Escolar Documentos

Profissional Documentos

Cultura Documentos

Simulation of Multi-Stage Flash (MSF) Desalination Process: Lian-Ying Wu, Sheng-Nan Xiao, Cong-Jie Gao

Enviado por

Abdelrahman AboudTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Simulation of Multi-Stage Flash (MSF) Desalination Process: Lian-Ying Wu, Sheng-Nan Xiao, Cong-Jie Gao

Enviado por

Abdelrahman AboudDireitos autorais:

Formatos disponíveis

Advances in Materials Physics and Chemistry, 2012, 2, 200-205

doi:10.4236/ampc.2012.24B052 Published Online December 2012 (http://www.SciRP.org/journal/ampc)

Simulation of Multi-stage Flash (MSF)

Desalination Process

Lian-ying Wu, Sheng-nan Xiao, Cong-jie Gao

College of Chemistry and Chemical Engineering, Ocean University of China, Shandong, Qingdao 266100, China

Received 2012

ABSTRACT

MSF seawater desalination has become an important technology to solve the scarce of fresh water resources in the world. But the

high energy cost is the bottle-neck of extendibility and application. In this paper, the principle of MSF is analyzed and the single

flash stage is divided into several elementary unit operations. The Aspen Plus is adopted to simulate MSF desalination process. The

effect factor of MSF system, such as the feed seawater temperature, the top brine temperatureTBT and the stage number, is

investigated and the optimum operation condition is obtained.

Keywords: Seawater Desalination; MSF; Process Simulation

1. Introduction ported by brine circulating pump into the condenser of the last

stage flash chamber of the heat recovery section. The recycling

The fresh water resource is one of the most important factors

brine, which flowing along with the opposite direction of the

which constrain the economic development, social progress and

flash brine flow direction, is heated by the flash steam produc-

human survival. Currently, there are more than 100 countries

ing in every flash room, and the flash steam is condensed. The

and regions, in where the fresh water is shortage, about 1.5

heated circulating brine coming out from the condenser tube of

billion people can not get the clean drinking water, 2.0 billion

the first flash chamber is transported into the brine heater and is

people are living without safe water, and the consumption of

further heated to a specified temperature, which is the top brine

water is increasing at a rate of 4% per year [1,2]. China is one

temperature (TBT). And then it flows into the lower level of the

of the countries that the United Nations recognized as the 13

first flash chamber, and the circulating brine begins to progres-

most water-poor countries, per capita fresh water resources is

sively flash along per flash stage. The flashed steam will be

only 1/4 of the world average level, and the temporal and spa-

condensed in the condenser tube, and then it flows into the

tial distribution of freshwater resources is uneven. And the

fresh water tank as product water.

lacking is characteristic with both at resources and water quali-

ty [3-5]. Water scarcity has become a major bottleneck that

constraints the world's sustainable economic development [6]. 3. The Simulation and Analysis of MSF

Desalination has become recognized as an effective measure Desalination Process

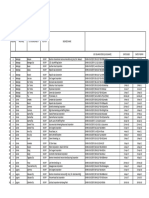

to solve the water shortage [1]. However, high energy con- Performance Ratio (PR) and the rate of brine flow (RBF) are

sumption is one of the major bottlenecks to limit its promotion two important parameters that have a major impact on the in-

and application. Therefore, it is important significance to seek vestment costs and the operating costs of the desalination sys-

methods to reduce the desalination energy consumption. This tems [10]. This paper mainly studies the influence of the feed

paper is trying to use Aspen Plus software to simulate the MSF seawater temperature, TBT and the number of flash stage on

desalination process and analyze the effects of the operating PR and RBF. Then, the expecting optimal operating conditions

parameters to the MSF desalination system. At the same time, of the multi-stage flash desalination system is provided.

the method of reducing energy consumption is provided as

The realization of the MSF process in the Aspen Plus

reference to the design of MSF system.

MSF desalination system is composed of N-level flash units.

