Escolar Documentos

Profissional Documentos

Cultura Documentos

Cebex 100: Plasticised Expanding Grout Admixture

Enviado por

DEBASISTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cebex 100: Plasticised Expanding Grout Admixture

Enviado por

DEBASISDireitos autorais:

Formatos disponíveis

Cebex 100 constructive solutions

Plasticised expanding grout admixture

Uses

Properties

Cebex 100 is an admixture for cementitious grouts where a

Chloride content : Nil as per BS:5075

reduced water/cement ratio and positive expansions are

required. Applications include bed grouting, duct grouting, Compressive : The plasticising action of

non-shrink infilling and jointing. strength Cebex 100 allows

reduction of the water

Advantages cement ratios of

cementitious grouts whilst

Gaseous expansion system compensates for plastic

maintaining flow properties.

shrinkage and settlement in properly designed

This gives improvement in

cementitious grout.

strength and long term

Reduced water/cement ratio mixes in the grout mix ensures durability when cured under

low permeability and long term durability in service. restraint.

Gives grout high fluidity with low water/cement ratio, thus

Setting Times : Cebex 100 does not

making placement or injection of the grout easy.

significantly alter the setting

No metallic iron content to corrode and cause staining or

times of cement based

deterioration due to rust expansion in the grout.

grouts.

Composition allows high early strength development in

grouts, without the use of chlorides. Expansion : The controlled positive

Characteristics expansion in unset grouts

Standards compliance incorporating Cebex 100

overcomes plastic

Cebex 100 is a suitable pressure grouting admixture settlement when measured

complying with BS: 8110 Part 1-1985, Section 8.9.4.6. in accordance with ASTM

C827. An unrestrained

Description expansion of up to 4% is

typical.

Cebex 100, a plasticised expanding grout admixture is

supplied as a powder. The material is a combination of a Time for expansion : 15 mintues - 2 hours.

plasticising agent and a gas producing expansion medium. Temperatures above 200C

The plastisicing agent allows the use of a reduced water/ may slightly reduce these

cement ratio with consequent increased strengths and times.

durability. The expansive medium counteracts the natural

Compatibility : Cebex 100 is

settlement and plastic shrinkage of the grout and aids stability

compatible with all types of

and cohesion.

portland cement. Cebex 100

Technical support may be used in mixes

containing certain other

Fosroc admixtures. Fosroc

Fosroc offers a comprehensive range of high performance,

shall be contacted for further

high quality concrete repair and construction products. In

information.

addition, Fosroc offers technical support service to specifiers,

end-users and contractors, as well as on-site technical

assistance in locations all over the country.

Cebex 100

Cebex 100

Specification clauses Application

It shall be ensured that areas to be grouted are clean, sound,

Performance specification

and then pre-wetted. The unrestrained surface area of the

All grouting (specify details and areas of application) must be grout must be kept to a minimum. The grout shall be placed

carried out with a cement based grout incorporating a within 20 minutes of mixing to gain the full benefit of the

plasticised, expanding powder admixture. The grout admixture expansion process. Usual placing or pumping procedures

must be iron-free and chloride-free and shall be added to the shall be adopted ensuring a continuous operation.

cement grout in the proportion of 225g per 50kg of cement. Curing

The grout admixture shall provide an expansion of up to 4% in

the plastic grout, by means of a gaseous system. The grout On completion of the grouting operation, any exposed areas

admixture must be stored, handled and mixed strictly in which are not to be cut back should be thoroughly cured by

accordance with the manufacturer's instructions. means of water application, concure* curing membrane or

wet hessian.

Supplier specification

Cleaning

All grouting (specify details and areas of application) must be

carried out using a cement based grout, incorporating Cebex Grouts mixed with Cebex 100 should be removed from tools

100 manufactured by Fosroc and applied strictly in accordance and equipment with clean water immediately after use. Cured

with the manufacturer's technical datasheet. material should be removed mechanically or with Reebaklens,

multi purpose cleaning agent.

Application instructions

Limitations

Mixing

Cebex 100 is incompatible with High Alumina Cement.

