Escolar Documentos

Profissional Documentos

Cultura Documentos

2015 - Polygerinos - Icra - Soft Robotic Glove For Hand Rehabilitation and Task Specific Training

Enviado por

Lester Marquez0 notas0% acharam este documento útil (0 voto)

75 visualizações7 páginasThis document presents a soft robotic glove designed for hand rehabilitation. The glove uses soft material actuators made of molded elastomeric bladders with fiber reinforcements that bend and flex upon fluid pressurization to safely move the fingers. The actuators are customized to each user's biomechanics and integrated into a soft textile glove. Sensors measure actuator pressure and a portable control box allows for preset finger motions. Preliminary results show patients with weak hands performing tasks like the Box-and-Block test more successfully with the soft robotic glove compared to without. The goal is to create an affordable, portable device to assist with hand rehabilitation and task specific training.

Descrição original:

(c)

Título original

2015 - Polygerinos - Icra - Soft Robotic Glove for Hand Rehabilitation and Task Specific Training (1)

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThis document presents a soft robotic glove designed for hand rehabilitation. The glove uses soft material actuators made of molded elastomeric bladders with fiber reinforcements that bend and flex upon fluid pressurization to safely move the fingers. The actuators are customized to each user's biomechanics and integrated into a soft textile glove. Sensors measure actuator pressure and a portable control box allows for preset finger motions. Preliminary results show patients with weak hands performing tasks like the Box-and-Block test more successfully with the soft robotic glove compared to without. The goal is to create an affordable, portable device to assist with hand rehabilitation and task specific training.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

75 visualizações7 páginas2015 - Polygerinos - Icra - Soft Robotic Glove For Hand Rehabilitation and Task Specific Training

Enviado por

Lester MarquezThis document presents a soft robotic glove designed for hand rehabilitation. The glove uses soft material actuators made of molded elastomeric bladders with fiber reinforcements that bend and flex upon fluid pressurization to safely move the fingers. The actuators are customized to each user's biomechanics and integrated into a soft textile glove. Sensors measure actuator pressure and a portable control box allows for preset finger motions. Preliminary results show patients with weak hands performing tasks like the Box-and-Block test more successfully with the soft robotic glove compared to without. The goal is to create an affordable, portable device to assist with hand rehabilitation and task specific training.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

Soft Robotic Glove for Hand Rehabilitation

and Task Specific Training

Panagiotis Polygerinos, Member, IEEE, Kevin C. Galloway, Emily Savage, Maxwell Herman,

Kathleen O Donnell and Conor J. Walsh*

Abstract This paper presents advancements in the design

of a portable, soft robotic glove for individuals with functional

grasp pathologies. The robotic glove leverages soft material

actuator technology to safely distribute forces along the length

of the finger and provide active flexion and passive extension.

These actuators consist of molded elastomeric bladders with

anisotropic fiber reinforcements that produce specific bending,

twisting, and extending trajectories upon fluid pressurization.

In particular, we present a method for customizing a soft

actuator to a wearers biomechanics and demonstrate in a

motion capture system that the ranges of motion (ROM) of the

two are nearly equivalent. The active ROM of the glove is

further evaluated using the Kapandji test. Lastly, in a case

study, we present preliminary results of a patient with very

weak hand strength performing a timed Box-and-Block test

with and without the soft robotic glove.

I. INTRODUCTION

In the US, there are approximately four million chronic

stroke survivors suffering from hemiparesis or similar

conditions, over 200,000 spinal cord injury (SCI) survivors

living with sustained neurological damage, and an estimated

1 of every 5,600 to 7,700 males have Duchenne/Becker

muscular dystrophy (DBMD) [1][4]. In the majority of these Figure. 1. A. The prototyped hydraulically actuated soft robotic glove. B.

Patient-clinician setup that utilizes the soft robotic glove to perform hand

cases, patients experience either partial or total absence of rehabilitation scenarios.

hand motor ability, and this loss of functionality can greatly

restrict activities of daily living (ADL) and considerably

training with the affected hand was shown to reorganize the

reduce quality of life [3]. Physical therapy to improve hand

cortex faster producing better functional improvements [6].

function often involves repetitive task practice (RTP)

Current rehabilitative methods, however, are costly, slow,

rehabilitation which requires breaking down a task into

and labor-intensive, placing a high demand on the training

discrete components and practicing these individual

and availability of the physical therapist [3].

movements, normally with the assistance of an occupational

Clinical studies indicate that hand impaired patients who

therapist, to improve hand strength, accuracy, and range of

use robotic assistance when performing intense repetitive

motion [3], [5]. In terms of function, repetitive rehabilitation

movements show significant improvement in hand motor

tasks are not sufficient to increase motor cortical

functionality when compared to patients without robotic

representations in the human brain. However, task specific

assistance [3], [5], [7], [8]. Currently, there are a variety of

research groups developing robotic rehabilitation systems for

This work is partially supported by the National Science Foundation

(grant # 1317744), the Wyss Institute, and the School of Engineering and

the hand that consist of multi-degree-of-freedom

Applied Sciences at Harvard University. exoskeletons; these are summarized in [9], [10]. The rigid

Manuscript received September 30, 2014; accepted January 30, 2015. designs of these robotic devices provide robust applications

*Corresponding author. capable of exerting high forces and executing challenging

Panagiotis Polygerinos, and Conor J. Walsh are with the Wyss Institute rehabilitation scenarios. However, these rigid devices are

for Biologically Inspired Engineering at Harvard University, and the

Harvard Biodesign Laboratory, School of Engineering and Applied

typically heavy, expensive and require care and time for

Sciences, Harvard University, Cambridge, MA, 02138, USA (e-mail: proper alignment with the biological joints. Thus these

polygerinos@wyss.harvard.edu; walsh@seas.harvard.edu). devices are typically not suitable for use during simulated

Kevin C. Galloway, Maxwell Herman and Kathleen O Donnell are with ADL, or task specific training, such as the Box-and-Block

the Wyss Institute for Biologically Inspired Engineering at Harvard test, or the Nine-Hole Peg Test. More recently, a number of

University, Cambridge, MA, 02138, USA (e-mail: hand rehabilitation robots have combined soft gloves with

kevin.galloway@wyss.harvard.edu; maxwell.herman@wyss.harvard.edu;

kathleen.o'donnell@wyss.harvard.edu). motors that drive cables, or used pressurizable soft actuators

Emily Savage is with the School of Engineering and Applied Sciences to support finger motion [9], [10]. Soft actuators offer a new

and Harvard College, Harvard University, Cambridge, MA, 02138, USA (e- actuation model that combines traditional robot design

mail: emilysavage01@college.harvard.edu).

integrated into a soft textile glove and mounted to the dorsal

side of the hand to recreate the desired motions in a safe and

compliant manner (section III). Fluidic pressure sensors

measure the internal pressure of soft actuators and provide

individual finger control, and a portable control box allows

for a variety of pre-set finger motions (section III). Finally, a

quantitative and qualitative characterization and evaluation of

the soft robotic glove explores patient outcomes of the device

(section IV).

