Escolar Documentos

Profissional Documentos

Cultura Documentos

Section 2. Metallic Sandwich Secondary Structure Repairs

Enviado por

robinyDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Section 2. Metallic Sandwich Secondary Structure Repairs

Enviado por

robinyDireitos autorais:

Formatos disponíveis

9/8/98 AC 43.

13-1B

CHAPTER 3. FIBERGLASS AND PLASTICS

SECTION 2. METALLIC SANDWICH SECONDARY STRUCTURE REPAIRS

3-10. REPAIRS TO METALLIC SAND- d. After locating the extent of the total

WICH SECONDARY STRUCTURE. Mag- damaged area by tapping or other nondestruc-

nesium, titanium, or stainless steel facings re- tive test methods, remove the damaged facing

quire special procedures that are not included and that portion of the core material that is also

in the following methods of repair. Aluminum affected. The depth to which the core must be

alloys such as 7075-T6, 2024-T3, and 2014-T6 removed will depend upon the type of core

are commonly used for the repair of facings for material and the method of repair. The re-

sandwich structural parts having aluminum placement core material must be the same

facings. For maximum corrosion resistance, material and core cell size as the original. Fab-

use only clad aluminum for repairs to clad ricate core material to shape, keeping the same

aluminum alloy facings. core ribbon or grain direction. When a sub-

stitution is permissible, wood or glass-fabric

a. Dents, scratches, or fractures, not ex- honey-comb cores are sometimes used in the

ceeding 1/4 inch in largest dimension in alu- repair of aluminum honeycomb cores, as they

minum facings, may be repaired with a suit- are generally easier to shape. Typical types of

able filler such as viscous epoxy resin. Dents core replacements are shown in figure 3-10.

that are delaminated shall not be filled but re- Resin fills can be used to replace the core and

paired. Thoroughly clean the repair area with facing where smaller core damage exists.

fine sandpaper and acetone before applying the Phenolic microballoons, low-density insulating

filler. After the resin has partially cured, re- materials, and/or other ingredients are added to

move any excess resin with a sharp plastic lower the density and give greater flexibility.

scraper. When the resin has completely cured,

sand to the original contour. If the damage in- e. For the repair of larger holes in which

cluded a fracture, reclean the area around the it is inconvenient to use a face patch because

filled hole and apply a surface patch. of aerodynamic smoothness requirements in

that area, both the core and facing are some-

b. Fractures or punctures in one facing times replaced with glass-fiber fabric discs and

and partial damage to the core of an alumi- resin. Undercut the core, as shown in fig-

num-faced laminate may be repaired by several ure 3-11, in order to obtain a better bonding of

different methods. The technique used will the fill with the facing. Fill the core cavity

depend upon the size of the damage, the with accurately shaped resin-saturated glass

strength required, and the aerodynamic loads cloth discs, and press each ply down to remove

of the area involved. If the repair requires any air bubbles. Special care should be taken

aerodynamic smoothness, the facing sur- that the final plies fit well against the under-

rounding the repair core cavity may have to be side of the top facing. When the core cavity is

step cut to one-half its thickness. This can be filled, close the cutout in the facing with resin-

done by using a router with an end mill bit and impregnated glass fiber fabric discs that have

a template. been precut to size.

c. Damage that extends completely f. Overlap repairs, typically called scab

through the core and both facings may be re- patches, have a long history of use in repairing

paired using the same general techniques as aircraft structures. These repairs simply cover

those used for repairing fiberglass laminates the damaged area with patch material. Overlap

when both facings are accessible. repairs can be bonded and/or mechanically

Par 3-10 Page 3-9

AC 43.13-1B 9/8/98

CHAPTER 3. FIBERGLASS AND PLASTICS

SECTION 2. METALLIC SANDWICH SECONDARY STRUCTURE REPAIRS

fastened. Figure 3-12 shows a cross-section of

a typical bonded and mechanically fastened re-

pair. The damaged area may or may not need

to be filled.

(1) Bonded overlap repairs work well

on most structures. The overlap repair consists

of a solid patch material such as metal, pre-

cured laminates, prepreg or wet layup material

co-cured in place.