For best results a mechanically powered grout mixer must be

used. For quantities upto 50kg, a slow speed drill fitted with a Estimating

hig shear paddle is suitable. Large quantities will require a

high volume drum mixer. It is essential that machine mixing Packaging

capacity and labour availability is adequate to enable the

grouting operation to be carried out continuously. This may Cebex 100 is supplied in 225 g packs.

require the use of a holding tank with provision for gentle Dosage

agitation to maintain fluidity. The selected water content should

be accurately measured into the mixer. The cement (and sand OPC Concreting Water Cebex Approx.

if required) shall be slowly added to Cebex 100. Mixing shall Sand 100 Yield

be continued for 5 minutes, making sure that a smooth even

50kg - 20-22 litres 225 g 36 litres

consistency is obtained.

50kg 50 kg 22-24 litres 225 g 57 litres

Note : For grout, mortar or concrete mixes with an aggregate/

cement ratio more than 1, 4 x 225 g units of Cebex 100 per

100 kg of cement, shall be used.

Cebex 100

Effects of overdosing Additional information

Drastic overdosing of Cebex 100 increases expansion and

Fosroc manufactures a wide range of products specifically

may cause frothing.

designed for the repair and refurbishment of damaged

Storage reinforced concrete. This includes repair mortars, fluid

microconcretes, chemical resistant epoxy mortars in addition

Shelf life to comprehensive package of protective coatings. In addition,

a wide range of complementary products are available. This

Cebex 100 has a shelf life of 6 months if kept in a dry store in includes joint sealants, waterproofing membranes, grouts and

its original packing. High temperature and humidity storage anchors and specialised flooring materials.

may reduce this period.

*Separate data sheets are available on these products.

Precautions

Health and Safety instructions

Cebex 100 is of low hazard.

Contact with the skin and eyes, or inhalation of dust should be

avoided. Suitable protective clothing, gloves eye/face protection

and dust mask should be worn. In case of contact with skin, it

shall be washed with clean water. In case of contact with eyes,

it shall be rinsed immediately with plenty of water and medical

attention shall be sought immediately.

Cebex 100

Denotes the trademark of Fosroc International Limited

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold subject

to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst

Fosroc endeavours to ensure that any advice, recommendation specification or information it may

give is accurate and correct, it cannot, because it has no direct or continuous control over where

or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products whether or not in accordance with any advice, specification, recommendation

Fosroc Chemicals (India) Pvt. Ltd. or information given by it.

Head Office telephone fax e-mail

111/3, Hafeeza Chamber II Floor,

++91 80-22240018/120 ++91 80-22233474 india@fosroc.com

K H Road, PBNo. 2744, Bangalore 560027

www.fosroc.com

Regional Offices

Bangalore Mumbai Delhi Kolkata

Shankar House, IV Floor 208/209, Persepolis First floor,1/2 East Patel Nagar 30/B Jodhpur Park

1 & 18, RMV Extension Sector 17, Vashi Opp: Vivek Cinema, Main Patel Rd Ground Floor

Bangalore 560 080 Navi Mumbai 400 703 New Delhi 110 008 Kolkata 700 068

Ph:080-2361 3161/2361 2004 Ph:022-2789 6412/14 Ph:011-25884903/4 Ph: 033 2472 5482

Fax : 080-2361 7454 Fax: 022 - 2789 6413 Fax: 011- 25884422 Fax: 033-2472 9921

email: Bangalore@fosroc.com email:Mumbai@fosroc.com email:Delhi@fosroc.com email:Kolkata@fosroc.com

Ahmedabad : (079) 26762799 Ankleshwar :(02646) 220704/224687 Bhubaneshwar : (0674) 2521176 Chennai (044) 24899949/24853383

Chandigarh : (0172) 2639360 Cochin : (0484) 2356668 Coimbatore : (0422) 2472966 Goa : (0832) 2542465 Guwahati (0361) 2548793

Hyderabad : (040) 27662324/27662425 Hubli (0836) 3402597 Indore : (0731) 504339/5061477 Jaipur : (0141) 2235349 Lucknow :(0522)

22239044 Nagercoil (04652) 2224849 Mangalore: (0824) 22272234 Visakhapatnam : (0891) 2564850

INDIA/2004/0305/E

Você também pode gostar

- TDS Cebex 100 India PDFDocumento3 páginasTDS Cebex 100 India PDFAnonymous XVEucVMsEAinda não há avaliações

