Escolar Documentos

Profissional Documentos

Cultura Documentos

Che 4170 Design Project Appendix A10

Enviado por

venkiee0 notas0% acharam este documento útil (0 voto)

53 visualizações4 páginasAppendix

Título original

Che 4170 Design Project Appendix a10

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoAppendix

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

53 visualizações4 páginasChe 4170 Design Project Appendix A10

Enviado por

venkieeAppendix

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 4

Appendix A10

CHE 4170 DESIGN PROJECT

PRODUCTION OF FATTY ALCOHOL BY USING

NON-HYDROGENATED PALM KERNEL FATTY

ACIDS THROUGH METHYL ESTER ROUTE

APPENDIX A10

GROUP 9

CHUA SONG EE 24324671

ISMAIL ALLANA 24533157

KHONG ZHI-WEI 25075829

MALCOLM SPYKERMAN 25069489

SHARAN SRINIVAS VENKATESH 23955783

NURUL ARFAIN MOHAMED SIRAJKUMAR 25070673

POON ZI YET 25510517

Submission Date: 26th October 2016

Page | A3.1

Appendix A10

Table of Contents

Appendix A10: Plant Layout....................................................................................................1

A10.3 Plant Layout Constraints...........................................................................................1

Appendix A10

Appendix A10: Plant Layout

A10.3 Plant Layout Constraints

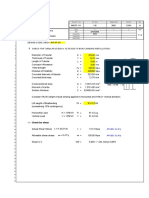

The equipment size and dimension is either estimated based on existing equipment OR

calculated as per Specification Sheet and Detailed Design in Chapter 4 and Chapter 5. Table

10.1 shows the estimated/calculated equipment dimension.

Table 10.1 Dimension of the Equipment in the plant.

Height

Length Width Thickness (Total)

Equipment (m) (m) Diameter (m) (m) (m)

(including

jacket and

R-201 - - 2.85 0.461 14.558 insulation)

DC-201 - - 2.5 0.06 15

DC-202 - - 2.98 0.06 9.97

F-302 - - 1.15 0.016 4.79

Di=0.28,

C-301 4.3 - Do=0.30 0.01 -

Di=1.10,

F-303 - - Do=1.14 0.02 3.09

Di=7.5,

T-101 - - Do=7.526 0.013 12.6 T=Storage Tank

Di=1.75,

R-101 - - Do=1.764 0.007 10.36 F=Flash Vessel

Di=6.0, DC=Distillation

T-102 - - Do=6.024 0.012 14.4 Column

Di=0.9,

F-101 - - Do=0.91 0.005 8.96 R=Reactor

Di=1.96,

DC-501 - - Do=2.1 0.06757 21 CON=Condenser

CON-501

(connected to Di=0.598,

DC-501) 3.66 - Do=0.611 0.003767 - B=Reboiler

B-501

(connected to Di=0.875,

DC-501) 3.66 - Do=0.89751 0.02251 - C=Cooler

Di=1.3,

F-301 - - Do=1.51 0.1 4.1552

F-401 - - 1.87 0.004 7.36

DC-401 - - 1.97 0.004 6.41

R-601 - - 1.7571 0.002 4.3928

R-602 - - 1.4473 0.002 3.618

Di=0.4348, 13.434

F-601 - - Do=0.442 0.007 4

F-602 - - Di=0.33, 0.007 10.1

Appendix A10 | Page | 1

Appendix A10

Do=0.35

Length Width Diameter Volum Equipment

(m) (m) Height (m) (m) e (m3) Tag

Dual Course

Filter 1 1 F-701

WW

Collection

Tank 4 4 5 80 T-701

High Load

Tank 4 4 5 80 T-702

Equalization

Tank 4 4 3 40 T-703

Dosage Tank

(Flocculant) 1 1 1 1 T-704

Flocculation

Tank 2 2 2 6 T-705

Aeration 61.45

Tank 4 4 4 (64) T-706

Pressure

Vessel 2 2 2 5 PV-701

Dissolved Air

Floatation

Clarifier 4 3.1 30 C-701 C=Clarifier

Secondary 52.817

Clarifier 4 4.1 02 C-701 C=Clarifier

Sludge

Thickner 3 2 10 TH-701

Belt Press

Dewatering

Unit 3 1 FP-701

Appendix A10 | Page | 2

Você também pode gostar

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationAinda não há avaliações