(2) Bolt or blind rivet. Mechanically

fastened, bolted, or blind rivet repairs are pri-

marily used for thick structures. Primary con-

cerns include bolt/rivet spacing, fastener di-

ameter, number of fasteners, and sealant type.

g. Core potting is the process of filling

the core cutout with a curable paste filler mate-

rial. If the damage is sustained in an area with

an already-potted core, the replacement core

should also be potted. In other cases, if the

honeycomb or foam core is damaged, it may

be potted rather than plugged if the damaged

area is small (1 inch or less). Remove the face

sheet with a power router, using a router tem-

plate to prevent injury to undamaged face skin.

The router may be adjusted to remove one of

the face skins only, a face skin and part of the

core, a face skin and all of the core, or both the

face skins and the core. (See figure 3-13.)

FIGURE 3-10. Typical types of core replacement.

FIGURE 3-11. Typical undercut core material cavity.

Page 3-10 Par 3-10

9/8/98

CHAPTER 3. FIBERGLASS AND PLASTICS AC 43.13-1B

SECTION 2. METALLIC SANDWICH SECONDARY STRUCTURE REPAIRS

(1) It may be necessary when routing a

tapered section such as an aileron to use a

wedge-shaped block between the routing tem-

plate and the upper surface. This will allow

the router to cut the core material parallel with

the lower surface. (See figure 3-14.)

(2) Select the appropriate potting adhe- FIGURE 3-12. Cross section of bonded and bolted over-

lap repairs.

sive as recommended by the manufacturer.

Mix a sufficient quantity of filler to fill the

hole and add microballoons if they are needed

to serve as a filler. When the resin and filler

are thoroughly mixed according to the manu-

facturers recommendations, pour the mixture

into the hole filling all of the cells, then work

out all of the bubbles with a toothpick. If per-

forming an overlay repair fill the core cavity to

slightly above the parts surface. If performing

a flush repair, fill the core cavity to slightly

above the original core.

FIGURE 3-13. Honeycomb core removal.

(3) Cure the compound according to the

manufacturers directions. Trim the top of the

cured potting compound flush with the surface,

for the type of repair you are performing.

h. A core plug repair replaces damaged

core material with a shaped piece of similar

core material.

(1) Complete removal of core material

to the opposite face generally requires some

hand-cutting with a core knife. Figure 3-15

shows core material being removed with a core FIGURE 3.14 Removing honeycomb core from a

knife. The core can be peeled away from the tapered control surface.

skin bond using duckbill pliers. Sanding is

then required to remove irregular accumula-

tions of adhesive from the undamaged inner

face. Remove only enough adhesive to pro-

duce a smooth finish.

CAUTION: Care should be used

when peeling core material from thin-

skin sandwich face sheets, because the

skin can be damaged by pulling on the

core.

FIGURE 3-15. Removal of core with core knife.

Par 3-10 Page 3-11

AC 43.13-1B CHAPTER 3. FIBERGLASS AND PLASTICS 9/8/98

SECTION 2. METALLIC SANDWICH SECONDARY STRUCTURE REPAIRS

(2) A core plug should be fabricated as

follows. Select the core density. Cell size and

ribbon direction and thickness should be at

least the same as that used in the original con-

struction. Trim the sides of the plug to a loose

fit in the routed cavity. Trim the plug height so

the top of the plug sits .001 inch higher than

the level of the original surface. The core will

compress and set during cure thereby requiring

the extra height. Carefully remove the

trimmed core plug from the machined cavity.

Use a vacuum cleaning device to remove any

dust or particles remaining on the core plug or

in the repair area. Clean the core plug by

rinsing with an approved solvent and wrap the

plug in a clean polyethylene bag until needed

for assembly.

