Escolar Documentos

Profissional Documentos

Cultura Documentos

NEC Tabla 310-16

Enviado por

Miguel Encarnacion100%(3)100% acharam este documento útil (3 votos)

4K visualizações2 páginasNEC Tabla 310-16

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoNEC Tabla 310-16

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(3)100% acharam este documento útil (3 votos)

4K visualizações2 páginasNEC Tabla 310-16

Enviado por

Miguel EncarnacionNEC Tabla 310-16

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 2

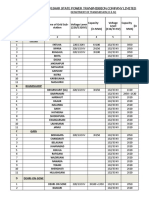

CONDUCTOR AMPACITIES - NEC Table 310-16

Allowable Ampacities Of Insulated Conductors Rated 0-2000 Volts,

60-90C, Not More Than 3 Conductors in Raceway or Cable or Earth

(directly buried), Based On Ambient Temperature Of 30C (86F).

-------------------------------------------------------------------------------

Size | Temperature Rating Of Conductor | Size

| | | || | | |

| 60C | 75C | 90C || 60C | 75C | 90C |

|(140F)| (167F) | (194F) || (140F) | (167F) | (194F) |

-------------------------------------------------------------------------------

| TYPES | TYPES | TYPES || TYPES | TYPES | TYPES |

| TW* | FEPW* |TA,TBS,SIS || TW* |RH*,RHW* |TBS, SA |

| UF* | RH*,RHW* |SA,FEP*,MI || UF* |THHW*,THW*|SIS,THHN* |

| |THHW*,THW*|FEPB*,RHW-2|| |THWN*,USE*|THHW*,THW-2|

AWG | |THWN*,USE*|RHH*,THHN* || |XHHW* |THWN-2,RHH*| AWG

kcmil | |XHHW*,ZW* |THHW*,THW-2|| | |RHW-2,USE-2| kcmil

| | |THWN-2,XHH || | |XHH,XHHW |

| | |USE-2,XHHW*|| | |XHHW-2,ZW-2|

| | |XHHW-2,ZW-2|| | | |

-------------------------------------------------------------------------------

| COPPER || ALUMINUM OR COPPER CLAD ALUM. |

-------------------------------------------------------------------------------

18 | .... | .... | 14 || .... | .... | .... | ...

16 | .... | .... | 18 || .... | .... | .... | ...

14 | 20* | 20* | 25* || .... | .... | .... | ...

