Escolar Documentos

Profissional Documentos

Cultura Documentos

Trelleborg Seapile & Seatimber

Enviado por

sivakumarTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Trelleborg Seapile & Seatimber

Enviado por

sivakumarDireitos autorais:

Formatos disponíveis

66

SEAPILE &

SEATIMBER

SeaPile and SeaTimber are advanced

composite plastics with superior

properties to timber, steel and

concrete for many marine structures

and applications.

They can withstand heavy impacts

by absorption of energy through

recoverable deflection. SeaPile and

SeaTimber never rot, corrode or

decay. They are impervious to marine

borers, yet are totally non-polluting.

Manufactured from a recycled

plastic matrix with unique glass fibre

reinforcement bars, the stiffness of

SeaPile and SeaTimber can be varied

and controlled to suit each project.

This makes the material the ideal

choice for fenders, to build marine

structures, and for coastal protection

without damaging the environment.

Features

B Low lifecycle cost

B Will not rot, corrode or decay

B Unaffected by marine borers

B Choice of modulus to suit different

applications

B Can be pile driven, sawn and drilled

B Low friction coefficient Durable low

B Ultra low maintenance friction skin

B Custom colours available

B Unlimited lengths*

SeaTimber 100% recycled

plastic matrix

Applications

B Fender piles and systems

B Structural piles

B Bridge protection

B Guidewalls and locks

B Corner fenders

B Dolphins

SeaPile

B Navigation markers

B Walings and bullrails

Fibreglass

* subject to transport restrictions reinforcements

Standard manufacturing and performance tolerances apply (see pages 1236 to 1239)

M1100-S06-V1.1-EN. Trelleborg AB, 2007

67

SEAPILE & SEATIMBER

SeaPile

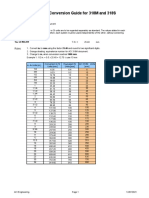

SeaPile Diameter Rebar Size Yield Weight

section inch mm quantity inch mm lb/in2 MPa lb/ft kg/m

10 (6-1) 1 25 4300 29.65 2429 3643

10 (6-1.25) 6 1.25 32 5837 40.24 2531 3746

10 (6-1.375) 1.375 35 6766 46.65 2632 3948

10 (8-1) 1 25 5431 37.45 2535 3752

10 254

10 (8-1.25) 1.25 32 7482 51.59 2632 3948

10 (8-1.375) 8 1.375 35 8720 60.12 2733 4049

10 (8-1.5) 1.5 38 10036 69.20 2835 4252

10 (8-1.625) 1.625 41 11424 78.77 2936 4354

13 (8-1) 1 25 3842 26.49 3948 5871

13 (8-1.25) 8 1.25 32 5207 35.90 4150 6174

13 (8-1.375) 1.375 35 6028 41.56 4251 6376

13 (12-1) 1 25 5365 36.99 4150 6174

13 330

13 (12-1.25) 1.25 32 7413 51.11 4353 6479

13 (12-1.375) 12 1.375 35 8643 59.59 4555 6782

13 (12-1.5) 1.5 38 9947 68.58 4657 6885

13 (12-1.625) 1.625 41 11315 78.01 4859 7188

16 (16-1) 1 25 4928 33.98 6174 91110

16 (16-1.25) 1.25 32 6785 46.78 6478 95116

16 (16-1.375) 1.375 35 7899 54.46 6681 98121

16 406 16

16 (16-1.5) 1.5 38 9078 62.59 6883 101124

16 (16-1.625) 1.625 41 10313 71.11 7086 104128

16 (16-1.75) 1.75 44 11599 79.97 7389 109132

Modulus, stiffness and other material properties are available on request.

