento36 páginasNABL 122-05 W.E.F. 01.01.16-Specific Criteria For Calibration Laboratories in Mechanical Discipline - Density and Viscosity Measurement PDFzilangamba_s4535Ainda não há avaliações

- 107-Cross Hatch Cutter PDFDocumento3 páginas107-Cross Hatch Cutter PDFMohamed NouzerAinda não há avaliações

- Fluke - Counter - CalDocumento2 páginasFluke - Counter - CalpolancomarquezAinda não há avaliações

- Power Quality Analysis Calibration CertificateDocumento3 páginasPower Quality Analysis Calibration Certificateradha krishnaAinda não há avaliações

- Sanas TR 79-03Documento9 páginasSanas TR 79-03Hi Tech Calibration ServicesAinda não há avaliações

- Nabl News Letter 40Documento40 páginasNabl News Letter 40Bala MuruAinda não há avaliações

- Broman 210 Contact Resistance TesterDocumento1 páginaBroman 210 Contact Resistance TesterjorgemichelaAinda não há avaliações

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Documento1 página(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8Ainda não há avaliações

- A New Ultrasonic Flow Metering Technique Using Two Sing-Around Paths, Along With The Criticism of The Disadvantages Inherent in Conventional Ultrasonic Flow Metering Transducers PDFDocumento10 páginasA New Ultrasonic Flow Metering Technique Using Two Sing-Around Paths, Along With The Criticism of The Disadvantages Inherent in Conventional Ultrasonic Flow Metering Transducers PDFvitor_pedroAinda não há avaliações

- MSL Technical Guide 2 Infrared Thermometry Ice Point: Introduction and ScopeDocumento2 páginasMSL Technical Guide 2 Infrared Thermometry Ice Point: Introduction and ScopeEgemet SatisAinda não há avaliações

- ..Percentage Oxygen Analyzer Calibration ProcedureDocumento5 páginas..Percentage Oxygen Analyzer Calibration ProcedureVignesh KanagarajAinda não há avaliações

- Leeb Hardness Tester H5 Calibration PDFDocumento1 páginaLeeb Hardness Tester H5 Calibration PDFশেখ আতিফ আসলামAinda não há avaliações

- Pressure Transmitter Calibration Procedure - InstrumentationToolsDocumento10 páginasPressure Transmitter Calibration Procedure - InstrumentationToolsKyi ZawAinda não há avaliações

- Tensile Testing Basics Tips TrendsDocumento5 páginasTensile Testing Basics Tips TrendsJonathan Elias MoralesAinda não há avaliações

- Theoretical Uncertainty of Orifice Flow Measurement TechWpaperDocumento8 páginasTheoretical Uncertainty of Orifice Flow Measurement TechWpaperFikri AchdanAinda não há avaliações

- Use and Calibration of SpectrophotometerDocumento11 páginasUse and Calibration of SpectrophotometerTinashe W MangwandaAinda não há avaliações

- Lab1 Straightness Composite Lab 2 PDFDocumento9 páginasLab1 Straightness Composite Lab 2 PDFawad91Ainda não há avaliações

- Microphone and Sound Level Meter Calibration in FR PDFDocumento7 páginasMicrophone and Sound Level Meter Calibration in FR PDFumair2kplus492Ainda não há avaliações

- Hydrometer Calibration by Hydrostatic Weighing With Automated Liquid Surface PositioningDocumento15 páginasHydrometer Calibration by Hydrostatic Weighing With Automated Liquid Surface PositioningSebastián MorgadoAinda não há avaliações

- Gas CalibrationDocumento6 páginasGas CalibrationSatiah WahabAinda não há avaliações

- Magnetic Field IndicatorsDocumento2 páginasMagnetic Field IndicatorsdantegimenezAinda não há avaliações

- Gas Detection CalibrationDocumento5 páginasGas Detection Calibrationكاظم محمدAinda não há avaliações

- Laboratory Quality Manual: Haren Textiles Pvt. LTDDocumento44 páginasLaboratory Quality Manual: Haren Textiles Pvt. LTDAjay KajaniyaAinda não há avaliações

- Making and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForDocumento8 páginasMaking and Curing Concrete Test Specimens in The Laboratory: Standard Practice ForAhmed AbidAinda não há avaliações

