Escolar Documentos

Profissional Documentos

Cultura Documentos

Section 14. Handling and Care of Aircraft Recovered

Enviado por

blackhawkDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Section 14. Handling and Care of Aircraft Recovered

Enviado por

blackhawkDireitos autorais:

Formatos disponíveis

9/8/98 AC 43.

13-1B

CHAPTER 6. CORROSION, INSPECTION & PROTECTION

SECTION 14. HANDLING AND CARE OF AIRCRAFT RECOVERED

FROM WATER IMMERSION.

6-220. GENERAL. Aircraft recovered from b. If the above specified deter-

partial or total immersion in standing water or gent/alcohol materials are not available, use

flash floods require an in-depth inspection and water-emulsion cleaning compound

cleaning of both the exterior and interior areas. (MIL-C-43616). Add one part compound to

Water-immersion increases the probability of nine parts water. If the MIL cleaning com-

corrosive attack, it removes lubricants, deterio- pound is not available, use any available mild

rates aircraft materials, and destroys electrical household detergent solution with fresh tap

and avionics components. water.

a. Sea water, because of salt content, is 6-222. RECIPROCATING ENGINES

more corrosive than fresh water. However, AND PROPELLERS. Remove the propeller

fresh water may also contain varying amounts from the engine and the engine from the air-

of salt and, as drying occurs, the salt concen- craft. The exterior of the engine and propeller

tration is increased and corrosive attack accel- should be washed with steam, or fresh water,

erated. preferably hot.

b. Prompt action is the most important a. Major accessories, engine parts, etc.,

factor following recovery of an aircraft from should be removed and all surfaces flushed

water-immersion. Components of the aircraft with fresh water, preferably hot. If facilities

which have been immersed, such as the are available, immerse the removed parts, time

powerplant, accessories, airframe sections, permitting, in hot water or hot oil, 180 F, for a

actuating mechanisms, screws, bearings, short time. Soft water is preferred. Change

working surfaces, fuel and oil systems, wiring, the water frequently. All parts must be com-

radios, and radar should be disassembled, as pletely dried by air blast or other means. If no

necessary, and the contaminants completely heat-drying facility is available, wipe the

removed. cleaned parts with suitable drying cloths.

6-221. INITIAL FRESH WATER OR b. The constant-speed propeller mecha-

DETERGENT WASH. As soon as possible nism should be disassembled, as required, to

after the aircraft is recovered from water- permit complete decontamination. Clean parts

immersion, thoroughly wash all internal and with steam or fresh water, preferably hot. Dry

external areas of the aircraft using a wa- the cleaned parts in an oven, but if a heat-

ter/detergent solution as follows: drying facility is not available, wipe the

cleaned parts with suitable drying cloths.

a. Mix liquid detergent (MIL-D-16791,

type I) and isopropyl alcohol (TT-I-735) in ra- 6-223. AIRFRAME. The salvable compo-

tio of eight parts detergent, to 20 parts of alco- nents of the fuselage, wings, empennage, sea-

hol. Add the detergent/alcohol mixture to plane and amphibian hulls and floats, and

72 parts of tap water and mix thoroughly. For movable surfaces should be processed as fol-

use, add one part of the preceding concentrate lows:

to nine parts of tap water (warm water if avail-

able) and mix thoroughly.

Par 6-220 Page 6-43

AC 43.13-1B 9/8/98

CHAPTER 6. CORROSION, INSPECTION & PROTECTION

SECTION 14. HANDLING AND CARE OF AIRCRAFT RECOVERED

FROM WATER IMMERSION.

a. The fabric from fabric-covered sur- g. All drain plugs or drive screws in tu-

faces should be removed and replaced. bular structures should be removed and the

structure blown out with compressed air. If

b. Clean the aircraft interior and exterior water has reached the tubular interiors, care-

using steam under pressure with steam clean- fully flush with hot fresh water and blow out

ing compound. Direct the steam into all seams water with compressed air. Roll the structure

and crevices where corrosive water may have as necessary to remove water from pockets.

penetrated. Avoid steam cleaning electrical Fill the tubes with hot linseed oil, approxi-

equipment, such as terminal boards and re- mately 180 F, drain oil and replace drain

lays. plugs or drive screws.

