Escolar Documentos

Profissional Documentos

Cultura Documentos

Ball Milling Specifications Peru

Enviado por

alinoriDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ball Milling Specifications Peru

Enviado por

alinoriDireitos autorais:

Formatos disponíveis

Moly-Cop Peru

Grinding Balls

Technical Specifications

Re-Grind and Ball Milling

Moly-Cop Peru manufactures grinding balls to exacting internal specifications at its two grinding media production facilities in Arequipa and Lima. The

balls are manufactured from high carbon alloy steel bars and then forged into balls. Balls for use in the mineral processing ball milling operations are

designed for maximum abrasion resistance using high carbon content and high hardness levels.

Product Specifications

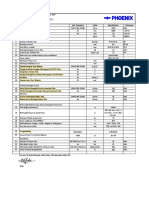

Sizes: Moly-Cop Peru manufactures grinding balls

Chemistry (weight %)

in nominal sizes from 1.0 to 5.0 in diameter.

Balls in the range of 1 to 1.5 in diameter are used Nominal Ball C Mn Si Cr Mo Nominal Ball

primarily in re-grinding applications. Grinding Diameter (inch) Min Max Min Max Min Max Min Max Min Max Weight (gms)

balls in the range of 2.0 to 4.0 in diameter are 1.0 0.75 1.10 0.65 1.15 0.10 0.40 0.00 0.20 0.00 0.20 67

used in ball milling applications.

1.5 0.75 1.10 0.65 1.15 0.10 0.40 0.00 0.20 0.00 0.20 227

Chemistry: An individual chemical profile has been 2.0 0.75 1.10 0.65 1.15 0.10 0.40 0.25 0.65 0.00 0.20 539

developed for each diameter ball to correspond 2.5 0.75 1.10 0.65 1.15 0.10 0.40 0.20 0.80 0.00 0.20 1,052

with the requirements for heat treatment. Specific 3.0 0.75 1.10 0.65 1.15 0.10 0.40 0.20 0.80 0.00 0.20 1,819

alloy additions are included to produce optimum

3.5 0.75 1.10 0.65 1.15 0.10 0.40 0.20 0.80 0.00 0.20 2,888

physical properties. The chemistry of the balls is

controlled through a close collaboration with our 4.0 0.75 1.10 0.65 1.15 0.10 0.40 0.40 0.90 0.00 0.20 4,311

bar suppliers and robust internal quality systems. S = 0.035 Max, P = 0.035 Max

Surface and Volumetric Hardness: Surface and

cross-sectional hardness of the balls depends on Hardness (rockwell C)

the microstructure of the steel which is altered

Nominal Ball Volume Hardness

using carefully selected heat treatment variables

Diameter (inch) Min Max

specifically designed for each particular alloy. An

indication of the quality of the finished product is 1.0 60 65

the hardness range. 1.5 60 65

2.0 60 65

Density: The theoretical apparent packing density

of the balls in a ball charge is 4520 kg/m3. 2.5 60 65

3.0 60 65

Supply and Quality Guarantee 3.5 59 65

4.0 60 65

Long established strategic relationships with

local and foreign raw material suppliers allow us

to ensure all balls supplied to our customers are The above is intended as a guide only. Individual ball hardness readings may fall outside the range listed above.

made from the highest quality products and meet

strict Moly-Cop specifications. This combined

with our global manufacturing network gives our

customers the confidence in the quality of the

product that only Moly-Cop is able to assure.

Packaging Options

Bulk: Balls can be transported in bulk by open top

trucks.

Bags: Balls can be supplied in polypropylene bags

which have secure bag straps to reduce time and

effort in loading and unloading. While bags are

treated to resist UV rays, bags should be protected

from direct sunlight to maximize shelf life.

Drums: Recycled drums can also be supplied.

Drums are more efficient for some modes of

Bulk transported in truck Polypropylene Bags Recycled drums on wooden pallets

transportation and can also be delivered on

wooden pallets.

