Escolar Documentos

Profissional Documentos

Cultura Documentos

Sus 329j4l

Enviado por

Afronie Cepoz D'nextDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sus 329j4l

Enviado por

Afronie Cepoz D'nextDireitos autorais:

Formatos disponíveis

DATA SHEET

NTK STAINLESS STEEL

NIPPON METAL INDUSTRY CO., LTD.

NTK R-40

1. Chemical composition (%) : Table 1

Table 1

JIS C Si Mn P S Ni Cr Mo N

7.50- 26.00- 3.50- 0.30-

NTK R-40 SUS329J4L 0.030 1.00 1.50 0.040 0.030

5.50 24.00 2.50 0.08

2. General characteristics :

NTK R-40(SUS329J4L) is a high chromium stainless steel containing nickel and molybdenum, having

duplex structure of austenite and ferrite. It shows excellent resistance to pitting corrosion and stress corrosion

cracking by solution containing chlorides.

NTK R-40 has higher mechanical strength compared with Type 304.

3. Applications :

Water tanks, Tubing for deep sour oil , gas wells and chemical tanker, Other chemical equipment.

4. Forms available :

Plate, Sheet, Strip

5. Physical properties (annealed condition) : Table 2

Table 2

Modulus of elasticity 103N/mm2 190

Basically mass kg/mmm2 7.80

Specific electrical resistance(20) cm 79

Specific heat (0100) J/gcm 0.50

Thermal conductivity (0100) W/cm 0.19

Mean coefficient of (20100) 10-6/ 11.5

thermal expansion (30300) 13.0

Melting point range 14101490

Magnetism Ferromagnetic

6. Mechanical properties : Table 3 & 4

Table 3 Typical mechanical properties at room temperature (annealed condition)

Hot rolled plate Cold rolled sheet

Tensile strength N/mm 2 818 882

Proof stress N/mm2 622 701

Elongation % 28 25

Hardness Hv 250 275

Bending R=t 180deg. no cracking no cracking

Thickness of test piece : Plate 6mm Sheet 2mm

Table 4 Typical short-time elevated temperature tensile strength

Test temperature () room 100 200 300 400

temp.

Tensile strength (N/mm2) 818 780 750 770 760

Thickness of test piece : 6mm

7. Corrosion resistance :

7.1 Acid resistance :

NTK R-40 has superior resistance to environment containing hydrogen sulfide, carbon dioxide and

chloride at high temperature.

NTK R-40 has better resistance to nitric, sulfuric, acetic and phosphoric acids than Type 316.

The result of 5% sulfuric acid boil solution test are shown in Table 5.

Table 5 Result of 5% sulfuric acid boil solution test

Designation of grade NTK R-40 SUS 316 SUS 317

Corrosion ratio (g/m2h) 0.38 9.33 4.56

7.2 Intergranular resistance :

NTK R-40 has no danger of intergranular attack frequently seen on austenitic stainless steels.

7.3 Pitting corrosion :

NTK R-40 has very good resistance to pitting corrosion. The results of ferric chloride test and the results of

pitting and crevice corrosion potential measurements in NaCl solution are shown in Table 6 & 7.

Table 6 Results of ferric chloride test

Designation of grade NTK R-40 SUS 316

Corrosion ratio (g/m2h) 0.01 5.1

Test solution : 10 % FeCl3 + 0.05 N NaCl

Temperature : 30 Time : 24 hr

Table 7 Results of pitting and crevice corrosion

Potential measurement (V vs. SCE)

Designation of grade NTK R-40 SUS 316 SUS 304

Pitting potential 1.0 0.45 0.30

Crevice potential 1.0 0.20 0.10

air open, Test solution : 3.5 % NaCl, Temperature : 30

7.4 Stress corrosion cracking (SCC) :

Resistance of NTK R-40 to SCC due to chloride solutions is superior to those of Type 304 and 316 steels.

8. Embrittlement :

Heating NTK R-40 around 850 increase brittlement from precipitation of sigma phase.

NTK R-40 is subject to embrittlement at room temperature after exposure around 475.

So, It is generally used at temperature of under 350 .