c. Areas that have been steam cleaned h. Clean sealed wood, metallic, and other

should be rinsed immediately with either hot non-metallic areas, excluding acrylic plastics,

or cold fresh water. with warm water. Replace wood, metalite, and

other porous materials exposed to water-

d. Touch up all scratches and scars on immersion unless surfaces are adequately

painted surfaces using zinc chromate primer or sealed to prevent penetration by water. Virtu-

preservative. ally all solvents and phenolic type cleaning

agents are detrimental to acrylics and will ei-

e. Undrained hollow spaces or fluid en- ther soften the plastic or cause crazing.

trapment areas should be provided temporary

draining facilities by drilling out rivets at the i. Remove instruments and radios and ap-

lowest point. Install new rivets after drainage. plicable cables and plumbing, and repair and

inspect as necessary.

f. Remove and replace all leather, fabric

upholstery, and insulation. Plastic or rubber 6-234. [RESERVED.]

6-224.

foam that cannot be cleaned of all corrosive

water must be replaced.

Page 6-44 Par 6-223

Você também pode gostar

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingNo EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingNota: 5 de 5 estrelas5/5 (3)

- LRLayupGuideNov091.pdf 16 20Documento5 páginasLRLayupGuideNov091.pdf 16 20Cip GrecuAinda não há avaliações

- Sample Preventive Maintenance Schedule: Starting Engine(s)Documento2 páginasSample Preventive Maintenance Schedule: Starting Engine(s)Edmund YoongAinda não há avaliações

- Chapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Documento14 páginasChapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Juan F. MamaniAinda não há avaliações

- Chapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1Documento75 páginasChapter 9. Aircraft Systems and Components: 9/27/01 AC 43.13-1B CHG 1carmen solanoAinda não há avaliações

- Water Washing of Steam Turbine Rotors SOW PDFDocumento4 páginasWater Washing of Steam Turbine Rotors SOW PDFsarsan nedumkuzhiAinda não há avaliações

- Section 4. Corrosion Preventive MaintenanceDocumento2 páginasSection 4. Corrosion Preventive MaintenanceblackhawkAinda não há avaliações

- Storage Tanks Demolition and Making SafeDocumento6 páginasStorage Tanks Demolition and Making SafeEko KurniawanAinda não há avaliações

- AMT 2202 Final Learning Module 3Documento10 páginasAMT 2202 Final Learning Module 3Ian SolomonAinda não há avaliações

- Ice and Rain Protection - 4 - Rafie Adib Azizi - 3431901013Documento3 páginasIce and Rain Protection - 4 - Rafie Adib Azizi - 3431901013Rafi Adib AziziAinda não há avaliações

- Safety Talk On-Safety During ShutdownDocumento10 páginasSafety Talk On-Safety During Shutdownchakri4all100% (1)

- Compliance Statement ElmDocumento5 páginasCompliance Statement ElmdeepakjoyinAinda não há avaliações

- Preparing The Ship For Dry DockDocumento4 páginasPreparing The Ship For Dry Dockdanilo laraAinda não há avaliações

- Group 4 - Amtg123Documento13 páginasGroup 4 - Amtg123Jon LavaAinda não há avaliações

- IAMI Revision Answers AuxiliaryDocumento19 páginasIAMI Revision Answers AuxiliaryStewart LongAinda não há avaliações

- Aviation Mechanics Magazine Jan Feb89Documento16 páginasAviation Mechanics Magazine Jan Feb89benAinda não há avaliações

- How To Mothball and Decommission Industrial PlantsDocumento4 páginasHow To Mothball and Decommission Industrial Plantswholenumber100% (2)

- Cleaning and CorrosionDocumento31 páginasCleaning and Corrosionshimi yayAinda não há avaliações

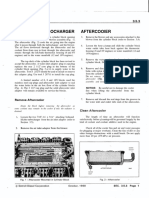

- Turbocharger Aftercooler: NoticeDocumento5 páginasTurbocharger Aftercooler: NoticeLuwīsi Karikamo RomaniAinda não há avaliações

- Basic Corrosion Removal TechniquesDocumento4 páginasBasic Corrosion Removal TechniquesFikri MohamadAinda não há avaliações

- NTSB (USCG) Exhaust SpecsDocumento10 páginasNTSB (USCG) Exhaust SpecsAnonymous Kr13NEBAinda não há avaliações