- Deutz Fahr Agrotron K100 Tractor Parts Catalogue ManualDocumento21 páginasDeutz Fahr Agrotron K100 Tractor Parts Catalogue ManuallaopaodunAinda não há avaliações

- Exhaust System CalculationDocumento2 páginasExhaust System CalculationZa YonAinda não há avaliações

- Bernoulli & HydrostaticDocumento25 páginasBernoulli & HydrostaticAB20 219 RUTHIRAN ARUMUGAMAinda não há avaliações

- Lab Report Experiment # 3 Head Loss in Pipes Pnge 211: An Introduction To Fluid MechanicsDocumento7 páginasLab Report Experiment # 3 Head Loss in Pipes Pnge 211: An Introduction To Fluid MechanicsNISHANT395Ainda não há avaliações

- Flare CalculationDocumento22 páginasFlare CalculationHomer SilvaAinda não há avaliações

- Static Pressure CalculationsDocumento28 páginasStatic Pressure CalculationsAnonymous ixIhrPM2100% (1)

- Friction Loss Ke Jarak (M) K R R Lubang Duct Duct Lubang TotalDocumento4 páginasFriction Loss Ke Jarak (M) K R R Lubang Duct Duct Lubang TotalRidho qurniawanAinda não há avaliações

- Footing Design Final 02.11.12Documento76 páginasFooting Design Final 02.11.12Amarjit Kulkarni0% (1)

- Steam CondenserDocumento2 páginasSteam CondenserAlphaEcc EngineeringTeamAinda não há avaliações

- Simulación 1Documento1 páginaSimulación 1Omar Ronald Caldeoçron CondorAinda não há avaliações

- CO2 Condenser 02-03-2023-15 PMDocumento37 páginasCO2 Condenser 02-03-2023-15 PMahmad santosoAinda não há avaliações

- Kaercher B 40 C BP Walk Behind Scrubber Parts ListDocumento39 páginasKaercher B 40 C BP Walk Behind Scrubber Parts ListLaszlo SzatmaryAinda não há avaliações

- BQS501 - WBLFF (WMN)Documento25 páginasBQS501 - WBLFF (WMN)Umairah FathiniAinda não há avaliações

- Priced Fitting & Pipe ModDocumento14 páginasPriced Fitting & Pipe ModMiko AbiAinda não há avaliações

- Pau-T1-02-01 PDFDocumento1 páginaPau-T1-02-01 PDFKyi LwinAinda não há avaliações

- Example Foundation Calculation by AfesDocumento25 páginasExample Foundation Calculation by AfesPanithi Brahmasâkhâ100% (1)

- Load Rating Training Session 4ADocumento45 páginasLoad Rating Training Session 4Atofa01Ainda não há avaliações

- External Static Pressure, 9020Documento1 páginaExternal Static Pressure, 9020UMARAinda não há avaliações

- P 4Documento3 páginasP 4Miguel Jesús Díaz RodríguezAinda não há avaliações

- 299 - Elliptical Head Design Tool Ver E4.01Documento1 página299 - Elliptical Head Design Tool Ver E4.01BAHADIRAinda não há avaliações

- 299 - Elliptical Head Design Tool Ver E4.01Documento1 página299 - Elliptical Head Design Tool Ver E4.01mohamed faragAinda não há avaliações

- 299 - Elliptical Head Design Tool Ver E4.01Documento1 página299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaAinda não há avaliações

- Diseño de Cabeza ElípticaDocumento1 páginaDiseño de Cabeza ElípticapedroluischoqueAinda não há avaliações

- Cost - Of.equipments (Furnace C Factor)Documento7 páginasCost - Of.equipments (Furnace C Factor)Pablo Jesus Graterol MelendezAinda não há avaliações

- Tank Calc SheetDocumento4 páginasTank Calc SheetAbhijeetAinda não há avaliações

- Screw Conveyor Calcultation SheetDocumento11 páginasScrew Conveyor Calcultation Sheethardik033Ainda não há avaliações

- Static Regain Method NEWDocumento6 páginasStatic Regain Method NEWMarzookAinda não há avaliações

- Parts Manual: Forklifts C 500 H X4Documento152 páginasParts Manual: Forklifts C 500 H X4Miguel ViegasAinda não há avaliações