SeaTimber

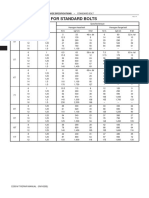

SeaTimber Height Width Rebar Size Yield X-X Yield Y-Y Weight

section inch mm inch mm qty inch mm lb/in2 MPa lb/in2 MPa lb/ft kg/m

12 8 (No rebar) 860 5.93 860 5.93 2531 3746

12 8 (4-1) 1 25 3868 26.67 3421 23.59 2632 3948

12 8 (4-1.25) 1.25 32 5155 35.54 4381 30.21 2733 4049

12 8 (4-1.375) 12 305 8 254 1.375 35 5928 40.87 4964 34.23 2834 4251

4

12 8 (4-1.5) 1.5 38 6746 46.51 5588 38.53 2835 4252

12 8 (4-1.625) 1.625 41 7606 52.44 6250 43.09 2935 4352

12 8 (4-1.75) 1.75 44 8501 58.61 6948 47.90 2936 4354

10 10 (No rebar) 860 5.93 860 5.93 2733 4049

10 10 (4-1) 1 25 3443 23.74 3443 23.74 2835 4252

10 10 (4-1.25) 1.25 32 4517 31.14 4517 31.14 2936 4354

10 10 (4-1.375) 10 305 10 254 1.375 35 5163 35.6 5163 35.60 3036 4554

4

10 10 (4-1.5) 1.5 38 5849 40.33 5849 40.33 3037 4555

10 10 (4-1.625) 1.625 41 6571 45.31 6571 45.31 3138 4657

10 10 (4-1.75) 1.75 44 7325 50.5 7325 50.5 3138 4657

12 12 (No rebar) 860 5.93 860 5.93 3947 5870

12 12 (4-1) 1 25 2706 18.66 2706 18.66 4049 6073

12 12 (4-1.25) 1.25 32 3466 23.90 3466 23.90 4150 6174

12 305 12 305

12 12 (4-1.375) 4 1.375 35 3923 27.05 3923 27.05 4151 6176

12 12 (4-1.5) 1.5 38 4406 30.38 4406 30.38 4251 6376

12 12 (4-1.625) 1.625 41 4914 33.88 4914 33.88 4252 6377

Modulus, stiffness and other material properties are available on request.

Standard manufacturing and performance tolerances apply (see pages 1236 to 1239)

M1100-S06-V1.1-EN. Trelleborg AB, 2007

68

SEAPILE & SEATIMBER

Lifecycle cost

s

re

u

ct

ru

st

n

de

o

Wo

Relative costs

Break-even

in 6 years

SeaPile

0

0 5 10 15 20 25

Years

SeaPile and SeaTimber cost far less during the lifetime of a structure because they need little if any maintenance.

Real comparisons with timber structures show the break-even point is just six years, sometimes far less.

SeaPile and SeaTimber can resist

greater loads and deflections than

wood, concrete and steel. When

tested to ultimate load, SeaPile

and SeaTimber absorb 15 times

d

ce

Based on the energy of Southern Yellow

or

250250mm

f

in

test sections Pine. In practical terms this means

re

less damage, maintenance and

FG

r

Load

downtime, leading to a lower lifecycle

be

cost.

im

aT

Se

d

force

unrein

b er

m

aTi

Se

ellow Pine

hern Y

Sout

Deflection

Standard manufacturing and performance tolerances apply (see pages 1236 to 1239)

M1100-S06-V1.1-EN. Trelleborg AB, 2007

69

SEAPILE & SEATIMBER

Installation

Piling Cutting Drilling

Various connecting methods are available to increase pile length. SeaPile and SeaTimber lengths can also be attached

to steel pile extensions. A DVD explaining SeaPile and SeaTimber handling and installation methods is available.

Pile driving data

4

Soil prole Pile length 15.2m, flat cut ends, no drive shoe, no drive helmet, hammer: MKT 9B3

Pile length 16.8t, with drive shoe and drive helmet, hammer: MKT 9B3

6

Very loose

sand and silt

8

Tip elevation = 9.7 metres

Depth (metres)

10

Dense to very

dense layered

clayey sand

and sandy clay

12

14 Bottom of

test boring

Tip elevation = 14.9 metres

16

0 10 20 30 40 50 60 70 80 90 100

Hammer blows per metre

Standard manufacturing and performance tolerances apply (see pages 1236 to 1239)