CAUTION: When handling film ad-

hesives, prepreg fabrics, or parts with

prepared surfaces, latex gloves must FIGURE 3-16. Details of core repair.

be worn.

may be cured to save time. Some restraining

(3) Using a film adhesive, the core plug method, such as vacuum bagging, may be de-

should be installed as follows. Select the ap- sirable over the core splice adhesive as this

propriate adhesive film. Cut one disk of adhe- material usually foams up and out during cure.

sive to the same shape and size as the perime- Cure the adhesive according to the manufac-

ter of the repair cutout if the repair extends turers directions and allow the area to cool.

through the entire core thickness. Cut two

disks if a partial depth core repair is being (5) Trim the top of the cured core plug

made. Cut one strip of core splice adhesive to flush with either the original core or the mold

wrap around the core perimeter to its full line, depending on the type of laminate repair

depth. For a partial depth core repair, also cut to be performed. Proceed with laminate repair.

out a fiberglass or aluminum disk, again

matching the size and the shape of the repair 3-11. FINISHING. The type of finish

cutout. Figure 3-16 shows the details of a par- coating applied to a metallic sandwich repair

tial depth core repair. Preassemble the pieces. will normally be determined by the exposed

material and the application of the part or as-

(4) Wipe the bottom and sides of the sembly. Rain erosion of plastic parts, the need

cutout area with solvent. Allow the area to for electrical or dielectric properties, and/or the

dry. Insert the core plug assembly with splice necessity for anti-corrosion coatings must be

adhesive applied to the perimeter into the core considered when the choice of finish is made.

cutout. Ensure the core plug ribbon direction Plastic-faced parts such as radomes are fin-

matches that of the parent core. In the case of ished primarily for rain erosion while alumi-

a partial depth core repair, the plug and disk num- or other metal-faced laminates are

Page 3-12 Par 3-10

9/8/98 AC 43.13-1B

CHAPTER 3. FIBERGLASS AND PLASTICS

SECTION 2. METALLIC SANDWICH SECONDARY STRUCTURE REPAIRS

finished for corrosion protection. For coatings

to perform their function properly, it is essen-

tial that they be applied to surfaces that are

clean, free of voids, and smooth. The edges of

all parts not protected by a bonding of alumi-

num or glass-fabric laminate must be sealed to

reduce the rate of moisture absorption.

3-17. [RESERVED.]

3-12.

Par 3-11 Page 3-13 (and 3-14)

Você também pode gostar

- Operating Instructions Welding Robot Manipulator PDFDocumento84 páginasOperating Instructions Welding Robot Manipulator PDFRodrigo Cariz75% (12)

- 850k Diagrama ElectricoDocumento1 página850k Diagrama Electricollesli17Ainda não há avaliações

- User Manual SteadyControlDocumento57 páginasUser Manual SteadyControlrobiny100% (2)

- Aircraft Composite RepairDocumento98 páginasAircraft Composite Repairbobbarleys100% (4)

- SAMI On RunwayDocumento12 páginasSAMI On RunwayMastani Bajirao100% (1)

- GRP Repair Manual PDFDocumento29 páginasGRP Repair Manual PDFArjed Ali Shaikh100% (1)

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento11 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robiny100% (1)

- Value Stream Map TrainingDocumento90 páginasValue Stream Map Trainingjcastellon14370100% (8)

- Damage Repair Techniques For Sandwich PanelsDocumento17 páginasDamage Repair Techniques For Sandwich PanelsOsama Aadil SaadiAinda não há avaliações

- Attachment Composite - Repair 001Documento14 páginasAttachment Composite - Repair 001zekAinda não há avaliações

- Damage Evaluation and Repair of Composite Structures: Gary Savage & Mark Oxley, Honda Racing F1 TeamDocumento11 páginasDamage Evaluation and Repair of Composite Structures: Gary Savage & Mark Oxley, Honda Racing F1 TeamregorAinda não há avaliações

- Fiberglass Repair Composite RepairDocumento5 páginasFiberglass Repair Composite RepairMichael Dunne (Bicycle Connect)Ainda não há avaliações

- EM 1110-2-2002 ch6Documento23 páginasEM 1110-2-2002 ch6shaik saifulla lAinda não há avaliações

- Repair: Re Pair in Single-Skin ConstructionDocumento15 páginasRepair: Re Pair in Single-Skin ConstructionMirceaAinda não há avaliações

