Escolar Documentos

Profissional Documentos

Cultura Documentos

CHG PDF

Enviado por

ronaldTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CHG PDF

Enviado por

ronaldDireitos autorais:

Formatos disponíveis

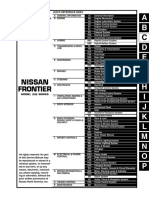

ELECTRICAL & POWER CONTROL

SECTION CHG

CHARGING SYSTEM

B

E

CONTENTS

PRECAUTION ............................................... 2 POWER GENERATION VOLTAGE VARI- F

ABLE CONTROL SYSTEM OPERATION IN-

PRECAUTIONS ................................................... 2 SPECTION ......................................................... 8

Precaution for Supplemental Restraint System Inspection Procedure ................................................ 8 G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................... 2 B TERMINAL CIRCUIT ..................................... 10

Precaution for Power Generation Variable Voltage Description ...............................................................10

H

Control System .......................................................... 2 Diagnosis Procedure ...............................................10

PREPARATION ............................................ 3 L TERMINAL CIRCUIT ..................................... 11

Description ...............................................................11 I

PREPARATION ................................................... 3 Diagnosis Procedure ...............................................11

Special Service Tool ................................................. 3

Commercial Service Tool .......................................... 3 S TERMINAL CIRCUIT ..................................... 12

Description ...............................................................12 J

BASIC INSPECTION .................................... 4 Diagnosis Procedure ...............................................12

DIAGNOSIS AND REPAIR WORKFLOW .......... 4 CHARGING SYSTEM ....................................... 13 K

Work Flow ................................................................. 4 Wiring Diagram ........................................................13

FUNCTION DIAGNOSIS ............................... 5 SYMPTOM DIAGNOSIS .............................. 19

L

CHARGING SYSTEM .......................................... 5 CHARGING SYSTEM ....................................... 19

System Diagram ........................................................ 5 Symptom Table .......................................................19

System Description ................................................... 5 CHG

Component Description ............................................ 5 ON-VEHICLE REPAIR ................................. 20

POWER GENERATION VOLTAGE VARI- GENERATOR .................................................... 20

ABLE CONTROL SYSTEM ................................. 6 Removal and Installation - QR25DE Models ...........20 N

System Diagram ........................................................ 6 Removal and Installation - VQ40DE Models ...........21

System Description ................................................... 6

Component Description ............................................. 6 SERVICE DATA AND SPECIFICATIONS O

(SDS) ............................................................ 23

COMPONENT DIAGNOSIS .......................... 7

SERVICE DATA AND SPECIFICATIONS

CHARGING SYSTEM PRELIMINARY IN- (SDS) ................................................................. 23 P

SPECTION ........................................................... 7 Generator ................................................................23

Inspection Procedure ................................................ 7

Revision: October 2009 CHG-1 2010 Frontier

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000005531987

The Supplemental Restraint System such as AIR BAG and SEAT BELT PRE-TENSIONER, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution for Power Generation Variable Voltage Control System INFOID:0000000005272432

CAUTION:

For this model, the battery current sensor that is installed to the negative battery cable measures the

charging/discharging current of the battery and performs various engine controls. If an electrical com-

ponent is connected directly to the negative battery terminal, the current flowing through that compo-

nent will not be measured by the battery current sensor. This condition may cause a malfunction of

the engine control system and battery discharge may occur. Do not connect an electrical component

or ground wire directly to the battery terminal.

Revision: October 2009 CHG-2 2010 Frontier

PREPARATION

< PREPARATION >

PREPARATION A

PREPARATION

Special Service Tool INFOID:0000000005272433

B

Tool number Description

(Kent-Moore No.) C

Tool name

Tests batteries, starting and charging sys-

() Model GR-8 tems. D

Multitasking Battery Diagnostic Sta- For operating instructions, refer to diagnostic

tion station instruction manual.

AWIIA1239ZZ

F

Commercial Service Tool INFOID:0000000005272434

Tool name Description

G

Power tool Loosening bolts, nuts and screws

PIIB1407E

CHG

Revision: October 2009 CHG-3 2010 Frontier

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION >

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow INFOID:0000000005272435

OVERALL SEQUENCE

AWMIA1142GB

Revision: October 2009 CHG-4 2010 Frontier

CHARGING SYSTEM

< FUNCTION DIAGNOSIS >

FUNCTION DIAGNOSIS A

CHARGING SYSTEM

System Diagram INFOID:0000000005272436

B

I

ALMIA0207GB

J

System Description INFOID:0000000005272437

The generator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator. K

Component Description INFOID:0000000005272438

L

Component part Description

Terminal 1 Refer to CHG-10, "Description".

