Escolar Documentos

Profissional Documentos

Cultura Documentos

Sizing of Steam Coil of Insulated Tank Rev 3 PDF

Enviado por

dhavalesh1Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sizing of Steam Coil of Insulated Tank Rev 3 PDF

Enviado por

dhavalesh1Direitos autorais:

Formatos disponíveis

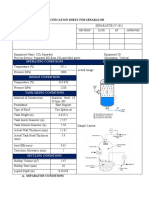

Title of Calculation: Sizing of heating coil for the insulated tank

VKS MSS 3

Client: State Company For Oil Projects (SCOP) VKS MSS 2

Ref doc.: GAD for Fuel Oil Storare Dome Roof Tank VKS MSS 1

Ref Doc no.: 184-TK-13-M-01 Rev A Prep'd by App'd by Rev

1 (1) INPUT DATA

2 Content of the tank Fuel Oil

3 Diameter of Tank m 34

4 Height of the Tank m 12

5 Max height of the liquid m 10.5

6 Thickness of shell

7 sec-1 tank bottom to 2m mm 22

8 sec-2 next 2m mm 19

9 sec-3 & 4 next 4 m mm 15

10 sec-5 next 2m mm 11

11 sec-6 next 2 m mm 7

12 Material of the tank Carbon steel

13 Insulation on walls and top 2" thick rockwool

14 SG of fuel oil 0.96

15 Ambient temp deg C 20

16 Final temp of liquid deg C 100

17 Steam pressure at coil inlet kg/cm2(g) 7

18 Heatng time allowable days 3.0

19 (2) ASSUMED DATA

20 Density of Tank material kg/m3 7850

21 Specific heat of Tank material kJ/kg-C 0.5

22 Specific heat of Fuel Oil in tank kJ/kg-C 1.88

23 (3) CALCULATIONS

24 (i) Heat require for liquid

25 Volume of Fuel oil m3 9533

26 Mass of Fuel Oil kg 9151836

27 Temperature rise deg C 80

28 Heating time sec 259200

29 Heat required kW 5310

30 (ii) Heat require for Tank material

31 Volume of tank material m3 19

32 Mass of tank material kg 149251

33 Temperature rise deg C 80

34 Heat required kW 23

35 (iii) Heat loss from tank sides+top

36 Mean liquid temperature deg C 60

37 Temperature diff deg C 40

38 Heat Transfer Coeff (insulated tank) W/m2-C 2.3

39 Total surface area for heat loss m2 2190

40 Heat loss kW 201

41 (iv) Total heat transfer required kW 5535

Sizing of steam coil of insulated tank Rev 3 1 of 2

Title of Calculation: Sizing of heating coil for the insulated tank

VKS MSS 3

Client: State Company For Oil Projects (SCOP) VKS MSS 2

Ref doc.: GAD for Fuel Oil Storare Dome Roof Tank VKS MSS 1

Ref Doc no.: 184-TK-13-M-01 Rev A Prep'd by App'd by Rev

42 (v) Heat transfer area required

43 Steam pressure at coil inlet kg/cm2(g) 7

44 Temp at the steam deg C 169

45 Specific volume of steam m3/kg 0.243904

46 Mean liquid temperature deg C 60

47 Temp difference deg C 109

48 Heat Transfer Coeff for steam coil W/m2-C 100

49 Heat transfer area required m2 508

50 Inclusive of 10 % margin m2 559 559 559

51 Nominal dia of coil pipe inches 2 3 4

52 Sch of pipe mm 80 80 80 3

53 ID of pipe mm 49.2 73.7 97.2

54 Surface area per unit length m2/m 0.189 0.279 0.358

55 Length m 2955 2002 1560

56 (vi) Steam requirment, coil capacity, no. of coils

57 Specific enthalpy of evaporation kJ/kg 2049.8

58 Steam flowrate required kg/hr 9721 9721 9721

59 Max velocity in coil m/s 30 30 30

60 CSA of coil m2 0.0019012 0.004266 0.00742

61 Volumetric flow m3/hr 205 461 801

62 Specific volume of steam m3/kg 0.243904 0.243904 0.243904

63 Max steam possible kg/hr 842 1889 3286

64 No. of different coils required n 11.55 5.15 2.96 3

65

66 (4) CONCLUSION

67 1. Size of the coil - options ND 2" 3" 4"

68 2. No. of coils 12 5 3

69 3. No. of inlets for steam 12 5 3

70 4. No. of outlets for condensed steam 12 5 3

71 5. Length of each coil 246 400 520

72 6. Total length of coils 2952 2000 1560 3

73

74 (5) REMARKS

75 (i) The coil should slope towards outlet i.e. condensate side.