Figure 2(a) represents the actual structure of a flash unit; Fig-

2. The Principle of MSF Desalination ure 2(b) shows the structural decomposition of a flash unit. The

The MSF system (shows in Figure 1) consists of three sections: flash unit is split up into four compartments: the pre-heater, the

heat-rejection, heat-recovery and brine heater. The heat-rejec- flash chamber, the fresh water room and the steam room. Then

tion and heat-recovery consist of a number of flash chambers it is very easy to be described with the Aspen Plus. The pre-

(stages) connected to one another. Raw seawater first come into heater in top of the flash chamber could be simulated by the

the heat-recovery section to condense the steam produced in the HETRAN module of the Aspen Plus, the flash chamber could

flash chamber, at the same time it is heated. Most of the water be used FLASH module to be simulated and the fresh water

coming from the heat-rejection section return to the sea, and the room and the steam room could be used MIXER module to be

remaining part will be mixed with part of the brine rejected simulated. After the MSF is be transformed, the single flash

from the last stage of the heat-rejection section; and then trans- unit will be constructed based on the actual logistics connection

Copyright 2012 SciRes. AMPC

L. -Y. WU ET AL. 201

Figure 1. A circulating-brine multistage flash (MSF) desalination plant.

Figure 2. The structure of a single flash stage.

of the stream. Subsequently, connecting the multiple flash units between 20 ~30. When the feed seawater temperature goes

sequential, the simulation of the process of MSF system is beyond to 30, the changed trend of PR becomes to be gently.

achieved in the Aspen Plus. The chart of RBF vs. feed seawater temperature is shown as

Figure 4. The value of RBF almost changed and the line is

4. Analysis of Simulation Results level when the feed seawater temperature is varied from 10

to 20. But it was rapidly increasing when the feed water

4.1. The Influence of Feed Seawater Temperature temperature passed 20.

Here, the heat recovery section and the heat rejection section While the freshwater production, the TBT and the number of

are specified as 18 stages and 3 stages in the MSF system. The flash stage are specified as a constant, the lower of the feed

TBT is set to 110 and the freshwater production is set to seawater temperature, the more of the steam required to heat

100t/h. The difference between feed seawater temperature and the brine to TBT. But when the feed seawater temperature

the rejected brine temperature is 10. The feed seawater tem- beyond to 25, the temperature of circulating brine, which

perature is varied from 10 to 35 with interval of 5.The coming out from the first stage flash pre-heater and being

vary trend of PR and RBF long the feed seawater temperature is heated by the multi-stage pre-heater, slowly changed. And the

obtained. The results are shown in Figure 3, Figure 4. required amount of heating steam tends to change slowly, so

Figure 3 gives the chart of feed seawater temperature vs. PR. the PR became relatively gentle. At the same number of flash

From the chart, the PR of the MSF system showed a gradually stages, the temperature of rejected brine increased when the

rising trend when the feed seawater temperature is increased. feed seawater temperature is increased. Because the tempera-

The PR of MSF system did not change significantly and over ture difference of between the feed seawater and the rejected

the range of 10 ~ 20, but it was approximately straight up brine is set to 10. However, the TBT is keep as an unvaried

Copyright 2012 SciRes. AMPC

202 L. -Y. WU ET AL.

v a l u e , 4.2. The Influence of TBT

therefore the total difference in temperature and the stage tem-

Here, the heat recovery section and the heat rejection section

perature difference will be reduced simultaneously. Conse-

are specified as 18 stages and 3 stages respectively in the MSF

quently, the producing fresh water of per unit flash stage will be system. The freshwater production is set to 100t/h. The feed

decreased. In order to produce the same quantity of fresh water, water temperature is set to 25 and the temperature of re-

the amount of circulating brine must be increased. Increasing jected brine temperature is set to 35. The TBT is varied from

the amount of circulating brine flowrate will make huge oper- 80 to 120 with interval of 10. The simulation results

ating costs. Summarizing, the appropriate feed seawater tem- are shown in Figure 5 and Figure 6.

perature is about 25.

11

10

9

PR

10 15 20 25 30 35

sea water temperature/

Figure 3. Effect of feed seawater temperature on the PR.

840000

820000

800000

RBF/(kg/h)

780000

760000

740000

720000

10 15 20 25 30 35

sea water temperature/

Copyright 2012 SciRes. AMPC

L. -Y. WU ET AL. 203

Figure 4. Effect of feed seawater temperature on the RBF.

