Escolar Documentos

Profissional Documentos

Cultura Documentos

RT Inspection Lubrication Service Log 24201

Enviado por

ArisDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

RT Inspection Lubrication Service Log 24201

Enviado por

ArisDireitos autorais:

Formatos disponíveis

GROVE

ROUGH TERRAIN CRANE INTRODUCTION

Inspection & Lubrication Manual

Purposes of this manual: How to use this manual: Notes:

1) To serve as a guide when making required Signature Verification Record Page: 1) Before performing any inspection on the

inspections & lubrications on your Manitowoc Grove Each person to inspect and/or lubricate this Manitowoc Manitowoc Grove Crane the inspector must have

Crane. Refer to your Crane Operator's and/or Service Grove Crane is required to print/sign/initial their name. read the Safety section of the Operator's manual.

Manual, and your Engine Operation and Maintenance

Manual, for details. Inspection & Lubrication Service Log Pages: 2) The same inspector who performed the initital

1) Check off each item as satisfactory completed. inspection when the item was considered as

2) To serve as a one year permanent written log of the unsatisfactory should perform the inspection after

inspection & lubrication service activity on your 2) Leave blank items that were found unsatisfactory. repairs, adjustments, etc., have been performed.

Manitowoc Grove Crane.

3) Record initials of person performing the tasks outlined. 3) Lubrication is to be performed in accordance

Note: Federal regulations require that written, dated, Record hour meter readings (not for Daily or 10 Hour with instructions in the Operator's Manual and only

and signed inspections records be maintained. checks). after reading the Safety section of the Operator's

Manual.

This manual is not intended to replace any 4) For unsatisfactory items record each in the Service &

preoperational checks required by an owner or local or Repair Record pages in the back of this manual. 4) You will need a separate Service Log for each

state safety board. 10 hour shift your crane is operated.

Service & Repair Record Pages:

Record problems and resolutions on these pages. 5) Ordering part number for additional copies of

this manual is 9828100654.

Manual Content:

Daily or 10 Hour Check List

Weekly or 50 Hour Check List

Monthly or 250 Hour Check List

3 Month, 6 Month, 12 Month, or 500 Hour Check List

6, 12, 24+ Month, or 1000, 2000, 4000 Hour Check List

1000 Mile Check List

Signature Verification Record

Service & Repair Record

Inspection & Lubrication Manual

Published 5-05-2009, Control # 242-01 1

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 28

Change filter 14 29

Check for deterioration, damage or excessive wear 15 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 2

GROVE

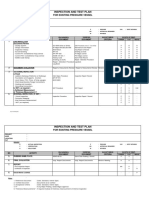

RT INSPECTION & LUBRICATION SERVICE LOG

January Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24

25

26

27

29

Inspector's Initials:

Daily or 10 Hour Check List January

Published 5-05-2009, Control # 242-01 3

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 4

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

February Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List February

Published 5-05-2009, Control # 242-01 5

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 6

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

March Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List March

Published 5-05-2009, Control # 242-01 7

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 8

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

April Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List April

Published 5-05-2009, Control # 242-01 9

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 10

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

May Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List May

Published 5-05-2009, Control # 242-01 11

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 12

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

June Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List June

Published 5-05-2009, Control # 242-01 13

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 14

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

July Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List July

Published 5-05-2009, Control # 242-01 15

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 16

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

August Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List August

Published 5-05-2009, Control # 242-01 17

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 18

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

September Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List September

Published 5-05-2009, Control # 242-01 19

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 20

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

October Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List October

Published 5-05-2009, Control # 242-01 21

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 22

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

November Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List November

Published 5-05-2009, Control # 242-01 23

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Daily or 10 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Daily or 10 Hour Check List

Published 5-05-2009, Control # 242-01 24

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

December Daily or 10 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Day of Inspection