CHG

Terminal 2 Refer to CHG-11, "Description".

Generator Terminal 3 Refer to CHG-12, "Description".

Used for the power generation voltage variable control system. N

Terminal 4

Refer to CHG-6, "System Description".

The IC regulator warning function activates to illuminate the

charge warning lamp if any of the following symptoms occur while

Combination meter (Charge warning lamp) generator is operating:

O

Excessive voltage is produced.

No voltage is produced.

Used for the power generation voltage variable control system. P

IPDM E/R

Refer to CHG-6, "System Description".

Revision: October 2009 CHG-5 2010 Frontier

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

< FUNCTION DIAGNOSIS >

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

System Diagram INFOID:0000000005272439

ALMIA0057GB

System Description INFOID:0000000005272440

Power generation variable voltage control system has been adopted. By varying the voltage to the generator,

engine load due to power generation of the generator is reduced and fuel consumption is decreased.

NOTE:

When any malfunction is detected in the power generation variable voltage control system, power generation

is performed according to the characteristic of the IC regulator in the generator.

Component Description INFOID:0000000005272441

Component part Description

The battery current sensor is installed on the battery cable at the

negative terminal. The battery current sensor detects the charg-

Battery current sensor

ing/discharging current of the battery and sends a voltage signal

to the ECM according to the current value detected.

The battery current sensor detects the charging/discharging cur-

rent of the battery. The ECM judges the battery condition based on

this signal.

The ECM judges whether to request more output via the power

generation voltage variable control according to the battery condi-

ECM

tion.

When performing the power generation voltage variable control,

the ECM calculates the target power generation voltage according

to the battery condition and sends the calculated value as the pow-

er generation command value to the IPDM E/R.

The IPDM E/R converts the received power generation command

IPDM E/R value into a pulse width modulated (PWM) command signal and

sends it to the IC regulator.

The IC regulator controls the power generation voltage by the tar-

get power generation voltage based on the received PWM com-

mand signal.

Generator (IC regulator)

When there is no PWM command signal, the generator performs

the normal power generation according to the characteristic of the

IC regulator.

Revision: October 2009 CHG-6 2010 Frontier

CHARGING SYSTEM PRELIMINARY INSPECTION

< COMPONENT DIAGNOSIS >

COMPONENT DIAGNOSIS A

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection Procedure INFOID:0000000005272442

B

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight. C

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair battery terminals connection. D

2.CHECK FUSE

Check for blown fuse and fusible link. E

Unit Power source (Power supply terminals) Fuse or Fusible Link

Battery (terminal 3) Fuse 30

Generator F

Battery (terminal 1) Fusible Link A

Combination meter Ignition switch ON (terminal 2) Fuse 14

Is the inspection result normal? G

YES >> GO TO 3

NO >> Be sure to eliminate cause of malfunction before installing new fuse or fusible link.

H

3.CHECK GENERATOR GROUND TERMINAL CONNECTION

Verify connector E209 terminal 5 (generator ground harness) is clean and tight.

Is the inspection result normal? I

YES >> GO TO 4

NO >> Repair connection.

4.CHECK DRIVE BELT TENSION J

Check drive belt tension. Refer to EM-14, "Checking Drive Belts" (QR25DE) or EM-127, "Checking Drive

Belts" (VQ40DE).

K

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair as needed.

L

CHG

Revision: October 2009 CHG-7 2010 Frontier

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

< COMPONENT DIAGNOSIS >

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPER-

ATION INSPECTION

Inspection Procedure INFOID:0000000005272443

Regarding Wiring Diagram information, refer to CHG-13, "Wiring Diagram".

CAUTION:

When performing this inspection, always use a charged battery that has completed the battery inspec-

tion. (When the charging rate of the battery is low, the response speed of the voltage change will

become slow. This can cause an incorrect inspection.)

1.CHECK ECM (CONSULT-III)

Perform ECM self-diagnosis with CONSULT-III. Refer to EC-69, "CONSULT-III Function (ENGINE)"

(QR25DE) or EC-528, "CONSULT-III Function (ENGINE)" (VQ40DE).

Self-diagnostic results content

No malfunction detected>> GO TO 2

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2.CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT-III and start the engine.

