Escolar Documentos

Profissional Documentos

Cultura Documentos

Air Compressor PDF

Enviado por

Jana VinayaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Air Compressor PDF

Enviado por

Jana VinayaDireitos autorais:

Formatos disponíveis

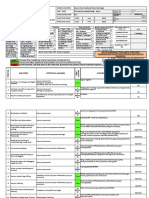

SAFETY OPERATING PROCEDURES

AIR COMPRESSOR

Safety glasses must be worn Appropriate footwear with

at all times in work areas. substantial uppers must be worn.

Long and loose hair must be Close fitting/protective clothing

contained. must be worn.

Contents under pressure Beware of tripping hazards

PRE-OPERATIONAL SAFETY CHECKS

1. Check air hoses couplings and attachments are in

good working order before use

2. Check working area is clear of other people,

flammable materials and other hazards

3. Regularly open drain valve to empty condensate

4. Guard(s) and shielding must be in place

5. Keep oil and flammable materials clear from air fitters

and joints

6. Decompress air from compressor prior to removing

any caps or air equipment

7. Ensure hose connections are secure to avoid hose

coming losing during use

8. Ensure correct pressure rated hoses and fittings

9. Faulty equipment must not be used. Immediately

report suspect machinery.

USAGE:

Only trained and competent persons are to use air compressors and their attachments

Start the compressor, noting pressure increase and cut-out/cut-in pressure. The pressure to be maintained

between 1000 1200 bars.

Listen for any air leaks from any flexible airlines and immediately report if any leaks are observed.

Empty compressor of air before transporting, servicing or if not to be used for extended period of time.

Do not point a stream of compressed air towards your body or another person

At regular intervals condensation drain valve should be opened and the system allowed to drain

ADJUSTMENT AND MAINTENANCE:

Only trained and competent persons to operator compressors

Isolate from electricity, empty compressed air and allow to cool before beginning work on compressor

Leave the machine, hose and work area in a safe, clean and tidy state.

Regular maintenance, lubrication, cleaning to occur

Weekly once Air filter to be cleaned.

POTENTIAL HAZARDS:

Unsecured hoses whipping under pressure

Compressed air

Você também pode gostar

- 01 PTP Survey ProcedureDocumento3 páginas01 PTP Survey ProcedureAnonymous 1XnVQmAinda não há avaliações

- Project: Location: DateDocumento3 páginasProject: Location: DateMark Roger Huberit IIAinda não há avaliações

- (KPCC) Sop - Gas BoosterDocumento12 páginas(KPCC) Sop - Gas BoosterWindy Nitaejun HorvejkulAinda não há avaliações

- Fire Hydrant Inspection Test ChecklistDocumento3 páginasFire Hydrant Inspection Test ChecklistZaky Fachrur Rozi100% (1)

- Pertadex English PDFDocumento8 páginasPertadex English PDFSuginoMarwotoAinda não há avaliações

- Rescue Plan Template - PHSSDocumento5 páginasRescue Plan Template - PHSSrian1099100% (1)

- Direct Manpower: PM1 PM2 PM3 PM4 PM5 PM6 PM7Documento55 páginasDirect Manpower: PM1 PM2 PM3 PM4 PM5 PM6 PM7crys suryo pAinda não há avaliações

- Sop Shutdown PrecedureDocumento3 páginasSop Shutdown PrecedureeswaranAinda não há avaliações

- SDS - Jotun Thinner No. 02 - Marine - Protective - English (Uk) - SingaporeDocumento10 páginasSDS - Jotun Thinner No. 02 - Marine - Protective - English (Uk) - SingaporeAmi Terecef Gamboa MirandaAinda não há avaliações

- Form Hirarc TemplateDocumento421 páginasForm Hirarc Templateanke irenaAinda não há avaliações

- Sop Boring PetrowoodDocumento8 páginasSop Boring PetrowoodfirmansyachAinda não há avaliações