M1100-S06-V1.1-EN. Trelleborg AB, 2007

610

SEAPILE & SEATIMBER

Applications

The SeaPile can generally be used in the same applications as traditional timber piling. Examples include:

Dolphins Fender piling Light structural piling

Wale

Dock

Chock

Pile

3-pile 7-pile 19-pile

cluster cluster cluster

Dolphins, or groups of piles, are Piles are used extensively as vertical Piles are used to support the loads

placed near piers and wharves to fenders set out in front of a marine of light-duty piers and wharves.

guide vessels into their moorings, structure. During the berthing of a Structural piling generally uses

to fend them away from structures, ship, fender piles act as a buffer bracing between piles to increase

or to serve as mooring points. to absorb and dissipate the impact the strength and stiffness of the

Compared with timber, considerably energy of the ship. They also provide foundation for the structure.

fewer SeaPiles are needed to absorb a barrier to prevent vessels from

the same impact energy. going underneath the pier.

Navigational aids Bridge pier protection

Piles and dolphins are widely used to create protective structures for bridge

piers, and to guide vessels into the channel and away from bridge supports.

3-pile clusters are used in impact zones, single piles in less vulnerable areas.

Bridge

Bridge

Pier

Pier

Single piles or dolphins are used Centreline of channel

to support lights, daybeacons, fog

signals and radar beacons.

Bridge

Bridge

Pier

Pier

Refer to the SeaPile and

SeaTimber Design Manual for

more information and examples. Centreline of bridge

Standard manufacturing and performance tolerances apply (see pages 1236 to 1239)

M1100-S06-V1.1-EN. Trelleborg AB, 2007

611

SEAPILE & SEATIMBER

Proven

in practice

Standard manufacturing and performance tolerances apply (see pages 1236 to 1239)

M1100-S06-V1.1-EN. Trelleborg AB, 2007

Você também pode gostar

- Offshore Pad Eyes and Shackle DimensionsDocumento8 páginasOffshore Pad Eyes and Shackle DimensionsNhut100% (1)

- PD 6698-2009 PDFDocumento30 páginasPD 6698-2009 PDFsivakumarAinda não há avaliações

- Courtyard HousesDocumento29 páginasCourtyard HousesAndreeaAinda não há avaliações

- Banco de Dados - Https - Mega - Co.nz - #F!edRGmCIC!RS7TIjy7Krd4blcpLk2 - HW ComDocumento1 páginaBanco de Dados - Https - Mega - Co.nz - #F!edRGmCIC!RS7TIjy7Krd4blcpLk2 - HW ComDANIEL KREWERAinda não há avaliações

- ReinforcementDocumento34 páginasReinforcementKristle Jane VidadAinda não há avaliações

- Cable Wire Catalogue PDFDocumento47 páginasCable Wire Catalogue PDFyoupick10Ainda não há avaliações

- Activity 3 - Cuyugan, Ma. Lourdes J. EDUC 307Documento2 páginasActivity 3 - Cuyugan, Ma. Lourdes J. EDUC 307malouAinda não há avaliações

- Pasir PutihDocumento7 páginasPasir PutihChaterine OliviaAinda não há avaliações

- Angrenaje Conice 2 PDFDocumento19 páginasAngrenaje Conice 2 PDFpaula09Ainda não há avaliações

- CANAN Steel Deck Catalogue - 2023Documento48 páginasCANAN Steel Deck Catalogue - 2023Clarice Lispector100% (1)

- Aberdare Low Voltage Cables SectionDocumento5 páginasAberdare Low Voltage Cables Sectionorkuma shiaondoAinda não há avaliações

- Aberdare Low Voltage Cables Section PDFDocumento5 páginasAberdare Low Voltage Cables Section PDFPercy GoitsemangAinda não há avaliações

- Stud Bolts DIN 976-1: 2002-12: 1. ScopeDocumento6 páginasStud Bolts DIN 976-1: 2002-12: 1. ScopejayAinda não há avaliações

- Crosby G-209R ROV ShackleDocumento1 páginaCrosby G-209R ROV ShacklenatAinda não há avaliações