Moly-Cop S.A. Peru

Moly-Cop Lima Plant Moly-Cop La Joya Plant Updated July 2014

Av. Santa Rosa 110, Santa Anita, Lima - Peru Calle Jacinto Ibanez 131, Parque Industrial, Arequipa - Peru

Tel: +51 (1) 362 7332 / Fax: +51 (1) 362 7332 Tel: +51 (1) 24 18 08

www.molycop.com

Você também pode gostar

- 03mill SlidesDocumento21 páginas03mill SlidesNael El SayyadAinda não há avaliações

- Magotteaux - XLIFT PaperDocumento11 páginasMagotteaux - XLIFT PaperHamed MostafaAinda não há avaliações

- Molycop Symposium - November 2012: Application and Ropemaking Technology Andrew Morgan - Technical Supt Molycop RopesDocumento30 páginasMolycop Symposium - November 2012: Application and Ropemaking Technology Andrew Morgan - Technical Supt Molycop RopesrodrigoAinda não há avaliações

- The Rhodax® Process For Dry Mix Preparation in Anodes PlantsDocumento37 páginasThe Rhodax® Process For Dry Mix Preparation in Anodes PlantsGupta AnacoolzAinda não há avaliações

- Wear Rate Calculator MonoDocumento2 páginasWear Rate Calculator MonoBùi Hắc HảiAinda não há avaliações

- 31 MER VRM Inspections - Rev JSJ 120507Documento45 páginas31 MER VRM Inspections - Rev JSJ 120507Camilo CamposAinda não há avaliações

- 21C MPT Surface Reconditioning For Roller Jackets and Table Plates in Vertical Roller MillsDocumento23 páginas21C MPT Surface Reconditioning For Roller Jackets and Table Plates in Vertical Roller MillsCamilo CamposAinda não há avaliações

- Ball Mills - Guidelines For Sample Amount and Ball ChargeDocumento4 páginasBall Mills - Guidelines For Sample Amount and Ball ChargeAndrejs AndrejsAinda não há avaliações

- Cpb-Sem2011-P11-Axial Sampling and Tromp CurveDocumento54 páginasCpb-Sem2011-P11-Axial Sampling and Tromp Curvechibssa alemayehu100% (1)

- (J-1) Burner TypesDocumento1 página(J-1) Burner Typesgie pradanaAinda não há avaliações

- FLS - Teoría Funcionamiento CF Silo 2Documento9 páginasFLS - Teoría Funcionamiento CF Silo 2Nicolás CanelliAinda não há avaliações

- Inspection Reports On PfistersDocumento12 páginasInspection Reports On PfistersMohammed El rajyAinda não há avaliações

- SeparatorsDocumento6 páginasSeparatorsKADİR durmaz100% (1)

- MBT CalculatorDocumento2 páginasMBT Calculatorsempatik721100% (1)

- Blast Furnace Slag Weathering StudyDocumento8 páginasBlast Furnace Slag Weathering StudyARNALDO BATTAGIN100% (3)

- Transformations E.12Documento36 páginasTransformations E.12Dilnesa EjiguAinda não há avaliações

- Media Charge - Optimal Ball SizeDocumento6 páginasMedia Charge - Optimal Ball SizeMetalurgia ProcesosAinda não há avaliações

- EN - VRM For Raw Material - 320 TPHDocumento24 páginasEN - VRM For Raw Material - 320 TPHneroc69581Ainda não há avaliações

- Helical Gearbox InstallationDocumento8 páginasHelical Gearbox InstallationKUNALJAYAinda não há avaliações

- Ball Mill Inspection - Chap 2Documento5 páginasBall Mill Inspection - Chap 2Min MCLAinda não há avaliações

- AFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Documento1 páginaAFR Fact Sheet: Fly Ash AFR Co-Processed Volume ('000 T)Safrin SangiaAinda não há avaliações

- Ball Mill Internals: GRINDING I - Training SessionDocumento31 páginasBall Mill Internals: GRINDING I - Training SessionFran jimenezAinda não há avaliações

- Pacific Booker - Morrison HPGR Polycom Test ReportDocumento20 páginasPacific Booker - Morrison HPGR Polycom Test ReportMeghshyam Karkera100% (1)

- Reverse Air Bag House - BrochureDocumento4 páginasReverse Air Bag House - BrochureZahir Khira100% (1)

- 06 - XRD - FreelimeDocumento20 páginas06 - XRD - FreelimeNihar Ranjan TripathyAinda não há avaliações

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocumento2 páginasBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyAinda não há avaliações

- Ball Mill Inspection - Chap 1Documento6 páginasBall Mill Inspection - Chap 1Min MCLAinda não há avaliações