II. SOFT SEGMENTED FIBER-REINFORCED ACTUATORS

A. Actuator Design

Expanding on prior work [14], the soft actuator design

presented in this work consist of thin profile, rectangular

elastomeric bladders reinforced with strain limiting materials

(i.e. materials with a Youngs modulus much larger than the

elastomeric bladder, such as fibers) to create anisotropic

properties in the bladder wall [14], [15]. Upon fluid

pressurization, the bladder will preferentially strain

in directions determined by the fiber reinforcements. Figure

2, illustrates four classes of programmable motions using

fiber reinforcements, namely bend, bend-twist, extend, and

extend-twist. In the example of the bending actuator, a strain

limiting layer (e.g. woven material) [16] constrains one face

of the bladder from stretching, and a symmetric arrangement

of helical fiber threads constrains radial swelling. Upon

pressurization, the wall of the actuator with the strain limited

layer can be approximated as inextensible (i.e. fixed length),

whereas all the other portions of the actuator are allowed to

grow lengthwise. This asymmetrical strain along the length

of the actuator causes it to bend or curl in the direction of the

Figure. 2. Combination of fiber-reinforced actuator components and their

unpressurized and pressurized behaviors. A. Soft fiber-reinforced bending

actuator. B. Soft fiber-reinforced bend-twist actuator. C. Soft fiber-

reinforced extending actuator. D. Soft fiber-reinforced extend-twist-

actuator.

principles with active soft materials, enabling a novel class of

applications [11], [12]. A wearable soft robotic device has the

potential to increase the benefits of rehabilitative therapy by

providing greater affordability, significant portability, lower

weight, easier customization, increased ROM, safer human-

robotic interactions, and the ability to conduct task specific

training or exercises that simulate ADL.

In this paper, we present our advancements in the design

of a hydraulically actuated soft rehabilitation glove [13] that

can perform motions similar to those of human fingers

(Figure 1A). A system such as this could enable patients with

muscular dystrophy, incomplete spinal cord injuries, acute

strokes, and in general pathologies that lead to muscle

weakness, to perform repetitive rehabilitative tasks, or regain

hand function while conducting ADL at home on their own,

or in clinic under the supervision of a clinician (Figure 1B).

This approach could also offer better patient outcomes

through rehabilitative therapy by extending the dose of

therapy beyond clinic and into home. The device presented

Figure. 3. Illustration of a generic soft segmented fiber-reinforced

here utilizes inexpensive fiber-reinforced, elastomeric actuator in: A. exploded view showing fiber reinforcements, elastomer

actuators that can be quickly custom-designed to fit the material, and inextensible layers, and B. pressurized view showing a

anatomy of individual users (section II). The actuators are combination of motions.

strain limiting layer. The manufacturing process to make

these soft actuators has been described in prior work [13].

These fiber-reinforcement designs also enable more

complex motions in which more than one motion can be

programmed in series along the length of a single

actuator. We define these as multi-segment soft actuators

[13],[17]. Figure 3 illustrates this concept, where fiber

reinforcements are used to create segments that bend, extend,

and bend-twist.

With respect to the hand, multi-segment soft actuators

offer a simple method to safely support the full range of

motion of each digit. In fact, only two types of multi-

segment soft actuators are necessary to support complete

hand closure. The first actuator type includes bending and

Figure. 4. MATLAB GUI for customized rapid actuator length

extending segments to support the four fingers closing toward development. Points with manual cursor dragging capabilities are shown

the palmar surface. The extending segments are important for in blue, corresponding to the finger tip, DIP, PIP, and MCP joints.

compensating the offset distance between the actuator and the

dorsal side of the hand when the finger is flexing. The second

actuator type supports the range of motion of the thumb in Standard Sizing option, or more generalized option, outputs

achieving opposition motion, where the actuator bends above actuator sizes within approximately 5% accuracy of a custom

the interphalangeal (IP) and metacarpophalangeal (MCP) size, and the only input required is middle finger length. This

joints, extends in between segments and bends/twists along option outputs reference tables for Small, Medium, and

another segment (around the carpometacarpal (CMC) joint). Large middle finger lengths to determine the actuator

segment sizes. The middle finger was chosen as a

B. Custom Actuator Design for Hand Impaired Users determinant of size due to a common method for glove sizing

The general geometry of the multi-segment soft actuators systems that relies on middle finger length. The data in these

was mainly defined by their efficiency [14] and the finger reference tables originate from the results of a participant

anatomy of the end-user. In prior work [13], the shape of study (n=25) in which the middle finger was used as a

semi-circular fiber-reinforced actuators was utilized. baseline indicator of size to divide participants into three

However, in this work to lower the profile a rectangular ranked groups: Small the bottom third, Middle the center

actuator design was used which sits on its flat side above third, and Large the upper third. The final actuator size in

each finger. Its cross-sectional width was set to 20 mm to the GUI was averaged within each size grouping of

match the width of the average fingers, and height to 7 mm to participants. The MATLAB GUI allows for rapid, remote

ensure a low profile. processing of hand images and prompt (< 5 minutes for the

To provide maximum rehabilitative benefit, the actuator Custom Sizing option) output of actuator lengths, reducing

should conform precisely to the finger anatomy of the the time spent on actuator development.