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Operator's Manual 1

2 Signal and Running Lights & Horn 2, 3

3 Back-up Alarm 7

4 Gauges and Instruments 3, 5, 7

5 Brakes (Swing, Foot & Parking) 3, 7

6 Boom Angle Indicator 7

7 Load Moment Indicator 7, 19

8 Antitwo-Block (A2B) Elec. & Hyd. 7, 19

9 Brakes and Air System (if equipped) 3, 7, 13

10 Tires 21, 10, 6

11 Hourmeter 3, 5, 19

12 Hydraulic Tank 4, 6

13 Hydraulic Oil Filter 4

14 Wire Rope 20

15 Hoists 1, 6, 7

16 Boom and Attachments 1, 6, 7

17 Crankcase 4, 6

18 Transmission/Torque Converter 4

19 Cooling System 4

20 Fuel/Water Separator 13

21 Air Cleaner 4, 9

22 Hook Block & Headache Ball Safety Latch 3, 9, 10

23 Lock-out Cylinder & Slew Potentiometer 7, 8

24 0 0

25 0 0

26 0 0

27 0 0

29 0 0

Inspector's Initials:

Daily or 10 Hour Check List December

Published 5-05-2009, Control # 242-01 25

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Weekly or 50 Hours Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Weekly or 50 Hours Check List

Published 5-05-2009, Control # 242-01 26

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

Weekly or 50 Hours Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code January February March April May June

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 Wk

1 Turntable Gearbox 4

2 Turntable Gearbox (1st 250 hours) 27

3 Outrigger Beans, Tubes and Barrels 16, 18

4 Sheaves 7, 10,

5 Counterwieght 11, 16

6 Coolant Strainer (1st 100 hours) 12

7 Belts 8, 10

8 Pumps & Motors 9

9 Wheel Lugs 11

10 Transmission Filter (1st 50 & 100 hours) 14

11 Boom Upper & Lower Wear Pads 18

12 Wiring 22

13 Battery and Cable Clamps 23

14 Hoists 4, 9

15 Outrigger Float Pads 1, 16

16 Hydraulic Hoses 26

17 Air Compressor Oil Level 4, 8

18

19

20

21

22

Inspector's Initials:

Hourmeter Reading:

Weekly or 50 Hours Check List

Published 5-05-2009, Control # 242-01 27

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Weekly or 50 Hours Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Weekly or 50 Hours Check List

Published 5-05-2009, Control # 242-01 28

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

Weekly or 50 Hours Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code July August September October November December

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 Wk

1 Turntable Gearbox 4

2 Turntable Gearbox (1st 250 hours) 27

3 Outrigger Beans, Tubes and Barrels 16, 18

4 Sheaves 7, 10,

5 Counterwieght 11, 16

6 Coolant Strainer (1st 100 hours) 12

7 Belts 8, 10

8 Pumps & Motors 9

9 Wheel Lugs 11

10 Transmission Filter (1st 50 & 100 hours) 14

11 Boom Upper & Lower Wear Pads 18

12 Wiring 22

13 Battery and Cable Clamps 23

14 Hoists 4, 9

15 Outrigger Float Pads 1, 16

16 Hydraulic Hoses 26

17 Air Compressor Oil Level 4, 8

18 0 0

19 0 0

20 0 0

21 0 0

22 0 0

Inspector's Initials:

Hourmeter Reading:

Weekly or 50 Hours Check List

Published 5-05-2009, Control # 242-01 29

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Monthly or 250 Hours Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Monthly or 250 Hours Check List

Published 5-05-2009, Control # 242-01 30

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

Monthly or 250 Hours Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code

January February March April May June

1 Hook Block 18

2 Side Wear Pads 18

3 Cable Sheaves 18

4 Pivot Shaft 18

5 Extension Sheave & Roller 18

6 Nose Sheave 18

7 Cable Follower Arms 18

8 Swingaway Hanger Wear Pads 18

9 Headache Ball 18

10 Hose Roller (RT890E & RT9130E) 18

11 Crankcase (RT880E & RT890E) 14, 27

12 Fire Extingulsher 1

13 Cold Weather Starting Aid 1, 3, 9, 19

14 Batteries 4

15 Valves 9, 16

16 Cylinders 9, 16

17 Boom 16

18 Hoses 6, 9, 15

19 Hose Clamps, Guards, Shields 1

20 Jib & Lattice Extension Pins (if equipped) 1, 15

21 Turntable Bolts (1st 300 Hours) 11

22 Radiator 16

Inspector's Initials:

Hourmeter Reading:

Monthly or 250 Hours Check List

Published 5-05-2009, Control # 242-01 31

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

Monthly or 250 Hours Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

Monthly or 250 Hours Check List

Published 5-05-2009, Control # 242-01 32

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

Monthly or 250 Hours Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code

July August September October November December

1 Hook Block 18

2 Side Wear Pads 18

3 Cable Sheaves 18

4 Pivot Shaft 18

5 Extension Sheave & Roller 18

6 Nose Sheave 18

7 Cable Follower Arms 18

8 Swingaway Hanger Wear Pads 18

9 Headache Ball 18

10 Hose Roller (RT890E & RT9130E) 18

11 Crankcase (RT880E & RT890E) 14, 27

12 Fire Extingulsher 1

13 Cold Weather Starting Aid 1, 3, 9, 19

14 Batteries 4

15 Valves 9, 16

16 Cylinders 9, 16

17 Boom 16

18 Hoses 6, 9, 15

19 Hose Clamps, Guards, Shields 1

20 Jib & Lattice Extension Pins (if equipped) 1, 15

21 Turntable Bolts (1st 300 Hours) 11

22 Radiator 16

Inspector's Initials:

Hourmeter Reading:

Monthly or 250 Hours Check List

Published 5-05-2009, Control # 242-01 33

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

3 Months, 6 Months, 12 Months, or 500 Hour Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

3 Months, 6 Months, 12 Months, or 500 Hour Check List

Published 5-05-2009, Control # 242-01 34

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

3 Months, 6 Months, 12 Months, or 500 Hour Check List

Line Item

Inspection

Items to be Inspected/Lubricated Code Interval Months (Or 500 hours,

whichever comes first)

Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec

1 Steering & Suspension Pivot & King Pins 18 Three (3) Months

2 Axle 4 Three (3) Months

3 Crankcase (RT600E, RT9130E) 14, 27 Three (3) Months

4 Fuel Filter (RT600E) 14 Three (3) Months

5 Drive Train Slip Joints 18 Three (3) Months

6 Transmission Filter 14 Three (3) Months

7 Cooling System (RT9130E) 14 Three (3) Months

8 Lift Cylinder Pins (Not on RT880E & RT890E) 18 Three (3) Months

9 Cab Tilt Cylinder (RT880E, RT890E & RT9130E) 18 Three (3) Months

10 Cab Pillow Block (RT880E, RT890E & RT9130E) 18 Three (3) Months

11 Mounting Bolts (Trans, Eng, Hoist, Gearbox, Axle) 11 Three (3) Months

12 Turntable Bolts 11 Three (3) Months

13 Muffler 9 Three (3) Months

14 Boom 8 Three (3) Months

15 Crane Structure 16 Three (3) Months

16 Differential Breather 3 Three (3) Months

17 Crankcase (RT530E-2, RT540E & RT700E) 14, 27 Six (6) Months

18 Fuel Filter (Not RT600E) 14 Six (6) Months

19 Strainer (RT880E, RT890E, & RT9130E) 25 Six (6) Months

20 Turntable Bearing & Drive Pinion 18 Six (6) Months

21 Turntable Gear Box 27 Twelve (12) Months

22 Boom Mast Sheave (Not on RT9130E) 18 Twelve (12) Months

23 Hose Reel 18 Six (6) Months

Inspector's Initials:

Hourmeter Reading:

3 Months, 6 Months, 12 Months, or 500 Hour Check List

Published 5-05-2009, Control # 242-01 35

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

6 Months, 12 Months, 24+ Months or 1000 Hours, 2000 Hours, 4000 Hours

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operating machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 0 28

Change filter 14 0 29

Check for deterioration, damage or excessive wear 15 0 30

6 Months, 12 Months, 24+ Months or 1000 Hours, 2000 Hours, 4000 Hours

Published 5-05-2009, Control # 242-01 36

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

6 Months, 12 Months, 24+ Months or 1000 Hours, 2000 Hours, 4000 Hours

Line Item

Inspection

Items to be Inspected/Lubricated Code Hours (or) Months Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec

1 Transmission/Torque Converter 9, 27 1000 6 Months

2 Swing Gearbox 9, 27 1000 6 Months

3 Boom Wear Pads 10, 12 1000 6 Months

4 Axle Differentials 9 1000 6 Months

5 Axle Planetary Hubs - Front 3 1000 6 Months

6 Axle Planetary Hubs - Rear 3 1000 6 Months

7 Brake Lines 3, 10 1000 6 Months

8 Hoists 9, 27 1000 12 Months

9 Coolant Strainer 12 2000 12 Months

10 Cooling System (RT: 530E-2, 540E, 600E, 700E) 9, 27 2000 12 Months

11 Retarder (RT9130E) 18 2000 12 Months

12 Axle Differentials 9, 27 4000 24 Months

13

14

15

16

17

18

19

20

21

22

Inspector's Initials:

Hourmeter Reading:

6 Months, 12 Months, 24+ Months or 1000 Hours, 2000 Hours, 4000 Hours

Published 5-05-2009, Control # 242-01 37

GROVE

RT INSPECTION & LUBRICATION SERVICE CODES

1000 Mile Check List

Task to Perform Code Task to Perform Code

Is item properly installed on machine 1 Check for cracked or broken structures and welds 16

Check for cracked or broken glass 2 Service as required by engine manufacturer 17

Check for proper working order 3 Lubricate 18

Check for proper service/level 4 Check connectors and wiring for proper alignment and insulation 19

Check for proper reading while operating engine 5 Check wire for damaged, frayed, or broken strands 20

Check for excess dirt, grease, or foreign matter 6 Check for proper inflation/pressure 21

Check for proper operation while operation machine 7 Check for loose or damaged wiring 22

Check for proper adjustment 8 Check that clamps are tight and not corroded 23

Check for cracks or leaks 9 Check complete path for any condition that could damage rope 24

Check for excessive wear 10 Replace 25

Check torque 11 Check for leaks at connection points 26

Clean or replace 12 Drain and fill 27

Drain moisture 13 28

Change filter 14 29

Check for deterioration, damage or excessive wear 15 30

1000 Mile Check List

Published 5-05-2009, Control # 242-01 38

GROVE

RT INSPECTION & LUBRICATION SERVICE LOG

1000 Mile Check List

Line Item

Inspection

Items to be Inspected Code Thousands

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

1 Wheel Lugs 11

2 Tie Rod Balljoints 10

3 Steering Knuckles 10

4 Drag Link U-Joint 10

5 Drag Link Ends 10

6 Clutch Release Bearing 8

7 Gearshift Control 7, 8

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Mileage:

Inspector's Initials:

1000 Mile Check List

Published 5-05-2009, Control # 242-01 39

GROVE

RT SIGNATURE VERIFICATION RECORD

Authorized Personnel Only

Print Name Clearly Sign Name Initials to use

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 40

GROVE

RT SERVICE & REPAIR RECORD

Authorized Personnel Only

Description of Problem Found Page Line Initials Date Service, Adjustments, or Repairs Performed Initials Date

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 41

GROVE

RT SERVICE & REPAIR RECORD

Authorized Personnel Only

Description of Problem Found Page Line Initials Date Service, Adjustments, or Repairs Performed Initials Date

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 42

GROVE

RT SERVICE & REPAIR RECORD

Authorized Personnel Only

Description of Problem Found Page Line Initials Date Service, Adjustments, or Repairs Performed Initials Date

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 43

GROVE

RT SERVICE & REPAIR RECORD

Authorized Personnel Only

Description of Problem Found Page Line Initials Date Service, Adjustments, or Repairs Performed Initials Date

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 44

GROVE

RT SERVICE & REPAIR RECORD

Authorized Personnel Only

Description of Problem Found Page Line Initials Date Service, Adjustments, or Repairs Performed Initials Date

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 45

GROVE

RT SERVICE & REPAIR RECORD

Authorized Personnel Only

Description of Problem Found Page Line Initials Date Service, Adjustments, or Repairs Performed Initials Date