- 1999Spr GeblerDocumento5 páginas1999Spr Geblerwagzarus14Ainda não há avaliações

- Bhubaneswar College of Engineering: Department of Aeronautical Engineering AE2357 Airframe Laboratory ManualDocumento14 páginasBhubaneswar College of Engineering: Department of Aeronautical Engineering AE2357 Airframe Laboratory ManualSambeetSekharPandaAinda não há avaliações

- Chapter 1. Wood Structure: F 1-4. Consideration of Grain Direction WhenDocumento19 páginasChapter 1. Wood Structure: F 1-4. Consideration of Grain Direction WhenrobinyAinda não há avaliações

- WTC Composites Day2Documento118 páginasWTC Composites Day2junjie yiAinda não há avaliações

- SP Use Maintenance - 2017 01 - enDocumento10 páginasSP Use Maintenance - 2017 01 - enEngr Ahmed FadulAinda não há avaliações

- Types of Shotcrete and Applications: A. Repair. Shotcrete Can Be Used To Repair TheDocumento5 páginasTypes of Shotcrete and Applications: A. Repair. Shotcrete Can Be Used To Repair Thepaul machariaAinda não há avaliações

- Unit-V Design of Moulds Molding PartsDocumento8 páginasUnit-V Design of Moulds Molding Partsyuvaraj4509Ainda não há avaliações

- March-2020 CDRDocumento4 páginasMarch-2020 CDRShivam SharmaAinda não há avaliações

- Case Studies in Structural Repair of Pretensioned Concrete ProductsDocumento6 páginasCase Studies in Structural Repair of Pretensioned Concrete Productsmekkawi6650Ainda não há avaliações

- MMS Seco - BearingsDocumento21 páginasMMS Seco - BearingsAnthony Lezcano MAinda não há avaliações

- Repairing The Surface of Concrete 01102010Documento6 páginasRepairing The Surface of Concrete 01102010dingwen1974Ainda não há avaliações

- Pages From Cocrete-978-3-89958-086-0.volltext - FreiDocumento18 páginasPages From Cocrete-978-3-89958-086-0.volltext - FreiGopi KrishnanAinda não há avaliações

- Class A Asphalt Shingles Surfaced With Mineral Granules: Standard Specification ForDocumento2 páginasClass A Asphalt Shingles Surfaced With Mineral Granules: Standard Specification ForMohammad YaseenAinda não há avaliações

- Design and Analysis of Filament Wound Composite Pressure Vessel With Integrated-End DomesDocumento9 páginasDesign and Analysis of Filament Wound Composite Pressure Vessel With Integrated-End DomesmrezaianAinda não há avaliações

- International Journal of Adhesion & Adhesives: H. Errouane, Z. Sereir, A. ChateauneufDocumento9 páginasInternational Journal of Adhesion & Adhesives: H. Errouane, Z. Sereir, A. ChateauneufMike PenceAinda não há avaliações

- Design Consideration For Metal Forming: 1.extrusionDocumento2 páginasDesign Consideration For Metal Forming: 1.extrusionyeswanthAinda não há avaliações

- Assignment 3Documento5 páginasAssignment 3Sumirthan ThamotharampillaiAinda não há avaliações

- 3p PP PPP 3p P P PP 3pp PPP P 3p PPPPPPP !P PPP !P PP 3ppppppppp 3p PPP !P PP P PP PP !P PP PPP PDocumento1 página3p PP PPP 3p P P PP 3pp PPP P 3p PPPPPPP !P PPP !P PP 3ppppppppp 3p PPP !P PP P PP PP !P PP PPP PRezve AhmedAinda não há avaliações

- Repair of Composites: By: Ariadne D. MirandaDocumento15 páginasRepair of Composites: By: Ariadne D. MirandaBea Llana100% (1)

- Joint DetailsDocumento2 páginasJoint Detailsmusibo911Ainda não há avaliações

- Impact Behavior of Sandwich Panels Made of Composite MaterialDocumento5 páginasImpact Behavior of Sandwich Panels Made of Composite MaterialInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- PW 06stakingDocumento4 páginasPW 06stakingMiguel ArriecheAinda não há avaliações