- Water Level Calibration EZDocumento3 páginasWater Level Calibration EZHarry Wart WartAinda não há avaliações

- Infrared Thermometer Calibration - A Complete Guide: Application NoteDocumento6 páginasInfrared Thermometer Calibration - A Complete Guide: Application NoteSomkiat K. DonAinda não há avaliações

- BS7882 2008 Uncertainty Paper 2Documento9 páginasBS7882 2008 Uncertainty Paper 2Student ForeignAinda não há avaliações

- Purpose of CalibrationDocumento2 páginasPurpose of Calibrationsakata_abera4Ainda não há avaliações

- Virginia Calibration MethodsDocumento81 páginasVirginia Calibration MethodsWillard ApengAinda não há avaliações

- Standard Practices For Force Calibration and Verification of Testing MachinesDocumento14 páginasStandard Practices For Force Calibration and Verification of Testing MachinesviverefeliceAinda não há avaliações

- Reference Standar of Calibration and Classification of Force Measuring SystemsDocumento9 páginasReference Standar of Calibration and Classification of Force Measuring SystemsRenaldo MoontriAinda não há avaliações

- 376 - 385 UtmDocumento10 páginas376 - 385 UtmwieirraAinda não há avaliações

- Jeep 112Documento7 páginasJeep 112Ishan LakhwaniAinda não há avaliações

- ULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurDocumento2 páginasULR: CC226721000004771F: Plot No.B-202, MIDC, Butibori, NagpurKiranAinda não há avaliações

- Bmts-Cp-003a CBR Mould BsDocumento2 páginasBmts-Cp-003a CBR Mould BsvirajAinda não há avaliações

- U 926 Muffle FurnaceDocumento11 páginasU 926 Muffle FurnaceAmit KumarAinda não há avaliações

- Metrology: ME3190 Machine Tools and MetrologyDocumento64 páginasMetrology: ME3190 Machine Tools and MetrologySujit MuleAinda não há avaliações

- How To Convert Thermocouple Milivolts To TemperatureDocumento9 páginasHow To Convert Thermocouple Milivolts To TemperaturesakthiAinda não há avaliações

- Brinell Hardness TestDocumento4 páginasBrinell Hardness Testrony_lesbtAinda não há avaliações

- 08 ParallelismMeasurement80Documento31 páginas08 ParallelismMeasurement80maddy_scribdAinda não há avaliações

- Procedure For Calibration and Installation of InstrumentsDocumento62 páginasProcedure For Calibration and Installation of InstrumentsAbdul SammadAinda não há avaliações

- IQ Procedure & Report ALP AutoclaveDocumento9 páginasIQ Procedure & Report ALP AutoclavePhong LeAinda não há avaliações

- Fake Breakout: - Fake Breakout Is A Trap To Hit SL For Buyers/sellers/bothDocumento8 páginasFake Breakout: - Fake Breakout Is A Trap To Hit SL For Buyers/sellers/bothAnonymous 3AwzgDlWxAinda não há avaliações

- Sila Samadhi Panna SD 21.6 Piya TanDocumento18 páginasSila Samadhi Panna SD 21.6 Piya TanPiya TanAinda não há avaliações

- 003 Torque Wrench16486-2017Documento22 páginas003 Torque Wrench16486-2017DiptiAinda não há avaliações

- SOP For UV-Vis SpectrophotometerDocumento7 páginasSOP For UV-Vis SpectrophotometerArchana PatraAinda não há avaliações

- Physics PracticalDocumento25 páginasPhysics PracticalVaibhav KumarAinda não há avaliações

- Charpy Impact TestingDocumento5 páginasCharpy Impact TestingArctic AlaskanAinda não há avaliações

- Angle Measurement 2Documento7 páginasAngle Measurement 2Jonathan Da Costa100% (1)

- Calibration of Light MeterDocumento2 páginasCalibration of Light MeterSatwant SinghAinda não há avaliações

- Astm E4 03 PDFDocumento9 páginasAstm E4 03 PDFHi Tech Calibration ServicesAinda não há avaliações

- 1-Cal-Procedure - BalanceDocumento12 páginas1-Cal-Procedure - BalanceHi Tech Calibration Services100% (1)

- FocalSpec Online Coil Edge Quality Measurement - 8 2012Documento24 páginasFocalSpec Online Coil Edge Quality Measurement - 8 2012Pradeep Beldar100% (1)