individual patient by controlling the placement of the

inextensible layers. Deviations from the appropriate size may III. THE HAND REHABILITATION SYSTEM

cause distortions in the natural movement of the hand or

A. Design Considerations for a Soft Robotic Glove

discomfort in the wearer over continued use, particularly

through RTP rehabilitation, task specific training, and The grasping forces of individuals with hand impairments

rehabilitation through ADL. In the past, finger measurements are found to be reduced in magnitude or, in some cases,

were taken by hand, and final calculations for corresponding nonexistent [18]. Nevertheless, the grasping forces required

actuator sizes were made from repetitive data input. To to manipulate objects that are encountered during daily living

reduce error in sizing and assist in the speed and accuracy of do not exceed 10 to 15N [19]. With this in mind, the soft

fabrication, a Graphical User Interface (GUI) was developed actuators for a hand rehabilitation device do not necessarily

to provide a simple, quick method for determining actuator need to generate the maximum grip strength of a healthy

length and a customizable option that specifies actuator individual. It is important, however, that the forces generated

segmentation according to unique patient anatomy. do not impede natural finger motions or cause discomfort to

Figure 4 displays the developed MATLAB interface, the wearer. One way to accomplish this is to distribute the

which allows the user to upload a photo of the hand to the forces along the fingers to minimize pressure location points.

central screen. For any picture upload, a ratio tool provides a Besides customizing the soft actuators to the patient finger

scaling method to convert from pixels to physical length, and lengths (section IIB) the textile design of the soft

the output of the GUI is a table listing the required actuator rehabilitation device should allow for some additional

segment lengths for each finger, as well as the total lengths. customization. The ability to further adjust the textile

A Custom Sizing option allows the user to input locations components can potentially simplify donning and doffing for

for the tip, distal interphalangeal (DIP), proximal users with poor hand mobility. Furthermore, all interfacing

interphalangeal (PIP) for non-thumb fingers, and components of the soft actuators to the hand should be made

metacarpophalangeal (MCP) of the finger using points with with compliant, soft materials/textiles that offer minimal

manual cursor dragging capabilities. The GUI stores the mechanical impedance to finger motion when the device is

locations of the points and uses the distances between the being worn but not operated.

points to calculate the actuator segmentation size. A

Figure. 6. A. Front and side views of the soft robotic glove control box.

B.The soft glove control box showing the electrohydraulic components.

hook and loop straps are used for securing individual

Figure. 5. Schematic of the soft robotic glove outlining the two textile

actuators. The other textile component (labeled layer 2 in

layers that couple the soft actuators to the users hand. Figure 5B) houses the soft actuator in stretchable spandex

material with an adjacent pocket for the finger, and a hook

pad near the actuator base. The glove is fitted to the wearer

Another consideration is the weight of the components by securing layer 1 to the wrist and inserting fingers into the

that are mounted on the hand and arm as any additional pockets of layer 2. Layer 2 can then be pre-tensioned before

weight will likely restrict the movement of an impaired user. securing it to layer 1 with the hook and loop straps. The

Previous devices for the hand have set a design requirement pretensioning component applies light forces to hold the hand

of 0.5Kg for all components on the hand [20], but making in the extended position. In this design, the pressurized

them as light as possible will likely be important. The actuator applies forces to flex the fingers, and upon

advantage of a soft robotic system is that made of lightweight depressurization the soft actuators behave as elastic return

materials. Any additional electromechanical components springs to return the fingers to the extended hand state.

(battery, pump, and electronics) required for actuation can be

housed in a small table-top control box away from the hand. C. Control Box

To account for the ROM of fingers, the soft actuators To minimize additional weight on the hand and arm, the

should be able to replicate the kinematic movements of the devices hydraulic pump and supporting electro-mechanical

biological fingers as much as possible. Therefore, certain components were enclosed into a portable, electrical, table

requirements for the device are essential: first, at most three top NEMA box that provides in-and-out protection against

joints are needed for every actuator; second, index, middle, water leaks, dust and other hazards. As shown in Figure 6,

ring, and little finger actuator segments (corresponding to the the control box integrates in a single casing: (a) the power

DIP, PIP and MCP finger joints) should bend together in the components, with: a lithium polymer (Li-Po) battery of 5Ah,

same plane; finally, the thumb actuator should bend at least and a wall mount power supply; (b) the electronics, with:

two of its segments in the same plane, having the third bend- voltage regulators, PWM signal controllers for the valves,

twist segment that accounts for the motion created by the and a microcontroller (Arduino Yun, Arduino) with two

CMC joint of the finger (combination of flexion and embedded processorsone that facilitates wireless

abduction) bend out of plane. transmission of data regarding the glove state, and the other

On the performance side of the robotic glove, the device that computes the glove control algorithms; and (c) the

should be able to approximate an actuation frequency (30 hydraulics, with: fluidic pressure sensors (150PGAA5,

flexing/extending hand cycles/minute) and an operation time Honeywell, Morristown, NJ) for regulation of pressure within

that is adequate to enable rehabilitation scenarios. Based on each finger actuator, solenoid valves (M series, Gems

this information, the soft actuators should be able to actuate Sensors & Controls, Plainville, CT), a miniature diaphragm

with a frequency of 0.5Hz while a battery should provide hydraulic pump (LTC series, Parker Hannifin Corp.), and a

continuous operation for at least two hours. water reservoir.

B. Soft Glove Description The equipped battery is able to provide continuous

operation power for about 3 hours, and voltmeters on the side

The soft wearable robotic glove features an open palm of the control box inform the user when recharging is

design and consists of a two-component textile framework required. Additionally, mechanical switches are located at the

that couples the soft actuators to the users hand. One textile lid of the box, allowing for manual control of the gloves

component (labeled layer 1 in Figure 5A) anchors to the wrist individual finger actuators. An emergency button is located at

via hook and loop straps and consists of a flexible loop the lid, offering a fail-safe layer protection in case of an

material that covers the dorsal surface of the hand; additional electromechanical malfunction. Lastly, push-to-connect

Figure. 8. A. Force sensors are measuring the contact interaction between

a segmented fiber-reinforced actuator and an analog of the biological

index finger. B. The force distribution pattern along the analog finger.

markers were positioned in the same vertical plane, able to

compare motion paths of joints/segments and shape of

finger/actuators at all stages of pressurization. Similarly,

markers were placed on the biological thumb finger joints

and corresponding actuator segments (Figure 7B).