- Servicing Replenishing Fuel System Servicing 1. Information: Chapter 20-14-00, 201 Chapter 20-15-00, 201Documento13 páginasServicing Replenishing Fuel System Servicing 1. Information: Chapter 20-14-00, 201 Chapter 20-15-00, 201Анна ЛободаAinda não há avaliações

- Aftercooler Core - Clean/Test: Shutdown SIS Previous ScreenDocumento3 páginasAftercooler Core - Clean/Test: Shutdown SIS Previous ScreenTASHKEELAinda não há avaliações

- Cleaning and CorrosionDocumento79 páginasCleaning and CorrosionJuly TadeAinda não há avaliações

- Internal - 3 Afme Part - A 1. What Are The Types Aircraft Hydraulic FluidDocumento6 páginasInternal - 3 Afme Part - A 1. What Are The Types Aircraft Hydraulic FluidNambi RajanAinda não há avaliações

- Propeller Flushing and Preserving: DescriptionDocumento3 páginasPropeller Flushing and Preserving: DescriptionBhupender RamchandaniAinda não há avaliações

- Adsorption Chiller Guide SpecificationsDocumento6 páginasAdsorption Chiller Guide Specificationsmdalt9180Ainda não há avaliações

- Unimog U 20Documento28 páginasUnimog U 20Badeng LawotAinda não há avaliações

- ML784 Application ProcedureDocumento18 páginasML784 Application Procedurearmn77Ainda não há avaliações

- Maintenance PracticeDocumento16 páginasMaintenance PracticeBookMaggotAinda não há avaliações

- Lembar Inspeksi Bell 412 600 FH 12 MonthDocumento6 páginasLembar Inspeksi Bell 412 600 FH 12 MonthReza Setyo PermadiAinda não há avaliações

- Flushing Air Conditioner ProcedureDocumento3 páginasFlushing Air Conditioner Proceduredimchien100% (1)

- CL II MEPDocumento8 páginasCL II MEPKichaaAinda não há avaliações

- Dry-Dock Repair ListDocumento6 páginasDry-Dock Repair ListAnwarul Islam100% (3)

- Maintenance PracticeDocumento17 páginasMaintenance PracticeBookMaggotAinda não há avaliações

- MA3017 - 5 Dry Docking Preparation PDFDocumento129 páginasMA3017 - 5 Dry Docking Preparation PDFARIF100% (1)

- TM-Tank Cleaning Guide Revised 26 Dec 2006-Very Useful p1 To 5Documento89 páginasTM-Tank Cleaning Guide Revised 26 Dec 2006-Very Useful p1 To 5Aung Htet KyawAinda não há avaliações

- SBS 1H24 5Documento8 páginasSBS 1H24 58znff8bpjyAinda não há avaliações

- Aol / Bol / Oca Series: General Information MaintenanceDocumento1 páginaAol / Bol / Oca Series: General Information MaintenancePRASHANT KANTEAinda não há avaliações

- Class 1 ExamDocumento6 páginasClass 1 ExamIgor MatosAinda não há avaliações

- Aviation Storage TanksDocumento6 páginasAviation Storage Tanksram71990Ainda não há avaliações

- Scope of Works For Preventive Maintenance of AcuDocumento3 páginasScope of Works For Preventive Maintenance of AcuNc2 aircon60% (5)

- Storage Checklists: Short-Term Storage (Less Than 60 Days)Documento7 páginasStorage Checklists: Short-Term Storage (Less Than 60 Days)Karatebird100% (2)

- Cartilla Mantenimiento Brazo ArtDocumento9 páginasCartilla Mantenimiento Brazo ArtFabian Jara RodriguezAinda não há avaliações

- Regulation Fuel-Chemical Storage Tank InstallationDocumento2 páginasRegulation Fuel-Chemical Storage Tank InstallationArun HarshanAinda não há avaliações

- AAEDR-F-005 Rev 1 (Extended Storage PA)Documento6 páginasAAEDR-F-005 Rev 1 (Extended Storage PA)Jose G LopezAinda não há avaliações

- Insp Checklist - LO FlushingDocumento3 páginasInsp Checklist - LO Flushingaanouar7750% (2)

- Analysis of Cycle Time Reduction During Shroud Hydro Test of Boiler DRUM OF 500/600MWDocumento12 páginasAnalysis of Cycle Time Reduction During Shroud Hydro Test of Boiler DRUM OF 500/600MWiaset123Ainda não há avaliações

- Pyrophoric Vessel HandlingDocumento4 páginasPyrophoric Vessel HandlinggshdavidAinda não há avaliações