- VRM Fan ..Documento2 páginasVRM Fan ..harikrushnaAinda não há avaliações

- Pyro & Cooler Heat & Mass Balance Ed1Documento2 páginasPyro & Cooler Heat & Mass Balance Ed1JCSAinda não há avaliações

- Soft Pyrojet Butrner - P-13-0052 PDFDocumento160 páginasSoft Pyrojet Butrner - P-13-0052 PDFSankuparlang ShullaiAinda não há avaliações

- Section Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessDocumento27 páginasSection Clinker Et Broyage Ciment: Contrat 119 Mecanique ProcessYhaneAinda não há avaliações

- Optimization of A Fully Air Swept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With The Aid PDFDocumento10 páginasOptimization of A Fully Air Swept Dry Grinding Cement Raw Meal Ball Mill Closed Circuit Capacity With The Aid PDFJunaid MazharAinda não há avaliações

- Training CERROWAL: Operation and Maintenance of The POLYCOM High Pressure Grinding RollDocumento17 páginasTraining CERROWAL: Operation and Maintenance of The POLYCOM High Pressure Grinding RollManuel Peralta BeltranAinda não há avaliações

- Department of Chemical EngineeringDocumento19 páginasDepartment of Chemical EngineeringPandia RajanAinda não há avaliações

- 2.4 Solid Fuel Handling SystemDocumento29 páginas2.4 Solid Fuel Handling SystemNind's Chef100% (1)

- Portland Cement Clinker - LafargeDocumento10 páginasPortland Cement Clinker - Lafargeمهندس فهمي عبدالعزيزAinda não há avaliações

- 2022-04-08 - HPGR Adantages in Ore GrindingDocumento24 páginas2022-04-08 - HPGR Adantages in Ore Grindingpanchada.srinivasuAinda não há avaliações

- Lafarge Ravena Modernization FEISDocumento97 páginasLafarge Ravena Modernization FEISLafargeRavenaFactsAinda não há avaliações

- Duo Dan MillDocumento4 páginasDuo Dan Millnhungocbk92_22841857Ainda não há avaliações

- Kiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DDocumento1 páginaKiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DMohamed SelimAinda não há avaliações

- Introduction of Bag Filters Constructional FeaturesDocumento32 páginasIntroduction of Bag Filters Constructional FeaturesTin NguyenAinda não há avaliações

- CEM TRAIN-09 VentilationDocumento19 páginasCEM TRAIN-09 VentilationmohamedredaAinda não há avaliações

- Loesche Overview EN PDFDocumento34 páginasLoesche Overview EN PDFNguyễn Quang Hưng100% (1)

- VDZ Cement Manufacturing Course FlyerDocumento4 páginasVDZ Cement Manufacturing Course FlyerfaheemqcAinda não há avaliações

- Quality Requirements For CrMo Alloys SAG Mill Liner and GratesDocumento16 páginasQuality Requirements For CrMo Alloys SAG Mill Liner and GratesFrancis ChavezAinda não há avaliações

- Ball MillDocumento2 páginasBall Millpadma26327Ainda não há avaliações

- The Selection and Design of Mill LinersDocumento11 páginasThe Selection and Design of Mill Linersluis martinezAinda não há avaliações

- Auditoría Molino 5Documento22 páginasAuditoría Molino 5ElZeroMJAinda não há avaliações

- Shree Project FinalDocumento20 páginasShree Project FinalMostafa KordyAinda não há avaliações

- Factors Influencing The Grinding EfficiencyDocumento27 páginasFactors Influencing The Grinding Efficiencygrameshkreddy2013Ainda não há avaliações

- Mill Performance Analysis and ComparisonDocumento22 páginasMill Performance Analysis and ComparisonHerwin Navarrete100% (1)

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDocumento3 páginasA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresAinda não há avaliações

- Separator Dynamic SealDocumento4 páginasSeparator Dynamic SealDilnesa EjiguAinda não há avaliações

- Procemin 2015 Sizing Stages of Weir High Pressure Grinding Rolls Mills, Based On Pilot TestsDocumento25 páginasProcemin 2015 Sizing Stages of Weir High Pressure Grinding Rolls Mills, Based On Pilot TestsNereo SpenglerAinda não há avaliações

