Escolar Documentos

Profissional Documentos

Cultura Documentos

FS Sagd PDF

Enviado por

ebastien20 notas0% acharam este documento útil (0 voto)

38 visualizações1 páginaTítulo original

FS_SAGD.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

38 visualizações1 páginaFS Sagd PDF

Enviado por

ebastien2Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

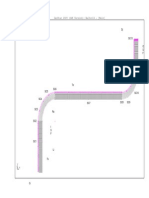

Talk about SAGD

Steam Assisted Gravity Drainage Process Facts about SAGD

In Alberta, 80 per cent (135 billion barrels) of the oil Projects using steam assisted gravity drainage

sands are buried too deep below the surface for open technology are becoming more common.

pit mining and can only be accessed through in-situ

methods such as Steam Assisted Gravity Drainage There are currently about 16 SAGD projects in Alberta

(SAGD). With the SAGD technique, a pair of compared to less than five before 2000.

horizontal wells, situated 4 to 6 metres above the

other, is drilled from a central well pad. In a plant The surface impact associated with SAGD operations

nearby, water is transformed into steam which then is similar to that of conventional oil and gas operations

travels through above-ground pipelines to the wells because the bitumen recovery process occurs

and enters the ground via a steam injection (top) well. underground in both SAGD and conventional oil -

The steam heats the heavy oil to a temperature at recovery method.

which it can flow by gravity into the producing (bottom)

well. The steam injection and oil production happen A well pad surface disturbance is less than 10 per cent

continuously and simultaneously. of the total resource area being accessed underground,

since one well pad can have multiple wells.

The resulting oil and condensed steam emulsion is

then piped from the producing well to the plant, where In 2012 , Albertas total in-situ bitumen production was

it is separated and treated. The water is recycled for about 990,000 barrels per day, a 16 per cent increase

generating new steam. from 2011. This accounts for 52 per cent of total crude

bitumen production of about 1.9 million barrels per day.

By 2022 in-situ production is forecast to reach 2.2

million barrels per day.

Up to 90 per cent of the water used during extraction is

recycled.

Steam oil ratio, an efficiency measure of steam assisted

gravity drainage operations, has been significantly

lowered and one project in Alberta is achieving a ratio

as low as two. This means using two barrels of water,

injected as steam, to produce one barrel of oil.

A lower ratio also means less use of natural gas. It can

take as little as one gigajoule per barrel to heat water

into steam, which results in lower greenhouse gas

emissions.

Emissions for SAGD project are around .06 tonnes of

carbon dioxide equivalent per barrel of bitumen. When

emissions from SAGD are compared with combined

emissions from mining and upgrading, the carbon

dioxide emissions per barrel are at par.

Notably, the emissions ratio of SAGD extraction and

non-upgraded mined bitumen extraction is around 3:2.

November 2013

Você também pode gostar

- Merc Service Manual 23 454 502 EnginesDocumento1.027 páginasMerc Service Manual 23 454 502 EnginesHayduke them91% (11)

- Coil DesignDocumento69 páginasCoil DesignSadique Shaikh100% (1)

- TT CatalogDocumento56 páginasTT Cataloglp1990Ainda não há avaliações

- Solar Turbines: Liquid Fuel Oil Treatment System System Operation and Maintenance ManualDocumento696 páginasSolar Turbines: Liquid Fuel Oil Treatment System System Operation and Maintenance Manualwilson chaconAinda não há avaliações

- Pipeline Risk AnalysisDocumento14 páginasPipeline Risk AnalysishanselozgumusAinda não há avaliações

- Parker Hydraulic Accumulator Products HY10-1630Documento203 páginasParker Hydraulic Accumulator Products HY10-1630Yusuf Sukma IndrianaAinda não há avaliações

- Tier4F Emission Treatment Technology CompleteDocumento46 páginasTier4F Emission Treatment Technology CompleteDragan100% (1)

- ТРАКЕР 380Documento1.124 páginasТРАКЕР 380Владимир100% (4)

- Multilateral Wells Outline 1-05Documento3 páginasMultilateral Wells Outline 1-05abdounouAinda não há avaliações

- Nitrogeoin Rejection Technology For Abu DhabiDocumento10 páginasNitrogeoin Rejection Technology For Abu DhabiBeshuoAinda não há avaliações

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDocumento12 páginas004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezAinda não há avaliações

- ER80S Ni1 PDFDocumento2 páginasER80S Ni1 PDFebastien2Ainda não há avaliações

- D210-375 MedAir PDFDocumento4 páginasD210-375 MedAir PDFjulianmataAinda não há avaliações

- TurbineMeter-RMG TRZ 03Documento6 páginasTurbineMeter-RMG TRZ 03Puri NugrahatiAinda não há avaliações