- 1st Class Motor Examination QuestionsDocumento2 páginas1st Class Motor Examination Questionsmy generalAinda não há avaliações

- SCBA Technical SpecificationsDocumento5 páginasSCBA Technical Specificationsphe zenAinda não há avaliações

- APHDocumento15 páginasAPHKarthi KeyanAinda não há avaliações

- Technical SpecificationDocumento7 páginasTechnical SpecificationRaisa AviannyAinda não há avaliações

- Installation & Maintenance Instructions: Models HA, HDD, USA and USHDDocumento7 páginasInstallation & Maintenance Instructions: Models HA, HDD, USA and USHDAjay Raju.bAinda não há avaliações

- HVAC Guide Specifications 39M Total Energy Recovery Wheel SectionDocumento7 páginasHVAC Guide Specifications 39M Total Energy Recovery Wheel Sectionhardik033Ainda não há avaliações

- Maintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESDocumento2 páginasMaintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESVelmar diseño y construccionAinda não há avaliações

- Adsobtion Chiller SpecDocumento6 páginasAdsobtion Chiller Specioan1946Ainda não há avaliações

- Installation, Operation and Maintenance Manual: Axial Propeller Wall FansDocumento8 páginasInstallation, Operation and Maintenance Manual: Axial Propeller Wall FansHernan RomeroAinda não há avaliações

- Mechanical and Heavy Equipment - CSM-5thEditionDocumento6 páginasMechanical and Heavy Equipment - CSM-5thEditionRehman MuzaffarAinda não há avaliações

- Fds Hydr0l Hte SeriesDocumento10 páginasFds Hydr0l Hte SeriesHwauei Mate10Ainda não há avaliações

- 04removal InstallationDocumento28 páginas04removal InstallationblackhawkAinda não há avaliações

- (EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualDocumento65 páginas(EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualblackhawkAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento16 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento84 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento30 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkAinda não há avaliações

- (EMM Book1 TOC) (Chapter 72 TOC) : (Main Menu)Documento43 páginas(EMM Book1 TOC) (Chapter 72 TOC) : (Main Menu)blackhawkAinda não há avaliações

- 01descrjption and OperationDocumento15 páginas01descrjption and OperationblackhawkAinda não há avaliações

- 072 90 00 EngineAcessoryDocumento30 páginas072 90 00 EngineAcessoryblackhawkAinda não há avaliações

- 由陆-32MTBE: AbcdefghDocumento1 página由陆-32MTBE: AbcdefghblackhawkAinda não há avaliações

- (EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualDocumento25 páginas(EMM Book1 TOC) (Chapter 72 TOC) : TB3 - 117 Engine Maintenance ManualblackhawkAinda não há avaliações

- 072 90 13 ChipDetectorDocumento6 páginas072 90 13 ChipDetectorblackhawkAinda não há avaliações

- 072 58 00 ExhaustSectionDocumento22 páginas072 58 00 ExhaustSectionblackhawkAinda não há avaliações

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Documento12 páginasTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)blackhawkAinda não há avaliações

- Fuel and Control System - Schematic Diagram: From Neighboring EngineDocumento1 páginaFuel and Control System - Schematic Diagram: From Neighboring EngineblackhawkAinda não há avaliações

- Ec135 Mmel en 2015.12.15 D0Documento114 páginasEc135 Mmel en 2015.12.15 D0blackhawkAinda não há avaliações

- Stage 2 NGV A Sembly. - Rotor.: - Engine Third Suppor1 AssemblyDocumento10 páginasStage 2 NGV A Sembly. - Rotor.: - Engine Third Suppor1 AssemblyblackhawkAinda não há avaliações

- TB3-117 Maintenance Manual: (5) (2) 4) End (3) (2) End 4)Documento59 páginasTB3-117 Maintenance Manual: (5) (2) 4) End (3) (2) End 4)blackhawkAinda não há avaliações

- Inspection and Repaer of Control Cables and TurnbucklesDocumento13 páginasInspection and Repaer of Control Cables and TurnbucklesblackhawkAinda não há avaliações

- Combustion Chamber Description and Operation: L. GeneralDocumento14 páginasCombustion Chamber Description and Operation: L. GeneralblackhawkAinda não há avaliações