In a healthy hand participant study, the soft robotic glove

was worn by a user who was instucted to keep hand and

fingers passive for the duration of the test. The graphs of

Figure 7 represent the motion paths of joints and segments

for both index and thumb actutor-finger pairs when the

actuators were pressurized. The kinematic representation of

the actuators and the corresponding biological finger at the

final pressurized state are shown in the same figure. It is

noted that the observed offsets between actuators and fingers

originate from the original offset placement of markers

(unpressurized state), which demonstatres how the soft

segmented actutors are capable of bending, extending and

twisting to smoothly recreate the finger motion and shape of

finger when pressurized.

In another test, an analog of a biological finger was

fabricated (3D printed) with passive hinge joints and used to

illustrate the ability of the soft segmented actuators to

Figure. 7. Motion capture and comparison of joint location and trajectories

distribute forces along the finger length when pressurized.

between the soft segmented actuators and the A. biological index finger,

B. biological thumb finger. The results demonstrate that the actuators Force sensors (TakkStrip, Takktile LLC, MA) were

segments conform around the fingers and recreate their natural integrated at the dorsal side of the analog finger (Figure 8A)

trajectories. to record the contact interaction. Above the sensors a soft

segmeted actuator was mounted and constrained in the same

tubing couplings with shut-off valves are located at the side fashion as the constraints found on the soft robotic glove

of the box, which enable easy connecting and disconnecting (section IIIB). Pressurization makes the actuator grow around

of the soft robotic glove from the control box. the analog finger joints while distributed forces flex the

finger (Figure 8B).

IV. EVALUATION B. User Evaluation

A. Actuator Evaluation In hand rehabilitation, finger opposition using the thumb

is considered one of the most challenging exercises for users

A three dimensional visual motion capture system (Vicon

with grasping difficulties. Hence, to evaluate the range of

T040, Vicon Motion Systems Ltd. UK) was utilized to

motion of the soft robotic glove and its ability to provide

evaluate the ability of the soft segmented actuators to

gross and pinch grasping motions, the standardized Kapandji

conform to the biological finger shape while being

test [21] was implemented in a healthy participant. To do so,

pressuized. Reflective motion capture markers were placed

the soft actuators on the robotic glove were actuated by

on the side of layer 2 Figure 5B (dorsal level of finger) at

means of fluidic pressurization. This enabled the guiding of

the finger tip, DIP, PIP, and MCP joint locations in order to

passive biological fingers of the user and recreated opposition

track the biological index finger. Additional markers were

motions. In Figure 9B-F, a series of photographs demonstrate

placed at middistance of the equivalent bending segments on

the ability of the soft robotic glove to reach each finger and

the side of the soft segmented actuator (marker loactions are

perform the necessary motions as dictated by the

shown in Figure 7A). In this way, the corresponding pairs of

standardized test. In addition, Figure 9G-H demonstrates

Figure. 9. Range of motion of the soft robotic glove. A. Pretention of the fabric sleeves surrounding the fiber-reinforced actuators offers full hand

extension. B-F. Executing the Kapandji test [21] with the soft robotic glove for thumb range of motion. G. Finger flexion with index finger straight. H.

Index finger flexion.

actuated robotic glove uses soft segmented elastomeric

actuators with fiber reinforcements that enabled specific

bending, twisting and extending motions. With the aid of a

GUI, a method to quickly customize the actuators to the

wearers fingers biomechanics was demonstrated, ensuring a

more accurate and comfortable replication of hand ROM and

grasping motions. The custom soft actuators were mounted to

the dorsal side of the hand with a glove-like textile

Figure. 10. Evaluation of the glove with the standardized box-and-block framework that offered a thin and lightweight profile. To

hand functional test: A. Without assistance from the soft robotic glove operate the soft robotic glove, a portable hardware control

the hand impaired participant is having difficulties grasping the blocks. box system was developed. The complete system was

B. With assistance from the soft wearable glove the participant was able

to grasp the blocks faster and with better accuracy.

evaluated in a series of motion capture experiments and in a

Kapandji test and demonstrated that the custom actuators

additional types of motions that can be achieved with the could support the ROM of the biological fingers.

robotic glove. Lastly, the presence of elastic textile materials Additionally, an analog of a finger with embedded force

(section IIIB) confirmed that a gentle pre-tensioning of sensors was fabricated as a platform to demonstrate the

fingers can enable the hand of the user to maintain an ability of the actuators to distribute forces along the fingers.

extended state when the actuators were not pressurized Finally, in a pilot clinical evaluation, the soft robotic glove

(Figure 9A). allowed a participant with reduced hand function to perform

A test that assesses unilateral gross manual dexterity, faster and more precise functional grasping in a standardized

called the standardized Box-and-Block test, was performed Box-and-Block test.

on a participant with muscular dystrophy (subject gave In future work, a larger study with patients that suffer

informed consent and testing was approved by the Harvard from hand muscle weakness will be conducted to evaluate

Medical Institutional Review Board (IRB)). Based on this and improve further the soft robotic glove design. Sensing

standardize test protocol [22], the impaired participant was schemes will also be investigated to enable the soft robotic

asked to use the non-dominant hand to move as many glove to estimate user intent and assist in performing

wooden blocks from one compartment of a box to the other grasping motions, while a set of repetitive rehabilitation

over the course of 60 seconds. The same test was repeated scenarios will be programmed into the system. Additionally,

having the participant wear the soft robotic glove. The results long term effects from the glove usage will be studied to

showed that without the glove the participant was able to determine the level of hand motor skills and functional

move only 10 blocks while showing lack of precise finger improvement offered thourgh ADL and task specific

motion and hand coordination. With the soft robotic glove, rehabilitation training.

the participant demonstrated a 40% increase in picking REFERENCES

blocks and a notable increase in the precision and accuracy of

[1] V. L. Roger, A. S. Go, D. M. Lloyd-Jones, E. J. Benjamin, J. D.

the grasp. Figure 10A-B show both attempts, without and Berry, W. B. Borden, D. M. Bravata, S. Dai, E. S. Ford, and C. S.

with the glove. Activation of the soft actuator groups was Fox, Heart disease and stroke statistics--2012 update: a report

achieved manually by an assistant through mechanical from the American Heart Association., Circulation, vol. 125, no.

switches located on the control box. 1, p. e2, 2012.

