Escolar Documentos

Profissional Documentos

Cultura Documentos

Cleaning Validation of Albendazole Tablets 400 MG

Enviado por

sppTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Cleaning Validation of Albendazole Tablets 400 MG

Enviado por

sppDireitos autorais:

Formatos disponíveis

Cleaning Validation of Albendazole Tablets 400 mg

Bodavula Samba Siva Rao1*, Y. Surendhranath Reddy2, M. Jeybaskaran2

1. Department of Pharmacy, Khammam College of Pharmacy, Khammam, Andhra Pradesh, India

2. Browns College of Pharmacy, Khammam, Andhra Pradesh, India

The cleaning validation is to verify the effectiveness of the cleaning procedure for removal of

product residues, degradation products, preservatives, excipients and cleaning agents so that the

analytical monitoring may be reduced to a minimum in the routine phase. In addition one need to

ensure there is no risk associated with cross contamination of active ingredients. Cleaning

validation is intended to address special consideration and issues pertaining to validation

cleaning procedures for equipment used in the manufactured of pharmaceutical products,

radiopharmaceuticals, and biological drugs. The document is also intended to establish

inspection consistency and uniformity with respect to equipment cleaning procedures.

Keyword: Acceptable residual level (ARL), Cleaning equipment, Swabs and Wipes Method, Rinse

Method

INTRODUCTION: As a result of any pharmaceutical unit process, a residual level of the drug

substance remains on the equipment and facility even after clean up. This residual drug and possibly

traces of cleaning agents may be carried over into the next product resulting in adulteration of the

subsequent product. Hence, the cleaning methods developed should consistently lower the level of

residual to the acceptable residual level (ARL). Formulation and Mullen of Eli Lilly Company

established a method for finding out cleaning acceptance criteria limit for a multi-drug facility

in 1993.

Pierre Rousseau introduced matrix approaches to the solved complex cleaning Validation

Problems. Cleaning is a challenging task and the design of the cleaning system depending upon the

equipment use (dedicated/multipurpose), manufacture (continuous/batch), cleaning equipment

(manual/automated), preparation (commercial product/clinical supplies), product formulation i.e.,

type of materials being removed from the surface, drugs (low risk/high risk), sterile/non sterile,

solids/liquids and solubility (soluble/insoluble) of active ingredients. An acceptable cleaning system

should incorporate the following elements.

MATERIALS AND METHODS:

SAMPLING PROCEDURE

In order to evaluate a cleaning method, it is necessary to sample the product contact surfaces of the

equipment and establish the level of residuals present.

i) Swabs and Wipes Method

Swabbing is the most widely used sampling technique. Swabs may be saturated with solvent

such as water or alcohol, facilitating the solubilzation and physical removal of surface residues.

Advantages

Dissolves and physically remove sample.

Adequate to a wide variety of surfaces

Economical and widely available.

Allows sampling of a defined area.

Limitations

An invasive technique that may introduce fibers.

Results may be technique dependent.

Swab material and design may inhibit recovery and specificity of the method.

Evaluation of large, complex and hard-to reach areas difficult (e.g. crevices, pipes, valves, large

vessels).

In obtaining rinse samples, location, timing and volume are important considerations.

ii) Rinse Method Advantages

Adaptable to online monitoring.

Easy to sample and non-intrusive.

Allows sampling of a large surface area.

Allows sampling of porous surfaces.

Limitations

Residues may not be homogeneously

distributed.

Inability to detect location of residues.

Rinse volume is critical to ensure accurate

interpretation of results.

iii) Coupon sampling

Coupons of the same materials of construction as

the item to be cleaned can be affixed to the

equipment, spiked with the product, subject to the

cleaning procedures and then submitted to the

laboratory for direct analysis and recovery

studies.

Advantages

Allows for direct surface sampling.

Useful in cleaning method development.

Reduced variability in recovery.

Useful in evaluation of equipment

materials of construction.