- Form SIKA Baru Rev04 - 2019 - CETAKDocumento1 páginaForm SIKA Baru Rev04 - 2019 - CETAKBambang HariantoAinda não há avaliações

- Resources Management: Dr. Ahmed ElyamanyDocumento35 páginasResources Management: Dr. Ahmed ElyamanysajjaduetAinda não há avaliações

- TC220Documento2 páginasTC220blacx_rzkyAinda não há avaliações

- Check List HSEDocumento2 páginasCheck List HSEFernando Carrizales SánchezAinda não há avaliações

- Perhitungan Harga MaterialDocumento31 páginasPerhitungan Harga MaterialGregorius Galih DaniswaraAinda não há avaliações

- FRM HSE 00 32 Form Checklist Fire HydrantDocumento9 páginasFRM HSE 00 32 Form Checklist Fire HydrantAdrianus PramudhitaAinda não há avaliações

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDocumento10 páginasSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanAinda não há avaliações

- Catalog Oil Boom SL-10Documento2 páginasCatalog Oil Boom SL-10nurulAinda não há avaliações

- TDS 8201 PT NewDocumento2 páginasTDS 8201 PT NewWahyudi Rendiana NyotoAinda não há avaliações

- Tool Box Meeting SOP AISHADocumento2 páginasTool Box Meeting SOP AISHAanoushia alviAinda não há avaliações

- Valve Inspection, Exercising, and Maintenance SopDocumento14 páginasValve Inspection, Exercising, and Maintenance SopMehdi SoltaniAinda não há avaliações

- New Technology of H2S Removal - AK SeriesDocumento12 páginasNew Technology of H2S Removal - AK SeriesWaskito SantosoAinda não há avaliações

- Bentonite MSDS: Section 1: Chemical Product and Company IdentificationDocumento5 páginasBentonite MSDS: Section 1: Chemical Product and Company IdentificationMuhammad FadliAinda não há avaliações

- PT. ADHI KARYA (Persero) TBK: Safety Inspection Check ListDocumento2 páginasPT. ADHI KARYA (Persero) TBK: Safety Inspection Check ListHaidar AliAinda não há avaliações

- Receiving Inspection Check List PDFDocumento1 páginaReceiving Inspection Check List PDFavriamandaAinda não há avaliações

- Form Inspeksi Alat Berat (Compactor)Documento1 páginaForm Inspeksi Alat Berat (Compactor)HELMY RUSANDYAinda não há avaliações

- Risk Profile Pt. Tata Bara Utama Site Aceh: 1 Departemen Operation 5 Departemen PNLDocumento7 páginasRisk Profile Pt. Tata Bara Utama Site Aceh: 1 Departemen Operation 5 Departemen PNLbenzAinda não há avaliações

- Sop BoilerDocumento3 páginasSop BoilerBentar ELcAinda não há avaliações

- Routine Maintenance Schedule ACDocumento1 páginaRoutine Maintenance Schedule ACfernandoabel01100% (1)

- Mis Report Format in ExcelDocumento1 páginaMis Report Format in ExcelCh Rajesh SinghAinda não há avaliações

- Continental Industrial PDFDocumento359 páginasContinental Industrial PDFDavidAinda não há avaliações

- A9. Qcp-Jalitaka-Pt Yutaka Manufacturing IndonesiaDocumento11 páginasA9. Qcp-Jalitaka-Pt Yutaka Manufacturing Indonesialombak3 2017100% (1)

- Contractor Got Struck Down by MCC Panel On Sep29 2021 (Fatality Case) Rev10Documento16 páginasContractor Got Struck Down by MCC Panel On Sep29 2021 (Fatality Case) Rev10Albertus willyAinda não há avaliações

- Pengajuan Spare Part TH 2016Documento6 páginasPengajuan Spare Part TH 2016Samsul Hadi Wong NenjapAinda não há avaliações

- Reducing Tee Table Carbon Steel FittingDocumento8 páginasReducing Tee Table Carbon Steel FittingAlmario SagunAinda não há avaliações