12.0

11.5

11.0

10.5

PR

10.0

9.5

9.0

80 90 100 110 120

TBT/

Figure 5. Effect of top brine temperature on the PR.

1200000

1100000

1000000

RBF/(kg/h)

900000

800000

700000

600000

80 90 100 110 120

TBT/

Figure 6. Effect of top brine temperature on the RBF.

Figure 5 and Figure 6 give a PR chart of MSF and the RBF increased due to the producing fresh water quantity of single

chart of MSF respectively when the TBT is changed. From stage increased. So the RBF of MSF would be decreased to

Figures 5 and 6, the PR increased firstly and where-after de- guarantee the total production of fresh water to constant. On the

creased step by step with the TBT is increased. And the maxi- other hand, though the required amount of steam heating will

mum value of PR is obtained at 90. But the RBF chart of be large on account of hoisting the TBT. But the RBF was re-

MSF showed decreasing trend, and the reduced trend is wea- duced more obviously at the range of 80 ~ 90, so the result is

kened gradually while the TBT is increased. As the temperature that the PR increased rapidly and the required amount of steam

of rejected brine is constant, the total flash temperature differ- heating reduced markedly. While the TBT is higher than 90, the

ence of system and the flash temperature difference of per stage amount of increasing heat steam took the more important role

were increased after the TBT is increased. With the same num- in influence of PR than the amount of reducing RBF. Accor-

ber of flash stage, the total amount of fresh water would be dingly, the PR diminished when the TBT is higher than 90.

Copyright 2012 SciRes. AMPC

204 L. -Y. WU ET AL.

Therefore, considering the performance ratio and operating ence in temperature of single stage was decreasing when the

costs, the TBT of MSF system should be between 90 ~ 110 number of flash stage was increased. Therefore the flashing of

appropriate. brine would be more close to the reversible process, and the

energy loss would be reduced. At the same time, the brine

4.3. The Influence of Flash Stage Number pre-heater could recovery more heat and the required quantity

of heating steam could be cut down. Consequently, the PR

In this section, the PR and the RBF influenced by the flash should be increased. On the other hand, the closer the brine

stage number will be discussed. The given as fellow: the TBT evaporation process to the reversible process, the more the fresh

is 110, feed water temperature is 25, the temperature of water produced in an single-stage evaporation unit. To holding

discharged brine is 35 and the fresh water production is the same fresh water production, the number of flash stage is

100t/h in the MSF system. The results are depicted in Figure 7 bigger and the required amount of the circulating brine is little.

and Figure 8. But the more stage number, the equipment will become more

When the flash stage number is increased, the PR increased complexity and the investment costs will be higher. Consider-

gradually, and the more the stage number is, the greater the PR ing the investment costs and operating costs, the number of

is achieved. By contraries, the amount of the circulating brine flash stage should be more reasonable for the 20-25 level.

showed a decreasing trend.

As the same total difference in temperature is fixed, the differ-

16

15

14

13

12

PR

11

10

8

18 20 22 24 26 28 30

stage number

Figure 7. Effect of flash stage number on the PR.

Copyright 2012 SciRes. AMPC

L. -Y. WU ET AL. 205

770000

765000

760000

RBF/(kg/h)

755000

750000

745000

18 20 22 24 26 28 30

stage number

Figure 8. Effect of flash stage number on RBF.

5. Conclusions REFERENCES

In this paper, multi-stage flash desalination technology is ana- [1] Wang Junhong, Gao Naiyun. Development and application of

lyzed. The single flash unit is divided into several basic opera- seawater desalination[J]. Industrial Water Treatment, 2009, 28(5)

tions, and the Aspen Plus software is used to simulate the mul- [2] Bai Yuhui, Yan Zhengyuan. Summary of desalination technolo-

ti-stage flash desalination process. Several influenced factor of gy. Shandong Water Conservancy College. 1995.

the MSF system are discussed, such as the feed sea water tem- [3] Cai Xiaojun, Zhou Shaoxiang. Low-temperature multi-effect

perature, the TBT and the number of flash stage. The results desalination plant system analysis. North China Electric Power

University, 2009.