Authorized Personnel Only

Published 5-05-2009, Control # 242-01 46

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Performance Evaluation Report For Practicum TraineesDocumento2 páginasPerformance Evaluation Report For Practicum TraineesJ.S100% (3)

- T Rex PumpDocumento4 páginasT Rex PumpWong DaAinda não há avaliações

- BBO2020Documento41 páginasBBO2020qiuAinda não há avaliações

- Structural Behavior of Buried Pipe Bends and Their Effect On Pipeline Response in Fault Crossing AreasDocumento34 páginasStructural Behavior of Buried Pipe Bends and Their Effect On Pipeline Response in Fault Crossing AreasArisAinda não há avaliações

- 2011 National Electrical Code® - Hazardous Areas PDFDocumento151 páginas2011 National Electrical Code® - Hazardous Areas PDFyebri100% (1)

- 12 Drilling PreventersDocumento82 páginas12 Drilling PreventersDavid Kusuma100% (1)

- Check Overhead Crane BrakesDocumento1 páginaCheck Overhead Crane BrakesArisAinda não há avaliações

- EUR23252ENDocumento108 páginasEUR23252ENMohamed Abbas BissoAinda não há avaliações

- Chapter 4 OCWDocumento69 páginasChapter 4 OCWmr_heeraAinda não há avaliações

- ITP-PRESSURE VESSEL ExistingDocumento2 páginasITP-PRESSURE VESSEL ExistingArisAinda não há avaliações

- A Method of Calculus of Residual Lifetime For Lifting InstallationDocumento7 páginasA Method of Calculus of Residual Lifetime For Lifting InstallationArisAinda não há avaliações

- General Guide For CranesDocumento19 páginasGeneral Guide For CranesArisAinda não há avaliações

- Guide To Tower CranesDocumento10 páginasGuide To Tower CranesArisAinda não há avaliações

- Guide To Tower CranesDocumento10 páginasGuide To Tower CranesArisAinda não há avaliações

- General Guide For CranesDocumento19 páginasGeneral Guide For CranesArisAinda não há avaliações

- 8.tech Info - Rectangular SwingawayDocumento6 páginas8.tech Info - Rectangular SwingawayArisAinda não há avaliações

- CK 2500 PDFDocumento28 páginasCK 2500 PDFArisAinda não há avaliações

- Repair BoomDocumento60 páginasRepair BoomArisAinda não há avaliações

- Tech Info - Rectangular Boom Inspection ProcedureDocumento8 páginasTech Info - Rectangular Boom Inspection ProcedureArsalan IdreesAinda não há avaliações

- 1.rectangular4 PlateBoom Inspection ProcedureDocumento9 páginas1.rectangular4 PlateBoom Inspection ProcedureArisAinda não há avaliações

- RT Inspection Lubrication Service Log 24201Documento46 páginasRT Inspection Lubrication Service Log 24201ArisAinda não há avaliações

- 6.tech Info 2012 Megaform - InspectionDocumento8 páginas6.tech Info 2012 Megaform - InspectionArisAinda não há avaliações

- 8460 Boom Assembly, Disassembly and Length ChangesDocumento111 páginas8460 Boom Assembly, Disassembly and Length ChangesArisAinda não há avaliações

- 2.F2097Inspection MaintCheckList10302013Documento66 páginas2.F2097Inspection MaintCheckList10302013ArisAinda não há avaliações

- 8.tech Info - Rectangular SwingawayDocumento6 páginas8.tech Info - Rectangular SwingawayArisAinda não há avaliações

- 5.structual Inspection Procedure A-Frame JibDocumento5 páginas5.structual Inspection Procedure A-Frame JibArisAinda não há avaliações

- Class Division ElectricalDocumento26 páginasClass Division ElectricalArisAinda não há avaliações

- Sni 13 3474 1994 Asme B31 8 PDFDocumento262 páginasSni 13 3474 1994 Asme B31 8 PDFArisAinda não há avaliações

- 1.rectangular4 PlateBoom Inspection ProcedureDocumento9 páginas1.rectangular4 PlateBoom Inspection ProcedureArisAinda não há avaliações