- Band Gang Saw Blades 2008 en PDFDocumento15 páginasBand Gang Saw Blades 2008 en PDFZokac TeoAinda não há avaliações

- E Translicer Cutter: Precision Slicing With Maximum VersatilityDocumento2 páginasE Translicer Cutter: Precision Slicing With Maximum VersatilityLorenzo YapAinda não há avaliações

- TQC Cross Cut Adhesion Test - Cc3000: Product DescriptionDocumento4 páginasTQC Cross Cut Adhesion Test - Cc3000: Product DescriptionGeorgianaAinda não há avaliações

- Micro BladesDocumento73 páginasMicro BladesAissaAinda não há avaliações

- Project Work 4Documento6 páginasProject Work 4Abdul hamid MohammedAinda não há avaliações

- BS en 13888-2009Documento18 páginasBS en 13888-2009abualamal100% (2)

- Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesDocumento10 páginasThin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesabualamalAinda não há avaliações

- Simplified Approach For Soil-Spring Stiffness Prediction of Pile GroupDocumento12 páginasSimplified Approach For Soil-Spring Stiffness Prediction of Pile Groupabualamal100% (1)

- Astm e 100Documento32 páginasAstm e 100abualamalAinda não há avaliações

- Shear Area Correction-Direct ShearDocumento1 páginaShear Area Correction-Direct ShearabualamalAinda não há avaliações

- Load Carrying Capacity of PilesDocumento75 páginasLoad Carrying Capacity of PilesabualamalAinda não há avaliações

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDocumento10 páginasThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalAinda não há avaliações

- BS en 00003-5-1996Documento18 páginasBS en 00003-5-1996abualamalAinda não há avaliações

- Test Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamDocumento25 páginasTest Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamabualamalAinda não há avaliações

- BS en Iso 17892-12Documento36 páginasBS en Iso 17892-12abualamal80% (5)

- BS en 14602-2012Documento16 páginasBS en 14602-2012abualamal100% (1)

- Aggregates FMDocumento5 páginasAggregates FMabualamalAinda não há avaliações

- Astm C900 06Documento10 páginasAstm C900 06abualamalAinda não há avaliações

- Cement Grout AAADocumento4 páginasCement Grout AAAabualamalAinda não há avaliações

- EE (QC) (3) /DDA/Circular/2004/ F Circular No 151 DTDocumento21 páginasEE (QC) (3) /DDA/Circular/2004/ F Circular No 151 DTabualamalAinda não há avaliações

- Estimation of The Coefficient of Permeability in Deep Sedimentary GroundDocumento5 páginasEstimation of The Coefficient of Permeability in Deep Sedimentary GroundabualamalAinda não há avaliações

- Asphalt Test Specific GravityDocumento2 páginasAsphalt Test Specific GravityabualamalAinda não há avaliações

- Bearing Capacity and Settlement Response of Raft Foundation PDFDocumento6 páginasBearing Capacity and Settlement Response of Raft Foundation PDFabualamalAinda não há avaliações

- Methods For Determining Soil Water Repellency On Field-Moist SamplesDocumento6 páginasMethods For Determining Soil Water Repellency On Field-Moist SamplesabualamalAinda não há avaliações

- FAQ7Documento3 páginasFAQ7abualamalAinda não há avaliações

- Foundation Design Simply Explained by Faber and Mead PDFDocumento60 páginasFoundation Design Simply Explained by Faber and Mead PDFabualamalAinda não há avaliações

- SE1000Documento2 páginasSE1000abualamal100% (1)

- Shell Morlina S2 B 220 - TDSDocumento4 páginasShell Morlina S2 B 220 - TDSFandemen AdintaAinda não há avaliações

- Removal of Impurities From ClayDocumento5 páginasRemoval of Impurities From ClayPuturrú De FuáAinda não há avaliações

- Strut System Catalog 2018Documento308 páginasStrut System Catalog 2018angelo jay malubayAinda não há avaliações

- Dokumen - Tips 220kv RRVPNL Cable SpecificationDocumento22 páginasDokumen - Tips 220kv RRVPNL Cable SpecificationSoltani AliAinda não há avaliações

- Engineering-Civil (0543)Documento48 páginasEngineering-Civil (0543)myusuf_engineerAinda não há avaliações