9. Workability :

9.1 Cold workability :

When cold working such as bending or forming is performed, it must be taken into account that NTK R-40

has high mechanical strength and susceptibility to notch cracking.

9.2 Heat treatment :

About 1050 heating with quick cooling is suitable for annealing after hot or cold working and welding.

9.3 Weldability :

NTK R-40 can be easily welded as well as ordinary austenitic stainless steels such as Type 304. The

deposition efficiency of rods should be more 50 % in TIG arc welding.

Notice :

z Information in this document is only for the explanation of general characteristics and properties of our

products, not for the guarantee for our materials.

z Technical information in this document is subject to change by environment, condition and the purpose of

use.

z Any damage occurred by wrong in use by technical information mentioned in this document is

irresponsible.

201006

Você também pode gostar

- Materials Data for Cyclic Loading: Low-Alloy SteelsNo EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsNota: 5 de 5 estrelas5/5 (2)

- Highly Corrosion Resistant Stainless Steel Alloy NAS 255 (UNS N08904Documento4 páginasHighly Corrosion Resistant Stainless Steel Alloy NAS 255 (UNS N08904Miguel Martinez GuerreroAinda não há avaliações

- Quality 1.4362 Chemical Composition: Technical CardDocumento2 páginasQuality 1.4362 Chemical Composition: Technical CardTeodor EzaruAinda não há avaliações

- NAS 64 High Corrosion Resistant Duplex Stainless SteelDocumento4 páginasNAS 64 High Corrosion Resistant Duplex Stainless SteelDaoAinda não há avaliações

- CR Mo 4Documento2 páginasCR Mo 4Mohsen ParpinchiAinda não há avaliações

- 5 - Duplex Stainless Steels and Nickel AlloysDocumento44 páginas5 - Duplex Stainless Steels and Nickel AlloysdennykvgAinda não há avaliações

- Nas - 185N - e - 254 Smo - Uns - S31254Documento4 páginasNas - 185N - e - 254 Smo - Uns - S31254Marvin BasdenAinda não há avaliações

- Sandvik 2re10Documento7 páginasSandvik 2re10himan_chongiAinda não há avaliações

- Nas 329J3L: (Uns S32205, S31803)Documento4 páginasNas 329J3L: (Uns S32205, S31803)harry nataldoAinda não há avaliações

- 36NiCrMo16 10083 06 ENG 01Documento1 página36NiCrMo16 10083 06 ENG 01Guru Raj9739Ainda não há avaliações

- Nas 254N: (Uns S32053)Documento4 páginasNas 254N: (Uns S32053)munif finumAinda não há avaliações

- Data SAF2205 04Documento8 páginasData SAF2205 04il_yoo_1Ainda não há avaliações

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetDocumento10 páginasSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediAinda não há avaliações

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Documento7 páginasDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvAinda não há avaliações

- Den Här Sidan Finns Endast På Engelska Sandvik 12R10 / Sandvik T302 Spring WireDocumento5 páginasDen Här Sidan Finns Endast På Engelska Sandvik 12R10 / Sandvik T302 Spring WireJunior M. PozoAinda não há avaliações

- DH 1232NSDocumento1 páginaDH 1232NSGopiNathAinda não há avaliações

- E Magnets UK Neodymium Data SheetDocumento1 páginaE Magnets UK Neodymium Data SheetAndre CoraucciAinda não há avaliações

- 10 0000@www Onepetro org@conference-paper@NACE-2019-12783Documento13 páginas10 0000@www Onepetro org@conference-paper@NACE-2019-12783rajiv_quantumAinda não há avaliações

- Alloy 6082 - Rev2012Documento2 páginasAlloy 6082 - Rev2012Ysraels Santisteban DurandAinda não há avaliações

- Precision wire corrosion resistance Sandvik Sanicro 28Documento2 páginasPrecision wire corrosion resistance Sandvik Sanicro 28Prasanna MuleyAinda não há avaliações

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocumento3 páginasConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390Ainda não há avaliações

- Nitronic 50 SheetDocumento3 páginasNitronic 50 SheetSam PeñaAinda não há avaliações

- K48-50 Carbon Film ResistorsDocumento3 páginasK48-50 Carbon Film ResistorseminuscloudAinda não há avaliações

