Escolar Documentos

Profissional Documentos

Cultura Documentos

Index: Acoustic Emission Examination of Fiber-Reinforced Plastic Vessels, Article 11

Enviado por

Mauricio Esteban Fernandez RamirezTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Index: Acoustic Emission Examination of Fiber-Reinforced Plastic Vessels, Article 11

Enviado por

Mauricio Esteban Fernandez RamirezDireitos autorais:

Formatos disponíveis

INDEX

ACOUSTIC EMISSION EXAMINATION OF Sensor Location, Article 12, T-1243.3

FIBER-REINFORCED PLASTIC VESSELS, Sensor Spacing, Article 12, T-1243.4

Article 11 Multichannel Source Location, Article 12, T-1243.4.2

Calibration, Article 11, T-1141(b) Zone Location, Article 12, T-1243.4.1

Attenuation Characterization, Article 11, T-1141(b)(1) System Performance Check, Article 12, T-1243.5

Instrument Calibration, Article 11, Documentation, Article 12, T-1290

Mandatory Appendix II Equipment and Supplies, Article 12, T-1230

Sensor Locations and Spacings, Article 11, T-1141(c) Evaluation, Article 12, T-1280

System Performance Check, Article 11, T-1141(d) Criteria, Article 12, T-1281

Documentation, Article 11, T-1190 Examination Procedure, Article 12, T-1244

Environmental Conditions, Article 11, T-1124 Background Noise, Article 12, T-1244.2

Equipment and Supplies, Article 11, T-1130 During Examination, Article 12, T-1244.2.2

Evaluation, Article 11, T-1180 Prior to Loading, Article 12, T-1244.2.1

Criteria, Article 11, T-1181 Pressurization, Article 12, T-1244.3

Emissions During Load Hold, Article 11, T-1182 Sequence, Article 12, T-1244.3.2

Felicity Ratio Determination, Article 11, T-1183 Test Termination, Article 12, T-1244.3.3

--`,,```,,,,````-`-`,,`,,`,`,,`---

High Amplitude Events Criterion, Article 11, T-1184 Glossary of Terms, Article 12, Mandatory Appendix III

Total Counts Criterion, Article 11, T-1185 Instrumentation Performance Requirements, Article 12,

Examination Procedure, Article 11, T-1142 Nonmandatory Appendix I

AE Activity, Article 11, T-1142(d) Noise Reduction, Article 12, T-1222

Background Noise, Article 11, T-1142(b) Sensor Placement Guidelines, Article 12,

Stressing, Article 11, T-1142(c) Nonmandatory Appendix A

Test Termination, Article 11, T-1142(e) Sensors, Article 12, T-1223

Glossary of Terms, Article 11, Mandatory Appendix III Frequency, Article 12, T-1223.1

Instrument Settings, Article 11, T-1126 Mounting, Article 12, T-1223.2

Instrumentation Performance Requirements, Article 11, Surface Contact, Article 12, T-1223.3

Mandatory Appendix I Vessel Stressing, Article 12, T-1221

Noise Elimination, Article 11, T-1125 Written Procedure Requirements, Article 12, T-1225

Sensor Placement Guidelines, Article 11,

Nonmandatory Appendix A

CONTINUOUS ACOUSTIC EMISSION MONITORING,

Sensors, Article 11, T-1127

Article 13

Vessel Conditioning, Article 11, T-1121

AE Monitor, Article 13, T-1335

Vessel Stressing, Article 11, T-1122

Data Analysis and Display, Article 13, T-1335.4

Vessel Support, Article 11, T-1123

Data Storage, Article 13, T-1335.3

Written Procedure Requirements, Article 11, T-1128

Installation, Article 13, T-1349

Signal Identification, Article 13, T-1335.1

ACOUSTIC EMISSION EXAMINATION OF Signal Processing, Article 13, T-1335.2

METALLIC VESSELS, Article 12 AE System Operation, Article 13, T-1351

AE Source Location, Article 12, T-1224 Amplifiers, Article 13, T-1334

Calibration, Article 12, T-1243 Background Noise, Article 13, T-1345

Attenuation Characterization, Article 12, T-1243.2 Cables, Article 13, T-1333

Instrument Calibration, Article 12, Calibration, Article 13, T-1360

Mandatory Appendix II Intervals, Article 13, T-1363

On-Site System Calibration, Article 12, T-1243.1 Sensors, Article 13, T-1361

578

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

INDEX

System, Article 13, T-1362 Functional Verification, Article 13, T-1347.3

Detection and Source Location, Article 13, T-1362.1 Mounting, Article 13, T-332.3