- Cebex 100 BFLDocumento3 páginasCebex 100 BFLpeashAinda não há avaliações

- Cebex 100 PDFDocumento2 páginasCebex 100 PDFAjay sahaniAinda não há avaliações

- TDS Cebex 100 India3Documento3 páginasTDS Cebex 100 India3Kishore Nayak kAinda não há avaliações

- Cebex 100 PDFDocumento2 páginasCebex 100 PDFBijaya RaulaAinda não há avaliações

- Fosroc Cebex 100: Constructive SolutionsDocumento2 páginasFosroc Cebex 100: Constructive SolutionsbhupendraAinda não há avaliações

- Fosroc Cebex 100: Constructive SolutionsDocumento2 páginasFosroc Cebex 100: Constructive SolutionsShruti ShahAinda não há avaliações

- Fosroc Cebex 100: Constructive SolutionsDocumento2 páginasFosroc Cebex 100: Constructive SolutionsGcek AparichitAinda não há avaliações

- Cebex 100Documento2 páginasCebex 100Suraj shindeAinda não há avaliações

- TDS Cebex100 Saudi ArabiaDocumento2 páginasTDS Cebex100 Saudi ArabiaSabyasachi BangalAinda não há avaliações

- Cebex 100 UAEgjhgDocumento2 páginasCebex 100 UAEgjhgSushil RajakAinda não há avaliações

- Fosroc Cebex 100 0811 PDFDocumento2 páginasFosroc Cebex 100 0811 PDFghaghra bridgeAinda não há avaliações

- Cebex 100Documento3 páginasCebex 100herwin hanafiahAinda não há avaliações

- Cebex 100 grout expands and strengthens construction jointsDocumento2 páginasCebex 100 grout expands and strengthens construction jointsmathi vijayAinda não há avaliações

- HK Cebex 100Documento4 páginasHK Cebex 100batman12hkAinda não há avaliações

- Cebex 200Documento2 páginasCebex 200reshmitapallaAinda não há avaliações

- TDS Cebex 200 India2 PDFDocumento2 páginasTDS Cebex 200 India2 PDFKamal KumarAinda não há avaliações

- Cebex 200Documento2 páginasCebex 200Anonymous XVEucVMsEAinda não há avaliações

- Cebex 112Documento2 páginasCebex 112mohab hakimAinda não há avaliações

- Non-shrink cement grout admixtureDocumento2 páginasNon-shrink cement grout admixturetalatzahoorAinda não há avaliações

- Cebex 311 PDFDocumento4 páginasCebex 311 PDFSriraamAinda não há avaliações

- Cebex 100 Non-Shrink Grout AdmixtureDocumento19 páginasCebex 100 Non-Shrink Grout AdmixturePutu Roby Adhitya Sapanca100% (1)

- Cebex 305: Retarding Admixture For MortarDocumento4 páginasCebex 305: Retarding Admixture For MortartrickyggAinda não há avaliações

- Fosroc Cebex 100 0811Documento2 páginasFosroc Cebex 100 0811kannankrivAinda não há avaliações

- Cebex 100Documento2 páginasCebex 100manil_5Ainda não há avaliações

- Waterproof Mortar AdmixtureDocumento4 páginasWaterproof Mortar AdmixtureMoatz HamedAinda não há avaliações

- Cebex 305: Retarding Admixture For Mortar Uses Technical SupportDocumento4 páginasCebex 305: Retarding Admixture For Mortar Uses Technical SupportSyed HassaanAinda não há avaliações

- CEBEX100Documento2 páginasCEBEX100Tori SmallAinda não há avaliações

- CEBEX112Documento2 páginasCEBEX112reshmitapallaAinda não há avaliações

- Underwater Concrete Technologies in Marine ConstructionDocumento5 páginasUnderwater Concrete Technologies in Marine ConstructionHoney SinghAinda não há avaliações

- Cebex 100Documento2 páginasCebex 100Riyan Aditya NugrohoAinda não há avaliações

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocumento2 páginasConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsRaghavendra GaAinda não há avaliações

- Improvements in GroutingDocumento4 páginasImprovements in Groutingrahuldevpatel5Ainda não há avaliações