- Materilas-An Overview: 3.1 Austenitic Stainless Steel 316LDocumento13 páginasMaterilas-An Overview: 3.1 Austenitic Stainless Steel 316LRS CreationsAinda não há avaliações

- 36NiCrMo16 PDFDocumento2 páginas36NiCrMo16 PDFAmy GriffinAinda não há avaliações

- 1 4501 Super Duplex TubesDocumento3 páginas1 4501 Super Duplex TubesAlma JakirovićAinda não há avaliações

- Datasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Documento5 páginasDatasheet-Sandvik-11r51-En-V2020-08-27 13 - 59 Version 1Kashish100% (2)

- SINOXX 4006 Steel: Designation by StandardsDocumento3 páginasSINOXX 4006 Steel: Designation by StandardsKiranAinda não há avaliações

- Tempering Conditions For 30CrNiMo8Documento2 páginasTempering Conditions For 30CrNiMo8madyeAinda não há avaliações

- 34 CR Ni Mo 6Documento1 página34 CR Ni Mo 6Bogdan CraciunAinda não há avaliações

- Wear Resistance of Pulse Plasma Nitrided AISI 4140 and A355 SteelsDocumento7 páginasWear Resistance of Pulse Plasma Nitrided AISI 4140 and A355 Steelsdeepdreamx6400Ainda não há avaliações

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Documento2 páginasProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajAinda não há avaliações

- Macsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LDocumento4 páginasMacsteel VRN: Stainless Steel Plate, Sheet & Coil SX316/316LNirav PatelAinda não há avaliações

- 500mW Low Noise Zener DiodesDocumento5 páginas500mW Low Noise Zener DiodessergiogasAinda não há avaliações

- Temperature Sensor For Fluids TSF: RE 95180/2021-06-30 Replaces: 2020-03-27Documento12 páginasTemperature Sensor For Fluids TSF: RE 95180/2021-06-30 Replaces: 2020-03-27paolono maratonaAinda não há avaliações

- 15PGAMT001 Tantalum FinalDocumento25 páginas15PGAMT001 Tantalum Finalvijesh1432Ainda não há avaliações

- L1_34428_en__B_Boehler-AWS-ER309L_ss_en_1Documento1 páginaL1_34428_en__B_Boehler-AWS-ER309L_ss_en_1Edgar HornusAinda não há avaliações

- Sandvik SAF 2205: Duplex Stainless SteelDocumento8 páginasSandvik SAF 2205: Duplex Stainless SteelIuliu HurducaciAinda não há avaliações

- AUTROD 316LSiDocumento2 páginasAUTROD 316LSijoao guilhermeAinda não há avaliações

- T - Thermanit 25 - 09 CuT - de - en - 5Documento1 páginaT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANIAinda não há avaliações

- SS 6mo - 1.4547Documento1 páginaSS 6mo - 1.4547f_riseAinda não há avaliações

- UTP 6222 MoDocumento1 páginaUTP 6222 ModantegimenezAinda não há avaliações

- Buderus 7225Documento4 páginasBuderus 7225Ajeng GaleriAinda não há avaliações

- 41 CR 4Documento2 páginas41 CR 4Jhon ChitAinda não há avaliações

- 1.4305 Sae303 DatasheetDocumento2 páginas1.4305 Sae303 Datasheetehudingram6535Ainda não há avaliações

- Brand new NC3000 series Wide roughing coverage turning grade for steel and stainless steelDocumento4 páginasBrand new NC3000 series Wide roughing coverage turning grade for steel and stainless steeldemoracingeduAinda não há avaliações

- CR Om Ot He Rme-9 (M Od) Cromotherme-9 (SPL)Documento1 páginaCR Om Ot He Rme-9 (M Od) Cromotherme-9 (SPL)Parmasamy SubramaniAinda não há avaliações

- European Steel and Alloy Grades: S235JRC (1.0122)Documento2 páginasEuropean Steel and Alloy Grades: S235JRC (1.0122)farshid KarpasandAinda não há avaliações