12 | 25* | 25* | 30* || 20* | 20* | 25* | 12

10 | 30 | 35* | 40* || 25 | 30* | 35* | 10

8 | 40 | 50 | 55 || 30 | 40 | 45 | 8

6 | 55 | 65 | 75 || 40 | 50 | 60 | 6

4 | 70 | 85 | 95 || 55 | 65 | 75 | 4

3 | 85 | 100 | 110 || 65 | 75 | 85 | 3

2 | 95 | 115 | 130 || 75 | 90 | 100 | 2

1 | 110 | 130 | 150 || 85 | 100 | 115 | 1

1/0 | 125 | 150 | 170 || 100 | 120 | 135 | 1/0

2/0 | 145 | 175 | 195 || 115 | 135 | 150 | 2/0

3/0 | 165 | 200 | 225 || 130 | 155 | 175 | 3/0

4/0 | 195 | 230 | 260 || 150 | 180 | 205 | 4/0

250 | 215 | 255 | 290 || 170 | 205 | 230 | 250

300 | 240 | 285 | 320 || 190 | 230 | 255 | 300

350 | 260 | 310 | 350 || 210 | 250 | 280 | 350

400 | 280 | 335 | 380 || 225 | 270 | 305 | 400

500 | 320 | 380 | 430 || 260 | 310 | 350 | 500

600 | 355 | 420 | 475 || 285 | 340 | 385 | 600

700 | 385 | 460 | 520 || 310 | 375 | 420 | 700

750 | 400 | 475 | 535 || 320 | 385 | 435 | 750

800 | 410 | 490 | 555 || 330 | 395 | 450 | 800

900 | 435 | 520 | 585 || 355 | 425 | 480 | 900

1000 | 455 | 545 | 615 || 375 | 445 | 500 | 1000

1250 | 495 | 590 | 665 || 405 | 485 | 545 | 1250

1500 | 520 | 625 | 705 || 435 | 520 | 585 | 1500

1750 | 545 | 650 | 735 || 455 | 545 | 615 | 1750

2000 | 560 | 665 | 750 || 470 | 560 | 630 | 2000

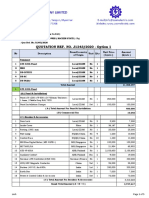

==== AMBIENT TEMPERATURE CORRECTION FACTORS ====

-------------------------------------------------------------------------------

Amb. | For ambient temperatures other than 30C(86F), multiply the | Amb.

Tmp.C| allowable ampacities above by the appropriate factor below. |Tmp.F

21-25 | 1.08 | 1.05 | 1.04 || 1.08 | 1.05 | 1.04 | 70-77

26-30 | 1.00 | 1.00 | 1.00 || 1.00 | 1.00 | 1.00 | 78-86

31-35 | .91 | .94 | .96 || .91 | .94 | .96 | 87-95

36-40 | .82 | .88 | .91 || .82 | .88 | .91 | 96-104

41-45 | .71 | .82 | .87 || .71 | .82 | .87 |105-113

46-50 | .58 | .75 | .82 || .58 | .75 | .82 |114-122

51-55 | .41 | .67 | .76 || .41 | .67 | .76 |123-131

56-60 | .... | .58 | .71 || .... | .58 | .71 |132-140

61-70 | .... | .33 | .58 || .... | .33 | .58 |141-158

71-80 | .... | .... | .41 || .... | .... | .41 |159-176

* Unless otherwise specifically permitted elsewhere in this Code, the over-

current protection for conductor types marked with an * shall not exceed 15

amperes for No. 14, 20 amperes for No. 12, and 30 amperes for No. 10 copper;

or 15 amperes for No. 12 and 25 amperes for No. 10 aluminum and copper-clad

aluminum after any correction factors for ambient temperature and number of

conductors have been applied.

Você também pode gostar

- Operation manual-HM5001 TTRDocumento15 páginasOperation manual-HM5001 TTRGio CJAinda não há avaliações

- Guia Del Usuario - CCM Modelo 6 - MCC Model 6 Square DDocumento568 páginasGuia Del Usuario - CCM Modelo 6 - MCC Model 6 Square DMaxAinda não há avaliações

- Hyundai CatalougeDocumento256 páginasHyundai CatalougekazishahAinda não há avaliações

- Eat OnDocumento160 páginasEat OnWashington MazziniAinda não há avaliações

- Iec 60269-2-1 Low-Voltage Fuses - Supplemetary Requirements For Fuses For Use by Authorized PersoDocumento264 páginasIec 60269-2-1 Low-Voltage Fuses - Supplemetary Requirements For Fuses For Use by Authorized PersoMarcelo Martini ViannaAinda não há avaliações

- AWG To mm2Documento1 páginaAWG To mm2adelfawzy1234100% (1)

- Manual de Supresor de TransitoriosDocumento8 páginasManual de Supresor de TransitoriosAlkaEnergy EnergyAinda não há avaliações

- ALSTOM - Interruptores Vacio PDFDocumento2 páginasALSTOM - Interruptores Vacio PDFadepomaAinda não há avaliações

- ANSI Device Function Number IEEE C37.2-2008Documento13 páginasANSI Device Function Number IEEE C37.2-2008Mihai Popescu100% (1)

- NEC Article 645.5: 645.5 Supply Circuits and Interconnecting CablesDocumento2 páginasNEC Article 645.5: 645.5 Supply Circuits and Interconnecting CablesFran Eduardo Amaya100% (1)

- IEC 61084-2-1 2017 (Canaletas)Documento27 páginasIEC 61084-2-1 2017 (Canaletas)Diana Cardona100% (1)