- Cebex 100Documento2 páginasCebex 100didonkimurayahooAinda não há avaliações

- Conplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsDocumento2 páginasConplast WL Xtra: Integral Waterproofi NG Liquid Admixture For Concrete, Plaster and MortarsPrasantaAinda não há avaliações

- Pressure GroutingDocumento1 páginaPressure GroutingKiran Kumar JhaAinda não há avaliações

- Cebex 100 PDFDocumento4 páginasCebex 100 PDFAnonymous IwqK1NlAinda não há avaliações

- Chapter - 1 1.1 General TheoryDocumento44 páginasChapter - 1 1.1 General TheoryVenkat Deepak SarmaAinda não há avaliações

- Cebex 112 PDFDocumento2 páginasCebex 112 PDFGururaj P KundapurAinda não há avaliações

- Auramix 200 High Performance Concrete AdmixtureDocumento2 páginasAuramix 200 High Performance Concrete AdmixtureRituraj RAinda não há avaliações

- CerachemDocumento2 páginasCerachemKapilAinda não há avaliações

- HAJIMOHAMMADI Et Al 2018Documento8 páginasHAJIMOHAMMADI Et Al 2018Lucas Yagor GrenzelAinda não há avaliações

- Sika Viscocrete - 3005.pt - enDocumento3 páginasSika Viscocrete - 3005.pt - enallanAinda não há avaliações

- Cebex Cable Grout PlusDocumento13 páginasCebex Cable Grout PlustalatzahoorAinda não há avaliações

- Fosroc Cebex Cable Grout Plus: Constructive SolutionsDocumento4 páginasFosroc Cebex Cable Grout Plus: Constructive SolutionsVincent JavateAinda não há avaliações

- ArticledesignandconstructionofliquidtightconcretestrucDocumento3 páginasArticledesignandconstructionofliquidtightconcretestrucalbertoxinaAinda não há avaliações

- Pagel-Joint Seal 100: Polymeric Water Swellable Water Bar For JointsDocumento2 páginasPagel-Joint Seal 100: Polymeric Water Swellable Water Bar For JointsZaid AhmedAinda não há avaliações

- Delvo Stabiliser: Cement Hydration Control AdmixtureDocumento2 páginasDelvo Stabiliser: Cement Hydration Control AdmixtureDoby YuniardiAinda não há avaliações

- 05 - TDS - Flowcable50Documento3 páginas05 - TDS - Flowcable50Alexi ALfred H. TagoAinda não há avaliações

- ADVA_SBR_TDSDocumento2 páginasADVA_SBR_TDSMohammed AbugharbiehAinda não há avaliações

- Concrete Technology in Focus: Efflorescence GuidelinesDocumento2 páginasConcrete Technology in Focus: Efflorescence GuidelinesnatabegaAinda não há avaliações

- Cebex 112: Mortar PlasticiserDocumento2 páginasCebex 112: Mortar PlasticiserBalasubramanian AnanthAinda não há avaliações

- Presentation On Self Healing Bendable ConcreteDocumento32 páginasPresentation On Self Healing Bendable ConcreteAJEET SINGHAinda não há avaliações

- Non-shrink underwater groutDocumento4 páginasNon-shrink underwater grouttin aungtunAinda não há avaliações

- Super Plasticizer For High Strength ConcreteDocumento2 páginasSuper Plasticizer For High Strength Concretedachepalli963Ainda não há avaliações

- ADVABOND_SBR_TDSDocumento2 páginasADVABOND_SBR_TDSMohammed AbugharbiehAinda não há avaliações

- MSDS-002 Sureflow 100Documento45 páginasMSDS-002 Sureflow 100joker batmanAinda não há avaliações

- Reebol PDFDocumento2 páginasReebol PDFBhupendra Singh RajputAinda não há avaliações

- Perfect MenardDocumento16 páginasPerfect MenardJuan Carlos Coronado FararoniAinda não há avaliações

- Ec7 WallapDocumento18 páginasEc7 WallapDEBASISAinda não há avaliações

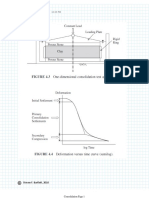

- Chapter 12. Analysis of Consolidation Under EmbankmentDocumento9 páginasChapter 12. Analysis of Consolidation Under EmbankmentDEBASISAinda não há avaliações