shown: when the fresh water production, the TBT and the

number of flash stage are fixed, the lower the feed water tem- [4] Jie Lixin, Ruan Guoling. Status and Prospect of reverse osmosis

desalination technology. China Water & Wastewater. 2000,

perature, the greater the amount of required external heating

16(3):24-27.

steam, the smaller the PR and the greater the amount of circu-

[5] Lin Siqing. Seawater reverse osmosis desalination technology

lating brine. Similarly, fasting the fresh water production, the

abroad, and Future. Water Treatment. 1998, 24(1): 1-6

feed sea water temperature and the number of flash stage, when

[6] Zhou Shaoxiang, Song Zhiping. Multi-stage flash desalination

the top brine temperature was increased, the PR increased at

cogeneration technology, theory and practice. North China Elec-

first and then decreased, but the RBF was gradually reduced; tric Power University.2001.

With the fresh water production, the TBT and the feed sea wa-

[7] Osman A. Hamed, Holayil A. Al-Otaibi. Prospects of operation

ter temperature constantly, the PR was increased gradually and of MSF desalination plants at high TBT and low antiscalant dos-

the RBF was reduced gradually when the flash stage number ing rate. ScienceDirect, Desalination 256 (2010) 181~189

was increasing. Synthetically, the best operating conditions of [8] Hittman Assciates,Inc.,OSW Res.Devel.Prog.Rep.,No.490,1969

the MSF system should be selected as follows: feed water tem-

[9] Wang Shichang, Seawater desalination project. Beijing: Chemi-

perature is 25, the TBT is 90 ~ 110, and the number of cal Industry Press. 2003: 8-29

flash stage is 20~ 25.

[10] Gao Congjie, Cheng Guohua. Desalination Technology and

Engineering Handbook. Beijing: Chemical Industry Press, 2004:

6. Acknowledgements 5-90

[11] Khawla AbdulMohsen Al-Shayji.Modeling,simulation,and opti-

This work was financially supported by National Natural

mization of large-scale commercial desalination plants, the Vir-

Science Foundation of China (20976173&21076202). ginia Polytechnic Institute and State University, April, 17, 1998.

Copyright 2012 SciRes. AMPC

Você também pode gostar

- Membrane Processes For Desalination: Overview: June 2012Documento38 páginasMembrane Processes For Desalination: Overview: June 2012Santi StgoAinda não há avaliações

- Desalination EngineeringDocumento8 páginasDesalination EngineeringShafayet A SiddiqueAinda não há avaliações

- Performance of RO Units at High TemperaturesDocumento10 páginasPerformance of RO Units at High TemperaturesRoy JudeAinda não há avaliações

- On The Brine Re-UtilizationDocumento14 páginasOn The Brine Re-UtilizationIbrahim Al-MutazAinda não há avaliações

- Steady-State Analysis of The Multiple Effect Evaporation Desalination ProcessDocumento15 páginasSteady-State Analysis of The Multiple Effect Evaporation Desalination ProcessRitheesh KakitaAinda não há avaliações

- Recirculation Process of Demineralization Water Treatment Plant To Reduce Conductivity Level of WaterDocumento8 páginasRecirculation Process of Demineralization Water Treatment Plant To Reduce Conductivity Level of WaterGulfam ShahzadAinda não há avaliações

- ManualDocumento65 páginasManualAtul GargAinda não há avaliações

- Seawater Desalination Power ConsumptionDocumento17 páginasSeawater Desalination Power ConsumptionPulkit GururaniAinda não há avaliações

- Water DesalinationDocumento19 páginasWater Desalinationravi_patidar_6Ainda não há avaliações

- Deep 4 ProcessDocumento1 páginaDeep 4 ProcessGeorge ChedraouiAinda não há avaliações

- Desalination RO DecouplingDocumento6 páginasDesalination RO DecouplingKevinXavierAinda não há avaliações

- Interfacial Mass Transfer vs. Formulation in Multiple Phase Anionic Surfactant-Oil-Water SystemsDocumento5 páginasInterfacial Mass Transfer vs. Formulation in Multiple Phase Anionic Surfactant-Oil-Water SystemsSahand NekoeianAinda não há avaliações

- 19 Water Desalination 6-1Documento20 páginas19 Water Desalination 6-1Omar AhmedAinda não há avaliações