- Sling Saver ShackleDocumento1 páginaSling Saver ShackleFatihTufanAinda não há avaliações

- Tabel Valori TermorezistentaDocumento7 páginasTabel Valori TermorezistentaCristian NedelcuAinda não há avaliações

- Chain Crosby® Grade 100Documento1 páginaChain Crosby® Grade 100CROSBYAinda não há avaliações

- Use of Crusher Stone Aggregate Bottom AsDocumento6 páginasUse of Crusher Stone Aggregate Bottom AsMan Bdr. MagarAinda não há avaliações

- Appendix: Transmitter (Source) Antenna SpecificationDocumento11 páginasAppendix: Transmitter (Source) Antenna SpecificationtedAinda não há avaliações

- British Steel Universal Beams PFC Datasheet PDFDocumento2 páginasBritish Steel Universal Beams PFC Datasheet PDFMayur MandrekarAinda não há avaliações

- British Steel Universal Beams PFC DatasheetDocumento2 páginasBritish Steel Universal Beams PFC DatasheetArjun S SanakanAinda não há avaliações

- Table 2 Awwa Standard Steel-Ring Flanges, Class B (86 Psi) and Class D (175-150 Psi) (Continued)Documento1 páginaTable 2 Awwa Standard Steel-Ring Flanges, Class B (86 Psi) and Class D (175-150 Psi) (Continued)carlosAinda não há avaliações

- British Steel Universal Beams PFC Datasheet PDFDocumento2 páginasBritish Steel Universal Beams PFC Datasheet PDFSam FarizoAinda não há avaliações

- British Steel Universal Beams PFC Datasheet PDFDocumento2 páginasBritish Steel Universal Beams PFC Datasheet PDFTony OngAinda não há avaliações

- ZN Alloy PropertiesDocumento1 páginaZN Alloy PropertiesTien VuAinda não há avaliações

- Dsi-Usa Dywidag Tie Rods Us 02Documento12 páginasDsi-Usa Dywidag Tie Rods Us 02Hery Mardiono HeryAinda não há avaliações

- Lab 2Documento18 páginasLab 2Dodiya NikunjAinda não há avaliações

- Dimensions of UNP Beams European Standard EN 10025-1/2Documento1 páginaDimensions of UNP Beams European Standard EN 10025-1/2Winny Winer DujmićAinda não há avaliações

- UpnDocumento1 páginaUpnWildan SholehAinda não há avaliações

- Gradation of Filter Material: (Waduk Telagawaja)Documento7 páginasGradation of Filter Material: (Waduk Telagawaja)Ady Darwiyasa Manson BatAinda não há avaliações

- 10GX Cables: Key Electrical Attributes - 10GX Bonded-Pair CableDocumento1 página10GX Cables: Key Electrical Attributes - 10GX Bonded-Pair CableCharly SkyblueAinda não há avaliações

- Material BreakdownDocumento5 páginasMaterial BreakdownjaymarAinda não há avaliações

- TechBuilder - MPPT CALCULATORDocumento6 páginasTechBuilder - MPPT CALCULATORBabumani MandiAinda não há avaliações

- Solucionario - Tovar Soto RobinsonDocumento11 páginasSolucionario - Tovar Soto RobinsonEnrique CarhuamacaAinda não há avaliações

- Sample Specifications: Mechanical Joint C153 Ductile Iron Compact FittingsDocumento8 páginasSample Specifications: Mechanical Joint C153 Ductile Iron Compact FittingsJohanAndrésVillarrealAinda não há avaliações

- Pad Eye Lifting PDFDocumento1 páginaPad Eye Lifting PDFnaval_05Ainda não há avaliações

- 252V Specification SheetDocumento1 página252V Specification SheetLin LinAinda não há avaliações

- UJI DCP Ruas Islamic CenterDocumento3 páginasUJI DCP Ruas Islamic CenterChalie GgazalihAinda não há avaliações

- Butterfly Valve DatasheetDocumento2 páginasButterfly Valve DatasheetKanthan DevanAinda não há avaliações