- Nema Pe5 1997Documento46 páginasNema Pe5 1997Horacio EneroAinda não há avaliações

- Overcurrent Relays: Digsilent Powerfactory Standard Relay Library Version 14Documento11 páginasOvercurrent Relays: Digsilent Powerfactory Standard Relay Library Version 14CARHUAMACA PASCUAL mh0% (1)

- IEEE STD 142-1982Documento135 páginasIEEE STD 142-1982NghiaAinda não há avaliações

- Ieee Guide For The Operation Classification Application and Coor PDFDocumento68 páginasIeee Guide For The Operation Classification Application and Coor PDFJaime Castañeda SanchezAinda não há avaliações

- IEEE STD C37.41 Ciclo TermicoDocumento9 páginasIEEE STD C37.41 Ciclo Termicofelipe sanchezAinda não há avaliações

- OPGW Design Data Sheet (SFSJ-J-11478) - VISA - I PDFDocumento2 páginasOPGW Design Data Sheet (SFSJ-J-11478) - VISA - I PDFAlejo Patiño ArboledaAinda não há avaliações

- ICEA-S 96-659 5kVDocumento2 páginasICEA-S 96-659 5kVAnamulKabirAinda não há avaliações

- Ieee C37-113Documento14 páginasIeee C37-113raul sanchezAinda não há avaliações

- AWG American Wire Gauge To Metric SQMM Millimeters Squared Conversion Table PDFDocumento1 páginaAWG American Wire Gauge To Metric SQMM Millimeters Squared Conversion Table PDFCarlos Davalos Cardenas100% (2)

- C57 109-1985Documento10 páginasC57 109-1985mjimenezg100% (1)

- Emergency Stop SIL2 and SIL3Documento3 páginasEmergency Stop SIL2 and SIL3SARFRAZ ALIAinda não há avaliações

- Iec 60034-8Documento25 páginasIec 60034-8Hung Luong100% (3)

- Ieee C57.92-1981Documento65 páginasIeee C57.92-1981yebri100% (1)

- Atprulebooktr PDFDocumento1.170 páginasAtprulebooktr PDFing.jmsolis0% (1)

- NEC Table 310.77 (Detail 1 - One Circuit, 3-1/c in Single Duct)Documento3 páginasNEC Table 310.77 (Detail 1 - One Circuit, 3-1/c in Single Duct)gyanendra_vatsa4380Ainda não há avaliações

- NEC Cable Chart Article 310Documento2 páginasNEC Cable Chart Article 310SalAinda não há avaliações

- Ieee 400Documento1 páginaIeee 400ricAinda não há avaliações

- DDS720 - Clou ShenzhenDocumento5 páginasDDS720 - Clou ShenzhenLhc JuliachsAinda não há avaliações

- Instruction Sheet D3208 MANUALDocumento48 páginasInstruction Sheet D3208 MANUALscalariAinda não há avaliações

- Drain Valve-DIN 42558Documento1 páginaDrain Valve-DIN 42558Eko SusantoAinda não há avaliações

- Sandia Guideline 2005Documento22 páginasSandia Guideline 2005Bruno MaresAinda não há avaliações

- Nema PB 1-2011Documento36 páginasNema PB 1-2011Kamal ArreazaAinda não há avaliações

- SCTM SCTM-N Brandsma Tyco Electronics Raychem Stress-Control Heatshrink Tubing DatasheetDocumento1 páginaSCTM SCTM-N Brandsma Tyco Electronics Raychem Stress-Control Heatshrink Tubing DatasheetJavier Silva VidalAinda não há avaliações

- Manual MelshortDocumento120 páginasManual MelshortEnrique León Salva100% (1)

- Normas para Pruebas en Mantenimientos de SubestacionesDocumento4 páginasNormas para Pruebas en Mantenimientos de SubestacionesCristianMedinaAinda não há avaliações

- Din 43670Documento1 páginaDin 43670arkupiAinda não há avaliações

- Inductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVDocumento6 páginasInductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVOscar Francisco Astudillo Paillamilla100% (1)