- AE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BDocumento3 páginasAE 6604 Aircraft Materials and Processes-Question Bank Unit I Part - BRahul100% (1)

- PumiceDocumento11 páginasPumiceMusa AtalaiAinda não há avaliações

- Head Office: 1/3-H-A-2, Street # 6, East Azad Nagar, Delhi-110051 (One KM From Welcome Metro Station)Documento6 páginasHead Office: 1/3-H-A-2, Street # 6, East Azad Nagar, Delhi-110051 (One KM From Welcome Metro Station)Vikash SharmaAinda não há avaliações

- Summary Cube Test As of 07052019 (Nehemiah Wall)Documento6 páginasSummary Cube Test As of 07052019 (Nehemiah Wall)Mohd Musa HashimAinda não há avaliações

- Effect of Different Veneering Techniques On The Fracture Strength of Metal and Zirconia FrameworksDocumento6 páginasEffect of Different Veneering Techniques On The Fracture Strength of Metal and Zirconia FrameworksAlicia Illa NAinda não há avaliações

- June 2014 Question Paper 62 PDFDocumento20 páginasJune 2014 Question Paper 62 PDFLast MadanhireAinda não há avaliações

- 66404Documento23 páginas66404amdevaAinda não há avaliações

- New Zealand Standart For ShootcreteDocumento11 páginasNew Zealand Standart For ShootcreteAbdul Wahid AlkindyAinda não há avaliações

- Astm D4060 10 PDFDocumento5 páginasAstm D4060 10 PDFHsiao Yoyo0% (1)

- African Child - Poem by Eku Mcgred2Documento10 páginasAfrican Child - Poem by Eku Mcgred2Jovert ManadongAinda não há avaliações

- Boiler Efficiency R K JainDocumento28 páginasBoiler Efficiency R K JainPriyesh KumarAinda não há avaliações

- Electrochemical DyeingDocumento19 páginasElectrochemical DyeingAmit Sharma100% (1)

- Sampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products For Compositional AnalysisDocumento8 páginasSampling Aluminum Ingots, Billets, Castings and Finished or Semi-Finished Wrought Aluminum Products For Compositional AnalysisHAMCHI MohammedAinda não há avaliações

- Product Information Flyer: CIMTECH® 285Documento2 páginasProduct Information Flyer: CIMTECH® 285sobheysaidAinda não há avaliações

- Hydrogenation: Processing Technologies: Walter E. Farr & Associates Olive Branch, MississippiDocumento12 páginasHydrogenation: Processing Technologies: Walter E. Farr & Associates Olive Branch, MississippiHamid Vahedi LarijaniAinda não há avaliações

- SUewBSEA CORROSION11Documento4 páginasSUewBSEA CORROSION11mayheartAinda não há avaliações

- What Is Reflow Tin Plating & What Are Its Benefits?Documento9 páginasWhat Is Reflow Tin Plating & What Are Its Benefits?cooperplatingcompanyAinda não há avaliações

- 20055-Two-Phase Compressibilility Factors For Retrogade GaseDocumento8 páginas20055-Two-Phase Compressibilility Factors For Retrogade GasedanonninoAinda não há avaliações

- 03main 06 06Documento52 páginas03main 06 06emregnesAinda não há avaliações

- COOL - 006 Advances in Liquid Coolant Technologies For Electronics Cooling 2005Documento7 páginasCOOL - 006 Advances in Liquid Coolant Technologies For Electronics Cooling 2005Leslie Diaz JalaffAinda não há avaliações

- Flexible Control Cables - YSLY: ApplicationsDocumento3 páginasFlexible Control Cables - YSLY: Applicationsloko221Ainda não há avaliações

- BQ - SewerageDocumento3 páginasBQ - SewerageZak HeroAinda não há avaliações

- ResourceDocumento2 páginasResourceSHAISTA AFREEN TEACHERAinda não há avaliações

- Heat Exchanger Checklist As Per TEMADocumento6 páginasHeat Exchanger Checklist As Per TEMAMONAAinda não há avaliações

- Burete EUR-I-PS-0045, RO-EN, V12 - Fisa Tehnica N2538Documento1 páginaBurete EUR-I-PS-0045, RO-EN, V12 - Fisa Tehnica N2538RizzoRo1Ainda não há avaliações