Escolar Documentos

Profissional Documentos

Cultura Documentos

FkOD Sizing As Per API PDF

Enviado por

Sandi Apriandi0 notas0% acharam este documento útil (0 voto)

37 visualizações5 páginasTítulo original

FkOD sizing as per API.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

37 visualizações5 páginasFkOD Sizing As Per API PDF

Enviado por

Sandi ApriandiDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 5

API Stondard 621 /1S0 23264

‘The second step in sizing a knockout drum is fo consider the effect any liquid contained in the drum can have

con reducing the volume available for vapourliquid disengagement. This liquid may resutt from

@) condensate that separates during a vapour release, or

) liquid streams that accompany @ vapour release.

‘The volume occupied by the liquid should be based on a release that lasts 20 min to 30 min. Longer hold-up

times can be required if it takes longer to stop the flow. Any accumulation of liquid retained from a prior

release (from pressure-teliet devices or other sources) should be added to the liquid indicated in items a) and b)

abave to determine the available vapour-disengaging space. If the knockout drum is used to contain large

liquid dumps from pressure-relief devices from other sources and there is ne significant fieshing, and the liquid

is rémoved promplly, itis not necessary to consider this liquid volume when determining the volume available

for vapour disengagement.

It is'Important to realize as part of the sizing considerations thal the maximum vepour release case does not

necessarily coincide with the maximum liquid, Therefore, the knockout-drum size should be determined

through consideration of both the maximum-vapour-release case as well as the release case with the

maximum amount of liquid.

The following sample calculations have been limited to the simplest of the designs (7.3.2.1, drum

configurations (a) end (b)|. The calculations for drum configurations (d) and (@) are similar, with one-half the

fiow rate determining one-half the vessel length, The normal calculations are used for drum configuration (c)

and are not duplicated here.

‘The following conditions are assumed.

— A single contingency results in the flow of 25,2 kgis (200 000 Ibyt) of a fluid with a liquid density of

1496.6 kgim? (31 Ib?) and a vapour density of 2,9 ka/m® (0,18 Ib), both at flowing concitions

— The gauge pressure is 13,8 kPa (2 psi), and the temperature is 148 °C (300 “F).

— The viscosity of the vapour is 0,01 mPas (0,01 cP).

—— The fluid equilibrium results in 3,9 kg/s (31 000 l/h) of liquid and 21,3 ka/s (169 000 Ib/h) of vapour.

In addition, 1,89 m® (00 US gal) of storage for miscellaneous drainings from the units is desired. The

‘schematic in Figure 17 applies. The croplet size selected as allowable is 300 um (0,012 in) in diameter.

118

‘API Standard 621 / 180 23251

a7

Koy

1 vapour and liquid safety relief valve releases

2. evel instrument to indicate when slop and drain volume has been consumed

‘3. minimum vapour space for dropout velocity

4 liquid hold-up from safety relief valves and other emergency releases,

5 slop and drain liquid

6 tofare

7 pumpout

Figure 17 — Flare knockout drum

“The vapour rate, Ry, in actual cubic metres per second (cubic feet per second), is determined as follows:

In St units:

243

Ry 7.34 mils

29

In USC units:

169.000

SiLcLues

- 3600x018 il ia

‘The drag coefficient, C, is determined from Figure 16 using Equation (29)

. (ota

485108 0,18(0,000880) (31-018) _5 apy

(0,01)

C-Re’

| From Figure 18, C-

19

API Standard 621 / ISO 28251

The dropout velocity, ue, is caleulated as follows:

In Stunits:

eae

ng 1450 | 22%800%10 x(496.0-29) | graye

25x43

In USC units:

32,2 0,000984x(31-0,18) |”*

ng =4160| 2220.000084 (91-018) )" 5 a5 75

Of8x13

‘A horizontal vessel with an inside diameter, D;, and a cylindrical length, Z, should be assumed. This gives the

following total cross-sectional area, 4y

A= pay 40)

Liquid hold-up for a 30-min release from the single contingency, in addition to the slop and drain volume, is

desired, The volume in the heads is neglected for simplicity. The liquid hold-up required, 4, in cubic metres

(cubic feet), is calculated as folows:

‘The slop and drain volume of 1,89 m3 (600 U.S gal, 66,8 f9) occupies a bottom segment as follows:

In SI units:

1

Z sae 4) a)

In USC units:

1

Age ee ) (42)

‘A total of 3,9 kg/s (21 000 Ib/h) of condensed liquids with a density of 496,6 kgm? (31 ib/t®) accumulated for

30 min occupies a cross-sectional segment [see 7.3.2.1.2 a)] as follows:

A

In St units:

3 i

ae eigxeo-e0{) (43)

In USC units

31000 30/1

ene eee 1a)

A2° s(z)

“The cross-sectional area remaining or the vapour flow is expressed as follows:

A A(Art aa) 48)

120

API Standard 521 / ISO 23281

The vertical depths of the liquid and vapour spaces are determined using standard geometry and the total

num diameter, %, is calculated using Equation (46):

nahithathy (46)

where

ha Is the depth of slops and drains;

(hu +h) Is the depth ofall iquid accumulation;

by is the remaining vertical space for the vapour flow.

‘The adequacy of the vapour space is verified by determining the liquid dropout time, #, using Equation (47)

In SI units:

_{*_\4

(lz) ae

In USC unis

wy

(Sy net } 8)

where

is the liquid dropout time, expressed in seconds;

h

ty is the vertical drop available for liquid dropout, expressed in centimetres (inches);

1, is the dropout velocity, expressed in metres per second (feet per second).