- Socket Weld Flange Inches / Pounds: CLASS 1500Documento1 páginaSocket Weld Flange Inches / Pounds: CLASS 1500KamalAinda não há avaliações

- StandardDocumento3 páginasStandardulhas_nakashe100% (1)

- Triaxial Compression Test: Sample#2Documento46 páginasTriaxial Compression Test: Sample#2muhammad junaidAinda não há avaliações

- Sea Water PumpDocumento4 páginasSea Water PumpGureAinda não há avaliações

- Solar PV Panels The Best Option: Reliability ServiceDocumento2 páginasSolar PV Panels The Best Option: Reliability ServicejprakashusAinda não há avaliações

- Alloy Shackles: (Meets The Performance Requirements of RR-C-271 & EN13889)Documento1 páginaAlloy Shackles: (Meets The Performance Requirements of RR-C-271 & EN13889)iyan supriadiAinda não há avaliações

- Analisis Trabajo IDocumento4 páginasAnalisis Trabajo IElda Torres CenturionAinda não há avaliações

- Ficha Tecnica Mylard Tipo A DupontDocumento2 páginasFicha Tecnica Mylard Tipo A DupontJuan Hilares AlejandroAinda não há avaliações

- Sas 500 O12 50mm Sas 555 700 O63 5 MM and Sas 550 O12 50mmDocumento12 páginasSas 500 O12 50mm Sas 555 700 O63 5 MM and Sas 550 O12 50mmTargetRockAinda não há avaliações

- Crosby Swivels: S-1 Jaw & HookDocumento1 páginaCrosby Swivels: S-1 Jaw & HookRei_budAinda não há avaliações

- Metrication Conversion GuideDocumento10 páginasMetrication Conversion GuideMudasir DaudAinda não há avaliações

- Specified Torque For Standard Bolts: Service SpecificationsDocumento1 páginaSpecified Torque For Standard Bolts: Service SpecificationsMax K.Ainda não há avaliações

- Tightening TorqueDocumento2 páginasTightening TorqueMiguel QueirosAinda não há avaliações

- Momenti Pritezanja Vijaka PDFDocumento2 páginasMomenti Pritezanja Vijaka PDFMladen Čorokalo100% (1)

- Tightening Torque: English Units: (Coarse Thread Series)Documento2 páginasTightening Torque: English Units: (Coarse Thread Series)bpavlidisAinda não há avaliações

- Tightening TorqueDocumento2 páginasTightening TorqueWONG TSAinda não há avaliações

- Tightening Torque PDFDocumento2 páginasTightening Torque PDFPablo Alvarez GuichouAinda não há avaliações

- RPM Mechanical's Guide to Tightening Torque ValuesDocumento2 páginasRPM Mechanical's Guide to Tightening Torque ValuesVenkatasubramanian IyerAinda não há avaliações

- Tightening Torque - RPM Mechanical Inc PDFDocumento2 páginasTightening Torque - RPM Mechanical Inc PDFJesús SuárezAinda não há avaliações

- MyLinkBudget SheetDocumento2 páginasMyLinkBudget SheetRaman TrivediAinda não há avaliações

- Everything You Need to Know About AAAC Aluminum Alloy ConductorsDocumento2 páginasEverything You Need to Know About AAAC Aluminum Alloy ConductorsManuel Navarro100% (1)

- N2XYDocumento5 páginasN2XYSamuel SantosAinda não há avaliações

- Government Publications: Key PapersNo EverandGovernment Publications: Key PapersBernard M. FryAinda não há avaliações

- MTS Extent-1Documento36 páginasMTS Extent-1sivakumarAinda não há avaliações

- Countersunk Hollowbolt CECertEnglish852Documento2 páginasCountersunk Hollowbolt CECertEnglish852sivakumarAinda não há avaliações

- ABG BBA Findrains 567 To SHW F18 DRAWINGDocumento1 páginaABG BBA Findrains 567 To SHW F18 DRAWINGsivakumarAinda não há avaliações

- Multipurpose Tug FendersDocumento44 páginasMultipurpose Tug FenderssivakumarAinda não há avaliações