- Uns s32760Documento3 páginasUns s32760NitinAinda não há avaliações

- UTOPEX2Documento4 páginasUTOPEX2emregnesAinda não há avaliações

- 40NiCrMo7 PDFDocumento2 páginas40NiCrMo7 PDFAmy GriffinAinda não há avaliações

- GFW 625Documento1 páginaGFW 625amit singhAinda não há avaliações

- Technical Data Sheet: Stainless Steel: SuperausteniticDocumento5 páginasTechnical Data Sheet: Stainless Steel: SuperausteniticSue EpicAinda não há avaliações

- 308H Tig Welding Wire for Stainless SteelsDocumento1 página308H Tig Welding Wire for Stainless SteelsFilipe CordeiroAinda não há avaliações

- PART 92 Cu-Ni Welding - Part 1 Cu-Ni Material PropertiesDocumento16 páginasPART 92 Cu-Ni Welding - Part 1 Cu-Ni Material Propertiesravindra_jivaniAinda não há avaliações

- SUPRA50®: Chemical Composition (Weight %)Documento3 páginasSUPRA50®: Chemical Composition (Weight %)malaya tripathyAinda não há avaliações

- Austenitic Standard GradesDocumento6 páginasAustenitic Standard Gradesfierro44Ainda não há avaliações

- Datasheet-Sanicro-41-En-V2019-09-19 07 - 09 Version 1Documento7 páginasDatasheet-Sanicro-41-En-V2019-09-19 07 - 09 Version 1Rubén Leal RuizAinda não há avaliações

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocumento3 páginasStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalAinda não há avaliações

- Handbook of RefractoryDocumento331 páginasHandbook of RefractoryAamirMalikAinda não há avaliações

- Welding Advanced Chromium Alloys for High-Temperature ServiceDocumento5 páginasWelding Advanced Chromium Alloys for High-Temperature Servicesaji_t1984100% (1)

- Katalog Gasket TOMBODocumento3 páginasKatalog Gasket TOMBOAfronie Cepoz D'nextAinda não há avaliações

- Flange DrawingDocumento1 páginaFlange DrawingAfronie Cepoz D'nextAinda não há avaliações

- Zeron 100-Data SheetDocumento8 páginasZeron 100-Data SheetAfronie Cepoz D'nextAinda não há avaliações

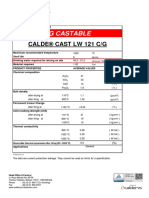

- Msds Calde Cast LW 121 CGDocumento5 páginasMsds Calde Cast LW 121 CGAfronie Cepoz D'nextAinda não há avaliações

- Asme Sec I A2001Documento4 páginasAsme Sec I A2001Sidney LinsAinda não há avaliações

- Sec 1 PT PBDocumento9 páginasSec 1 PT PBAfronie Cepoz D'nextAinda não há avaliações

- Tds Calde Cast LW 121 CGDocumento1 páginaTds Calde Cast LW 121 CGAfronie Cepoz D'nextAinda não há avaliações

- CertificateDocumento18 páginasCertificateAfronie Cepoz D'nextAinda não há avaliações

- NAS 64 High Corrosion Resistant Duplex Stainless SteelDocumento4 páginasNAS 64 High Corrosion Resistant Duplex Stainless SteelAfronie Cepoz D'nextAinda não há avaliações

- NPT (Asme B1.20.1)Documento5 páginasNPT (Asme B1.20.1)Afronie Cepoz D'nextAinda não há avaliações

- Pipe Schedule Segun ASME B36.1 PDFDocumento1 páginaPipe Schedule Segun ASME B36.1 PDFalberthf_1Ainda não há avaliações

- Qualification of 2 1⁄4 Cr 1 Mo Steel PQRDocumento7 páginasQualification of 2 1⁄4 Cr 1 Mo Steel PQRAfronie Cepoz D'nextAinda não há avaliações

- List of Volumes ASM Metal HandbookDocumento1 páginaList of Volumes ASM Metal HandbookAfronie Cepoz D'nextAinda não há avaliações

- Cooling TowersDocumento23 páginasCooling TowersAfronie Cepoz D'nextAinda não há avaliações

- Incoloy Alloy 825Documento4 páginasIncoloy Alloy 825Roman PaduaAinda não há avaliações

- Novirost Sample TeaserDocumento2 páginasNovirost Sample TeaserVlatko KotevskiAinda não há avaliações