- Igcc Power Plants: (A New Technology To Answer Global Warming)Documento16 páginasIgcc Power Plants: (A New Technology To Answer Global Warming)venky123456789Ainda não há avaliações

- Carbon Intensity of Blue Hydrogen RevisedDocumento16 páginasCarbon Intensity of Blue Hydrogen RevisedaniketbondeAinda não há avaliações

- LNG WeldingDocumento12 páginasLNG Weldingrodofgod100% (1)

- Sun To Gas UAEDocumento11 páginasSun To Gas UAEAnonymous YOeo7EIVurAinda não há avaliações

- Chapter 1Documento111 páginasChapter 1Radhi Abdullah100% (1)

- Design and Analysis of Bagasse Dryer To Recover Energy of Water Tube Boiler in A Sugar FactoryDocumento8 páginasDesign and Analysis of Bagasse Dryer To Recover Energy of Water Tube Boiler in A Sugar FactorySolooloo Kebede NemomsaAinda não há avaliações

- Hydrogen For Power Gen Gea34805Documento18 páginasHydrogen For Power Gen Gea34805Siddhant DhallAinda não há avaliações

- Pearl GTLDocumento3 páginasPearl GTLLeonardo AmpueroAinda não há avaliações

- Sodium Bicarbonate Carbon CaptureDocumento15 páginasSodium Bicarbonate Carbon CaptureDimitriAinda não há avaliações

- FINAL Hydrogen - Decarbonising Heat Position Paper Single Pages Low ResDocumento28 páginasFINAL Hydrogen - Decarbonising Heat Position Paper Single Pages Low Resjbloggs2007Ainda não há avaliações

- Flare Gas Capture For LNG ProductionDocumento9 páginasFlare Gas Capture For LNG ProductionKommu RohithAinda não há avaliações

- Hidrogenio Verde-ENGDocumento14 páginasHidrogenio Verde-ENGwernecksantos2952Ainda não há avaliações

- Talk About SAGD: Steam Assisted Gravity Drainage Process Facts About SAGDDocumento1 páginaTalk About SAGD: Steam Assisted Gravity Drainage Process Facts About SAGDkuzapAinda não há avaliações

- Talk About SAGD: Steam Assisted Gravity Drainage Process Facts About SAGDDocumento1 páginaTalk About SAGD: Steam Assisted Gravity Drainage Process Facts About SAGDshan07011984Ainda não há avaliações

- A New Kinetic Model For Pyrolysis of Athabasca BitumenDocumento13 páginasA New Kinetic Model For Pyrolysis of Athabasca BitumenMejbahul SarkerAinda não há avaliações

- 04 Zero Net Presentation To Remy - 05-06-2021 - CopieDocumento32 páginas04 Zero Net Presentation To Remy - 05-06-2021 - CopieCHAHLI YounesAinda não há avaliações

- Energy Efficiency and Emissions Intensity of SAGDDocumento8 páginasEnergy Efficiency and Emissions Intensity of SAGDMejbahul SarkerAinda não há avaliações

- Hydrogen OverviewDocumento2 páginasHydrogen OverviewSiddhant DhallAinda não há avaliações

- Air Liquide 2022 Article On Off Gas Use in SMRDocumento5 páginasAir Liquide 2022 Article On Off Gas Use in SMRKokil JainAinda não há avaliações

- 2019 R32 HVRFDocumento8 páginas2019 R32 HVRFОсама А.ШоукиAinda não há avaliações

- DecarbonisationTechnology PTLDocumento6 páginasDecarbonisationTechnology PTLjmod7867Ainda não há avaliações

- Has The Time For Partial Upgrading of Heavy Oil and Bitumen Arrived?Documento8 páginasHas The Time For Partial Upgrading of Heavy Oil and Bitumen Arrived?a_893597811Ainda não há avaliações

- Coal Fired Boiler OptionDocumento1 páginaCoal Fired Boiler OptionMukund PhapaleAinda não há avaliações

- Biogas Enrichment & Bottling Technology For Vehicular UseDocumento4 páginasBiogas Enrichment & Bottling Technology For Vehicular Useउमेश पाण्डेयAinda não há avaliações

- EOR by SNFDocumento3 páginasEOR by SNFMohitAinda não há avaliações

- Charcoal Production With Reduced EmissionsDocumento4 páginasCharcoal Production With Reduced EmissionsskljoleAinda não há avaliações

- Bowman 1986Documento17 páginasBowman 1986siaAinda não há avaliações

- Maghraby Et Al-2022-Journal of Engineering and Applied ScienceDocumento11 páginasMaghraby Et Al-2022-Journal of Engineering and Applied ScienceRoberto BianchiAinda não há avaliações