[2] N. S. C. I. S. Center, Spinal cord injury. Facts and figures at a

glance, J. Spinal Cord Med., vol. 28, no. 4, pp. 379380, 2005.

V. CONCLUSION [3] C. D. Takahashi, L. Der-Yeghiaian, V. Le, R. R. Motiwala, and S.

In this paper, we presented a soft robotic glove designed C. Cramer, Robot-based hand motor therapy after stroke, Brain,

vol. 131, no. 2, pp. 425437, 2008.

to assist individuals with functional grasp pathologies [4] M. M. H. P. Janssen, A. Bergsma, A. C. H. Geurts, and I. J. M. de

perform hand rehabilitation exercises. The hydraulically Groot, Patterns of decline in upper limb function of boys and

men with DMD: an international survey, J. Neurol., pp. 120,

2014.

[5] S. L. Wolf, C. J. Winstein, J. P. Miller, E. Taub, G. Uswatte, D.

Morris, C. Giuliani, K. E. Light and D. Nichols-Larsen, Effect of

constraint-induced movement therapy on upper extremity

function 3 to 9 months after stroke: the EXCITE randomized

clinical trial, Jama, vol. 296, no. 17, pp. 20952104, 2006.

[6] N. A. Bayona, J. Bitensky, K. Salter, and R. Teasell, The role of

task-specific training in rehabilitation therapies, Top. Stroke

Rehabil., vol. 12, no. 3, p. 58, 2005.

[7] S. Ueki, H. Kawasaki, S. Ito, Y. Nishimoto, M. Abe, T. Aoki, Y.

Ishigure, T. Ojika, and T. Mouri, Development of a hand-assist

robot with multi-degrees-of-freedom for rehabilitation therapy,

Mechatronics, IEEE/ASME Trans., vol. 17, no. 1, pp. 136146,

2012.

[8] N. G. Kutner, R. Zhang, A. J. Butler, S. L. Wolf, and J. L.

Alberts, Quality-of-life change associated with robotic-assisted

therapy to improve hand motor function in patients with subacute

stroke: a randomized clinical trial, Phys. Ther., vol. 90, no. 4, pp.

493504, 2010.

[9] P. Heo, G. M. Gu, S. Lee, K. Rhee, and J. Kim, Current hand

exoskeleton technologies for rehabilitation and assistive

engineering, Int. J. Precis. Eng. Manuf., vol. 13, no. 5, pp. 807

824, May 2012.

[10] P. Maciejasz, J. Eschweiler, K. Gerlach-Hahn, A. Jansen-Troy, S.

Leonhardt, and others, A survey on robotic devices for upper

limb rehabilitation, J. Neuroeng. Rehabil., vol. 11, no. 3, 2014.

[11] F. Ilievski, A. D. Mazzeo, R. F. Shepherd, X. Chen, and G. M.

Whitesides, Soft robotics for chemists, Angew. Chemie, vol.

123, no. 8, pp. 19301935, 2011.

[12] C. Majidi, Soft Robotics: A PerspectiveCurrent Trends and

Prospects for the Future, Soft Robot., vol. 1, no. P, pp. 511,

2013.

[13] P. Polygerinos, Z. Wang, K. C. Galloway, R. J. Wood, and C. J.

Walsh, Soft robotic glove for combined assistance and at-home

rehabilitation, Rob. Auton. Syst., 2014.

[14] P. Polygerinos, Z. Wang, B. Overvelde, K. Galloway, R. J. Wood,

K. Bertoldi, and C. J. Walsh, Modeling of Soft Fiber Reinforced

Bending Actuators, IEEE Trans. Robot., 2015.

[15] R. Deimel and O. Brock, A Compliant Hand Based on a Novel

Pneumatic Actuator, in 2013 IEEE Inter. Conf. Robot. and

Autom. (ICRA), 2013, pp. 20392045.

[16] K. C. Galloway, P. Polygerinos, C. J. Walsh, and R. J. Wood,

Mechanically programmable bend radius for fiber-reinforced

soft actuators, in IEEE Inter. Conf. Adv. Robot., 2013.

[17] P. Maeder-York, T. Clites, E. Boggs, R. Neff, P. Polygerinos, D.

Holland, L. Stirling, K. Galloway, C. Wee, and C. Walsh,

Biologically Inspired Soft Robot for Thumb Rehabilitation, J.

Med. Device., vol. 8, no. 2, p. 20933, 2014.

[18] L. Dovat, O. Lambercy, R. Gassert, T. Maeder, T. Milner, T. C.

Leong, and E. Burdet, HandCARE: a cable-actuated

rehabilitation system to train hand function after stroke, IEEE

Trans. neural Syst. Rehabil. Eng., vol. 16, no. 6, pp. 582591,

2008.

[19] K. Matheus and A. M. Dollar, Benchmarking grasping and

manipulation: properties of the objects of daily living, in

IEEE/RSJ Inter. Conf. Intel. Robot. Sys. (IROS), 2010, pp. 5020

5027.

[20] P. M. Aubin, H. Sallum, C. Walsh, and A. Correia, A Pediatric

Robotic Thumb Exoskeleton for at-Home Rehabilitation, in

IEEE Inter. Conf. Rehab. Robot.(ICORR), 2013.

[21] A. Kapandji, Cotation clinique de lopposition et de la contre-

opposition du pouce, in Annales de Chirurgie de la Main, 1986,

vol. 5, no. 1, pp. 6773.

[22] V. Mathiowetz, G. Volland, N. Kashman, and K. Weber, Adult

norms for the Box and Block Test of manual dexterity, Am J

Occup Ther, vol. 39, no. 6, pp. 386391, 1985.