‘The velocity of W vapour passes, based on one vapour pass, is determined from Equations (49) and (80) for a

volume flow rate of 7,34 mols (260 £316)

tn St units:

734) 1

i (FI wy ) -

In USC units

2601

~Plz] ”

where

A, Is the cross-sectional area, expressed in square metres (square feel),

WN is the number of vapour passes;

1, is the vapour velocity, expressed in metres per second (feet per second).

at

API Standard 621/180 23251

“The drum length required, Lyn 18 determined as follows:

Epa = hy -9-N 6)

Imi, Shall be less then or equal to the above assumed cylindrical drum length, 1; otherwise, the calculation

shall be repeated with a newly assumed cylindrical drum length.

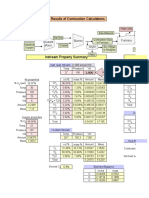

‘Tables 15 and 16 summarize the preceding calculations for one pass for horizontal drums with various inside

diameters to determine the most economical drum size. Drum diameters in 15 cm (6in) increments are

assumed, in accordance with standard head sizes.

Table 16 — Optimizing the size of a horizontal knockout drum (SI urits)

Trial | D,* | 2 Cross-sectional area Vertical dopth oftiquid and | @° | 9 | Ln?

No. ‘vapour spaces

m2 on

AL | 4 | te | ay | tor Partha] te |e

1 | 244 | 579 | 467 | 03 | 245 | 190 | 30 | 140 | 104 | 244 | 145 | 39 | 56

220 | 625 | 40 | 020 | 227 | x83 | 20 | 137 | 91 | 220 | 128] 48 | 62

243 | 686 | 367 | 028 | 207 | 122 | 26 | 133 | a1 | a3 | 413 | 60 | 67

198 | 7.62 | 3.08 | 0,25 | 198 | os | 27 | 128 | 70 | 198 | 098 | 75 | 74

NOTE + The data inthis tabo ao In accordance with fe example von n text forone pass vapour fw

NOTE 2 The values inthis tole are roundd-off conversions ofthe values in Tabo 1,

J> fe the assumed drum inside ameter, expressed in metres

Lis the assumed drum eylndcal length, expressed in metres,

Je ae moriqu aropout me, expressed in secends.

|é ye the vapour veloc, expressed in malios per second,

Je tin sth required drum length, expressed innate,

It can be concluded from Table 15 that

— all of the drum sizes above fulfill the design requirements;

— the most suitabie drum size should be selected according to the design pressure, material requirements

‘and corrosion allowance 2s well as layout, transportation and ather considerations;

= the choice of two-pass flow, as shown in Figure 17, is optional.

422

Você também pode gostar

- Design CalculationsDocumento50 páginasDesign CalculationsSandi ApriandiAinda não há avaliações

- (Liter) (Inch) (MM) (Inch) (MM) (Inch) (MM) (Inch) (MM) (MM) (MM) (MM) (MM) (MM) (MM) (MM) Approx. (KG)Documento1 página(Liter) (Inch) (MM) (Inch) (MM) (Inch) (MM) (Inch) (MM) (MM) (MM) (MM) (MM) (MM) (MM) (MM) Approx. (KG)Sandi ApriandiAinda não há avaliações

- Drawing ListDocumento6 páginasDrawing ListSandi ApriandiAinda não há avaliações

- Water in Air Calculator - Version 3Documento7 páginasWater in Air Calculator - Version 3Marusan PetpookaewAinda não há avaliações

- ARI STD 300-2000Documento9 páginasARI STD 300-2000Sandi ApriandiAinda não há avaliações

- Burner CalculationDocumento7 páginasBurner CalculationSandi ApriandiAinda não há avaliações

- Gas Yellow BookDocumento88 páginasGas Yellow BookSandi ApriandiAinda não há avaliações

- Cal Tank Foundation-Ring WallDocumento4 páginasCal Tank Foundation-Ring WallSandi ApriandiAinda não há avaliações

- 16-126 Fire Water F Optimasisc1Documento1 página16-126 Fire Water F Optimasisc1Sandi ApriandiAinda não há avaliações

- Waste Water 0Documento72 páginasWaste Water 0Sandi ApriandiAinda não há avaliações

- Medical Air System Calc - 0Documento12 páginasMedical Air System Calc - 0Sandi ApriandiAinda não há avaliações

- Operation Manual: Panduan PengoperasianDocumento56 páginasOperation Manual: Panduan PengoperasianSandi ApriandiAinda não há avaliações

- Louser Lift - Co.id Brochure PassengerLiftDocumento28 páginasLouser Lift - Co.id Brochure PassengerLiftSandi ApriandiAinda não há avaliações

- IZE14001 VRVXpress ManualDocumento80 páginasIZE14001 VRVXpress ManualSandi ApriandiAinda não há avaliações

- Simulation of AglomerationDocumento6 páginasSimulation of AglomerationSandi ApriandiAinda não há avaliações

- Dairy Ingredients Fax: Bulk DensityDocumento3 páginasDairy Ingredients Fax: Bulk DensitySandi ApriandiAinda não há avaliações

- AHLSTAR - UP Process PumpsDocumento16 páginasAHLSTAR - UP Process PumpsSandi ApriandiAinda não há avaliações

- Max Piping Oper PressDocumento8 páginasMax Piping Oper PressSandi ApriandiAinda não há avaliações

- Conveyor Design DraftDocumento47 páginasConveyor Design DraftSandi Apriandi100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)