76 (ii) Coil should not be welded with support to allow expansion during start up.

77 (iii) Provide steam trap between control valve and tank inlet.

78

Sizing of steam coil of insulated tank Rev 3 2 of 2

Você também pode gostar

- Waste (Used) Oil Burners, Heaters and BoilersDocumento6 páginasWaste (Used) Oil Burners, Heaters and BoilersMohd Tanveer AshrafAinda não há avaliações

- Drydocking SpecificationsDocumento53 páginasDrydocking SpecificationsAung Paing OoAinda não há avaliações

- Coil HeatDocumento4 páginasCoil HeatTarmana Antt50% (2)

- Heat Transfer in Jacketed VesselDocumento2 páginasHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Tank Emisiion CalcDocumento16 páginasTank Emisiion CalcAdhe GedeAinda não há avaliações

- LNG Man Es Methane Slip Technical PaperDocumento20 páginasLNG Man Es Methane Slip Technical PaperLeo TvrdeAinda não há avaliações

- Cement Kiln Pyro BalanceDocumento40 páginasCement Kiln Pyro BalanceGanapathy SubramaniamAinda não há avaliações

- NT42 Calculation Heat Transfer of Storage Tank Rail TankDocumento2 páginasNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHAinda não há avaliações

- EIND 3184 15 Liquid Flash Vessel SizingDocumento20 páginasEIND 3184 15 Liquid Flash Vessel SizingzamijakaAinda não há avaliações

- Chimney Draft CalculationsDocumento4 páginasChimney Draft CalculationsTushar KhannaAinda não há avaliações

- Heat Exchanger DesignDocumento48 páginasHeat Exchanger DesignJose SotoAinda não há avaliações

- Batch Time Calculation For Isothermal Cooling in Internal Coil Vessel With AgitationDocumento2 páginasBatch Time Calculation For Isothermal Cooling in Internal Coil Vessel With Agitationdhavalesh1100% (1)

- Pump Sizing Calculation (2ggg)Documento28 páginasPump Sizing Calculation (2ggg)dhavalesh1Ainda não há avaliações

- Calculation of Scrubber DiameterDocumento44 páginasCalculation of Scrubber DiameterRamakrishna SomuAinda não há avaliações

- Heat Transfer Design Methods by John MC Ketta PDFDocumento607 páginasHeat Transfer Design Methods by John MC Ketta PDFAlberto LazzarettiAinda não há avaliações

- Double Pipe Heat Exchanger Design: Chemical Engineering SpreadsheetsDocumento2 páginasDouble Pipe Heat Exchanger Design: Chemical Engineering Spreadsheetsrudy_423522658Ainda não há avaliações

- Catalogo Frankin FuelDocumento362 páginasCatalogo Frankin FuelChristian Alberto Soto MullerAinda não há avaliações

- Radiation and Convection Heat TransferDocumento5 páginasRadiation and Convection Heat TransfergsdaundhAinda não há avaliações

- Advanced Distillation Technologies: Design, Control and ApplicationsNo EverandAdvanced Distillation Technologies: Design, Control and ApplicationsAinda não há avaliações

- Experienced Based Rules of Chemical EngineeringDocumento33 páginasExperienced Based Rules of Chemical Engineeringintania66Ainda não há avaliações

- Limpet Coil On Dish Design As Per PD5500Documento1 páginaLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNEAinda não há avaliações

- Ics Guidance On Eu MRVDocumento13 páginasIcs Guidance On Eu MRVMartin NiAinda não há avaliações

- Steam Coil DesignDocumento2 páginasSteam Coil DesignHendri SinagaAinda não há avaliações

- Tank Venting Requirements (API 2000) 2Documento3 páginasTank Venting Requirements (API 2000) 2RubensBoerngenAinda não há avaliações

- 4 Study of Small Scale LNG CarrierDocumento25 páginas4 Study of Small Scale LNG CarrierSangeethRoshan100% (1)