Você também pode gostar

- Design of An Assistive, Glove-Based Exoskeleton: Chad G. Rose and Marcia K. O'MalleyDocumento2 páginasDesign of An Assistive, Glove-Based Exoskeleton: Chad G. Rose and Marcia K. O'MalleyYoussef NagatyAinda não há avaliações

- Stroke Rehabilitation Using Exoskeleton-Based Robotic Exercisers: Mini ReviewDocumento6 páginasStroke Rehabilitation Using Exoskeleton-Based Robotic Exercisers: Mini ReviewAnh HuyAinda não há avaliações

- 2013 - Polygerinos - Towards A Soft Pneumatic Glove For Hand RehabilitationDocumento7 páginas2013 - Polygerinos - Towards A Soft Pneumatic Glove For Hand RehabilitationEbrahim AwadAinda não há avaliações

- Biomimetics 08 00614Documento16 páginasBiomimetics 08 00614Ebenezer MarteyAinda não há avaliações

- Individual Finger ControlDocumento26 páginasIndividual Finger Controlmb.farooqui02Ainda não há avaliações

- 2020 A Hybrid, Soft Exoskeleton Glove Equipped With A TelescopicDocumento7 páginas2020 A Hybrid, Soft Exoskeleton Glove Equipped With A TelescopicANSHUMAAN P BHAGATAinda não há avaliações

- Design and Testing of A Soft Parallel Robot Based On Pneumatic Artificial Muscles For Wrist RehabilitationDocumento11 páginasDesign and Testing of A Soft Parallel Robot Based On Pneumatic Artificial Muscles For Wrist Rehabilitation王根萌Ainda não há avaliações

- Soft Robotic GloveDocumento9 páginasSoft Robotic GloveGeorge SamAinda não há avaliações

- A Method For Quantifying Interaction Forces in Wearable RobotsDocumento6 páginasA Method For Quantifying Interaction Forces in Wearable RobotsSathvik BhatAinda não há avaliações

- Hand Function Assistance in Stroke SurvivorsDocumento14 páginasHand Function Assistance in Stroke SurvivorsMd. Mizanur RahmanAinda não há avaliações

- Upper-Body Motion Mode Recognition Based On Imus For A Dynamic Spine BraceDocumento4 páginasUpper-Body Motion Mode Recognition Based On Imus For A Dynamic Spine BraceLaura CursaruAinda não há avaliações

- Design, Control, and Testing of A Thumb Exoskeleton With Series Elastic ActuationDocumento21 páginasDesign, Control, and Testing of A Thumb Exoskeleton With Series Elastic ActuationÖmer GürAinda não há avaliações

- A Novel Elbow Pneumatic Muscle Actuator For Exoskeleton Arm in Post-Stroke RehabilitationDocumento6 páginasA Novel Elbow Pneumatic Muscle Actuator For Exoskeleton Arm in Post-Stroke RehabilitationSathvik BhatAinda não há avaliações

- A Hybrid Arm-Hand Rehabilitation Robot With EMG-Based Admittance ControllerDocumento11 páginasA Hybrid Arm-Hand Rehabilitation Robot With EMG-Based Admittance ControllerHoney RoseAinda não há avaliações

- Novel Soft Bending Actuator-Based Power Augmentation Hand Exoskeleton Controlled by Human IntentionDocumento22 páginasNovel Soft Bending Actuator-Based Power Augmentation Hand Exoskeleton Controlled by Human IntentionAlemeAinda não há avaliações

- Micromachines 2544656 Peer Review v1Documento21 páginasMicromachines 2544656 Peer Review v1Parvin AkterAinda não há avaliações

- 10 1016@j JHT 2020 03 024Documento10 páginas10 1016@j JHT 2020 03 024eduar yecid duarte gomezAinda não há avaliações

- A Novel Soft Elbow ExosuitDocumento8 páginasA Novel Soft Elbow Exosuiteyao100% (1)

- Haptic Devices Wearability Based Taxonomy and Literature ReviewDocumento25 páginasHaptic Devices Wearability Based Taxonomy and Literature ReviewJohn SmithAinda não há avaliações

- 15 2021 MDPI Study To Increase The TRL of Exoskeleton ERMIS BasDocumento16 páginas15 2021 MDPI Study To Increase The TRL of Exoskeleton ERMIS BasUS SILVA (MEX)Ainda não há avaliações

- Information Processing Via Human Soft TissueDocumento16 páginasInformation Processing Via Human Soft Tissuefredkasket1Ainda não há avaliações

- Machines 10 00918Documento13 páginasMachines 10 00918Trần ChiếnAinda não há avaliações

- A Fairly Simple Mechatronic Device For Training Human Wrist MotionDocumento15 páginasA Fairly Simple Mechatronic Device For Training Human Wrist Motionalamin khondakerAinda não há avaliações

- Type Synthesis of Self-Alignment Parallel Ankle Rehabilitation Robot With Suitable Passive Degrees of FreedomDocumento16 páginasType Synthesis of Self-Alignment Parallel Ankle Rehabilitation Robot With Suitable Passive Degrees of Freedommo.hajian1402Ainda não há avaliações

- An Index Finger Exoskeleton With Series Elastic Actuation For Rehabilitation: Design, Control and Performance CharacterizationDocumento27 páginasAn Index Finger Exoskeleton With Series Elastic Actuation For Rehabilitation: Design, Control and Performance CharacterizationPhạm Quốc BảoAinda não há avaliações

- Oscillator-Based Assistance of Cyclical Movements: Model-Based and Model-Free ApproachesDocumento13 páginasOscillator-Based Assistance of Cyclical Movements: Model-Based and Model-Free Approaches李磊Ainda não há avaliações

- Hierarchical Classification of Subject-CooperativeDocumento20 páginasHierarchical Classification of Subject-CooperativeEhsan JafariAinda não há avaliações

- Design and Simulation of Leg-Exoskeleton Suit For RehabilitationDocumento8 páginasDesign and Simulation of Leg-Exoskeleton Suit For RehabilitationAlbert ArtandiAinda não há avaliações

- Design and Optimization of An Index Finger Exoskeleton With Semi-Wrapped Fixtures and Series Elastic ActuatorsDocumento10 páginasDesign and Optimization of An Index Finger Exoskeleton With Semi-Wrapped Fixtures and Series Elastic ActuatorsمحمدAinda não há avaliações

- 03 Hand Rehabilitation of Stroke PatientsDocumento6 páginas03 Hand Rehabilitation of Stroke PatientsMd. Mizanur RahmanAinda não há avaliações