- TB3-117 Mantenance Manual: Turbine Assembly - Description Ano OperationDocumento1 páginaTB3-117 Mantenance Manual: Turbine Assembly - Description Ano OperationblackhawkAinda não há avaliações

- AW119Kx ASMTCDocumento888 páginasAW119Kx ASMTCblackhawkAinda não há avaliações

- TM 1 1500 323 24 1Documento1.032 páginasTM 1 1500 323 24 1blackhawkAinda não há avaliações

- Tables 7-12Documento6 páginasTables 7-12blackhawkAinda não há avaliações

- TM 1 1500 328 23Documento99 páginasTM 1 1500 328 23blackhawk100% (1)

- BoltsDocumento6 páginasBoltsblackhawkAinda não há avaliações

- A119Documento1.060 páginasA119blackhawk100% (1)

- Section 8. Aluminum and Aluminum AlloysDocumento4 páginasSection 8. Aluminum and Aluminum AlloysblackhawkAinda não há avaliações

- Chapter 6. Corrosion, Inspection & ProtectionDocumento2 páginasChapter 6. Corrosion, Inspection & ProtectionblackhawkAinda não há avaliações

- Section 8. Aluminum and Aluminum AlloysDocumento4 páginasSection 8. Aluminum and Aluminum AlloysblackhawkAinda não há avaliações

- Chapter 6. Corrosion, Inspection & ProtectionDocumento1 páginaChapter 6. Corrosion, Inspection & ProtectionblackhawkAinda não há avaliações

- Blue Beach Master PlanDocumento2 páginasBlue Beach Master PlanDR4SaleAinda não há avaliações

- Squat EffectDocumento3 páginasSquat Effectrhumbline9Ainda não há avaliações

- Workshop Layout DrawingDocumento1 páginaWorkshop Layout DrawingSoufiane Faidi0% (2)

- Me f412 - PPC HandoutDocumento3 páginasMe f412 - PPC HandoutAbhinav PathakAinda não há avaliações

- Siddhachal Elite BrochureDocumento27 páginasSiddhachal Elite BrochureLokesh BangaloreAinda não há avaliações

- Sales & MerchandisingDocumento3 páginasSales & MerchandisingShiela May Aggabao0% (1)

- My PPT Presentation On ULTRA TECH CEMENTDocumento13 páginasMy PPT Presentation On ULTRA TECH CEMENTAshish Kumar Pani67% (3)

- Floor SystemDocumento14 páginasFloor SystemCJ Ong100% (1)

- Building Over MuskegDocumento4 páginasBuilding Over MuskegMayyouAinda não há avaliações

- MEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner GuideDocumento8 páginasMEM05008C Perform Advanced Manual Thermal Cutting, Gouging and Shaping - Learner Guidequestionbank.com.au50% (2)

- Nepal: Kathmandu Sustainable Urban Transport ProjectDocumento21 páginasNepal: Kathmandu Sustainable Urban Transport ProjectADBGADAinda não há avaliações

- CRJ Freighter BrochureDocumento4 páginasCRJ Freighter Brochurejuan carlos balderas silva100% (1)

- Case - Freshippo & Tmall (Cainiao)Documento15 páginasCase - Freshippo & Tmall (Cainiao)Bonnie DAinda não há avaliações

- HandBook KomatsuDocumento7 páginasHandBook KomatsuLuis L Quisberth G75% (4)

- Pal ExpressDocumento3 páginasPal ExpressCharmaine MagdangalAinda não há avaliações

- Introduction To Aviation IndustryDocumento10 páginasIntroduction To Aviation IndustryMohd MohsinAinda não há avaliações

- Astm D 4220Documento11 páginasAstm D 4220Nikolay Drumev100% (1)

- Special Concreting MethodsDocumento27 páginasSpecial Concreting MethodsAmit SinghAinda não há avaliações

- GANTREX® MK6 Rail PadDocumento4 páginasGANTREX® MK6 Rail PadwickremasingheAinda não há avaliações

- 5Documento23 páginas5Signore DwiczAinda não há avaliações

- Accidental DamageDocumento29 páginasAccidental Damagestan80Ainda não há avaliações

- IPSCM - Week 4Documento14 páginasIPSCM - Week 4Redhwan85Ainda não há avaliações

- Coal Terminals Information Handbook Port Waratah Coal Services Limited A.B.N. 99 001 363 828Documento59 páginasCoal Terminals Information Handbook Port Waratah Coal Services Limited A.B.N. 99 001 363 828Dimas Apri SaputraAinda não há avaliações