- Reverse Osmosis: Common Process Variables in RO Sea Water DesalinationDocumento3 páginasReverse Osmosis: Common Process Variables in RO Sea Water DesalinationIswahyudi MertosonoAinda não há avaliações

- Environmental Engineering Assignment ON Desalination of WaterDocumento17 páginasEnvironmental Engineering Assignment ON Desalination of WaterAditya JalanAinda não há avaliações

- Lab 5 Drinking Water Treatment PDFDocumento10 páginasLab 5 Drinking Water Treatment PDFgagileAinda não há avaliações

- Sustainable Water Desalination Bahrain 2017Documento31 páginasSustainable Water Desalination Bahrain 2017Karruppusamy ChellaiahAinda não há avaliações

- Summary of A Conceptual Design of Low Fouling and High Recovery FO-MSFDocumento1 páginaSummary of A Conceptual Design of Low Fouling and High Recovery FO-MSFFaisal MumtazAinda não há avaliações

- Water DesalinatorDocumento34 páginasWater DesalinatorFour WheelsAinda não há avaliações

- Summary of A Conceptual Design of Low Fouling and High Recovery FO-MSF-DESKTOP-47LO0PODocumento1 páginaSummary of A Conceptual Design of Low Fouling and High Recovery FO-MSF-DESKTOP-47LO0POFaisal MumtazAinda não há avaliações

- Sewage Manual CPEEHO 2Documento314 páginasSewage Manual CPEEHO 2Gokulnath MahalingamAinda não há avaliações

- Pontetial of Energi Ocean ThermalDocumento12 páginasPontetial of Energi Ocean ThermalAbiyani Choirul HudaAinda não há avaliações

- ECO07002FU1Documento10 páginasECO07002FU1Rare Earth LLCAinda não há avaliações

- A49. Ref 42 Del A36Documento6 páginasA49. Ref 42 Del A36KjuiAinda não há avaliações

- Control of Multi-Stage Flash Desalination Plants: A SurveyDocumento11 páginasControl of Multi-Stage Flash Desalination Plants: A SurveyUnta ArabAinda não há avaliações

- Temperature Effect On Peak Width and Column Efficiency in Subcritical Water ChromatographyDocumento6 páginasTemperature Effect On Peak Width and Column Efficiency in Subcritical Water ChromatographyDANNA SOFIA SANCHEZ CAMACHOAinda não há avaliações

- Membrane DistillationDocumento14 páginasMembrane DistillationMuhammad Ali100% (1)

- 2014 EGYPT HDH 1-s2.0-S001191641400109X-mainDocumento11 páginas2014 EGYPT HDH 1-s2.0-S001191641400109X-mainAicha Chorak Franky TissoukiAinda não há avaliações

- Advanced Mechanical Vapor-Compression Desalination System: Jorge R. Lara, Omorinsola Osunsan and Mark T. HoltzappleDocumento20 páginasAdvanced Mechanical Vapor-Compression Desalination System: Jorge R. Lara, Omorinsola Osunsan and Mark T. Holtzappleayman jummaAinda não há avaliações

- Comparison of Dissolved Air Flotation and Sedimentation PDFDocumento5 páginasComparison of Dissolved Air Flotation and Sedimentation PDFPrie TeaAinda não há avaliações

- Training ProgrammeDocumento28 páginasTraining Programmesriramg1Ainda não há avaliações

- 5.life Cycle Assessment of MSF, MED andDocumento12 páginas5.life Cycle Assessment of MSF, MED andluisgonzalezf95Ainda não há avaliações

- Unesco - Eolss Sample Chapters: Some Practical Aspects of Desalination ProcessesDocumento9 páginasUnesco - Eolss Sample Chapters: Some Practical Aspects of Desalination ProcessesSuci FajriatiAinda não há avaliações

- 1500-Article Text-6328-1-10-20180531Documento12 páginas1500-Article Text-6328-1-10-20180531Quentin LeeAinda não há avaliações

- Optimal Design of A Hybrid RO/MSF Desalination System in A non-OPEC CountryDocumento14 páginasOptimal Design of A Hybrid RO/MSF Desalination System in A non-OPEC CountryFadl EssaAinda não há avaliações