- Elliptical Head Design Tool: Pressure Vessel Engineering LTDDocumento1 páginaElliptical Head Design Tool: Pressure Vessel Engineering LTDJaveed KhanAinda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design ToolssierroAinda não há avaliações

- 300 - F&D Head Design Tool Ver E4.01Documento1 página300 - F&D Head Design Tool Ver E4.01Mo ZeroAinda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design Toolnaveen_86Ainda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design ToolJaveed KhanAinda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design Toolnaveen_86Ainda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design Toolbai tap hoa vo coAinda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design ToolSudjono BroAinda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design ToolSudjono BroAinda não há avaliações

- Pressure Drop Calculation For EvaporatorDocumento5 páginasPressure Drop Calculation For EvaporatorCaleb FalcoteloAinda não há avaliações

- Cantilever Beam ReportDocumento5 páginasCantilever Beam ReportJoseph TuzonAinda não há avaliações

- Ausa C 250 X x4 Parts Manual Katalog DelovaDocumento20 páginasAusa C 250 X x4 Parts Manual Katalog Delovawilliam100% (48)

- HTFF350AW Service ManualDocumento24 páginasHTFF350AW Service ManualUEEAinda não há avaliações

- Caseres VentiDocumento3 páginasCaseres VentiVan Eldridge Kyle CaseresAinda não há avaliações

- RVK Energy LTD: Sheet 1 of 6Documento6 páginasRVK Energy LTD: Sheet 1 of 6lightsonsAinda não há avaliações

- Design - Portal Beam, Column & Footing FinalDocumento8 páginasDesign - Portal Beam, Column & Footing FinalLiving LifeAinda não há avaliações

- Ausa C 400 X x4 Parts Manual Katalog DelovaDocumento10 páginasAusa C 400 X x4 Parts Manual Katalog Delovadarryl100% (50)

- Canal Hydraulics DesignDocumento1.541 páginasCanal Hydraulics DesignSamarakoon Banda100% (2)

- Machine Design FormulasDocumento8 páginasMachine Design FormulasHarpreet Randhawa100% (1)

- Tabs and PicsDocumento44 páginasTabs and PicsShealtiel Regine Cinco-AyalaAinda não há avaliações

- Elliptical Head Design ToolDocumento1 páginaElliptical Head Design ToolJosé Juan Jiménez AlejandroAinda não há avaliações

- Calculation Note (R.C Work) Automatic WarehouseDocumento8 páginasCalculation Note (R.C Work) Automatic WarehouseUkuy TaryanaAinda não há avaliações

- Tank Sounding Manual (MANUAL-T - 4681251 - 1 - A) - 1Documento143 páginasTank Sounding Manual (MANUAL-T - 4681251 - 1 - A) - 1Hung LeAinda não há avaliações

- Cost Summary For Equipment Installation Work (PKG-1/2/3) : PROJECT: Ruwias Refinery ExpansionDocumento9 páginasCost Summary For Equipment Installation Work (PKG-1/2/3) : PROJECT: Ruwias Refinery ExpansionjnmanivannanmechAinda não há avaliações

- C6 ReportDocumento13 páginasC6 Reportfaizan_abidAinda não há avaliações

- BB 12.h 4030.sounding TableDocumento286 páginasBB 12.h 4030.sounding TableToni ToniAinda não há avaliações

- Parts Manual: Forklifts C 400 H X4Documento117 páginasParts Manual: Forklifts C 400 H X4Miguel ViegasAinda não há avaliações

- Ausa C 350 X x4 Parts Manual Katalog DelovaDocumento124 páginasAusa C 350 X x4 Parts Manual Katalog DelovadobasAinda não há avaliações

- Tailing LugDocumento3 páginasTailing LugSajad AbdulAinda não há avaliações

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocumento8 páginasCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankAinda não há avaliações

- Reboiler 1Documento12 páginasReboiler 1kishna009Ainda não há avaliações

- En 5103 Assignment - 2: Sharan Srinivas V 20155291104Documento16 páginasEn 5103 Assignment - 2: Sharan Srinivas V 20155291104venkieeAinda não há avaliações

- Membranes: A Review of CFD Modelling and Performance Metrics For Osmotic Membrane ProcessesDocumento30 páginasMembranes: A Review of CFD Modelling and Performance Metrics For Osmotic Membrane ProcessesvenkieeAinda não há avaliações