- SOP-Pumps 20161031Documento4 páginasSOP-Pumps 20161031SubburajMechAinda não há avaliações

- Material Safety Data Sheet: Cap - PP - Msds - Hf10TqDocumento2 páginasMaterial Safety Data Sheet: Cap - PP - Msds - Hf10TqYogig TriAinda não há avaliações

- Ozone Solutions MSDS Ozone PDFDocumento4 páginasOzone Solutions MSDS Ozone PDFJunaid AhmadAinda não há avaliações

- JHA Dryer Hot CommissioningDocumento5 páginasJHA Dryer Hot CommissioningJowel MercadoAinda não há avaliações

- Trafo B & DDocumento4 páginasTrafo B & Dlithasinergi.01Ainda não há avaliações

- Appendix E - HVAC Inspection ChecklistDocumento1 páginaAppendix E - HVAC Inspection ChecklistanbunilavanAinda não há avaliações

- Drill Pad Handover Checklist From Operation To Drill SupervisorDocumento1 páginaDrill Pad Handover Checklist From Operation To Drill SupervisorAji SatrioAinda não há avaliações

- Task Procedure Analysis Worksheet: Traffic Control EquipmentDocumento4 páginasTask Procedure Analysis Worksheet: Traffic Control EquipmentJorgeCorkeAinda não há avaliações

- Hydraulic Press ProcedureDocumento2 páginasHydraulic Press ProcedureARMANAinda não há avaliações

- CTU UnloadDocumento2 páginasCTU UnloadaneshseAinda não há avaliações

- Abb MCCB PDFDocumento98 páginasAbb MCCB PDFwiznueAinda não há avaliações

- Plan Permit To WorkDocumento31 páginasPlan Permit To WorkZinZin KyawAinda não há avaliações

- Induction HSEDocumento29 páginasInduction HSEavriamandaAinda não há avaliações

- Perancangan Mesin Perajang Daun Tembakau: Anwar Hidayat, Drs. Bambang Setyo H.P, M.PDDocumento13 páginasPerancangan Mesin Perajang Daun Tembakau: Anwar Hidayat, Drs. Bambang Setyo H.P, M.PDFikri SiplhoAinda não há avaliações

- MSDS Agenda 25 ECDocumento3 páginasMSDS Agenda 25 ECSadhana SentosaAinda não há avaliações

- Boom BarrierDocumento2 páginasBoom BarrierRamkumar KumaresanAinda não há avaliações

- Operational and Maintenance ManualsDocumento7 páginasOperational and Maintenance ManualsHenok TeshomeAinda não há avaliações

- Mechanic Name: . Shift: . No Unit: . ModelDocumento2 páginasMechanic Name: . Shift: . No Unit: . ModelAsef Dwy AfixxAinda não há avaliações

- Soal Ujian ISO 9001Documento20 páginasSoal Ujian ISO 9001Budi SusantoAinda não há avaliações

- Job Permit FM Hse 801 005Documento2 páginasJob Permit FM Hse 801 005nd100% (1)

- Air CompressorDocumento2 páginasAir CompressorJana Vinaya100% (2)

- Sec 14 Compressed Air and Gas SafetyDocumento9 páginasSec 14 Compressed Air and Gas SafetyEsamKhalilAlQadiAinda não há avaliações

- Pages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-2Documento6 páginasPages From 432912277-Manual-Air-Compresor-Atlas Copco-GA75-2-2Tolias EgwAinda não há avaliações

- Pandiyan 32066867Documento1 páginaPandiyan 32066867Jana VinayaAinda não há avaliações

- J S SurendiranDocumento2 páginasJ S SurendiranJana VinayaAinda não há avaliações

- Sfam0039513 PDFDocumento4 páginasSfam0039513 PDFJana VinayaAinda não há avaliações

- DejaVu FontsDocumento2 páginasDejaVu FontsCristina MariaAinda não há avaliações