- Scarf Repair of Composite Laminates: 2016 ApopDocumento4 páginasScarf Repair of Composite Laminates: 2016 ApopAtef R. SawalmehAinda não há avaliações

- Ferrocement FinalDocumento9 páginasFerrocement Finalyash runwalAinda não há avaliações

- 4 Construction - Fabrication of FerrocementDocumento24 páginas4 Construction - Fabrication of FerrocementRafael CuaAinda não há avaliações

- Chippings For Surface Dressings Note03Documento2 páginasChippings For Surface Dressings Note03CarolAinda não há avaliações

- D 4601 Â " 98 RDQ2MDEDocumento2 páginasD 4601 Â " 98 RDQ2MDEMigue EnriquezAinda não há avaliações

- 10 1 1 536 9127 PDFDocumento17 páginas10 1 1 536 9127 PDFeng jamaAinda não há avaliações

- Composite Materials Note Form Nptel in PDFDocumento33 páginasComposite Materials Note Form Nptel in PDFM.Thirunavukkarasu100% (1)

- Ori-T003.0 - Ori-T003.0Documento2 páginasOri-T003.0 - Ori-T003.0mario salazarAinda não há avaliações

- Study of Composite Sandwich Structure and Bending Characteristics - A ReviewDocumento6 páginasStudy of Composite Sandwich Structure and Bending Characteristics - A ReviewAkhsanto AnanditoAinda não há avaliações

- BS 1881-Part 109-83Documento3 páginasBS 1881-Part 109-83AntonAinda não há avaliações

- Paint Application Guide No. 11: SSPC: The Society For Protective CoatingsDocumento6 páginasPaint Application Guide No. 11: SSPC: The Society For Protective CoatingsaRiTo!Ainda não há avaliações

- D 2626 - 97 - Rdi2mjy - PDFDocumento3 páginasD 2626 - 97 - Rdi2mjy - PDFdelta lab sangliAinda não há avaliações

- 123 - Concrete CoverDocumento2 páginas123 - Concrete CoverrealchicAinda não há avaliações

- SW Vs Kammprofile GsktsDocumento4 páginasSW Vs Kammprofile GsktsFilipAinda não há avaliações

- Section 5. Finishing Wood StructuresDocumento3 páginasSection 5. Finishing Wood StructuresrobinyAinda não há avaliações

- Self-Healing of Composite Structures in A Space Environment: R S Trask, I P Bond and C O A SemprimoschnigDocumento8 páginasSelf-Healing of Composite Structures in A Space Environment: R S Trask, I P Bond and C O A SemprimoschnigyorasAinda não há avaliações

- Development of Wear-Resistant BucketDocumento6 páginasDevelopment of Wear-Resistant BucketWiyono [BSI]Ainda não há avaliações

- Joining StructuresDocumento5 páginasJoining Structuresmilan44Ainda não há avaliações

- Prefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Documento3 páginasPrefabricated Asphalt Reservoir, Pond, Canal, and Ditch Liner (Exposed Type)Edmundo Jaita CuellarAinda não há avaliações

- Emaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion InhibitorDocumento4 páginasEmaco S88 Ci: Sprayable, Fiber-Reinforced Structural Repair Mortar With Integral Corrosion Inhibitormohamed ayadAinda não há avaliações

- Topic: 2.0 Aggregates: 2.4 Physical Properties of AggregateDocumento9 páginasTopic: 2.0 Aggregates: 2.4 Physical Properties of AggregatesitiAinda não há avaliações

- Branson - Part Design For Ultrasonic Welding PDFDocumento6 páginasBranson - Part Design For Ultrasonic Welding PDFOsama MohammedAinda não há avaliações

- Causes, Evaluation and Repair of Cracks in ConcreteDocumento9 páginasCauses, Evaluation and Repair of Cracks in ConcreteSachin RathaurAinda não há avaliações

- Adhesive Bonding TechnologyDocumento26 páginasAdhesive Bonding TechnologymichaelbaroneAinda não há avaliações