- Hydrophilic WaterstopsDocumento5 páginasHydrophilic WaterstopsClive WongAinda não há avaliações

- Asdo Tie Bar Design Capacities: Product DataDocumento2 páginasAsdo Tie Bar Design Capacities: Product DatasivakumarAinda não há avaliações

- Sono WZ Concrete Sensor Product BrochureDocumento8 páginasSono WZ Concrete Sensor Product BrochuresivakumarAinda não há avaliações

- ECIA Guidelines 2018 Terrestrial Freshwater Coastal and Marine V1.2 April 22 CompressedDocumento44 páginasECIA Guidelines 2018 Terrestrial Freshwater Coastal and Marine V1.2 April 22 CompressedsivakumarAinda não há avaliações

- Guidelines for Floating JettiesDocumento31 páginasGuidelines for Floating Jettiesye yint100% (1)

- Shoring Brochure 2022 LR 1Documento84 páginasShoring Brochure 2022 LR 1sivakumarAinda não há avaliações

- PERI Formwork Load Calculator ResultsDocumento3 páginasPERI Formwork Load Calculator ResultssivakumarAinda não há avaliações

- SB Brace Frame: Reliable Load Transfer For Single-Sided Forming Operations Up To 8.75 M HighDocumento48 páginasSB Brace Frame: Reliable Load Transfer For Single-Sided Forming Operations Up To 8.75 M HighpouyaAinda não há avaliações

- Earthquake Resistant Design PDFDocumento5 páginasEarthquake Resistant Design PDFgavisita123Ainda não há avaliações

- Jun19 1E QPDocumento32 páginasJun19 1E QPsivakumarAinda não há avaliações

- Guidelines for Floating JettiesDocumento31 páginasGuidelines for Floating Jettiesye yint100% (1)

- Year 11 Chemistry Reaction Rate LO and SCDocumento1 páginaYear 11 Chemistry Reaction Rate LO and SCsivakumarAinda não há avaliações

- Critical Lift Plan For Pile Load Test-2Documento14 páginasCritical Lift Plan For Pile Load Test-2sivakumarAinda não há avaliações

- Eurocode Guide - OnlineDocumento56 páginasEurocode Guide - OnlinetiemyewAinda não há avaliações

- Year 11 Mock TimetableDocumento2 páginasYear 11 Mock TimetablesivakumarAinda não há avaliações

- FADesignManual v2 14 SP PDFDocumento88 páginasFADesignManual v2 14 SP PDFpandu lambangAinda não há avaliações

- Year 11 Plate Tectonics AssessmentDocumento4 páginasYear 11 Plate Tectonics AssessmentsivakumarAinda não há avaliações

- 25 - 11 - 2017 1 - 37 PM Office LensDocumento1 página25 - 11 - 2017 1 - 37 PM Office LenssivakumarAinda não há avaliações

- 074 Fo403Documento1 página074 Fo403sivakumarAinda não há avaliações

- FRP GRP Gratings Load Table 03Documento1 páginaFRP GRP Gratings Load Table 03sivakumarAinda não há avaliações

- Security Instructions Within KNB ProjectDocumento6 páginasSecurity Instructions Within KNB ProjectsivakumarAinda não há avaliações

- ASCE 7-16 Supplement 1Documento16 páginasASCE 7-16 Supplement 1sivakumarAinda não há avaliações

- Marine & Offshore Catalog Channel Tray SystemsDocumento34 páginasMarine & Offshore Catalog Channel Tray SystemssivakumarAinda não há avaliações

- 5 - Aggregate Specifications and Blending PDFDocumento23 páginas5 - Aggregate Specifications and Blending PDFsivakumarAinda não há avaliações

- The Easy-To-Work-With Company.: Fiberglass Cable Tray & Strut Systems (800) 326-8842Documento56 páginasThe Easy-To-Work-With Company.: Fiberglass Cable Tray & Strut Systems (800) 326-8842sivakumarAinda não há avaliações

- Vanity Counter Type 2Documento1 páginaVanity Counter Type 2Novelyn LoqueroAinda não há avaliações