2. The selector lever is in P or N position and all of the electric loads and A/C, etc. are turned OFF.

3. Select ALTERNATOR DUTY in Active Test of ENGINE, and then check the value of BATTERY

VOLT monitor when DUTY value of ALTERNATOR DUTY is set to 40.0 %.

BATTERY VOLT

2 seconds after setting the : 12 - 13.6 V

DUTY value of ALTERNA-

TOR DUTY to 40.0 %

4. Check the value of BATTERY VOLT monitor when DUTY value of ALTERNATOR DUTY is set to

80.0%.

BATTERY VOLT

20 seconds after setting : +0.5 V or more against

the DUTY value of ALTER- the value of BATTERY

NATOR DUTY to 80.0 % VOLT monitor when

DUTY value is 40.0 %

Is the measurement value within specification?

YES >> Inspection End.

NO >> GO TO 3

3.CHECK IPDM E/R (CONSULT-III)

Perform IPDM E/R self-diagnosis with CONSULT-III. Refer to PCS-15, "CONSULT - III Function (IPDM E/R)".

Self-diagnostic results content

No malfunction detected>> GO TO 4

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

4.CHECK HARNESS BETWEEN GENERATOR AND IPDM E/R

Revision: October 2009 CHG-8 2010 Frontier

POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM OPERATION

INSPECTION

< COMPONENT DIAGNOSIS >

1. Turn ignition switch OFF.

2. Disconnect generator connector E205 and IPDM E/R connector A

E122.

3. Check continuity between generator harness connector E205

(A) terminal 4 and IPDM E/R harness connector E122 (B) termi-

B

nal 37.

A B

Continuity C

Connector Terminal Connector Terminal

E205 4 E122 37 Yes ALMIA0196ZZ

4. Check continuity between generator harness connector E122 D

(A) terminal 4 and ground.

A E

Continuity

Connector Terminal

E205 4 Ground No

F

Are the continuity test results as specified?

YES >> Replace IPDM E/R. Refer to PCS-33, "Removal and Installation of IPDM E/R".

NO >> Repair harness or connector between IPDM E/R and generator. G

CHG

Revision: October 2009 CHG-9 2010 Frontier

B TERMINAL CIRCUIT

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

Description INFOID:0000000005272444

The terminal 1 (B) circuit supplies power to charge the battery and operate the vehicles electrical system.

Diagnosis Procedure INFOID:0000000005272445

Regarding Wiring Diagram information, refer to CHG-13, "Wiring Diagram".

1.CHECK TERMINAL 1 CONNECTION

1. Turn ignition switch OFF.

2. Verify terminal 1 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal 1 connection. Confirm repair by performing complete Starting/Charging system

test. Refer to diagnostic station instruction manual.

2.CHECK TERMINAL 1 CIRCUIT

Check voltage between generator connector E206 terminal 1 and

ground.

(+)

(-) Voltage

Connector Terminal

E206 1 Ground Battery voltage

Is voltage reading as specified?

YES >> GO TO 3.

NO >> Check harness for open between generator and fusible

ALMIA0197ZZ

link.

3.CHECK TERMINAL 1 CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator

connector E206 terminal 1.

(+)

(-) Voltage

Connector Terminal

E206 1 Battery positive terminal Less than 0.2V

Is the voltage reading as specified?

YES >> Terminal 1 circuit is normal. Refer to CHG-4, "Work

ALMIA0198ZZ

Flow".

NO >> Check harness between battery and generator for high resistance.

Revision: October 2009 CHG-10 2010 Frontier

L TERMINAL CIRCUIT

< COMPONENT DIAGNOSIS >

L TERMINAL CIRCUIT

A

Description INFOID:0000000005272446

The terminal 2 (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the B

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the charge warning lamp illuminates with the engine running, a

malfunction is indicated.

C

Diagnosis Procedure INFOID:0000000005272447

D

Regarding Wiring Diagram information, refer to CHG-13, "Wiring Diagram".

E

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector E205 terminal 2 is clean and tight.

Is the connection secure? F

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by performing complete Starting/Charging system test.

Refer to diagnostic station instruction manual. G

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector E205.

2. Apply ground to generator harness connector E205 terminal 2 H

with the ignition switch in the ON position.

Charge lamp should illuminate I

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-4, "Work Flow".