- IEEE 1187 Recommended Practice For Installation Design and Installation of Valve-RegulatedDocumento46 páginasIEEE 1187 Recommended Practice For Installation Design and Installation of Valve-RegulatedMarco Antonio Esquivel BarretoAinda não há avaliações

- Vision Revo Le TP200 (512V 100AH)Documento2 páginasVision Revo Le TP200 (512V 100AH)sergiob63Ainda não há avaliações

- Nema WC-53 2008Documento43 páginasNema WC-53 2008Vatsal100% (1)

- Adoption IEC 60146 1 3Documento7 páginasAdoption IEC 60146 1 3dfcghvbhjbAinda não há avaliações

- Cross-Reference - AWG To Metric Size (With Ampacity) of Insulated ConductorsDocumento1 páginaCross-Reference - AWG To Metric Size (With Ampacity) of Insulated ConductorsJoeDabid94% (16)

- 8460 01 PDFDocumento11 páginas8460 01 PDFKatherinne ChicaAinda não há avaliações

- HC110 Load Chart No JibDocumento10 páginasHC110 Load Chart No JibRie ReiAinda não há avaliações

- PV Elite 2019 LicenseeDocumento4 páginasPV Elite 2019 LicenseeHajaMideenAinda não há avaliações

- Mathematics of Macrotonal and Microtonal Music by Adi CoxDocumento182 páginasMathematics of Macrotonal and Microtonal Music by Adi CoxAdrian CoxAinda não há avaliações

- Plate TT R Utv Til PlastingDocumento9 páginasPlate TT R Utv Til Plastingmagnusgjerstad00Ainda não há avaliações

- Item ListDocumento5 páginasItem ListMadhu BabuAinda não há avaliações

- Plate TT R Utv Til PlastDocumento9 páginasPlate TT R Utv Til Plastmagnusgjerstad00Ainda não há avaliações

- Heavies Removal Column PreDesign DetailsDocumento7 páginasHeavies Removal Column PreDesign DetailsAditya JainAinda não há avaliações

- RETREAT CAPE TOWN From 20220912 To 20220925 000801Documento4 páginasRETREAT CAPE TOWN From 20220912 To 20220925 000801Muhammad Mustapha BeggAinda não há avaliações

- Co 57 Data ReportDocumento4 páginasCo 57 Data ReportmosaddakAinda não há avaliações

- LBS Item List 23.01.2020Documento30 páginasLBS Item List 23.01.2020Suresh ThanneruAinda não há avaliações

- 02-Person Measure - PoppyDocumento3 páginas02-Person Measure - PoppyMusik&PuisiAinda não há avaliações

- 328 ElectsDocumento182 páginas328 ElectsairtelAinda não há avaliações

- I Need SleepDocumento6 páginasI Need SleepmuhammadfaishalcaesarioadisyabanaAinda não há avaliações

- Natural Frequency For The Operating CaseDocumento1 páginaNatural Frequency For The Operating CaseHajaMideenAinda não há avaliações

- Electrical NotesDocumento200 páginasElectrical NotesAnkush Kumar100% (2)

- IBM System 360 RPG Debugging Template and Keypunch CardNo EverandIBM System 360 RPG Debugging Template and Keypunch CardAinda não há avaliações

- PSS Connectivity Load FlowDocumento32 páginasPSS Connectivity Load FlowChief Engineer TransOMAinda não há avaliações

- AAAdddd 1Documento3 páginasAAAdddd 1Anonymous ufMAGXcskMAinda não há avaliações

- Tech Specs Su Kam Solar Street LightDocumento5 páginasTech Specs Su Kam Solar Street LightjprakashusAinda não há avaliações

- Tapashwi Power ControlsDocumento7 páginasTapashwi Power Controlsnani yeshuAinda não há avaliações

- Doubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsDocumento6 páginasDoubly-Fed Induction Machine Models For Stability Assessment of Wind FarmsArun RajendranAinda não há avaliações

- Nishikant Power System Internship Report Docs 1Documento23 páginasNishikant Power System Internship Report Docs 1Darshan PawarAinda não há avaliações