- Service Manual RCF Art 500 ADocumento3 páginasService Manual RCF Art 500 AFederico Torre0% (1)

- Roof truss detailsDocumento1 páginaRoof truss detailsRassal KarimAinda não há avaliações

- Chapter 0. Computer Fundamentals SumanDocumento21 páginasChapter 0. Computer Fundamentals SumanSuman JyotiAinda não há avaliações

- SF 100Documento2 páginasSF 100mandorAinda não há avaliações

- Video System Management Software GuideDocumento129 páginasVideo System Management Software GuideIdrusAinda não há avaliações

- Outdoor Workplace Lighting StandardsDocumento17 páginasOutdoor Workplace Lighting StandardsRoberto MiletAinda não há avaliações

- Ribbed Slab DesignDocumento4 páginasRibbed Slab Designyusuf abdinasir100% (1)

- Quiz 2Documento2 páginasQuiz 2JonathanAinda não há avaliações

- Pro ManualDocumento67 páginasPro ManualAlan De La FuenteAinda não há avaliações

- Mod Bus Map FormatDocumento48 páginasMod Bus Map FormatFredAinda não há avaliações

- Pos 140 03 Ig PDFDocumento282 páginasPos 140 03 Ig PDFanand.g7720Ainda não há avaliações

- Boq - Fencing EstimateDocumento2 páginasBoq - Fencing EstimateAugustine Believe100% (3)

- Elements of Architecture and Principles of DesignDocumento11 páginasElements of Architecture and Principles of DesignAbeja ConsolacionAinda não há avaliações

- Bcom VB NotesDocumento22 páginasBcom VB Notesnisha tiwariAinda não há avaliações

- 1 Composite Beam Theory: Developed by Scott Civjan University of Massachusetts, AmherstDocumento27 páginas1 Composite Beam Theory: Developed by Scott Civjan University of Massachusetts, Amherstsaleemm_2Ainda não há avaliações

- Properties of Papercrete Concrete: Building Material: Mr. Yogesh D. Shermale, Dr. Mahaveer B. VarmaDocumento6 páginasProperties of Papercrete Concrete: Building Material: Mr. Yogesh D. Shermale, Dr. Mahaveer B. VarmaMadan Mohan ReddyAinda não há avaliações

- Energy Savings in HVACDocumento6 páginasEnergy Savings in HVACSuman RachaAinda não há avaliações

- STAAD Pro V8i Analytic Service Structure AnalysisDocumento28 páginasSTAAD Pro V8i Analytic Service Structure AnalysisramAinda não há avaliações

- A Project About Wild Animals Protection Week and Kalakad Mundanthurai Tiger ReserveDocumento50 páginasA Project About Wild Animals Protection Week and Kalakad Mundanthurai Tiger ReserveSweetAinda não há avaliações

- Event Design Portfolio - Shyam Sundar MeherDocumento19 páginasEvent Design Portfolio - Shyam Sundar MeherShyam MeherAinda não há avaliações

- Status Rfi Pie Rack & Sleeper.Documento20 páginasStatus Rfi Pie Rack & Sleeper.Kurnia AryadiAinda não há avaliações

- Crown Solutions Presentation PDFDocumento19 páginasCrown Solutions Presentation PDFSuresh KumarAinda não há avaliações

- Oracle Nosql Database,: 12.1.3.5, COMMUNITY EDITIONDocumento5 páginasOracle Nosql Database,: 12.1.3.5, COMMUNITY EDITIONCarlos Mario HerreraAinda não há avaliações

- IGCA Home Visit ReportDocumento7 páginasIGCA Home Visit Reportspostula5207Ainda não há avaliações

- The Diy Guide: Creating A Cultural CentreDocumento9 páginasThe Diy Guide: Creating A Cultural Centreanon_181246883Ainda não há avaliações

- Book 2Documento15 páginasBook 2SUNIL PATELAinda não há avaliações

- Bhartia Infra Projects LTD.: Guwahati, Assam Test ReportDocumento13 páginasBhartia Infra Projects LTD.: Guwahati, Assam Test Reportsuresh kumarAinda não há avaliações