- 39Documento26 páginas39supriyo1970Ainda não há avaliações

- Concrete Construction Article PDF Form ReuseDocumento3 páginasConcrete Construction Article PDF Form ReuseiveyAinda não há avaliações

- Spencer Electroplating ServiceDocumento24 páginasSpencer Electroplating Servicespencer electroplatingAinda não há avaliações

- Self-healing Ceramic Matrix Composites: A MonographNo EverandSelf-healing Ceramic Matrix Composites: A MonographAinda não há avaliações

- Module 01-01 Mathematics: ArithmeticDocumento139 páginasModule 01-01 Mathematics: ArithmeticrobinyAinda não há avaliações

- PART-66 Syllabuses: Module 1. MathematicsDocumento2 páginasPART-66 Syllabuses: Module 1. MathematicsrobinyAinda não há avaliações

- M o D U L e 0 1 - 0 3 A Mathematics - Geometry: Simple Geometrical ConstructionsDocumento43 páginasM o D U L e 0 1 - 0 3 A Mathematics - Geometry: Simple Geometrical ConstructionsrobinyAinda não há avaliações

- M o D U L e 0 1 - 0 3 C Mathematics: Geometry TrigonometryDocumento36 páginasM o D U L e 0 1 - 0 3 C Mathematics: Geometry TrigonometryИлларион ПанасенкоAinda não há avaliações

- M1 Math - Algebra - Algebraic Expressions PDFDocumento67 páginasM1 Math - Algebra - Algebraic Expressions PDFAdrian LauAinda não há avaliações

- AG 01 03a B1 B2 B3 0602Documento84 páginasAG 01 03a B1 B2 B3 0602robinyAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento3 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyAinda não há avaliações

- 7290engine Oil and Breather SystemDocumento27 páginas7290engine Oil and Breather SystemrobinyAinda não há avaliações

- Ag 01 01 A 0602Documento69 páginasAg 01 01 A 0602robinyAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento27 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robiny100% (1)

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento20 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento84 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento13 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento10 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyAinda não há avaliações

- Addinex 1Documento5 páginasAddinex 1robinyAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento23 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyAinda não há avaliações

- 7230 CompressorDocumento57 páginas7230 Compressorrobiny100% (1)

- State Standard,: Specification, InstmctionDocumento2 páginasState Standard,: Specification, Instmctionrobiny100% (1)

- Appendix 4Documento5 páginasAppendix 4robinyAinda não há avaliações

- Appendix 5 Peculiarities of Engine Transportation, Storage, Unpacking and Packing in Metal Shipping Container Manufactured by Klimov JSCDocumento3 páginasAppendix 5 Peculiarities of Engine Transportation, Storage, Unpacking and Packing in Metal Shipping Container Manufactured by Klimov JSCrobinyAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento84 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento14 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyAinda não há avaliações

- AppendixDocumento19 páginasAppendixrobinyAinda não há avaliações

- TB3-117 Maintenance Manual: The Shelf Life of The Prepared Siloxane Enamel Is Five Days. 2. Antistick AgentDocumento2 páginasTB3-117 Maintenance Manual: The Shelf Life of The Prepared Siloxane Enamel Is Five Days. 2. Antistick AgentrobinyAinda não há avaliações

- Faa Ir M 8040 - 1C PDFDocumento77 páginasFaa Ir M 8040 - 1C PDFபிரேம் ஆனந்த்Ainda não há avaliações

- 01descrjption and OperationDocumento15 páginas01descrjption and OperationblackhawkAinda não há avaliações

- Srmgsa PDFDocumento121 páginasSrmgsa PDFrobinyAinda não há avaliações

- Steadycontrol® Rotor: New Technology For Rotor Track and Balance TuningDocumento13 páginasSteadycontrol® Rotor: New Technology For Rotor Track and Balance TuningrobinyAinda não há avaliações

- IIB Modules 10 11Documento4 páginasIIB Modules 10 11Joan GroizardAinda não há avaliações

- Genie Z60Documento2 páginasGenie Z60jishorAinda não há avaliações

- Synthesis: Partial OxidationDocumento5 páginasSynthesis: Partial OxidationTrangSkyAinda não há avaliações