- A Soft Exosuit For Flexible Upper-Extremity RehabilitationDocumento14 páginasA Soft Exosuit For Flexible Upper-Extremity RehabilitationSathvik BhatAinda não há avaliações

- Robust Control of A Cable-Driven Soft Exoskeleton Joint For Intrinsic Human-Robot InteractionDocumento11 páginasRobust Control of A Cable-Driven Soft Exoskeleton Joint For Intrinsic Human-Robot InteractionHassan abokouraAinda não há avaliações

- A Practical 3d-Printed Soft Robotic Prosthetic Hand With Multi-Articulating CapabilitiesDocumento23 páginasA Practical 3d-Printed Soft Robotic Prosthetic Hand With Multi-Articulating Capabilitiesmaryamsaleem430Ainda não há avaliações

- JP - 13Upper-Limb Powered Exoskeleton DesignDocumento10 páginasJP - 13Upper-Limb Powered Exoskeleton DesignCostinel BogheanuAinda não há avaliações

- Design and Implementation of A Control Architecture For Rehabilitation Robotic SystemsDocumento25 páginasDesign and Implementation of A Control Architecture For Rehabilitation Robotic Systemstanvir anwarAinda não há avaliações

- Elsevier: Nexos - AN SupportDocumento6 páginasElsevier: Nexos - AN SupportGuna SeelanAinda não há avaliações

- Mechatronics: M.A. Oliver-Salazar, D. Szwedowicz-Wasik, A. Blanco-Ortega, F. Aguilar-Acevedo, R. Ruiz-GonzálezDocumento16 páginasMechatronics: M.A. Oliver-Salazar, D. Szwedowicz-Wasik, A. Blanco-Ortega, F. Aguilar-Acevedo, R. Ruiz-GonzálezAjitAinda não há avaliações

- A High-Performance Redundantly Actuated Parallel Mechanism For Ankle RehabilitationDocumento12 páginasA High-Performance Redundantly Actuated Parallel Mechanism For Ankle RehabilitationIsti NisaAinda não há avaliações

- Robust Motion Control Architecture For An Upper-Limb Rehabilitation ExosuitDocumento18 páginasRobust Motion Control Architecture For An Upper-Limb Rehabilitation ExosuitJuan Carlos Quispe CruzAinda não há avaliações

- An Attention-Controlled Hand Exoskeleton For The Rehabilitation of Finger Extension and Flexion Using A Rigid-Soft Combined MechanismDocumento13 páginasAn Attention-Controlled Hand Exoskeleton For The Rehabilitation of Finger Extension and Flexion Using A Rigid-Soft Combined MechanismCarlos Arturo TorresAinda não há avaliações

- Simulating Ideal Assistive Devices To Reduce The Metabolic Cost of Walking With Heavy LoadsDocumento25 páginasSimulating Ideal Assistive Devices To Reduce The Metabolic Cost of Walking With Heavy LoadsZehra ÇİFCİBAŞIAinda não há avaliações

- Artículo 1Documento9 páginasArtículo 1Alex Jarillo SilvaAinda não há avaliações

- Exo-Glove: A Soft Wearable Robotic Hand For Stroke SurvivorsDocumento7 páginasExo-Glove: A Soft Wearable Robotic Hand For Stroke SurvivorsmaheshAinda não há avaliações

- Model-Based Online Learning and Adaptive Control For A Human-Wearable Soft Robot'' Integrated SystemDocumento21 páginasModel-Based Online Learning and Adaptive Control For A Human-Wearable Soft Robot'' Integrated SystemAlemeAinda não há avaliações

- Towards Realising Wearable Exoskeletons For Elderly PeopleDocumento6 páginasTowards Realising Wearable Exoskeletons For Elderly PeopleRatna SambhavAinda não há avaliações

- Icorr 2005 1501051Documento4 páginasIcorr 2005 1501051Amanuel TilayeAinda não há avaliações

- A Hand-Held Non-Robotic Surgical Tool With A Wrist and An ElbowDocumento9 páginasA Hand-Held Non-Robotic Surgical Tool With A Wrist and An ElbowwangyanhiterAinda não há avaliações

- Castiblanco Jenny2021Documento16 páginasCastiblanco Jenny2021Sayda Alisson Huacre TuctoAinda não há avaliações

- S12008-021-00779-9-Our RequirementDocumento15 páginasS12008-021-00779-9-Our RequirementMuthuvelan MutharasuAinda não há avaliações

- The Role of Feed-Forward and Feedback Processes For Closed-Loop Prosthesis ControlDocumento12 páginasThe Role of Feed-Forward and Feedback Processes For Closed-Loop Prosthesis ControlVALERIA NICOLE TORRES TERANAinda não há avaliações

- Actuators 11 00346Documento21 páginasActuators 11 00346صفاء الدين عادل حردان محمدAinda não há avaliações

- Hindavi 5513013Documento12 páginasHindavi 5513013Muthuvelan MutharasuAinda não há avaliações

- Ninapro DatasetDocumento8 páginasNinapro DatasetSindhu VasireddyAinda não há avaliações

- Home-Based Rehabilitation For Patients With Spinal Cord InjuryDocumento15 páginasHome-Based Rehabilitation For Patients With Spinal Cord InjuryonikabekunAinda não há avaliações

- 2014 Hand-Held Microsurgical Forceps With Force-Feedback ForDocumento6 páginas2014 Hand-Held Microsurgical Forceps With Force-Feedback ForANSHUMAAN P BHAGATAinda não há avaliações

- Scirobotics Abb0467Documento16 páginasScirobotics Abb0467Diana BejinaruAinda não há avaliações

- Vibration StimulationDocumento6 páginasVibration StimulationMedAinda não há avaliações

- Design and Robust Control of A 2 Dofs Lower Limb ExoskeletonDocumento6 páginasDesign and Robust Control of A 2 Dofs Lower Limb ExoskeletonsofiiiAinda não há avaliações

- Analysis of Grasping Strategies and Function in Hemiparetic Patients Using An Instrumented ObjectDocumento8 páginasAnalysis of Grasping Strategies and Function in Hemiparetic Patients Using An Instrumented ObjectUttam GrandhiAinda não há avaliações