- Justice Hegde Report On Illegal Mining in KarnatakaDocumento466 páginasJustice Hegde Report On Illegal Mining in KarnatakaNDTVAinda não há avaliações

- Nespresso Manual PDFDocumento7 páginasNespresso Manual PDFAeneasAinda não há avaliações

- Pier SpecificationsDocumento168 páginasPier SpecificationsRob MouzasAinda não há avaliações

- ACO RainDrain BrochureDocumento2 páginasACO RainDrain BrochureDoug WeirAinda não há avaliações

- Al6061 19720022808 1972022808Documento112 páginasAl6061 19720022808 1972022808jimrjonesXAinda não há avaliações

- Rice TradeDocumento2 páginasRice Tradeapi-372195697Ainda não há avaliações

- Supply Chain ManagementDocumento51 páginasSupply Chain Managementgubdia100% (1)

- Upcycling: 20 Creative Projects Made from Reclaimed MaterialsNo EverandUpcycling: 20 Creative Projects Made from Reclaimed MaterialsAinda não há avaliações

- Simplified Organization: Learn to Love What Must Be DoneNo EverandSimplified Organization: Learn to Love What Must Be DoneAinda não há avaliações

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterNo EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterNota: 4 de 5 estrelas4/5 (468)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeNo EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeNota: 5 de 5 estrelas5/5 (2)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingNo EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingNota: 4.5 de 5 estrelas4.5/5 (847)

- It's All Too Much: An Easy Plan for Living a Richer Life with Less StuffNo EverandIt's All Too Much: An Easy Plan for Living a Richer Life with Less StuffNota: 4 de 5 estrelas4/5 (232)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingNo EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingNota: 4.5 de 5 estrelas4.5/5 (79)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiNo EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiNota: 4.5 de 5 estrelas4.5/5 (5)

- The Martha Manual: How to Do (Almost) EverythingNo EverandThe Martha Manual: How to Do (Almost) EverythingNota: 4 de 5 estrelas4/5 (11)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.No EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Nota: 4 de 5 estrelas4/5 (17)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeNo EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeNota: 4.5 de 5 estrelas4.5/5 (164)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffNo EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffNota: 4.5 de 5 estrelas4.5/5 (578)

- The Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeNo EverandThe Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeNota: 3 de 5 estrelas3/5 (1)

- Simply Clean: The Proven Method for Keeping Your Home Organized, Clean, and Beautiful in Just 10 Minutes a DayNo EverandSimply Clean: The Proven Method for Keeping Your Home Organized, Clean, and Beautiful in Just 10 Minutes a DayNota: 4 de 5 estrelas4/5 (87)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingNo EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingNota: 4 de 5 estrelas4/5 (2998)

- Summary of KC Davis's How to Keep House While DrowningNo EverandSummary of KC Davis's How to Keep House While DrowningNota: 5 de 5 estrelas5/5 (1)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceAinda não há avaliações

- Organizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlNo EverandOrganizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlNota: 4.5 de 5 estrelas4.5/5 (206)

- How to Build a House: A Practical, Common-Sense Guide to Residential ConstructionNo EverandHow to Build a House: A Practical, Common-Sense Guide to Residential ConstructionNota: 4 de 5 estrelas4/5 (5)

- Mini Farming: Self-Sufficiency on 1/4 AcreNo EverandMini Farming: Self-Sufficiency on 1/4 AcreNota: 4.5 de 5 estrelas4.5/5 (6)

- Home Decor Cheat Sheets: Need-to-Know Stuff for Stylish LivingNo EverandHome Decor Cheat Sheets: Need-to-Know Stuff for Stylish LivingNota: 5 de 5 estrelas5/5 (5)

- Build Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideNo EverandBuild Your Own Sheds & Outdoor Projects Manual, Fifth Edition: Over 200 Plans InsideNota: 5 de 5 estrelas5/5 (1)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyNo EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyNota: 4 de 5 estrelas4/5 (40)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesNo EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesNota: 4 de 5 estrelas4/5 (11)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyNo EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyNota: 4 de 5 estrelas4/5 (278)

- Let It Go: Downsizing Your Way to a Richer, Happier LifeNo EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeNota: 4.5 de 5 estrelas4.5/5 (67)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsAinda não há avaliações