- Load-Bearing Glass Structures PDFDocumento16 páginasLoad-Bearing Glass Structures PDFbatteekhAinda não há avaliações

- ME5286RoboticsToday - 1-RobotArms2017 PDFDocumento5 páginasME5286RoboticsToday - 1-RobotArms2017 PDFchrisAinda não há avaliações

- City Sanitation Plan, UttarakhandDocumento101 páginasCity Sanitation Plan, UttarakhandHarish Kumar Mahavar100% (1)

- Estimate For Renovations of Kitchen Burzahama GanderbalDocumento2 páginasEstimate For Renovations of Kitchen Burzahama GanderbalShahii ShahbazAinda não há avaliações

- Lecture Slide 1 - Why You Should Be Excited Learning Control EngineeringDocumento18 páginasLecture Slide 1 - Why You Should Be Excited Learning Control EngineeringReyasAinda não há avaliações

- Water Supply Pressure TestDocumento3 páginasWater Supply Pressure TestarlanAinda não há avaliações

- CFR 2012 Title33 Vol2 Part127 (33cfr Section 127)Documento26 páginasCFR 2012 Title33 Vol2 Part127 (33cfr Section 127)Jaime Grajeda GarciaAinda não há avaliações

- #4 Standard 3 Wheel SKD CKD FinalDocumento15 páginas#4 Standard 3 Wheel SKD CKD Finalnatan makuAinda não há avaliações

- Husqvarna 36 Operators Manual PDFDocumento22 páginasHusqvarna 36 Operators Manual PDFJoshua RoyAinda não há avaliações

- GPR MS enDocumento68 páginasGPR MS enJMAinda não há avaliações

- Abp Catalog Heater AirconditioningDocumento4 páginasAbp Catalog Heater AirconditioningFABIO MOACIR KORNDOERFERAinda não há avaliações

- Lesson 34, Jen GabrielDocumento13 páginasLesson 34, Jen Gabrielxxmark_jen12xxAinda não há avaliações

- (PDF) UAP Doc 401-402Documento17 páginas(PDF) UAP Doc 401-402stanflynnAinda não há avaliações

- DGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingDocumento3 páginasDGMS - Tech - Circular No 03. 2009 Qualitative and Quantitative Assessment of Fire FightingminingnovaAinda não há avaliações

- PM3 Ops Bra PR F 3001 - Rev - A1 - Procedure PDFDocumento82 páginasPM3 Ops Bra PR F 3001 - Rev - A1 - Procedure PDFMohd HisammudinAinda não há avaliações

- Operations and Maintenance Manual: Chapter 3: Safety PrecautionsDocumento10 páginasOperations and Maintenance Manual: Chapter 3: Safety Precautionsamit64007Ainda não há avaliações

- Kitchen Mood BoardDocumento9 páginasKitchen Mood BoardKelly CantaraAinda não há avaliações

- Body Movement Detection For ComaDocumento4 páginasBody Movement Detection For ComaJiiva GopiAinda não há avaliações

- MFC Hubli Final Bill Jan 2013Documento12 páginasMFC Hubli Final Bill Jan 2013Nagaraj PatilAinda não há avaliações

- Saes A 007 PDFDocumento29 páginasSaes A 007 PDFsindalisindiAinda não há avaliações

- Ministry of Public Works, Liberia: Flakiness Index - FiDocumento2 páginasMinistry of Public Works, Liberia: Flakiness Index - FikwameAinda não há avaliações

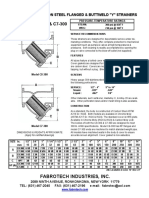

- MODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" StrainersDocumento1 páginaMODELS: C8-300 & C7-300: 300 Lb. Cast Carbon Steel Flanged & Buttweld "Y" Strainersanugrah_dimas5441Ainda não há avaliações

- SR Piping Designer/checkerDocumento4 páginasSR Piping Designer/checkerapi-78715367Ainda não há avaliações

- List of Dams and Reservoirs in India PDFDocumento5 páginasList of Dams and Reservoirs in India PDFAnonAinda não há avaliações