NO >> GO TO 3 J

ALMIA0200ZZ

K

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF. L

2. Disconnect the combination meter connector M24.

3. Check continuity between generator harness connector E205 (A

)terminal 2 and combination meter harness connector M24 (B)

terminal 2. CHG

Terminal Terminal

Continuity N

Connector Terminal Connector Terminal

E205 2 M24 2 Yes

4. Check continuity between generator harness connector E205 AWMIA0499ZZ O

(A) terminal 2 and ground.

Terminal P

Continuity

Connector Terminal

E205 2 Ground No

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to IP-11, "Removal and Installation".

NO >> Repair the harness or connector.

Revision: October 2009 CHG-11 2010 Frontier

S TERMINAL CIRCUIT

< COMPONENT DIAGNOSIS >

S TERMINAL CIRCUIT

Description INFOID:0000000005272448

The output voltage of the generator is controlled by the IC regulator at terminal 3 (S) detecting the input volt-

age. Terminal 3 circuit detects the battery voltage to adjust the generator output voltage with the IC regulator.

Diagnosis Procedure INFOID:0000000005272449

Regarding Wiring Diagram information, refer to CHG-13, "Wiring Diagram".

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if connector E205 terminal 3 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal connection. Confirm repair by performing complete Starting/Charging system test.

Refer to diagnostic station instruction manual.

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator harness connector E205 terminal

3 and ground.

3 - ground Battery voltage

Does battery voltage exist?

YES >> Refer to CHG-4, "Work Flow".

NO >> Check harness for open between generator and fuse.

ALMIA0201ZZ

Revision: October 2009 CHG-12 2010 Frontier

CHARGING SYSTEM

< COMPONENT DIAGNOSIS >

CHARGING SYSTEM

A

Wiring Diagram INFOID:0000000005272450

CHG

P

ABMWA0506GB

Revision: October 2009 CHG-13 2010 Frontier

CHARGING SYSTEM

< COMPONENT DIAGNOSIS >

ABMIA0298GB

Revision: October 2009 CHG-14 2010 Frontier

CHARGING SYSTEM

< COMPONENT DIAGNOSIS >

CHG

ABMIA1344GB

Revision: October 2009 CHG-15 2010 Frontier

CHARGING SYSTEM

< COMPONENT DIAGNOSIS >

ABMIA1345GB

Revision: October 2009 CHG-16 2010 Frontier

CHARGING SYSTEM

< COMPONENT DIAGNOSIS >

CHG

ABMIA1346GB

Revision: October 2009 CHG-17 2010 Frontier

CHARGING SYSTEM

< COMPONENT DIAGNOSIS >

ABMIA1347GB

Revision: October 2009 CHG-18 2010 Frontier

CHARGING SYSTEM

< SYMPTOM DIAGNOSIS >

SYMPTOM DIAGNOSIS A

CHARGING SYSTEM

Symptom Table INFOID:0000000005272451

B

Symptom Reference

C

Battery discharged

The charge warning lamp does not illuminate when the ignition

switch is set to ON.

D

The charge warning lamp does not turn OFF after the engine Refer to CHG-4, "Work Flow".

starts.

The charging warning lamp turns ON when increasing the engine E

speed.

CHG

Revision: October 2009 CHG-19 2010 Frontier

GENERATOR

< ON-VEHICLE REPAIR >

ON-VEHICLE REPAIR

GENERATOR

Removal and Installation - QR25DE Models INFOID:0000000005272452

AWMIA1172GB

1. Generator 2. Starter motor assembly 3. Terminal "1"

4. Generator lower stud

REMOVAL

1. Disconnect the negative battery terminal. Refer to PG-84, "Removal and Installation".

2. Remove engine under cover. Refer to EXT-13, "Removal and Installation".

3. Remove front RH fender protector. Refer to EXT-22, "Removal and Installation of Front Fender Protector".

4. Remove the drive belt. Refer to EM-14, "Removal and Installation".

5. Disconnect the generator harness connectors.

6. Remove generator mounting nut, using power tools.

7. Remove the generator upper bolt, using power tools.

8. Remove the generator.

INSTALLATION

Installation is in the reverse order of removal.

Be sure the generator spacer is in place on the lower stud.

Install the generator and check tension of drive belt. Refer to EM-14, "Checking Drive Belts".

Terminal "1" nut : 10.8 Nm (1.1 kg-m, 8 ft-lb)

CAUTION:

Be sure to tighten terminal "1" nut carefully.