Function Verification, Article 13, T-1362.2 Source Location and Sensor Mounting, Article 13, T-1327

Component Stressing, Article 13, T-1324 Signal Lead Installation, Article 13, T-1348

Coordination with Plant System Owner/Operator, Article Signal Pattern Recognition, Article 13, T-1343

13, T-1326

Data Processing, Interpretation, and Evaluation, Article EDDY CURRENT EXAMINATION OF TUBULAR

13, T-1352 PRODUCTS, Article 8

Data Recording and Storage, Article 13, T-1353 Calibration, Article 8, T-860

Equipment, Article 13, T-1330 Eddy Current Examination

Equipment Qualification, Article 13, T-1341 Coated Ferritic Materials, Article 8,

Evaluation/Results, Article 13, T-1380 Mandatory Appendix III

Data Processing, Interpretation, and Evaluation, Article Installed Nonferromagnetic Heat Exchanger Tubing,

13, T-1381.2 Article 8, Mandatory Appendix I

Data Requirements, Article 13, T-1381.1 Nonferromagnetic Heat Exchanger Tubing, Article 8,

Examination, Article 13, T-1370 Mandatory Appendix II

Non-Metallic Components, Article 13, Evaluation, Article 8, T-880

Mandatory Appendix III Glossary of Terms, Article 8, Mandatory Appendix IV

Non-Nuclear Components, Article 13, Personnel Qualification, Article 8, T-822

Mandatory Appendix II Reference Specimen, Article 8, T-831

Nuclear Components, Article 13, Mandatory Appendix I Written Procedure, Article 8, T-821

Glossary of Terms, Article 13, Mandatory Appendix VII Procedure Requirements, Article 8, T-841

Hostile Environment Applications, Article 13,

Mandatory Appendix V

Leak Detection Applications, Article 13, GENERAL REQUIREMENTS, Article 1

Mandatory Appendix VI Acceptance Standards, Article 1, T-180

Limited Zone Monitoring, Article 13, ASTM Standards and Recommended Practices, Article 1,

Mandatory Appendix IV T-170

Material Attenuation/Characterization, Article 13, T-1344 Authorized Inspector/Authorized Code Inspector, Article 1,

Noise Interference, Article 13, T-1325 T-170

Objectives, Article 13, T-1321 Calibration, Article 1, T-160

Personnel Qualification, Article 13, T-1323 and T-1371 Equipment, Article 1, T-130

Plant Startup, Article 13, T-1372 Evaluation, Article 1, T-180

Plant Steady-State Operation, Article 13, T-1373 Examinations and Inspections, Article 1, T-170

AE System Function Check, Article 13, T-1373.2 Fabricator, Article 1, T-150

Data Evaluation Interval, Article 13, T-1373.1 Glossary of Terms, Article 1, Mandatory Appendix I

Procedures, Article 13, T-1350 Installer, Article 1, T-150

Relative Indications, Article 13, T-1322 Limited Certification, Article 1, T-140(d)

Reports/Records, Article 13, T-1390 Manufacturer, Article 1, T-150

Calibration Records, Article 13, T-1364 NDE Personnel Certification, Article 1, T-140

Qualification Records, Article 13, T-1346 Procedure, Article 1, T-150

Reports to Plant System Owner/Operator, Article 13, Procedures, Special, Article T-150(a)

T-1391 Quality Assurance/Quality Control System, Article 1,

Senser Qualification, Article 13, T-1342 T-150

Sensitivity and Frequency Response, Article 13, Records/Documentation, Article 1, T-190

T-1342.1 Referencing Code Section, Article 1, T-150

Uniformity of Sensor Sensitivity, Article 13, T-1342.2

Sensors, Article 13, T-1332 LEAK TESTING, Article 10

Frequency, Article 13, T-1332.1 Bubble Test

Differential and Tuned Sensors, Article 13, T-1332.2 Direct Pressure Technique, Article 10,

Installation, Article 13, T-347 Mandatory Appendix I

Array Spacing, Article 13, T-1347.2 Vaccum Box Technique, Article 10,

Coupling, Article 13, T-1347.1 Mandatory Appendix II

579

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

2004 SECTION V

Calibration, Article 10, T-1060 Surface Preparation, Article 6, T-642

Calibration Leak Standards, Article 10, T-1063 Techniques, Article 6, T-651

Capillary Type Leak Standard, Article 10, T-1063.2 Nonstandard Temperature, Article 6, T-653