- TDS For Basket StrainerDocumento2 páginasTDS For Basket StrainerRAGHVENDRA PRATAP SINGHAinda não há avaliações

- Boiling Up Rate For Batch DistillationDocumento4 páginasBoiling Up Rate For Batch DistillationKanhaiyalal PatilAinda não há avaliações

- Calculations On An Adiabatic Continuous DryerDocumento11 páginasCalculations On An Adiabatic Continuous DryerCaleb Somai0% (1)

- Half Pipe CalculationDocumento3 páginasHalf Pipe CalculationCaptainTonies0% (1)

- HM 50 Guidelines For Tankcleaning - Products 5th EditionDocumento33 páginasHM 50 Guidelines For Tankcleaning - Products 5th Editionnivasmarine100% (5)

- Calculation Sheet For Pump Hydraulic (Fps Unit)Documento1 páginaCalculation Sheet For Pump Hydraulic (Fps Unit)chemical todiAinda não há avaliações

- Ael-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilDocumento2 páginasAel-2597-Mec-Cl-0305-R0 - Design Calculation of Heating CoilbecpavanAinda não há avaliações

- Jet Mixing CalculationDocumento3 páginasJet Mixing CalculationRachel FloresAinda não há avaliações

- Condenser DesignDocumento2 páginasCondenser DesignRahul ParmarAinda não há avaliações

- 2012 Erp Practice Exam 1Documento44 páginas2012 Erp Practice Exam 1shashinmishra4222Ainda não há avaliações

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocumento30 páginasJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Boiler Efficiency Calculation Tabel Data MethodDocumento2 páginasBoiler Efficiency Calculation Tabel Data MethodSomplak KudaAinda não há avaliações

- Vessel Volume Calculation1Documento2 páginasVessel Volume Calculation1eino6622Ainda não há avaliações

- Jacketed Vessel DesignDocumento5 páginasJacketed Vessel Designfunkkkky100% (1)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocumento7 páginasDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateneelAinda não há avaliações

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsDocumento9 páginasReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- 2X70 Power Plant Technical SpecificationDocumento53 páginas2X70 Power Plant Technical SpecificationChanna BasavaAinda não há avaliações

- FCM Parameter ListDocumento28 páginasFCM Parameter ListAdnanAinda não há avaliações

- Heat DutyDocumento7 páginasHeat Dutyingegnere1234Ainda não há avaliações

- Film Temp Calculation For Thermic Fluid ApplicationDocumento2 páginasFilm Temp Calculation For Thermic Fluid ApplicationmayurjannuAinda não há avaliações

- Vacuum Design DataDocumento354 páginasVacuum Design Datajlcheefei925850% (2)

- Specification Sheet For Separator: Operating Conditions SketchDocumento12 páginasSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- TEMA Shell & Bundle Entrance and Exit AreasDocumento3 páginasTEMA Shell & Bundle Entrance and Exit Areasnagtummala100% (3)

- Shell Co. Vs Vano (1954)Documento5 páginasShell Co. Vs Vano (1954)Benedick LedesmaAinda não há avaliações

- Design Calculation For Coil in The HFO Tank - TK14 & TK 15Documento4 páginasDesign Calculation For Coil in The HFO Tank - TK14 & TK 15chintanAinda não há avaliações

- D9.03XLS Storage Tank Heating Design - GGGGGDocumento3 páginasD9.03XLS Storage Tank Heating Design - GGGGGBarmar Sbahi0% (1)

- Shell Tube Heat Exchanger CalculationDocumento20 páginasShell Tube Heat Exchanger CalculationĐoàn TrangAinda não há avaliações

- Asme Tubesheet (Heater 10m2)Documento23 páginasAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Heatcalc: A Natural Gas Heat of Combustion CalculatorDocumento7 páginasHeatcalc: A Natural Gas Heat of Combustion CalculatorMuzzamilAinda não há avaliações

- Design 2 ReboilerDocumento5 páginasDesign 2 ReboilerAbdulrazzaqAL-MalikyAinda não há avaliações

- Rigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00Documento14 páginasRigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00semarasik_651536604100% (1)

- Superheated Steam Condensate TankDocumento4 páginasSuperheated Steam Condensate TankGanesh BhardwajAinda não há avaliações