For this model, the power generation voltage variable control system that controls the power generation volt-

age of the generator has been adopted. Therefore, the power generation voltage variable control system

operation inspection should be performed after replacing the generator, and then make sure that the system

operates normally. Refer to CHG-8, "Inspection Procedure".

Revision: October 2009 CHG-20 2010 Frontier

GENERATOR

< ON-VEHICLE REPAIR >

Removal and Installation - VQ40DE Models INFOID:0000000005272453

AWMIA1170GB

I

1. Generator 2. Engine block 3. Generator stay

REMOVAL J

1. Disconnect the negative battery terminal.Refer to PG-84, "Removal and Installation".

2. Partially drain engine coolant. Refer to CO-39, "Changing Engine Coolant".

3. Remove engine room cover. Refer to EM-138, "Removal and Installation". K

4. Remove air duct and resonator assembly. Refer to EM-139, "Exploded View".

5. Remove upper radiator hose.

6. Disconnect coolant reservoir hose from radiator. L

7. Remove the fan shroud. Refer to CO-43, "Exploded View".

8. Remove engine cooling fan (Motor driven type). Refer to CO-47, "Removal and Installation (Motor driven

type)". CHG

9. Remove the drive belt. Refer to EM-127, "Removal and Installation".

10. Remove generator stay, using power tools.

N

11. Remove the generator upper bolt, using power tools.

12. Disconnect the generator harness connectors.

13. Remove the generator. O

INSTALLATION

Installation is in the reverse order of removal.

Install the generator and check tension of drive belt. Refer to EM-127, "Adjustment". P

Terminal "1" nut : 10.8 Nm (1.1 kg-m, 8 ft-lb)

CAUTION:

Be sure to tighten terminal "1" nut carefully.

For this model, the power generation voltage variable control system that controls the power generation volt-

age of the generator has been adopted. Therefore, the power generation voltage variable control system

Revision: October 2009 CHG-21 2010 Frontier

GENERATOR

< ON-VEHICLE REPAIR >

operation inspection should be performed after replacing the generator, and then make sure that the system

operates normally. Refer to CHG-8, "Inspection Procedure".

Revision: October 2009 CHG-22 2010 Frontier

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS) A

SERVICE DATA AND SPECIFICATIONS (SDS)

Generator INFOID:0000000005272454

B

QR25DE VQ40DE

C

LR1110-724C TG15S147

Type*

Hitachi Valeo

Nominal rating 12V-110A 14V-130A D

Ground polarity Negative

Minimum revolution under no-load 1,100 rpm 1,200 rpm

E

More than 35A/1,300 rpm More than 52A/1,500 rpm

Hot output current (When 13.5 volts is ap- More than 70A/1,800 rpm More than 82A/1,800 rpm

plied) More than 91A/2,500 rpm More than 115A/2,500 rpm

More than 110A/5,000 rpm More than 130A/5,000 rpm F

Regulated output voltage 14.1 - 14.7V @ 20C (68F) 13.5 @ 5,000 rpm @ 20C (68F)

Adjustment range of power generation vari-

11.4 - 15.6V

able voltage control G

*: Always check with the Parts Department for the latest parts information

CHG

Revision: October 2009 CHG-23 2010 Frontier

Você também pode gostar

- ETP48300-C6D2 Embedded Power User Manual PDFDocumento94 páginasETP48300-C6D2 Embedded Power User Manual PDFjose benedito f. pereira100% (1)

- Festo Electro Pneumatic TextBook Advance Level PDFDocumento216 páginasFesto Electro Pneumatic TextBook Advance Level PDFHandriToarPangkerego100% (3)

- Manual AQMS-3000 PDFDocumento27 páginasManual AQMS-3000 PDFtresnatambaAinda não há avaliações

- ELECTRICAL & POWER CONTROL SYSTEMSDocumento23 páginasELECTRICAL & POWER CONTROL SYSTEMSDozer KamilAinda não há avaliações

- Charging System: SectionDocumento23 páginasCharging System: SectionederengAinda não há avaliações

- ELECTRICAL & POWER CONTROL SYSTEM OVERVIEWDocumento22 páginasELECTRICAL & POWER CONTROL SYSTEM OVERVIEWIvan A. VelasquezAinda não há avaliações

- ELECTRICAL & POWER CONTROL TIPSDocumento29 páginasELECTRICAL & POWER CONTROL TIPSgiancarlo sanchezAinda não há avaliações

- 2007 Nissan Frontier 18Documento42 páginas2007 Nissan Frontier 18Mardelis cisnerosAinda não há avaliações