- A D P P S: Face Support CalculationDocumento25 páginasA D P P S: Face Support CalculationDEBASIS100% (1)

- Astmd4719 87Documento8 páginasAstmd4719 87DEBASISAinda não há avaliações

- Calculation of Face PressureDocumento2 páginasCalculation of Face PressureDEBASISAinda não há avaliações

- TJ (April-May 17)Documento100 páginasTJ (April-May 17)DEBASIS100% (1)

- TJ Oct-Nov'17Documento82 páginasTJ Oct-Nov'17DEBASISAinda não há avaliações

- TJ (June-July 17)Documento72 páginasTJ (June-July 17)DEBASISAinda não há avaliações

- Skempton - Standard Penetration Test Procedures and Effects in Sands of Overburden, Relative Density, Ageing and OverconsolidationDocumento23 páginasSkempton - Standard Penetration Test Procedures and Effects in Sands of Overburden, Relative Density, Ageing and OverconsolidationDEBASIS100% (3)

- EPB ConditioningDocumento7 páginasEPB ConditioningDEBASISAinda não há avaliações

- Is 2131 1981 PDFDocumento15 páginasIs 2131 1981 PDFparvezAinda não há avaliações

- 0002 T SettlementimpactDocumento161 páginas0002 T SettlementimpactDEBASIS100% (1)

- Design of Segmental Lining in EQ ZoneDocumento11 páginasDesign of Segmental Lining in EQ ZoneDEBASISAinda não há avaliações

- Design of Segmental Lining in EQ ZoneDocumento11 páginasDesign of Segmental Lining in EQ ZoneDEBASISAinda não há avaliações

- Bored Tunnel Lining Design in Soft Soils - Analytical vs NumericalDocumento7 páginasBored Tunnel Lining Design in Soft Soils - Analytical vs NumericalDEBASISAinda não há avaliações

- Sprayed WaterproofingDocumento3 páginasSprayed WaterproofingDEBASISAinda não há avaliações

- An Innovative Method For Calculating Tunneling Induced SettlementDocumento129 páginasAn Innovative Method For Calculating Tunneling Induced SettlementDEBASISAinda não há avaliações

- DETERMINATION OF LOADS SAFETY REQUIREMENTS IN ALL STAGES OF CONSTRUCTIONDocumento1 páginaDETERMINATION OF LOADS SAFETY REQUIREMENTS IN ALL STAGES OF CONSTRUCTIONDEBASISAinda não há avaliações

- Sprayed WaterproofingDocumento3 páginasSprayed WaterproofingDEBASISAinda não há avaliações

- Menard Pressuremeter TestDocumento60 páginasMenard Pressuremeter TestDEBASIS100% (2)

- Wong (1984) Stability of Slurry TrenchesDocumento14 páginasWong (1984) Stability of Slurry TrenchesDEBASISAinda não há avaliações

- DETERMINATION OF LOADS SAFETY REQUIREMENTS IN ALL STAGES OF CONSTRUCTIONDocumento1 páginaDETERMINATION OF LOADS SAFETY REQUIREMENTS IN ALL STAGES OF CONSTRUCTIONDEBASISAinda não há avaliações

- ConsolidationDocumento20 páginasConsolidationDEBASISAinda não há avaliações

- Stocks RecommendationsDocumento7 páginasStocks RecommendationsDEBASISAinda não há avaliações

- Best Mutual Funds To Invest in 2017Documento4 páginasBest Mutual Funds To Invest in 2017DEBASISAinda não há avaliações

- BS NA en 1992-1-1 - UK National Annex To Eurocode 2. Design of Concrete StructuresDocumento26 páginasBS NA en 1992-1-1 - UK National Annex To Eurocode 2. Design of Concrete StructuresDEBASISAinda não há avaliações

- 150706-Engage - SPT N Vs PMT - FinalDocumento53 páginas150706-Engage - SPT N Vs PMT - FinalDEBASISAinda não há avaliações

- Wong (1984) Stability of Slurry TrenchesDocumento14 páginasWong (1984) Stability of Slurry TrenchesDEBASISAinda não há avaliações

- Anode Pads InstalationDocumento2 páginasAnode Pads InstalationNebu MathewAinda não há avaliações