Limitations

Coupon may not be representative of equipment contamination or cleaning as it is separate from

primarily surface.

Invasive

Might interfere with the cleaning process.

iv) Solvent Sampling

This technique uses a solvent not normally employed in the cleaning process to maximize recovery

residues.

Advantages

Commonly used in bulk chemical facilities

Applicable for actives, cleaning agents, excipients

Less technique dependent than swabs.

Allows sampling of a larger surface area.

Allows sampling of porous and delicate surface

Maximizes recovery to rinse.

Limitations

May require operator protection and other safety and environmental protection measures.

May require more than one sampling for broad spectrum analysis.

Reduced physical sampling of the surface.

May be difficult to accurately define the controlled area sampled, therefore usually used for

rinsing an entire piece of equipment such as a vessel.

May require the removal of solvent prior to equipment use for production.

v) Placebo and Product Sampling

Placebo sampling can be used to detects residues on equipment thorough the processing of a place

to batch subsequent to the cleaning process. Product sampling is similar to placebo sampling except

that it uses actual product.

Advantages

Points of product contact identical for the two batches

Applicable for hard to reach surfaces.

Require no additional sampling steps.

Limitations

Difficult to determine recovery

Lowers analytical specificity and inhibits detectability

Residues may not be homogenously distributed.

No direct measurement of residues on product contact surfaces.

Usually affords more analytical specificity, less recovery loss than swabs.

ACCEPTANCE CRIETRIA

Method of calculating Acceptance Criteria

i) Based on Therapeutic Daily Dose

The principle for the requirement is that the

standard Therapeutic Daily Dose (TDD) of the

following substance (contaminated substance, in

this called next) may be contaminated by no

more than a certain proportion (usually 1/1000

part) of the TDD of the substance investigated in

the cleaning validation (contaminating substance,

in this case called Previous). This method only

applies when the therapeutic daily dose is known.

It generally used for final product changeover

API Process A to API process B.

PROCEDURE

Establish the limit for Maximum Allowable Carryover (MACO) according to the following

equation.

MACO = TDD previous x MBS

SF x TDDnext

MACO: Maximum Allowable Carryover: acceptable transferred amount from the investigation product (Previous)

TDDprevious: Standard therapeutic dose of the investigated product (in the same dosage form as: TDD

TDDnext: Standard therapeutic dose of the daily dose for the next product.

MBS: Minimum batch size for the next product(s) (where MACO can end up)

SF: Safety factor (normally 1000 is used in calculations based on TDD).

ii) Based on Toxicology Data

In cases in which a therapeutic dose is not known (e.g. for intermediates and detergents), toxicity

data may be used for calculating MACO. Procedure Calculate the so-called NOEL number (No

Observable Effect Level) according to the following equation and use the result for the

establishment of MACO.

From the NOEL number a MACO can then be calculated according to

MACO: Maximum Allowable Carry over: acceptable transferred

amount from the investigated product (previous).

NOEL: No Observed Effect Level

LD50: Lethal Dose 50 in g/kg animal. The identification of the

animal (mouse, rat etc., ) and the way of entry (IV, oral etc., ) is

important.

2000: 2000 is an empirical constant

TDDnext: Largest normal daily dose for the next product

MBS: Minimum batch size for the next products (where

MACO can end up)

SF: Safety factor

The safety factor (SF) varies depending on the route of administration. Generally, a factor of 200

is employed when manufacturing APIs to be administered in oral dosage forms. SF can vary

depending on substance/dosage form according to (suppose tox values from oral administration) as

for example, as presented on the next page.

(iii) General Limit

If the calculation methods based on therapeutic doses or toxicological data result in unacceptably

high or irrelevant carryover figures, or toxicological data for intermediates are not know, the

approach of a general limit may be suitable.

Companies may choose to have such an upper limit as a policy. The general limit is often set as

an upper limit for the maximum concentration (MAXCONC) of a contaminating substance in a

subsequent batch.