- Charging System: SectionDocumento24 páginasCharging System: Sectionwilder0l0pezAinda não há avaliações

- Charging System: SectionDocumento34 páginasCharging System: SectionHakob AdamyanAinda não há avaliações

- Electrical & Charging System GuideDocumento29 páginasElectrical & Charging System Guidejoeldqcgh29Ainda não há avaliações

- Electrical & Power Control Charging System GuideDocumento24 páginasElectrical & Power Control Charging System GuideNapiAinda não há avaliações

- PCSDocumento96 páginasPCSluis CebergAinda não há avaliações

- Charging System: SectionDocumento25 páginasCharging System: SectionWilmer Elias Quiñonez HualpaAinda não há avaliações

- Charging System: SectionDocumento57 páginasCharging System: SectionLuis GarcíaAinda não há avaliações

- Charging System: SectionDocumento55 páginasCharging System: SectionLíder DieselAinda não há avaliações

- Charging System: SectionDocumento34 páginasCharging System: SectionJumadi AlkutsAinda não há avaliações

- Nissan CHGDocumento26 páginasNissan CHGjasleenAinda não há avaliações

- Charging System: SectionDocumento40 páginasCharging System: SectionhuusonbachkhoaAinda não há avaliações

- Nissan Sentra 2016Documento31 páginasNissan Sentra 2016wilder0l0pezAinda não há avaliações

- Starting & Charging System: SectionDocumento32 páginasStarting & Charging System: SectionLino Bello RezamanoAinda não há avaliações

- SC PDFDocumento32 páginasSC PDFLino Bello RezamanoAinda não há avaliações

- Charging System: SectionDocumento31 páginasCharging System: Sectionratatrampa25Ainda não há avaliações

- Charging System: SectionDocumento27 páginasCharging System: SectionCarlos Tito AmésquitaAinda não há avaliações

- Charging System: SectionDocumento35 páginasCharging System: Sectionpenk ypAinda não há avaliações

- Power Control System: SectionDocumento100 páginasPower Control System: SectiontecnicofigueroaAinda não há avaliações

- SC PDFDocumento36 páginasSC PDFRony CentenoAinda não há avaliações

- CHG PDFDocumento39 páginasCHG PDFMie GorengRacerAinda não há avaliações

- SC PDFDocumento38 páginasSC PDFROSILENE PASSOSAinda não há avaliações

- Charging SysDocumento31 páginasCharging SysLucasAinda não há avaliações

- Starting & Charging System: SectionDocumento36 páginasStarting & Charging System: SectionDiego496Ainda não há avaliações

- Charging System: SectionDocumento29 páginasCharging System: SectionDiego496Ainda não há avaliações

- CHG PDFDocumento30 páginasCHG PDFSebastián PeñaAinda não há avaliações

- 2014-Nissan-Pathfinder POWER CONTROL SYSTEMDocumento85 páginas2014-Nissan-Pathfinder POWER CONTROL SYSTEMgerardogmoralesAinda não há avaliações

- Nissan Titan Power Control SystemDocumento98 páginasNissan Titan Power Control SystemDaniel Aguirre100% (2)

- Charging System: SectionDocumento33 páginasCharging System: SectionDiego496Ainda não há avaliações

- Charging System: SectionDocumento33 páginasCharging System: SectionsKardoAinda não há avaliações

- Charging System: SectionDocumento30 páginasCharging System: SectionIvan A. VelasquezAinda não há avaliações

- Starting & Charging System: SectionDocumento36 páginasStarting & Charging System: Sectionmuki461100% (1)

- Charging System: SectionDocumento30 páginasCharging System: SectionZona Educación Especial ZacapaoaxtlaAinda não há avaliações

- PcsDocumento71 páginasPcsgsmsbyAinda não há avaliações

- Di PDFDocumento46 páginasDi PDFROSILENE PASSOSAinda não há avaliações

- Charging System: SectionDocumento29 páginasCharging System: SectionMax SamAinda não há avaliações

- Charging System: SectionDocumento30 páginasCharging System: SectioncesarAinda não há avaliações

- Power Control System: SectionDocumento80 páginasPower Control System: SectionAliAinda não há avaliações

- Starting & Charging System: SectionDocumento32 páginasStarting & Charging System: SectionSonia GarciaAinda não há avaliações

- Steering Control System: SectionDocumento22 páginasSteering Control System: SectionAgustin Borge GarciaAinda não há avaliações