- Economic and Technical Analysis of Reverse OsmosisDocumento13 páginasEconomic and Technical Analysis of Reverse OsmosisYoussefAinda não há avaliações

- Performance of Wastewater Treatment During Variable TemperatureDocumento7 páginasPerformance of Wastewater Treatment During Variable TemperatureDiannita CarrolinaAinda não há avaliações

- Solar Energy For Water DesalinationDocumento8 páginasSolar Energy For Water DesalinationJavier Alejandro RodriguezAinda não há avaliações

- Deuterium-Depleted Potable WaterDocumento4 páginasDeuterium-Depleted Potable WaterCodi Betts100% (2)

- Enhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater ManagementDocumento26 páginasEnhanced Solar Evaporation Using A Photo-Thermal Umbrella: Towards Zero Liquid Discharge Wastewater Managementgovinda reddyAinda não há avaliações

- PFR ReactorDocumento19 páginasPFR Reactorkhairi100% (1)

- KAI WANG ET. AL. 201state-Of-The-Art Review On Crystallization Control Technologies For water/LiBr Absorption Heat Pumps1Documento13 páginasKAI WANG ET. AL. 201state-Of-The-Art Review On Crystallization Control Technologies For water/LiBr Absorption Heat Pumps1roshnilkhan_54594071Ainda não há avaliações

- Solar Powered Multi-Stage Flash Distillation: Professional Development For EngineersDocumento8 páginasSolar Powered Multi-Stage Flash Distillation: Professional Development For EngineersAshish RajAinda não há avaliações

- ScienceDocumento8 páginasScienceTanveer RobiulAinda não há avaliações

- Desalination: Shalabh C. Maroo, D. Yogi GoswamiDocumento12 páginasDesalination: Shalabh C. Maroo, D. Yogi Goswamiابانوب جمالAinda não há avaliações

- 10 1016@j Ijheatmasstransfer 2016 09 029Documento10 páginas10 1016@j Ijheatmasstransfer 2016 09 029AnamAinda não há avaliações

- Water Treatment Plant: Case StudiesDocumento16 páginasWater Treatment Plant: Case Studieskesavaganesan58100% (2)

- Desalination: Mongi Ben Ali, Lakhdar KairouaniDocumento13 páginasDesalination: Mongi Ben Ali, Lakhdar KairouaniBir PremierAinda não há avaliações

- Desalination 464 (2019) 1-7Documento7 páginasDesalination 464 (2019) 1-7joeAinda não há avaliações

- Desalination Paper 2013Documento12 páginasDesalination Paper 2013Oliver RogersAinda não há avaliações

- Water Treatment SchemesDocumento26 páginasWater Treatment SchemesCao Xuan CanhAinda não há avaliações

- Multi-Stage Flash Desalination (MSF)Documento16 páginasMulti-Stage Flash Desalination (MSF)Mohamed NaserAinda não há avaliações

- Developments in Thermal Desalination Processes PDFDocumento14 páginasDevelopments in Thermal Desalination Processes PDFG.DAinda não há avaliações

- Sustainable Seawater Desalination by Permeate Gap Membrane Distillation TechnologyDocumento6 páginasSustainable Seawater Desalination by Permeate Gap Membrane Distillation Technologymona aminAinda não há avaliações

- Lenntech: What Is Membrane Performance Normalization?Documento6 páginasLenntech: What Is Membrane Performance Normalization?Manuel Alejandro Echeverry LopezAinda não há avaliações

- Report, 2.11Documento5 páginasReport, 2.11Muhammad TukurAinda não há avaliações

- 200 150 Dama-FakirDocumento14 páginas200 150 Dama-Fakirrosnah chaniagoAinda não há avaliações

- Dynamic Characteristics of A DMFCDocumento6 páginasDynamic Characteristics of A DMFCSofia KeetasoponAinda não há avaliações

- EIA - Energy Consumption by SectorDocumento21 páginasEIA - Energy Consumption by SectorBORJAAinda não há avaliações

- Ritonal: Iv. Learning Phases and Learning Activities I. Introduction (Time Frame: 90 Minutes) PresentationDocumento4 páginasRitonal: Iv. Learning Phases and Learning Activities I. Introduction (Time Frame: 90 Minutes) PresentationGrace cabiliAinda não há avaliações