- Elementary School: Cash Disbursements RegisterDocumento1 páginaElementary School: Cash Disbursements RegisterRonilo DagumampanAinda não há avaliações

- Sapkale Sandspit 2020Documento5 páginasSapkale Sandspit 2020jbs_geoAinda não há avaliações

- ContactsDocumento10 páginasContactsSana Pewekar0% (1)

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDocumento2 páginasOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossAinda não há avaliações

- L-1 Linear Algebra Howard Anton Lectures Slides For StudentDocumento19 páginasL-1 Linear Algebra Howard Anton Lectures Slides For StudentHasnain AbbasiAinda não há avaliações

- MSBI Installation GuideDocumento25 páginasMSBI Installation GuideAmit SharmaAinda não há avaliações

- Hardened Concrete - Methods of Test: Indian StandardDocumento16 páginasHardened Concrete - Methods of Test: Indian StandardjitendraAinda não há avaliações

- UW Computational-Finance & Risk Management Brochure Final 080613Documento2 páginasUW Computational-Finance & Risk Management Brochure Final 080613Rajel MokAinda não há avaliações

- Sop EcuDocumento11 páginasSop Ecuahmed saeedAinda não há avaliações

- Difference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDocumento2 páginasDifference Between OS1 and OS2 Single Mode Fiber Cable - Fiber Optic Cabling SolutionsDharma Teja TanetiAinda não há avaliações

- QSK45 60 oil change intervalDocumento35 páginasQSK45 60 oil change intervalHingga Setiawan Bin SuhadiAinda não há avaliações

- Globalisation - Theories of Digital CommunicationDocumento12 páginasGlobalisation - Theories of Digital CommunicationDiya Patel-10SAinda não há avaliações

- International Convention Center, BanesworDocumento18 páginasInternational Convention Center, BanesworSreeniketh ChikuAinda não há avaliações

- Philippine Architecture, Film Industry EvolutionDocumento4 páginasPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelAinda não há avaliações

- CadLink Flyer 369044 937 Rev 00Documento2 páginasCadLink Flyer 369044 937 Rev 00ShanaHAinda não há avaliações

- B3 Zoning Diagram, Atlantic Yards/Pacific ParkDocumento4 páginasB3 Zoning Diagram, Atlantic Yards/Pacific ParkNorman OderAinda não há avaliações

- BlueDocumento18 páginasBluekarishma nairAinda não há avaliações

- Econometrics Chapter 1 7 2d AgEc 1Documento89 páginasEconometrics Chapter 1 7 2d AgEc 1Neway AlemAinda não há avaliações

- Part I-Final Report On Soil InvestigationDocumento16 páginasPart I-Final Report On Soil InvestigationmangjuhaiAinda não há avaliações

- Meanwhile Elsewhere - Lizzie Le Blond.1pdfDocumento1 páginaMeanwhile Elsewhere - Lizzie Le Blond.1pdftheyomangamingAinda não há avaliações

- Haryana Retial GarmentsDocumento8 páginasHaryana Retial Garmentssudesh.samastAinda não há avaliações

- Weibull Statistic and Growth Analysis in Failure PredictionsDocumento9 páginasWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaAinda não há avaliações

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageDocumento29 páginasMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- Assignment-2: MCA204 Financial Accounting and ManagementDocumento6 páginasAssignment-2: MCA204 Financial Accounting and ManagementrashAinda não há avaliações

- Denial and AR Basic Manual v2Documento31 páginasDenial and AR Basic Manual v2Calvin PatrickAinda não há avaliações

- Bentone 30 Msds (Eu-Be)Documento6 páginasBentone 30 Msds (Eu-Be)Amir Ososs0% (1)

- Gattu Madhuri's Resume for ECE GraduateDocumento4 páginasGattu Madhuri's Resume for ECE Graduatedeepakk_alpineAinda não há avaliações

- Group 4 HR201 Last Case StudyDocumento3 páginasGroup 4 HR201 Last Case StudyMatt Tejada100% (2)

- Complaint Handling Policy and ProceduresDocumento2 páginasComplaint Handling Policy and Proceduresjyoti singhAinda não há avaliações