- J12432020 LS - Ko Win Myint Zaw, Digicom Co - LTDDocumento5 páginasJ12432020 LS - Ko Win Myint Zaw, Digicom Co - LTDwinmyintzawAinda não há avaliações

- Prophi PDFDocumento2 páginasProphi PDFfrostestAinda não há avaliações

- 615 - Electrical Vendor ListDocumento4 páginas615 - Electrical Vendor ListAchu UnnikrishnanAinda não há avaliações

- Photovoltaic Day03 To-Day 05 Page155-250Documento96 páginasPhotovoltaic Day03 To-Day 05 Page155-250ghonamyAinda não há avaliações

- Series DT4200E16-2YMDocumento20 páginasSeries DT4200E16-2YMraza14pkAinda não há avaliações

- Electrical Machines 2 Practical (Emmpra2)Documento5 páginasElectrical Machines 2 Practical (Emmpra2)Mduduzi Lucas MoyoAinda não há avaliações

- Current Transformer QuestionsDocumento2 páginasCurrent Transformer Questionsதுரைராஜ் இலட்சுமணன்Ainda não há avaliações

- User Manual: HGM170/170HCDocumento11 páginasUser Manual: HGM170/170HCazocarAinda não há avaliações

- Application of Buck-Boost Converter For Wind Energy ControlDocumento5 páginasApplication of Buck-Boost Converter For Wind Energy ControlIJIRST100% (2)

- Svetlana Technical Data - El34 - 6ca7 Tube SpecsDocumento2 páginasSvetlana Technical Data - El34 - 6ca7 Tube SpecsbellscbAinda não há avaliações

- 390W 405W Astrotwins: Enjoy The Energy of The UniverseDocumento2 páginas390W 405W Astrotwins: Enjoy The Energy of The UniversevesselAinda não há avaliações

- Hvi DVR 150 300 Web 2Documento1 páginaHvi DVR 150 300 Web 2Juli RokhmadAinda não há avaliações

- TManual Chapter 01Documento23 páginasTManual Chapter 01abhayambujAinda não há avaliações

- Toshiba 14 - 21r - t01 Ch. Ks1aDocumento61 páginasToshiba 14 - 21r - t01 Ch. Ks1aEric NoiretteAinda não há avaliações

- Zelio Analog RMCA61BDDocumento2 páginasZelio Analog RMCA61BDAkhmad FauziAinda não há avaliações

- CIGRE Curso HVDC - Perdas - Canelhas PDFDocumento10 páginasCIGRE Curso HVDC - Perdas - Canelhas PDFcarlosrenatorcAinda não há avaliações

- Catalog Telemecanique LC1 LR2 Overload Relay RefDocumento8 páginasCatalog Telemecanique LC1 LR2 Overload Relay Refthanggimme.phanAinda não há avaliações

- EE8301-Electrical Machines - I QB With AnswerDocumento19 páginasEE8301-Electrical Machines - I QB With AnswerPadukolai KarupaiahAinda não há avaliações

- Automatic Generation Control (AGC)Documento22 páginasAutomatic Generation Control (AGC)maan100% (1)

- 2 Panel VCB With CR Panel WBSEDCL ApprovedDocumento41 páginas2 Panel VCB With CR Panel WBSEDCL ApprovedjoyAinda não há avaliações

- Converters and Rectifiers (NEW)Documento29 páginasConverters and Rectifiers (NEW)I AM NOT CHINESEAinda não há avaliações

- Wecon VD2 SA Series Servo Drives Manual (Full V1.2) VfinalDocumento226 páginasWecon VD2 SA Series Servo Drives Manual (Full V1.2) VfinalJose Gregorio Lira SerranoAinda não há avaliações

- List of Mandatory Documents & Check ListDocumento6 páginasList of Mandatory Documents & Check ListDuraipandi RajaAinda não há avaliações

- VDB3722MA Driver With Microstep Série NovaDocumento16 páginasVDB3722MA Driver With Microstep Série NovaJefferson Alcantara GomesAinda não há avaliações