- Charging System: SectionDocumento28 páginasCharging System: SectionLuis Alfonso Ortiz ESpinosaAinda não há avaliações

- Charging System: SectionDocumento35 páginasCharging System: SectionH. Yusmira (Kang Otto)Ainda não há avaliações

- Nissan-Versa 2015 EN US Manual de Taller Ecu Modulo Carroceria Relay-Of-Ventilador Radiador Etc A21c4b9aaa.Documento72 páginasNissan-Versa 2015 EN US Manual de Taller Ecu Modulo Carroceria Relay-Of-Ventilador Radiador Etc A21c4b9aaa.victor borjaAinda não há avaliações

- Driver Information System: SectionDocumento56 páginasDriver Information System: SectionminaryAinda não há avaliações

- CHG Altima L32Documento30 páginasCHG Altima L32Henry SilvaAinda não há avaliações

- Bateria MotorDeArranque Alternador Nissan VersaDocumento34 páginasBateria MotorDeArranque Alternador Nissan VersaHumberto Vega SanchezAinda não há avaliações

- Charging System: SectionDocumento28 páginasCharging System: SectionPetter VillarroelAinda não há avaliações

- Electrical & Power Control GuideDocumento48 páginasElectrical & Power Control GuideАндрей Надточий100% (2)

- Power Control System: SectionDocumento34 páginasPower Control System: Sectionenrique revecoAinda não há avaliações

- Starting & Charging System Troubleshooting GuideDocumento26 páginasStarting & Charging System Troubleshooting GuideJagdeep Sekhon100% (2)

- Power Control System: SectionDocumento74 páginasPower Control System: SectionErick Gonzalo ChincheAinda não há avaliações

- Power Supply, Ground & Circuit Elements: SectionDocumento74 páginasPower Supply, Ground & Circuit Elements: SectionederengAinda não há avaliações

- Optimize CAN system circuit check guideDocumento60 páginasOptimize CAN system circuit check guideRony CentenoAinda não há avaliações

- Electric Power Steering Diagnostics and Repair GuideDocumento32 páginasElectric Power Steering Diagnostics and Repair GuideIRAKLI DVALADZEAinda não há avaliações

- Nissan Note Power Control SystemDocumento106 páginasNissan Note Power Control SystemDaniel Aguirre100% (1)

- Adp PDFDocumento165 páginasAdp PDFronaldAinda não há avaliações

- Adjustable Pedal: SectionDocumento14 páginasAdjustable Pedal: SectionmohhizbarAinda não há avaliações

- TM PDFDocumento281 páginasTM PDFronaldAinda não há avaliações

- SRC PDFDocumento86 páginasSRC PDFronaldAinda não há avaliações

- TM PDFDocumento281 páginasTM PDFronaldAinda não há avaliações

- TM PDFDocumento281 páginasTM PDFronaldAinda não há avaliações

- ST PDFDocumento36 páginasST PDFronaldAinda não há avaliações

- Acc PDFDocumento7 páginasAcc PDFronaldAinda não há avaliações

- SRC PDFDocumento86 páginasSRC PDFronaldAinda não há avaliações

- STR PDFDocumento26 páginasSTR PDFronaldAinda não há avaliações

- STR PDFDocumento26 páginasSTR PDFronaldAinda não há avaliações

- ST PDFDocumento36 páginasST PDFronaldAinda não há avaliações

- ST PDFDocumento36 páginasST PDFronaldAinda não há avaliações

- SRC PDFDocumento86 páginasSRC PDFronaldAinda não há avaliações

- Ext PDFDocumento33 páginasExt PDFronaldAinda não há avaliações

- DLN PDFDocumento330 páginasDLN PDFronaldAinda não há avaliações

- Em PDFDocumento252 páginasEm PDFronaldAinda não há avaliações

- STR PDFDocumento26 páginasSTR PDFronaldAinda não há avaliações

- Exl PDFDocumento150 páginasExl PDFronaldAinda não há avaliações

- FWD PDFDocumento10 páginasFWD PDFronaldAinda não há avaliações

- Ex PDFDocumento7 páginasEx PDFronaldAinda não há avaliações

- Fsu PDFDocumento25 páginasFsu PDFronaldAinda não há avaliações

- Engine Cooling System: SectionDocumento57 páginasEngine Cooling System: SectionronaldAinda não há avaliações