- EnergyDocumento11 páginasEnergyIvan SetiawanAinda não há avaliações

- Feasibility of Gas Production of Offshore Gas Hydrate Deposits by Integration With GTL ProcessDocumento10 páginasFeasibility of Gas Production of Offshore Gas Hydrate Deposits by Integration With GTL ProcessDirceu NascimentoAinda não há avaliações

- CO2 Capturing Using LimeDocumento4 páginasCO2 Capturing Using LimeDaniel ThorneAinda não há avaliações

- Use of CO2 For Heavy EORDocumento9 páginasUse of CO2 For Heavy EORYan LaksanaAinda não há avaliações

- Hiller 2011Documento20 páginasHiller 2011satya.usct.900450Ainda não há avaliações

- Natural Gas Dehydration Process Simulation and Optimisation A Case Study of Jubilee FieldDocumento10 páginasNatural Gas Dehydration Process Simulation and Optimisation A Case Study of Jubilee FieldGreat AmpongAinda não há avaliações

- Mott PresentationDocumento9 páginasMott PresentationEMS GlobalAinda não há avaliações

- Refineria Del Futuro 3Documento1 páginaRefineria Del Futuro 3Jose Marval RodriguezAinda não há avaliações

- Meeting Future Demands For Hydrogen: D.L. TrimmDocumento5 páginasMeeting Future Demands For Hydrogen: D.L. TrimmMazen OthmanAinda não há avaliações

- NictDocumento10 páginasNictAKSHAT TIWARIAinda não há avaliações

- LL DesdeDocumento14 páginasLL DesdeJulio SanchezAinda não há avaliações

- Chapter 1 - Introduction To Reservoir Engineering: Exercise 1.2: Energy EquivalenceDocumento10 páginasChapter 1 - Introduction To Reservoir Engineering: Exercise 1.2: Energy EquivalenceChatchai ChaninAinda não há avaliações

- CCP in Roads TxDoTDocumento46 páginasCCP in Roads TxDoTJimmy ThomasAinda não há avaliações

- FilesDocumento22 páginasFilesMahmoud ChihebAinda não há avaliações

- CCUS Chap - 8 030521Documento26 páginasCCUS Chap - 8 030521Ali AltowilibAinda não há avaliações

- Fluid Movement in A SAGD ProcessDocumento13 páginasFluid Movement in A SAGD ProcessmandersonAinda não há avaliações

- Life After SAGD - 20 Years Later - UnlockedDocumento7 páginasLife After SAGD - 20 Years Later - UnlockedLuã MonteiroAinda não há avaliações

- Green Hydrogen Water Use 56b96f577dDocumento4 páginasGreen Hydrogen Water Use 56b96f577dAfsanehAinda não há avaliações

- Blue h2 Energy Conversion and MangementDocumento17 páginasBlue h2 Energy Conversion and MangementDiego MaportiAinda não há avaliações

- Emission-Free Production of Hydrogen in Refineries: - Improved Product Quality and Reduced GHG EmissionsDocumento26 páginasEmission-Free Production of Hydrogen in Refineries: - Improved Product Quality and Reduced GHG Emissionscvolkan1Ainda não há avaliações

- Ciclo Del Carbon ClaseDocumento25 páginasCiclo Del Carbon ClaseLION_FIREAinda não há avaliações

- Gasifying Coke To Produce Hydrogen in RefineriesDocumento5 páginasGasifying Coke To Produce Hydrogen in RefineriesAtharva OfficeAinda não há avaliações

- Potential For Hydrogen Generation From in Situ Combustion of Athabasca BitumenDocumento12 páginasPotential For Hydrogen Generation From in Situ Combustion of Athabasca BitumenMejbahul SarkerAinda não há avaliações

- CCS PaperDocumento36 páginasCCS PaperJackyAinda não há avaliações

- State-Of-The-Art Nitrogen Rejection TechnologyDocumento16 páginasState-Of-The-Art Nitrogen Rejection Technologynabeel khanAinda não há avaliações

- What's Next Opn CO2Documento7 páginasWhat's Next Opn CO2SekarNTutyAinda não há avaliações

- Anaerobic Wastewater TreatmentDocumento42 páginasAnaerobic Wastewater Treatmentmdb7gwq6hqAinda não há avaliações

- Art Hydrogen For Energy TransitionDocumento3 páginasArt Hydrogen For Energy Transitionr.szustak50Ainda não há avaliações

- New KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard StraitDocumento12 páginasNew KBR Process For Coal To Ammonia: Kamal Gursahani, Siva Ariyapadi, Meghji Shah and Richard Straitvaratharajan g rAinda não há avaliações

- Decarbonisation of Steam CrackersDocumento7 páginasDecarbonisation of Steam CrackersAtharva OfficeAinda não há avaliações