The concentration (CONC) of the invesigated substance which can be accepted in the next

batch, according to dose related calculations, is:

CONC = MACO

MBS

MACO: Maximum Allowable Carryover: acceptable transferred amount from the investigated product

(previous). Calculated from therapeutic doses and /or tox data.

MACOppm: Maximum Allowable Carryover: acceptable transferred amount from the investigated

product (previous). Calculated from general ppm limit.

CONC: Concentration (kg/kg or ppm) of Previous substance in the next batch. Based on MACO calculated from therapeutic doses and / or tox

data.

MAXCONC: General limit for maximum allowed concentration (kg/kg or ppm) of Previous substance in the next batch.

MBS: Minimum batch size fir the next product(s) (where MACO can end up)

A general upper limit for the maximum concentration of a contaminating substance in a

subsequent batch (MAXCONC) is often set to ppm depending on the nature of products

produced from the individual company (e.g. toxicity, pharmacological activity,) ppm in APIs

is very frequent).

Note If you decide to employ the concept of levels of cleaning may be used for different

levels. Especially if the product cleaned out is within the same synthetic chain and covered by

the specification of the API, much higher (qualified) levels are acceptable.

If the calculated concentration (CONC) of the previous (based on MACO calculation from

therapeutic doses/tox data) exceeds the general upper limit (MAXCONC), then MAXCONC

level will be limit.

Swab Limits

If homogenous distribution is assumed on all surfaces, a recommended value can be set for the

content in a swab. This can be used as basic information for preparation of a method of

analysis and detection limit.

Procedure

Establish the target value for swab limit for the whole equipment train, using the following

equation:

Also other methods with different swab limits for different surfaces in a piece of equipment and/or

equipment train can be used. Using this approach, the total amount found on the equipment train has

to be below the MACO.

SAFETY FACTORS2

Typical products Applicable approach may

be Cndd = normal daily

dose

Topical 1/10th to 1/100th of ndd

Oral 1/100th to 1/1000th of ndd

Injections, Ophthalmics 1/1000th to t/10000th of ndd

Research & investigational 1/10000th to 1/100000th of ndd

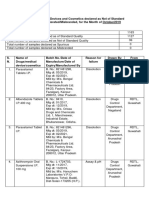

RESULTS AND DISSCUSSION:

Swabbing is the most widely used sampling technique. Swabs may be saturated with solvent

such as water or alcohol, facilitating the solubilization and physical removal of surface

residues (Sampling area: 30cm2).

(i) Albendazole tablets to Paracetamol tablets BP 100mg

Dispensing Booth

Sensitivity level = Sample absorbance x Standard amounts of 10ppm in 0.001%

Standard absorbance

Standard amount of 10ppm in 0.001% is 1mg.

= 0.1509mg

Concentration of drug by 30cm2 in sample II = 0.101 x 1 mg

0.742

= 0.1361mg

Concentration of drug by 30cm2 in sample III = 0.092 x 1mg

0.742

= 0.1240mg

Average concentration of drug / 30cm2 of the whole equipment

= 0.1509+0.1361+0.1240

3

= 0.137mg

The amount of drug present in 5229cm2 of Dispensing Booth

= 0.137 x 5229

30

= 23.8793mg (or) 0.0238ppm

Dispensing Balance:

Concentration of drug by 30cm2 in sample

= 0.101 x 1 mg

0.74

= 0.1375mg

The amount of drug present in 78.75cm2 of Dispensing Balance

= 0.137 x78.75

`30

= 0.3609mg (or) 0.000361ppm

Dispensing tools:

Concentration of drug by 30cm2 in sample = 0.027x 1 mg

0.742

= 0.0364mg

The amount of drug present in 60cm2 of Dispensing Tools

= 0.0364 x 60

30

= 0.0728mg (or) 0.000073ppm

Sifter

Concentration of drug by 30cm2 in = 0.109 x 1 mg

0.742 sample I

= 0.1469mg

Concentration of drug by 30cm2 in sample II

= 0.092 x 1 mg

0.742

= 0.1240mg

= 0.1354 mg

The amount of drug present in 1227cm2 of Sifter = 0.1354 X1227

30

= 5.5378mg (or) 0.00554 ppm

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- IV Therapy Calculations WorkbookDocumento42 páginasIV Therapy Calculations WorkbookDavid Rolevski100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Pharmacy Calculations Review: Pharmacy Tech Topics™ Volume 16 Number 3 July 2011Documento24 páginasPharmacy Calculations Review: Pharmacy Tech Topics™ Volume 16 Number 3 July 2011Mirumbi Kefa MomanyiAinda não há avaliações

- Critical Heart in Children and Infants 2019 PDFDocumento1.184 páginasCritical Heart in Children and Infants 2019 PDFLiz Mtz100% (1)

- RAMS Example 1Documento11 páginasRAMS Example 1sppAinda não há avaliações

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryDocumento11 páginasMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological Laboratoryspp100% (1)

- tr2608 Toc PDFDocumento10 páginastr2608 Toc PDFspp100% (1)

- Reviews in Food and Nutrition Toxicity, Volume 3 (CRC, 2005)Documento291 páginasReviews in Food and Nutrition Toxicity, Volume 3 (CRC, 2005)reader1453Ainda não há avaliações

- Pharmacy Internship Manual - New-1Documento14 páginasPharmacy Internship Manual - New-1Rajeswari enterpriseAinda não há avaliações

- Cleaning Validation (CV) Procedure and Protocol - Guideline SOPsDocumento30 páginasCleaning Validation (CV) Procedure and Protocol - Guideline SOPsDeepakAinda não há avaliações

- Carrel Beau. - Homoeopathy in Childhood DiseaseDocumento76 páginasCarrel Beau. - Homoeopathy in Childhood Diseaselighthillj100% (1)

- Iso 10993 11 2017Documento36 páginasIso 10993 11 2017Hector O ChavarriaAinda não há avaliações

- DPS 2012 3 2 300 304Documento5 páginasDPS 2012 3 2 300 304sppAinda não há avaliações

- Dareoct 19Documento6 páginasDareoct 19sppAinda não há avaliações

- Formulation 2Documento38 páginasFormulation 2sppAinda não há avaliações

- Zhang Asu 0010E 15975Documento148 páginasZhang Asu 0010E 15975sppAinda não há avaliações

- ECDD 37th Report FINAL PrelayoutDocumento45 páginasECDD 37th Report FINAL PrelayoutsppAinda não há avaliações

- KB003Documento4 páginasKB003sppAinda não há avaliações

- CN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentsDocumento3 páginasCN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentssppAinda não há avaliações

- US8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentsDocumento10 páginasUS8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentssppAinda não há avaliações

- CN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentsDocumento3 páginasCN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentssppAinda não há avaliações

- Rapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductsDocumento12 páginasRapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductssppAinda não há avaliações

- List of Units Indore SEZ PithampurDocumento4 páginasList of Units Indore SEZ PithampursppAinda não há avaliações

- PERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFDocumento5 páginasPERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFsppAinda não há avaliações

- Optimization and Use of Talc in Direct Compression Tablet FormulaDocumento307 páginasOptimization and Use of Talc in Direct Compression Tablet FormulasppAinda não há avaliações

- Composition of A Dossier To Register A Drug: The ContraindicationsDocumento2 páginasComposition of A Dossier To Register A Drug: The ContraindicationssppAinda não há avaliações

- PIC/S Assessment & Joint Reassessment ProgrammeDocumento15 páginasPIC/S Assessment & Joint Reassessment ProgrammesppAinda não há avaliações

- Risk Assessments and Sourcing Strategies For Excipients and ApisDocumento2 páginasRisk Assessments and Sourcing Strategies For Excipients and ApissppAinda não há avaliações