- enDocumento22 páginasenAnonymous iI88LtAinda não há avaliações

- How To Remove Scrap Materials From A Ball Mill CircuitDocumento5 páginasHow To Remove Scrap Materials From A Ball Mill Circuitsafwat hassanAinda não há avaliações

- 15.00 Paolo Bossi, MD, Sinai White CementDocumento38 páginas15.00 Paolo Bossi, MD, Sinai White CementMohd AliAinda não há avaliações

- Measurements of The Quality of Cement Produced From Looped LimestoneDocumento30 páginasMeasurements of The Quality of Cement Produced From Looped LimestoneCharlie Dean100% (1)

- Molycop - Tech Sheet Small Size Balls 003 MCAU - SMLTS1.3 - 290519 PDFDocumento3 páginasMolycop - Tech Sheet Small Size Balls 003 MCAU - SMLTS1.3 - 290519 PDFreza razaviAinda não há avaliações

- Home About Us Products & Market Media Contact: Minimum Standard RequirementsDocumento4 páginasHome About Us Products & Market Media Contact: Minimum Standard RequirementsAtiqur RahmanAinda não há avaliações

- Dr. Gearb X: KG1700-L2 7.5Kw-1/13.26Documento1 páginaDr. Gearb X: KG1700-L2 7.5Kw-1/13.26alinoriAinda não há avaliações

- RDX 3Documento1 páginaRDX 3alinoriAinda não há avaliações

- Pump SahandDocumento4 páginasPump SahandalinoriAinda não há avaliações

- Pump SahandDocumento20 páginasPump SahandalinoriAinda não há avaliações

- Adapter Sleeves For Metric Shafts: DimensionsDocumento3 páginasAdapter Sleeves For Metric Shafts: DimensionsalinoriAinda não há avaliações

- Flotation: Water TreatmentDocumento14 páginasFlotation: Water TreatmentalinoriAinda não há avaliações

- Optimization of Comminution Circuit Throughput and Product Size Distribution by Simulation and ControlDocumento64 páginasOptimization of Comminution Circuit Throughput and Product Size Distribution by Simulation and ControlalinoriAinda não há avaliações

- OLI Analyzer Overview: Chris DepetrisDocumento25 páginasOLI Analyzer Overview: Chris DepetrisalinoriAinda não há avaliações

- Review The Treatment: Book Magnetic Methods For OF Minerals by J. (Published by PresentDocumento2 páginasReview The Treatment: Book Magnetic Methods For OF Minerals by J. (Published by PresentalinoriAinda não há avaliações

- Bond Work Index Test Report Example 1Documento5 páginasBond Work Index Test Report Example 1alinoriAinda não há avaliações

- JKMRC PDFDocumento1 páginaJKMRC PDFalinoriAinda não há avaliações

- Monte Carlo Simulation Formula in Excel - Tutorial and Download - Excel TVDocumento21 páginasMonte Carlo Simulation Formula in Excel - Tutorial and Download - Excel TValinoriAinda não há avaliações

- Scope:: About The Ballparam - Open Spreadsheet ..Documento40 páginasScope:: About The Ballparam - Open Spreadsheet ..alinoriAinda não há avaliações

- Ballparam DirectDocumento47 páginasBallparam DirectalinoriAinda não há avaliações

- Kiuttu J, Ruuska J & Yliniemi L (2010) Advanced and Sustainable Beneficiation of Platinum Group Minerals (PGM) in Sulphide Poor Platinum (PGE) Deposits - BEPGE-project, Final Report. May 2010Documento27 páginasKiuttu J, Ruuska J & Yliniemi L (2010) Advanced and Sustainable Beneficiation of Platinum Group Minerals (PGM) in Sulphide Poor Platinum (PGE) Deposits - BEPGE-project, Final Report. May 2010alinoriAinda não há avaliações

- 10.0000@Www - mdpi.Com@Generic ADAA26A138DDDocumento3 páginas10.0000@Www - mdpi.Com@Generic ADAA26A138DDalinoriAinda não há avaliações

- Lecture3 Example ShellandtuberatingcalculationsDocumento4 páginasLecture3 Example Shellandtuberatingcalculationsunknown8787Ainda não há avaliações

- Nagendra G M: Teaching ExperienceDocumento3 páginasNagendra G M: Teaching Experiencenagendra_gmAinda não há avaliações

- Antoine LavoisierDocumento3 páginasAntoine LavoisierMark allenAinda não há avaliações