- FL PDFDocumento15 páginasFL PDFronaldAinda não há avaliações

- Door & Lock: SectionDocumento142 páginasDoor & Lock: SectionronaldAinda não há avaliações

- CCS PDFDocumento2 páginasCCS PDFronaldAinda não há avaliações

- Fax PDFDocumento16 páginasFax PDFronaldAinda não há avaliações

- Def PDFDocumento41 páginasDef PDFronaldAinda não há avaliações

- CL PDFDocumento25 páginasCL PDFronaldAinda não há avaliações

- 30 Years Strong Caterpillar 3406 Governor KitDocumento5 páginas30 Years Strong Caterpillar 3406 Governor KitAhmedhassan KhanAinda não há avaliações

- Assembling The Arduino Diecimila Compatible Freeduino Board USBDocumento8 páginasAssembling The Arduino Diecimila Compatible Freeduino Board USBMC. Rene Solis R.Ainda não há avaliações

- 2015 Parts CatalogDocumento124 páginas2015 Parts CatalogAmerica Martinez RodriguezAinda não há avaliações

- Spares For Solar SiteDocumento2 páginasSpares For Solar SiteSumit TyagiAinda não há avaliações

- Manual Mother Board K7VM3 AsrockDocumento64 páginasManual Mother Board K7VM3 AsrockJesse Emmy Pherz MarthzAinda não há avaliações

- Service Manual: Central Monitoring SystemDocumento80 páginasService Manual: Central Monitoring SystemASr AsrAinda não há avaliações

- Samsung 940bw Chassis Lha19wsDocumento65 páginasSamsung 940bw Chassis Lha19wsgabi_xyz100% (2)

- JK Hemi Installation GuideDocumento37 páginasJK Hemi Installation GuideChristian Andres Neira ParraAinda não há avaliações

- Load Cell Burster Series 8416Documento2 páginasLoad Cell Burster Series 8416ALEJANDRO IPATZIAinda não há avaliações

- Field Verificator User Manual: EnglishDocumento12 páginasField Verificator User Manual: EnglishMarcoAinda não há avaliações

- Diagrama Eléctrico 420f2Documento34 páginasDiagrama Eléctrico 420f2Angel Heber Diestra SantiagoAinda não há avaliações

- TCB Installation Booklet HRCDocumento11 páginasTCB Installation Booklet HRCAlexandre FonsecaAinda não há avaliações

- Ir 3300 Code ListDocumento45 páginasIr 3300 Code ListPrabhaPowerAinda não há avaliações

- Install of Grounding ModulesDocumento10 páginasInstall of Grounding Modulesolegprikhodko2809Ainda não há avaliações

- FTTX BrochureDocumento32 páginasFTTX Brochurefahmi810091Ainda não há avaliações

- Project Documentation - UMRR Serial Relay Option Data Sheet: Project Number: SMS Project NumberDocumento12 páginasProject Documentation - UMRR Serial Relay Option Data Sheet: Project Number: SMS Project NumberCORAL ALONSOAinda não há avaliações

- Adam 3937 PDFDocumento1 páginaAdam 3937 PDFAnton DAinda não há avaliações

- Intrinsically Safe Windobserver Anemometer: User ManualDocumento39 páginasIntrinsically Safe Windobserver Anemometer: User ManualSung-jin ParkAinda não há avaliações

- ACP UmDocumento37 páginasACP UmfebriAinda não há avaliações

- Controller P22000 PDFDocumento157 páginasController P22000 PDFEdin Raul Yalle RafaelAinda não há avaliações

- PT Installation Yamaha YZF R15 V3.0 MinDocumento32 páginasPT Installation Yamaha YZF R15 V3.0 MinMuhamad RaihanAinda não há avaliações

- MC 10115469 9999Documento6 páginasMC 10115469 9999Carlos YuliAinda não há avaliações

- Boq 132 - 33kv GssDocumento14 páginasBoq 132 - 33kv GssMathur DineshAinda não há avaliações

- MARANTZ SR5009 Service ManualDocumento195 páginasMARANTZ SR5009 Service ManualToni TonevAinda não há avaliações

- Dantherm HAC Accessory Controller Service ManualDocumento24 páginasDantherm HAC Accessory Controller Service ManualJernej SevšekAinda não há avaliações

- Daraga National High SchoolDocumento4 páginasDaraga National High Schoolseph bronAinda não há avaliações

- Wrda7 PDFDocumento86 páginasWrda7 PDFOskar ReyntjensAinda não há avaliações