- Computational Study of Water Desalination Using Forward OsmosisDocumento105 páginasComputational Study of Water Desalination Using Forward OsmosisvenkieeAinda não há avaliações

- Application of PID Controller in PV and Energy SystemsDocumento8 páginasApplication of PID Controller in PV and Energy SystemsvenkieeAinda não há avaliações

- The Effect of Working Temperature On The Performance of Water Desalination Using Forward Osmosis - A CFD StudyDocumento9 páginasThe Effect of Working Temperature On The Performance of Water Desalination Using Forward Osmosis - A CFD StudyvenkieeAinda não há avaliações

- 2017 MIT Seawater Property Tables R2a PDFDocumento53 páginas2017 MIT Seawater Property Tables R2a PDFsafar bahariAinda não há avaliações

- Dr.K.P.JAYA: Centre For Research Anna UniversityDocumento1 páginaDr.K.P.JAYA: Centre For Research Anna UniversityvenkieeAinda não há avaliações

- GFRG Design Manual - December 2012Documento168 páginasGFRG Design Manual - December 2012venkieeAinda não há avaliações

- Prastaara: Feasibility Study For The Proposed Warehouse Atmadukkarai, CoimbatoreDocumento1 páginaPrastaara: Feasibility Study For The Proposed Warehouse Atmadukkarai, CoimbatorevenkieeAinda não há avaliações

- Span CE LHDocumento1 páginaSpan CE LHvenkieeAinda não há avaliações

- LA-HPU Transportation & Installation Philosophy: Trip #1 Trip #2 Trip #3Documento8 páginasLA-HPU Transportation & Installation Philosophy: Trip #1 Trip #2 Trip #3venkieeAinda não há avaliações

- Revised Massing As Per STRR - 20201211 - Mayasandra LayoutDocumento1 páginaRevised Massing As Per STRR - 20201211 - Mayasandra LayoutvenkieeAinda não há avaliações

- Fa04 ModelDocumento1 páginaFa04 ModelvenkieeAinda não há avaliações

- Industrial ConstructionDocumento8 páginasIndustrial ConstructionvenkieeAinda não há avaliações

- SHL Unit of World of Span: Call: +91 44 2441 0478, +91 72000 56491Documento5 páginasSHL Unit of World of Span: Call: +91 44 2441 0478, +91 72000 56491venkieeAinda não há avaliações

- Crank Nicolson Method For Solving Parabolic Partial Differential EquationsDocumento17 páginasCrank Nicolson Method For Solving Parabolic Partial Differential EquationsvenkieeAinda não há avaliações

- Rapidwall Installation ManualDocumento157 páginasRapidwall Installation ManualvenkieeAinda não há avaliações

- Worksheet November 21 SolutionsDocumento7 páginasWorksheet November 21 SolutionsSainaath R0% (1)

- Grad A WarehouseDocumento1 páginaGrad A WarehousevenkieeAinda não há avaliações

- Pid Controller: Aishwarya J 2020213026Documento16 páginasPid Controller: Aishwarya J 2020213026venkieeAinda não há avaliações

- Jetty Installation StrategyDocumento48 páginasJetty Installation StrategyvenkieeAinda não há avaliações

- Modeling and Simulation of Forward Osmosis Process Using Agent-Based Model System (Taherian and Mousavi, 2017) PDFDocumento15 páginasModeling and Simulation of Forward Osmosis Process Using Agent-Based Model System (Taherian and Mousavi, 2017) PDFvenkieeAinda não há avaliações

- ENG List of Entry Point ProjectsDocumento11 páginasENG List of Entry Point ProjectsKhoonShihHsienAinda não há avaliações

- MATLABAssignmentDocumento5 páginasMATLABAssignmentvenkieeAinda não há avaliações

- CHDocumento2 páginasCHDebottamSarkarAinda não há avaliações

- Malay - A Guide To The Spoken LanguageDocumento87 páginasMalay - A Guide To The Spoken LanguagevenkieeAinda não há avaliações

- 30 Design of Welded JointsDocumento8 páginas30 Design of Welded JointsPRASAD326Ainda não há avaliações

- Offshore Structural DesignDocumento36 páginasOffshore Structural Designmesserklinge100% (1)

- Grating CatalougesDocumento1 páginaGrating CatalougesvenkieeAinda não há avaliações

- LOC CommunicationDocumento2 páginasLOC CommunicationvenkieeAinda não há avaliações