- Levofloxacin: The International PharmacopoeiaDocumento7 páginasLevofloxacin: The International PharmacopoeiasppAinda não há avaliações

- Studies On Cleaning Validation For A Cream and Ointment Manufacturing LineDocumento7 páginasStudies On Cleaning Validation For A Cream and Ointment Manufacturing LinesppAinda não há avaliações

- (PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacesDocumento16 páginas(PDF) a General LC-MS - MS Method for Monitoring Potential Β-Lactam Contamination in Drugs and Drug-Manufacturing SurfacessppAinda não há avaliações

- Beta Lactam Inactivation PDFDocumento11 páginasBeta Lactam Inactivation PDFsppAinda não há avaliações

- Article Wjpps 1470014870Documento14 páginasArticle Wjpps 1470014870sppAinda não há avaliações

- HBC 408Documento59 páginasHBC 408Stanley ChikoveAinda não há avaliações

- Absorption of Magnesium CompoundsDocumento8 páginasAbsorption of Magnesium CompoundsJo KAinda não há avaliações

- DSM PPT SlideDocumento237 páginasDSM PPT SlideAychluhm TatekAinda não há avaliações

- Formulation Science & Bioavailability: Pharmacological Parameters Study On Loop Diuretic Drug - FurosemideDocumento3 páginasFormulation Science & Bioavailability: Pharmacological Parameters Study On Loop Diuretic Drug - FurosemidevivianAinda não há avaliações

- Antidepressants in Breast Milk Comparative Analysis of Excretion RatiosDocumento8 páginasAntidepressants in Breast Milk Comparative Analysis of Excretion RatiosRubiAinda não há avaliações

- Flix o Tide InhalerDocumento5 páginasFlix o Tide InhalerEthik MoesAinda não há avaliações

- Skip To MainDocumento35 páginasSkip To MainAnonymous DqeRReAinda não há avaliações

- PercakapanDocumento3 páginasPercakapanfidelaAinda não há avaliações

- Research Revision Version 10 (Clean Copy)Documento27 páginasResearch Revision Version 10 (Clean Copy)Nesty Perez IIIAinda não há avaliações

- Midazolam Injection: New Zealand Data SheetDocumento14 páginasMidazolam Injection: New Zealand Data SheetAlin AdelineAinda não há avaliações

- Chemotherapy Protocol: RegimenDocumento6 páginasChemotherapy Protocol: RegimenAlexandra AndronescuAinda não há avaliações

- Fresofol 1 MCT-LCT PiDocumento18 páginasFresofol 1 MCT-LCT PiClaudia TiffanyAinda não há avaliações

- Sugar Industry HACCP ConceptDocumento33 páginasSugar Industry HACCP Conceptazeem dilawarAinda não há avaliações

- Daunorubicin PDFDocumento2 páginasDaunorubicin PDFmilahAinda não há avaliações

- Dosage Forms and Routes of AdministrationDocumento7 páginasDosage Forms and Routes of AdministrationSanjay Shirodkar100% (5)

- Ontario MOHLTC IVIG Request FormDocumento2 páginasOntario MOHLTC IVIG Request Formpkgill15Ainda não há avaliações

- Pharmacy CalculationsDocumento51 páginasPharmacy CalculationsWan TokAinda não há avaliações

- 2 Design of DOSAGE DESIGNDocumento16 páginas2 Design of DOSAGE DESIGNMarjo100% (1)

- BulletsDocumento14 páginasBulletsstuffednurseAinda não há avaliações

- Tinea CapitisDocumento7 páginasTinea CapitiswinAinda não há avaliações

- Colchicine DosageDocumento6 páginasColchicine DosageHam SotheaAinda não há avaliações

- Homoeopathic Drug Proving: Randomised Double Blind Placebo Controlled TrialDocumento9 páginasHomoeopathic Drug Proving: Randomised Double Blind Placebo Controlled TrialParag SharmaAinda não há avaliações