- Light - Reflection - Refraction - Diffraction - ReviewDocumento42 páginasLight - Reflection - Refraction - Diffraction - ReviewLester MarquezAinda não há avaliações

- ThermocoupleDocumento27 páginasThermocoupleLester MarquezAinda não há avaliações

- UP HW CH 10 SDocumento6 páginasUP HW CH 10 SLester MarquezAinda não há avaliações

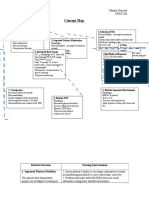

- Source: From: Mark Nino O. Magdayo Learning(s) : The Modern Machine Is A Collection of Interconnected Subsystems With Many Design Dependencies ThatDocumento1 páginaSource: From: Mark Nino O. Magdayo Learning(s) : The Modern Machine Is A Collection of Interconnected Subsystems With Many Design Dependencies ThatLester MarquezAinda não há avaliações

- "Fall For You" "Out of My League"Documento1 página"Fall For You" "Out of My League"Lester MarquezAinda não há avaliações

- HW1 Solutions PDFDocumento2 páginasHW1 Solutions PDFLester MarquezAinda não há avaliações

- CLC 7 Eap 1501Documento7 páginasCLC 7 Eap 1501onerose91Ainda não há avaliações

- Coplanar Non Concurrent Force SystemsDocumento23 páginasCoplanar Non Concurrent Force SystemsLester MarquezAinda não há avaliações

- Med Surg4Documento27 páginasMed Surg4Hasan A AsFourAinda não há avaliações

- Nursing Care PlanDocumento1 páginaNursing Care Planlaehaaa67% (3)

- ITO-Catalog - General ElectrotherapyDocumento28 páginasITO-Catalog - General ElectrotherapyGeki IovanAinda não há avaliações

- Abu Dhabi Early Intervention GuideDocumento29 páginasAbu Dhabi Early Intervention GuideKashif Aziz AwanAinda não há avaliações

- Present Considerations in The Kinetic Treatment of CoxarthrosisDocumento5 páginasPresent Considerations in The Kinetic Treatment of CoxarthrosisluizamgoAinda não há avaliações

- NPTE Candidate HandbookDocumento26 páginasNPTE Candidate HandbookKhalil AhmedAinda não há avaliações

- Competency Profile PhysiotherapyDocumento2 páginasCompetency Profile PhysiotherapyGretel EdelweissAinda não há avaliações

- Scientific Reconciliation of The Concepts and Principles of Rood ApproachDocumento10 páginasScientific Reconciliation of The Concepts and Principles of Rood Approachnandhini raguAinda não há avaliações

- Irish Dela Cruz Saludares: Summary QualificationsDocumento3 páginasIrish Dela Cruz Saludares: Summary QualificationsLudwig Santos-Mindo De Varona-LptAinda não há avaliações

- 2016.09 Chinesport General Catalogue 02 Electro-Medical EquipmentDocumento50 páginas2016.09 Chinesport General Catalogue 02 Electro-Medical EquipmentAdnan AhmedAinda não há avaliações

- HydrotherapyDocumento52 páginasHydrotherapyMpt Sports100% (1)

- Final Online Exam Guideline CBTDocumento105 páginasFinal Online Exam Guideline CBTfaisalaminwani121Ainda não há avaliações

- Combination of Massage Therapy With Ultramagnetic Therapy: Does It Affect Shoulder Pain Rehabilitation?Documento10 páginasCombination of Massage Therapy With Ultramagnetic Therapy: Does It Affect Shoulder Pain Rehabilitation?Alejandro Cordoba aparicioAinda não há avaliações

- Sport Hip Injuries PDFDocumento329 páginasSport Hip Injuries PDFIonela Manolache100% (3)

- Medicine Samples PrintDocumento19 páginasMedicine Samples PrintDowntoearthAinda não há avaliações

- 6TH Sem BSC Physics Project.2 H.M College. Manjeri 2Documento41 páginas6TH Sem BSC Physics Project.2 H.M College. Manjeri 2kcameppadi123Ainda não há avaliações

- FulltextDocumento9 páginasFulltextVivek Edamuriyil RamesanAinda não há avaliações

- Arthur Jason de Luigi (Ed.) - Adaptive Sports Medicine. A Clinical Guide-Springer (2018) PDFDocumento396 páginasArthur Jason de Luigi (Ed.) - Adaptive Sports Medicine. A Clinical Guide-Springer (2018) PDFDL PT&M100% (2)

- Community Health Nursing: Unit Plan ON Unit - ViDocumento5 páginasCommunity Health Nursing: Unit Plan ON Unit - ViSanthu Su100% (1)

- Clinical Desision in Therapeutik ExerciseDocumento335 páginasClinical Desision in Therapeutik ExerciseBrina BeBe Ifakristina100% (3)

- Concept Map MgenoviaDocumento5 páginasConcept Map Mgenoviaapi-302138606Ainda não há avaliações

- 003 Initial AssessmentDocumento5 páginas003 Initial AssessmentanumolAinda não há avaliações

- B.P.Ed. Third Semester (CBS) Examination Sports Medicine Physiotherapy and Rehabilitation (Elective Course)Documento6 páginasB.P.Ed. Third Semester (CBS) Examination Sports Medicine Physiotherapy and Rehabilitation (Elective Course)Devashish SahasrabudheAinda não há avaliações

- Burn RehabilitationDocumento4 páginasBurn RehabilitationSuneel Kumar PrajapatiAinda não há avaliações

- ClientsOnDemand ResultsDocumento70 páginasClientsOnDemand ResultsJim JosephAinda não há avaliações

- Pain Management CHNDocumento38 páginasPain Management CHNVaibhavi ShastriAinda não há avaliações

- Workplace Ergonomics ProposalDocumento6 páginasWorkplace Ergonomics ProposalIshan VermaAinda não há avaliações

- Roods ApproachDocumento23 páginasRoods ApproachyigoAinda não há avaliações

- Review Article Occupational Therapy Research in Schools: A Mapping ReviewDocumento9 páginasReview Article Occupational Therapy Research in Schools: A Mapping ReviewNataliaAinda não há avaliações