- Sizing of Steam Coil of Insulated Tank Rev 3Documento2 páginasSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Heat Balance GCLDocumento6 páginasHeat Balance GCLIrshad HussainAinda não há avaliações

- Crude Oil Storage Tank Heating CoilDocumento3 páginasCrude Oil Storage Tank Heating CoilbadelitamariusAinda não há avaliações

- TankHeatingCoil&BoilerCapacityRequirement Rev 2Documento1 páginaTankHeatingCoil&BoilerCapacityRequirement Rev 2sooner123456Ainda não há avaliações

- Batch Heating by SteamDocumento16 páginasBatch Heating by Steamtpchowo100% (1)

- Storage-Tank Heat TransferDocumento57 páginasStorage-Tank Heat Transfervitcon87100% (12)

- Final Energy Balance-Vizag DT 9-6-18Documento6 páginasFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYAinda não há avaliações

- Specification SheetDocumento3 páginasSpecification SheetKuknesvary PuniamurthyAinda não há avaliações

- Tank Normal Venting (API)Documento1 páginaTank Normal Venting (API)ام يمنى ايمنAinda não há avaliações

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86No EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 1.86Ainda não há avaliações

- Bricks and Thermal Concrete RFQDocumento3 páginasBricks and Thermal Concrete RFQSantoAinda não há avaliações

- Design. Ref - Decuments: API 650, 11TH - ED M09Documento9 páginasDesign. Ref - Decuments: API 650, 11TH - ED M09hgagAinda não há avaliações

- Questionaire Requested PIPEDocumento7 páginasQuestionaire Requested PIPERhizhailAinda não há avaliações

- Hospital Network List - 2018Documento84 páginasHospital Network List - 2018dhavalesh1Ainda não há avaliações

- Artigo 1fwM9K 2014Documento10 páginasArtigo 1fwM9K 2014Robert DanielsAinda não há avaliações

- Sr. No Tag No. MOC Capacity UOM Quantity Equipment Type Type of Agitator Additional Agitator RequirementDocumento2 páginasSr. No Tag No. MOC Capacity UOM Quantity Equipment Type Type of Agitator Additional Agitator Requirementdhavalesh1Ainda não há avaliações

- WWW - Goair.In: Go Airlines (India) LTDDocumento2 páginasWWW - Goair.In: Go Airlines (India) LTDdhavalesh1Ainda não há avaliações

- Design of Pressure Vessel 1Documento88 páginasDesign of Pressure Vessel 1dhavalesh1Ainda não há avaliações

- Column of Industrial Solvent Recovery Distillation ColumnDocumento7 páginasColumn of Industrial Solvent Recovery Distillation Columndhavalesh1Ainda não há avaliações

- Sheet2 Sheet3 Sheet4: IndexDocumento4 páginasSheet2 Sheet3 Sheet4: Indexdhavalesh1Ainda não há avaliações

- Line Sizing Single Phase FluidDocumento2 páginasLine Sizing Single Phase Fluidahmed nawazAinda não há avaliações

- Book 2Documento13 páginasBook 2dhavalesh1Ainda não há avaliações

- Op034094j Si 001Documento18 páginasOp034094j Si 001dhavalesh1Ainda não há avaliações

- Tayser AlsogyDocumento6 páginasTayser AlsogyNahzri AhmedAinda não há avaliações

- Column of Industrial Solvent Recovery Distillation ColumnDocumento7 páginasColumn of Industrial Solvent Recovery Distillation Columndhavalesh1Ainda não há avaliações

- ETP Data SummaryDocumento27 páginasETP Data Summarydhavalesh1Ainda não há avaliações

- Hikal Purchase Requisition SSta 031117dDocumento15 páginasHikal Purchase Requisition SSta 031117ddhavalesh1Ainda não há avaliações

- Book 2Documento1 páginaBook 2dhavalesh1Ainda não há avaliações

- RCC Tanks at 2ft Height From GroundDocumento6 páginasRCC Tanks at 2ft Height From Grounddhavalesh1Ainda não há avaliações

- Bookddddd 2Documento4 páginasBookddddd 2dhavalesh1Ainda não há avaliações

- EjectorDocumento7 páginasEjectordhavalesh1Ainda não há avaliações

- Basic Data SheetDocumento15 páginasBasic Data Sheeterkamlakar2234Ainda não há avaliações