- Handout Basic Electrical and Electronics AllisonDocumento6 páginasHandout Basic Electrical and Electronics AllisonSRIREKHAAinda não há avaliações

- Survey CE1011Documento34 páginasSurvey CE1011san htet aung100% (3)

- In Gov cbse-SSCMP-221966102021Documento1 páginaIn Gov cbse-SSCMP-221966102021Amod KumarAinda não há avaliações

- Quadratic Equation - MATH IS FUNDocumento8 páginasQuadratic Equation - MATH IS FUNChanchan LebumfacilAinda não há avaliações

- Neraca energiATK-2Documento29 páginasNeraca energiATK-2MauliyaLailaAinda não há avaliações

- Determinants of Profitability Performance: An Analysis of Class I Railroads in The United StatesDocumento18 páginasDeterminants of Profitability Performance: An Analysis of Class I Railroads in The United StatesJayaniAinda não há avaliações

- CMC en Muros de Estabilización (Paper Congreso) )Documento10 páginasCMC en Muros de Estabilización (Paper Congreso) )Agustín CuadradoAinda não há avaliações

- Pega Interview PreperationDocumento35 páginasPega Interview PreperationPramodh SSAinda não há avaliações

- 16 Kinetics Rigid BodiesDocumento30 páginas16 Kinetics Rigid BodiesNkoshiEpaphrasShoopalaAinda não há avaliações

- C & Embedded QuestionsDocumento109 páginasC & Embedded QuestionskalkikaliAinda não há avaliações

- PIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1Documento17 páginasPIA B2 - Module 2 (PHYSICS) SubModule 2.1 (Matter) Final1samarrana1234679Ainda não há avaliações

- 2d VIV PDFDocumento11 páginas2d VIV PDFRaghavAinda não há avaliações

- Notes: Edited by William AdkinsDocumento6 páginasNotes: Edited by William Adkinsjorge mario durango petroAinda não há avaliações

- FREE EthnicKnittingBookPattern HeadbandDocumento4 páginasFREE EthnicKnittingBookPattern HeadbandriyuuhiAinda não há avaliações

- Exercises 5Documento1 páginaExercises 5Jonathhan RecaldeAinda não há avaliações

- Coding Bobol ExcelDocumento4 páginasCoding Bobol ExcelMuhammad IsmunandarsyahAinda não há avaliações

- LUXEN SERIES 5 182 144cells 530-550w MONOFACIALDocumento2 páginasLUXEN SERIES 5 182 144cells 530-550w MONOFACIALOscar DuduAinda não há avaliações

- ReportDocumento1 páginaReportDrew DacanayAinda não há avaliações

- Project Solar Tracking SystemDocumento29 páginasProject Solar Tracking SystemJacob B Chacko100% (1)

- Calculations QuestionssDocumento42 páginasCalculations QuestionssAlluringcharmsAinda não há avaliações

- Flanges: SI SMEDocumento16 páginasFlanges: SI SMEbalaAinda não há avaliações

- EVADTS - 6-1 - 04 June 2009Documento232 páginasEVADTS - 6-1 - 04 June 2009Carlos TejedaAinda não há avaliações

- Workbook Theory Grade Six SampleDocumento4 páginasWorkbook Theory Grade Six SampleRobert TseAinda não há avaliações

- Control of Concentration in CSTR Using DMC and Conventional Pid Based On Relay Feedback MethodDocumento8 páginasControl of Concentration in CSTR Using DMC and Conventional Pid Based On Relay Feedback MethodSadagopan RajaAinda não há avaliações

- NTSE Stage - 1 Mock Test - 3Documento16 páginasNTSE Stage - 1 Mock Test - 3Apex Institute100% (1)

- Sam W Hoke Torch PatentDocumento5 páginasSam W Hoke Torch PatentRichard.nlAinda não há avaliações

- Physics 01-Introduction and Kinematics (2018) LabDocumento91 páginasPhysics 01-Introduction and Kinematics (2018) LabcedAinda não há avaliações

- Example 1 Strip Method VitalDocumento15 páginasExample 1 Strip Method Vitalbini122150% (2)

- Class and ObjectsDocumento15 páginasClass and ObjectsIwan SaputraAinda não há avaliações

- Fabry PerotDocumento11 páginasFabry PerotG. P HrishikeshAinda não há avaliações