- GSK IndictmentDocumento66 páginasGSK IndictmentJaredAinda não há avaliações

- Screenshot 2022-10-17 at 18.52.41Documento41 páginasScreenshot 2022-10-17 at 18.52.41Rod VincentAinda não há avaliações

- Properties of Sea WaterDocumento30 páginasProperties of Sea WaterHalima akterAinda não há avaliações

- Applied Thermal Engineering: Lars O. Nord, Olav BollandDocumento7 páginasApplied Thermal Engineering: Lars O. Nord, Olav BollandHugo SolìsAinda não há avaliações

- CENG 122 Project StatementDocumento11 páginasCENG 122 Project StatementRosalyne Artho-PhanAinda não há avaliações

- Load DistributionDocumento44 páginasLoad Distributionሽታ ዓለሜAinda não há avaliações

- Soldering and Welding in Pediatric DentistryDocumento4 páginasSoldering and Welding in Pediatric DentistryNilay ShahAinda não há avaliações

- Stress Analysis of Storage Tank Piping Jeba Anand NadarDocumento36 páginasStress Analysis of Storage Tank Piping Jeba Anand NadarTree Tawee100% (1)

- Backwards Heat Equation InfoDocumento1 páginaBackwards Heat Equation InfoMelissa Marie HernandezAinda não há avaliações

- Fast-Charge IC: Features General DescriptionDocumento14 páginasFast-Charge IC: Features General DescriptionAlejandro Cortegoso MartinezAinda não há avaliações

- Apollo Valves 20 104 03 Instruction Installation ManualDocumento2 páginasApollo Valves 20 104 03 Instruction Installation ManualRobinson JimenezAinda não há avaliações

- Chapter 1Documento111 páginasChapter 1Radhi Abdullah100% (1)

- CH 2 Drilling FluidsDocumento76 páginasCH 2 Drilling FluidsKaoru AmaneAinda não há avaliações

- Experiment 1 (Introduction)Documento16 páginasExperiment 1 (Introduction)Msfaeza HanafiAinda não há avaliações

- Dielectric Strength of Transformer OilDocumento2 páginasDielectric Strength of Transformer OilAnil VarriAinda não há avaliações

- Spaulding Lighting Seattle I-II-III Spec Sheet 9-87Documento2 páginasSpaulding Lighting Seattle I-II-III Spec Sheet 9-87Alan MastersAinda não há avaliações

- Worksheet Xi 4 - 9-23-8-9-23 - 02092023 - 194444Documento4 páginasWorksheet Xi 4 - 9-23-8-9-23 - 02092023 - 194444Adithya PramodAinda não há avaliações

- Instrumental Analysis ExamDocumento12 páginasInstrumental Analysis ExamacenisolaAinda não há avaliações

- Experimental Investigation On Black Cotton Soil Treated With Terrabind Chemical and Glass PowderDocumento12 páginasExperimental Investigation On Black Cotton Soil Treated With Terrabind Chemical and Glass PowderIJRASETPublicationsAinda não há avaliações

- MCQsDocumento8 páginasMCQsAsad MalikAinda não há avaliações

- Area Classification: (IEC/EN 60529)Documento1 páginaArea Classification: (IEC/EN 60529)nestkwt1Ainda não há avaliações

- Horizontal or Vertical Installation Check ValvesDocumento5 páginasHorizontal or Vertical Installation Check ValvesAVINASHRAJAinda não há avaliações

- Solid Boyd An Shell MecahnicsDocumento521 páginasSolid Boyd An Shell MecahnicsCiprian Mihai TărboiuAinda não há avaliações

- Unit10 - Phan111 RedoxDocumento57 páginasUnit10 - Phan111 RedoxAyille Dorado ArcigalAinda não há avaliações

- Absorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinDocumento24 páginasAbsorbance and Fluorescence Spectroscopies of Green Fluorescent ProteinMadel Tutor ChaturvediAinda não há avaliações

- ZJ70D Drilling Rig Maintenance ManualDocumento55 páginasZJ70D Drilling Rig Maintenance ManualQamar Shahzad100% (4)

- Steel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectDocumento1 páginaSteel Conv Belt - 1800-ST2250-8+6 FR-LRR-TKIL-NK ProjectCaspian DattaAinda não há avaliações