- Tube WeightDocumento10 páginasTube WeightImran KhanAinda não há avaliações

- Liquid Nitrogen Heat LossfDocumento1 páginaLiquid Nitrogen Heat Lossfdhavalesh1Ainda não há avaliações

- Hikal Purchase Requisition Sta 031117dDocumento17 páginasHikal Purchase Requisition Sta 031117ddhavalesh1Ainda não há avaliações

- RCC Tanks On The GroundDocumento6 páginasRCC Tanks On The Grounddhavalesh1Ainda não há avaliações

- Vspa 50Documento5 páginasVspa 50winarnobAinda não há avaliações

- Sensitive ChemicalsDocumento3 páginasSensitive Chemicalsdhavalesh1Ainda não há avaliações

- BottlenecksDocumento10 páginasBottlenecksdhavalesh1Ainda não há avaliações

- Safety Rupture Discs - Parr Instrument CompanyDocumento2 páginasSafety Rupture Discs - Parr Instrument Companydhavalesh1Ainda não há avaliações

- SOP - Quenching Pyrophoric MaterialsDocumento5 páginasSOP - Quenching Pyrophoric Materialsdhavalesh1Ainda não há avaliações

- Fuel Oil WikipediaDocumento7 páginasFuel Oil WikipediacantgetausernameAinda não há avaliações

- Cc2 CombustionDocumento22 páginasCc2 CombustionRenniel DingcongAinda não há avaliações

- General Service (GS) Control ValvesDocumento8 páginasGeneral Service (GS) Control ValvesGỗ MộcAinda não há avaliações

- Petroleum Refining Engineering: Dr. TVN. Padmesh Week 2Documento57 páginasPetroleum Refining Engineering: Dr. TVN. Padmesh Week 2Saswiny RitchieAinda não há avaliações

- Obrien CatalogueDocumento80 páginasObrien CatalogueRazvan GabyAinda não há avaliações

- SBV3 Pulsation Damper Brochure - UK - HY10-4065Documento6 páginasSBV3 Pulsation Damper Brochure - UK - HY10-4065santhoshkrishnaAinda não há avaliações

- Fuels: Principles of Classification of FuelsDocumento9 páginasFuels: Principles of Classification of FuelsPatrick Joshua GregorioAinda não há avaliações

- LNG Vessels and Their Bunkering - North America: Sean BondDocumento18 páginasLNG Vessels and Their Bunkering - North America: Sean BondMaximAinda não há avaliações

- Water and Sediment in Fuel OilsDocumento7 páginasWater and Sediment in Fuel OilsJoshua MeraAinda não há avaliações

- StandardsDocumento9 páginasStandardsmutawal1100% (1)

- Brave Royal Ship Management (BD) Limited: Bunkering PlanDocumento6 páginasBrave Royal Ship Management (BD) Limited: Bunkering PlanTowfiqAinda não há avaliações

- Good Bunkering PracticeDocumento6 páginasGood Bunkering PracticeParthiban NagarajanAinda não há avaliações

- Pennsylvania Crematorium RegulationsDocumento10 páginasPennsylvania Crematorium RegulationsBarbara MillerAinda não há avaliações

- Vizag Steel Plant ReportDocumento54 páginasVizag Steel Plant ReportAshok Chowdary Polavarapu100% (4)

- Study This Diagram of The Oil Distillation Process. Circle T (True) or F (False) in The DescriptionDocumento3 páginasStudy This Diagram of The Oil Distillation Process. Circle T (True) or F (False) in The DescriptionMahes WaranAinda não há avaliações

- Contoh Soal B.inggrisDocumento9 páginasContoh Soal B.inggrisPande RismadanaAinda não há avaliações

- 2016 - Chuyên Trần PhúDocumento20 páginas2016 - Chuyên Trần PhúRoland VietnamAinda não há avaliações

- Bunker IngDocumento6 páginasBunker IngJackielou LagmanAinda não há avaliações

- 2014 Fuel Regulation ATP 4-43-2Documento112 páginas2014 Fuel Regulation ATP 4-43-2Paul Barnard100% (1)

- European Marketscan: European Products ($/MT) ICE FuturesDocumento9 páginasEuropean Marketscan: European Products ($/MT) ICE FuturesWallace YankotyAinda não há avaliações