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Ainda não há avaliações

- Clean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementNo EverandClean Ironmaking and Steelmaking Processes: Efficient Technologies for Greenhouse Emissions AbatementAinda não há avaliações

- Interbond 1202UPC: Universal Pipe CoatingDocumento4 páginasInterbond 1202UPC: Universal Pipe Coatingebastien2Ainda não há avaliações

- Jotatemp 1000 Ceramic: Technical Data SheetDocumento5 páginasJotatemp 1000 Ceramic: Technical Data Sheetebastien2Ainda não há avaliações

- CH 4 QuizDocumento4 páginasCH 4 Quizebastien2Ainda não há avaliações

- Bta CT 0001Documento8 páginasBta CT 0001ebastien2Ainda não há avaliações

- Pointer Flutter / Dampening: Customer Information Bulletin 06 ... Dampening - WPD Revised 12-18-2012Documento1 páginaPointer Flutter / Dampening: Customer Information Bulletin 06 ... Dampening - WPD Revised 12-18-2012ebastien2Ainda não há avaliações

- Flexitallic SF 3300: 6915 HWY 225, Deer Park, TX 77536 USA TEL: 281.604.2400 FAX: 281.604.2415Documento2 páginasFlexitallic SF 3300: 6915 HWY 225, Deer Park, TX 77536 USA TEL: 281.604.2400 FAX: 281.604.2415ebastien2Ainda não há avaliações

- Bermuda Grass (Cynodon Dactylon) As A Pollen Resource For Honey Bee Colonies in The Lower Colorado River Agroecosystem1Documento7 páginasBermuda Grass (Cynodon Dactylon) As A Pollen Resource For Honey Bee Colonies in The Lower Colorado River Agroecosystem1ebastien2Ainda não há avaliações

- Sports3 CDadapco AM PDFDocumento20 páginasSports3 CDadapco AM PDFebastien2Ainda não há avaliações

- Expanded MetalDocumento2 páginasExpanded Metalebastien2Ainda não há avaliações

- Haven-Lockhart Marriage BondDocumento1 páginaHaven-Lockhart Marriage Bondebastien2Ainda não há avaliações

- Brochure Laserreinigen P-Laser 2016Documento4 páginasBrochure Laserreinigen P-Laser 2016ebastien2Ainda não há avaliações

- Chart Torques WGDocumento2 páginasChart Torques WGebastien2Ainda não há avaliações

- FEA Model: Stress ClassificationDocumento1 páginaFEA Model: Stress Classificationebastien2Ainda não há avaliações

- AC2000i Install HelpDocumento47 páginasAC2000i Install Helpebastien2Ainda não há avaliações

- Exam 1 Practice ChemistryDocumento56 páginasExam 1 Practice ChemistryJessicaAvetisAinda não há avaliações

- Green (Food Processing Industry)Documento4 páginasGreen (Food Processing Industry)BuLayugAinda não há avaliações

- Nissan CD17Documento3 páginasNissan CD17jose luis calixto requisAinda não há avaliações

- Dena Owner ManualDocumento162 páginasDena Owner ManualMilad AlEidAinda não há avaliações

- Modernization Recommendation Lube Oil Strainer HousingDocumento2 páginasModernization Recommendation Lube Oil Strainer Housingamir barekatiAinda não há avaliações

- ONGC Placement Paper Chemical EngineeringDocumento4 páginasONGC Placement Paper Chemical EngineeringPradeep Pratap ChaudharyAinda não há avaliações

- ANSI Tecnical ManualDocumento11 páginasANSI Tecnical ManualArmando BarrancoAinda não há avaliações

- Specifications Guide: Global Bunker FuelsDocumento35 páginasSpecifications Guide: Global Bunker Fuelsasad razaAinda não há avaliações

- DMM 2Documento2 páginasDMM 2api-279049687Ainda não há avaliações

- Energija Aktivacijepaper Icdl 2011 - 6roDocumento5 páginasEnergija Aktivacijepaper Icdl 2011 - 6rovzimak2355Ainda não há avaliações

- AAS and AFSDocumento4 páginasAAS and AFSbrad.hambly.89Ainda não há avaliações

- Testing and AdjustingDocumento32 páginasTesting and AdjustingVictor Nunez100% (2)

- HeatingDocumento74 páginasHeatingBertusvanHeerdenAinda não há avaliações

- Diesel Technology Part 2Documento4 páginasDiesel Technology Part 2api-289966050Ainda não há avaliações

- BP Ground Flare Control System PR OG1 0409ADocumento1 páginaBP Ground Flare Control System PR OG1 0409AJose BijoyAinda não há avaliações

- Ferrofluid For Alkaline FloodingDocumento0 páginaFerrofluid For Alkaline FloodingPondok HudaAinda não há avaliações