- Read The Instructions Carefully:: WWW - Tnpsc.gov - inDocumento2 páginasRead The Instructions Carefully:: WWW - Tnpsc.gov - inJana VinayaAinda não há avaliações

- Road Work in Progress Take Diversion For Car/Bus ParkingDocumento4 páginasRoad Work in Progress Take Diversion For Car/Bus ParkingJana VinayaAinda não há avaliações

- Sakthi Vinayaga LetterheadDocumento2 páginasSakthi Vinayaga LetterheadJana VinayaAinda não há avaliações

- MUKESH TRAVELS Ok PDFDocumento1 páginaMUKESH TRAVELS Ok PDFJana VinayaAinda não há avaliações

- Death Certificate 2015050590029160 PDFDocumento1 páginaDeath Certificate 2015050590029160 PDFJana VinayaAinda não há avaliações

- Parthiban Kanavu Part 3Documento98 páginasParthiban Kanavu Part 3ambalvananAinda não há avaliações

- Parthiban Kanavu Part (1 & 2) - KalkiDocumento85 páginasParthiban Kanavu Part (1 & 2) - KalkiBala SubramanianAinda não há avaliações

- Detail Social TradeDocumento1 páginaDetail Social TradeJana VinayaAinda não há avaliações

- Pandiyan 32066867Documento1 páginaPandiyan 32066867Jana VinayaAinda não há avaliações

- CouponDocumento3 páginasCouponJana VinayaAinda não há avaliações

- Mohamed ResumeDocumento2 páginasMohamed ResumeJana VinayaAinda não há avaliações

- Employment Application Form PDFDocumento7 páginasEmployment Application Form PDFJana VinayaAinda não há avaliações

- DejaVu FontsDocumento2 páginasDejaVu FontsCristina MariaAinda não há avaliações

- FAS False Floor StickerDocumento4 páginasFAS False Floor StickerJana VinayaAinda não há avaliações

- SIL Open Font LicenseDocumento2 páginasSIL Open Font LicenseJana VinayaAinda não há avaliações

- Mu - Siva Balan: Career ObjectiveDocumento3 páginasMu - Siva Balan: Career ObjectiveVinay JanaAinda não há avaliações

- S.Babu: Ph. No. +91 44 66310 200 Blood Group:A1 - Ve Res. Cell: +91 (0) 95000 40740 Cell: +91 (0) 98400 75897Documento2 páginasS.Babu: Ph. No. +91 44 66310 200 Blood Group:A1 - Ve Res. Cell: +91 (0) 95000 40740 Cell: +91 (0) 98400 75897Jana VinayaAinda não há avaliações

- EOL FORmDocumento1 páginaEOL FORmJana VinayaAinda não há avaliações

- Cash Bill: From, Alpha Technologies, No 126, First Cross, Indra Nagar, Adayar, Chennai - 20Documento2 páginasCash Bill: From, Alpha Technologies, No 126, First Cross, Indra Nagar, Adayar, Chennai - 20Vinay JanaAinda não há avaliações

- Spaak Construction To Be Done Work at Phase - IDocumento46 páginasSpaak Construction To Be Done Work at Phase - IJana VinayaAinda não há avaliações

- Annexure 05Documento1 páginaAnnexure 05Jana VinayaAinda não há avaliações

- Invoice SAF-1718-020 Jamna July 2017Documento1 páginaInvoice SAF-1718-020 Jamna July 2017Jana VinayaAinda não há avaliações

- Annual Report 2014-15 March15 PDFDocumento9 páginasAnnual Report 2014-15 March15 PDFJana VinayaAinda não há avaliações

- E.Ravichandran: Earth Movers & Blue Metal SuppliersDocumento1 páginaE.Ravichandran: Earth Movers & Blue Metal SuppliersJana VinayaAinda não há avaliações

- Invoice SAF-1718-021 JBM July 2017Documento5 páginasInvoice SAF-1718-021 JBM July 2017Jana VinayaAinda não há avaliações