- 8-En 5850-A - Stack Valves Cetop 07Documento7 páginas8-En 5850-A - Stack Valves Cetop 07abuzer1981Ainda não há avaliações

- Precast Culvert DrawingDocumento5 páginasPrecast Culvert Drawingraahul_nAinda não há avaliações

- Background: The Duct Tape BookDocumento5 páginasBackground: The Duct Tape BookCloudine IzonAinda não há avaliações

- Ae6401 AerodynamicsDocumento2 páginasAe6401 AerodynamicsShankar NayakAinda não há avaliações

- Astm F836M-16Documento7 páginasAstm F836M-16arcadioscoAinda não há avaliações

- Manuals PDFDocumento116 páginasManuals PDFhashashashasAinda não há avaliações

- LAI e HO (2012) - Behaviour of Uni Axially Loaded Concrete Filled Steel Tube Columns Confined byDocumento24 páginasLAI e HO (2012) - Behaviour of Uni Axially Loaded Concrete Filled Steel Tube Columns Confined byRenata MartiniAinda não há avaliações

- Unit 15 (DESIGN OF FOUNDATIONS)Documento48 páginasUnit 15 (DESIGN OF FOUNDATIONS)Zara Nabilah100% (31)

- SteelDocumento8 páginasSteelMxoli MbazoAinda não há avaliações

- Altro Fix 15 Data SheetDocumento1 páginaAltro Fix 15 Data SheetFloorkitAinda não há avaliações

- Shoring JackDocumento8 páginasShoring Jackmikeroack_11100% (1)

- JEE Physics AalneDocumento1 páginaJEE Physics AalneJUBIAinda não há avaliações

- Material Finish GuideDocumento7 páginasMaterial Finish GuideRomie CubalAinda não há avaliações

- Axial capacity of circular concrete-filled tube columnsDocumento20 páginasAxial capacity of circular concrete-filled tube columnsMona MahmoudAinda não há avaliações

- Resolve VP ApacDocumento20 páginasResolve VP ApacHoang-Vu BuiAinda não há avaliações

- Plastic BendingDocumento1 páginaPlastic BendingmajmjudAinda não há avaliações

- Contraction JointsDocumento5 páginasContraction JointsbiniamAinda não há avaliações

- 3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsDocumento32 páginas3.0 Stairways, Ramps, Stiles, Walkways, and Platforms: 3.1 Section ContentsBoy AlfredoAinda não há avaliações

- Fatigue FailureDocumento22 páginasFatigue FailureHimanshu YadavAinda não há avaliações

- Lampiran Laporan Survey Lalu LintasDocumento26 páginasLampiran Laporan Survey Lalu LintasSekar BeningAinda não há avaliações

- Research Article in Situ Needle Penetration Test and Its Application in A Sericite Schist Railway Tunnel, Southwest of ChinaDocumento10 páginasResearch Article in Situ Needle Penetration Test and Its Application in A Sericite Schist Railway Tunnel, Southwest of ChinaStefan JovanovicAinda não há avaliações

- Saint Gobain Gyproc Gypwall Classic 2017 03 PDFDocumento10 páginasSaint Gobain Gyproc Gypwall Classic 2017 03 PDFChithranjan Das KotekarAinda não há avaliações

- Lab ManualDocumento10 páginasLab ManualKen MakAinda não há avaliações

- Kirloskar Brothers Limited: A Kirloskar Group Company Established 1888Documento2 páginasKirloskar Brothers Limited: A Kirloskar Group Company Established 1888Mohan CharanchathAinda não há avaliações

- Boq BBTDocumento6 páginasBoq BBTbhavin24uAinda não há avaliações

- Answers To Exam-Style Questions: 8 Deforming SolidsDocumento2 páginasAnswers To Exam-Style Questions: 8 Deforming SolidsANONYMOUS MOOSEAinda não há avaliações

- Cube TestDocumento15 páginasCube TestFAHIEMAH ZAHRA YAAKUBAinda não há avaliações

- IRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Documento100 páginasIRC-78-2014 Standard Specifications and Code of Practice For Road Bridges, Section VII - Foundations and Substructure (Revised Edition)Saroon Afshan76% (29)

- Water Wastewater BrochurelrDocumento7 páginasWater Wastewater Brochurelrlamia97Ainda não há avaliações