- Laura Nougues Groundwater Drainage in New OrleansDocumento57 páginasLaura Nougues Groundwater Drainage in New OrleansManjunathAinda não há avaliações

- Res SyllabusDocumento1 páginaRes Syllabusvijay Karan kAinda não há avaliações

- 2059 w11 Ms 2Documento11 páginas2059 w11 Ms 2mstudy123456Ainda não há avaliações

- ESDMDocumento64 páginasESDMJyothis T SAinda não há avaliações

- 4th Generation BiofuelsDocumento5 páginas4th Generation BiofuelsKricel MaqueraAinda não há avaliações

- Evaluation of Secondary Compression of Sands and Silts From CPTUDocumento15 páginasEvaluation of Secondary Compression of Sands and Silts From CPTURameshAinda não há avaliações

- BiodiversityDocumento2 páginasBiodiversityHan ZhangAinda não há avaliações

- Civil Water Resource Management PPT (Lecture 2)Documento19 páginasCivil Water Resource Management PPT (Lecture 2)Kaushik RAinda não há avaliações

- Screeners Test Calendar 2022Documento7 páginasScreeners Test Calendar 2022Manoj Khatana GujjarAinda não há avaliações

- Agricultura RegenerativaDocumento13 páginasAgricultura RegenerativaLaura López ToroAinda não há avaliações

- Forage Working ExamsDocumento10 páginasForage Working ExamstemuwagelijAinda não há avaliações

- TLE6 AGRI. 2nd Quarter TestDocumento3 páginasTLE6 AGRI. 2nd Quarter TestElona Jane CapangpanganAinda não há avaliações

- Mimi ResearchDocumento29 páginasMimi ResearchSamuel AdamuAinda não há avaliações

- 02 Registration List RMMSCD Consolidated LPG Establishments With Valid SCC SepDocumento52 páginas02 Registration List RMMSCD Consolidated LPG Establishments With Valid SCC SepMartin SandersonAinda não há avaliações

- Class 8 Science Chapter 1 Revision NotesDocumento2 páginasClass 8 Science Chapter 1 Revision NotesmallicktahamAinda não há avaliações

- BD MaharashtraDocumento8 páginasBD MaharashtraOMSURYACHANDRANAinda não há avaliações

- 03 Forest Resources - Extent, Changing Nature, Use and Environmental ImplicationsDocumento34 páginas03 Forest Resources - Extent, Changing Nature, Use and Environmental ImplicationsSRO MCCAinda não há avaliações

- Vihowa FormationDocumento2 páginasVihowa FormationMuhammad FawadAinda não há avaliações

- On FloodsDocumento29 páginasOn FloodsharshbathijaAinda não há avaliações

- Bore WellDocumento4 páginasBore WellOm Prakash SinghAinda não há avaliações

- Water Crisis SynopsisDocumento11 páginasWater Crisis SynopsisVikash PeerthyAinda não há avaliações

- Performance Evaluation of A Common Effluent Treatment Plant For Tannery Industries PDFDocumento4 páginasPerformance Evaluation of A Common Effluent Treatment Plant For Tannery Industries PDFJavier Sulivan Paredes MurAinda não há avaliações

- Doris Hiam GalvezDocumento31 páginasDoris Hiam Galvezrichard gutierrezAinda não há avaliações

- Topic Introduction To Chipko Silent Valley Movement and BishnoisDocumento15 páginasTopic Introduction To Chipko Silent Valley Movement and BishnoisHarshal BharatiAinda não há avaliações

- Module 2 (Rocks)Documento8 páginasModule 2 (Rocks)JamesBuensalidoDellavaAinda não há avaliações

- ENVS 1301 Discussion Forum Unit 2 Solution 4 PDFDocumento2 páginasENVS 1301 Discussion Forum Unit 2 Solution 4 PDFKeshav PaudelAinda não há avaliações

- Name of StateDocumento10 páginasName of StatesawshivAinda não há avaliações

- ESCHandbook Chapter3 3.14Documento39 páginasESCHandbook Chapter3 3.14Larry Wayne Sumpter, JrAinda não há avaliações