- Inspection and Test Plan: Offshore Pipeline RecertificationDocumento3 páginasInspection and Test Plan: Offshore Pipeline RecertificationArisAinda não há avaliações

- ITP Tank RecertificationDocumento3 páginasITP Tank RecertificationArisAinda não há avaliações

- ITP ForkliftDocumento3 páginasITP ForkliftAris100% (2)

- Old Highland Park Baptist Church E01Documento74 páginasOld Highland Park Baptist Church E01Lawrence Garner100% (2)

- So Tim Penilik N10 16 Desember 2022 Finish-1Documento163 páginasSo Tim Penilik N10 16 Desember 2022 Finish-1Muhammad EkiAinda não há avaliações

- CSR Report On Tata SteelDocumento72 páginasCSR Report On Tata SteelJagadish Sahu100% (1)

- Javascript NotesDocumento5 páginasJavascript NotesRajashekar PrasadAinda não há avaliações

- 30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Documento64 páginas30 de Thi Hoc Ky 2 Mon Tieng Anh Lop 9 Co Dap An 2023Trần MaiAinda não há avaliações

- 2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyDocumento9 páginas2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyNMarkatosAinda não há avaliações

- Tanque: Equipment Data SheetDocumento1 páginaTanque: Equipment Data SheetAlonso DIAZAinda não há avaliações

- Sco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Documento4 páginasSco 8th Class Paper - B Jee-Main Wtm-15 Key&Solutions Exam DT 17-12-2022Udaya PrathimaAinda não há avaliações

- NSTP SlabDocumento2 páginasNSTP SlabCherine Fates MangulabnanAinda não há avaliações

- Portfolio AdityaDocumento26 páginasPortfolio AdityaAditya DisAinda não há avaliações

- Islcollective Present SimpleDocumento2 páginasIslcollective Present Simplecrisan mirunaAinda não há avaliações

- Matokeo CBDocumento4 páginasMatokeo CBHubert MubofuAinda não há avaliações

- USA Nozzle 01Documento2 páginasUSA Nozzle 01Justin MercadoAinda não há avaliações

- Chapter 15: Religion in The Modern World: World Religions: A Voyage of DiscoveryDocumento11 páginasChapter 15: Religion in The Modern World: World Religions: A Voyage of DiscoverysaintmaryspressAinda não há avaliações

- 2017-04-27 St. Mary's County TimesDocumento32 páginas2017-04-27 St. Mary's County TimesSouthern Maryland OnlineAinda não há avaliações

- Elementary Electronics 1968-09-10Documento108 páginasElementary Electronics 1968-09-10Jim ToewsAinda não há avaliações

- EC105Documento14 páginasEC105api-3853441Ainda não há avaliações

- D15 Hybrid P1 QPDocumento6 páginasD15 Hybrid P1 QPShaameswary AnnadoraiAinda não há avaliações

- Activity Sheet Housekeeping Week - 8 - Grades 9-10Documento5 páginasActivity Sheet Housekeeping Week - 8 - Grades 9-10Anne AlejandrinoAinda não há avaliações

- Module 4 How To Make Self-Rescue Evacuation Maps?Documento85 páginasModule 4 How To Make Self-Rescue Evacuation Maps?RejieAinda não há avaliações

- De On Tap So 4-6Documento8 páginasDe On Tap So 4-6Quy DoAinda não há avaliações

- Portfolio Write-UpDocumento4 páginasPortfolio Write-UpJonFromingsAinda não há avaliações

- Cs Fujitsu SAP Reference Book IPDFDocumento63 páginasCs Fujitsu SAP Reference Book IPDFVijay MindfireAinda não há avaliações

- Invitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Documento2 páginasInvitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Naresh KadyanAinda não há avaliações

- Resolution: Owner/Operator, DocketedDocumento4 páginasResolution: Owner/Operator, DocketedDonna Grace Guyo100% (1)

- Cs205-E S3dec18 KtuwebDocumento2 páginasCs205-E S3dec18 KtuwebVighnesh MuralyAinda não há avaliações

- Tylenol CrisisDocumento2 páginasTylenol CrisisNida SweetAinda não há avaliações