Permeation Type Leak Standard, Article 10, T-1063.1 Standard Temperature, Article 6, T-653

Pressure/Vaccum Gages, Article 10, T-1061 Restrictions, Article 6, T-654

Temperature Measuring Devices, Article 10, T-1062

Cleanliness, Article 10, T-1041

MAGNETIC PARTICLE EXAMINATION, Article 7

Documentation, Article 10, T-1090

Black Light Intensity, Article 7, T-731(c)(4)

Evaluation, Article 10, T-1080

Calibration, Article 7, T-760

Gages, Article 10, T-1031 Circular Magnetization Technique, Article 7, T-775

Location, Article 10, T-1031(b) Central Conductor Technique, Article 7, T-775.2

Range, Article 10, T-1031(a) Magnetizing Current, Article 7, T-775.2(b)

Glossary of Terms, Article 10, Mandatory Appendix VII Magnetizing Procedure, Article 7, T-775.2(a)

Halogen Diode Detector Probe Test, Article 10, Direct Contact Technique, Article 7, T-775.1

Mandatory Appendix III Magnetizing Current, Article 7, T-775.1(b)

Helium Mass Spectrometer Test Magnetizing Procedure, Article 7, T-775.1(a)

Detector Probe Technique, Article 10, Demagnetization, Article 7, T-755

Mandatory Appendix IV Equipment, Article 7, T-730

Tracer Probe and Hood Techniques, Article 10, Evaluation, Article 7, T-780

Mandatory Appendix V Examination, Article 7, T-770

Preliminary Leak Test, Article 10, T-1051 Direction of Examination, Article 7, T-771

Pressure Change Test, Article 10, Mandatory Appendix VI Examination Coverage, Article 7, T-772

Pressure/Vaccum (Pressure Limits), Article 10, T-1044 Examination Medium, Article 7, T-731

Procedure/Technique, Article 10, T-1050 Dry Particles, Article 7, T-731(a)

Sealing Openings, Article 10, T-1042 Fluorescent Particles, Article 7, T-731(c)

--`,,```,,,,````-`-`,,`,,`,`,,`---

Temperature, Article 10, T-1043 Wet Particles, Article 7, T-731(b)

Test, Article 10, T-1070 Glossary of Terms, Article 7, Mandatory Appendix II

Written Procedure, Article 10, T-1021 Lifting Power of Yokes, Article 7, T-762

Longitudinal Magnetization Technique, Article 7, T-774

Magnetizing Current, Article 7, T-774.3

LIQUID PENETRANT EXAMINATION, Article 6 Magnetizing Field Strength, Article 7, T-774.2

Black Light Intensity, Article 6, T-676.4(d) Magnetizing Procedure, Article 7, T-774.1

Magnetic Particle Field Indicator, Article 7, T-753

Control of Contaminants, Article 6, T-641

Magnetic Particle Examination of Coated Ferritic

Developing, Article 6, T-675

Materials, Article 7, Mandatory Appendix I

Dry Developer Application, Article 6, T-675.1

Magnetization Techniques, Article 7, T-752

Wet Developer Application, Article 6, T-675.2

Method of Examination, Article 7, T-751

Documentation/Records, Article 6, T-690

Multidirectional Magnetization Technique, Article 7,

Drying After Excess Penetrant Removal, Article 6, T-674

T-777

Drying After Preparation, Article 6, T-643

Magnetizing Field Strength, Article 7, T-777.2

Evaluation, Article 6, T-680 Magnetizing Procedure, Article 7, T-777.1

Excess Penetrant Removal, Article 6, T-673 Procedure/Technique, Article 7, T-750

Post Emulsifying Penetrants, Article 6, T-673.2 Prod Technique, Article 7, T-773

Solvent Removable Penetrants, Article 6, T-673.3 Magnetizing Current, Article 7, T-773.2

Water Washable Penetrants, Article 6, T-673.1 Magnetizing Procedure, Article 7, T-773.1

Glossary of Terms, Article 6, Mandatory Appendix 1 Prod Spacing, Article 7, T-773.3

Interpretation, Article 6, T-676 Records, Article 7, T-790

Liquid Penetrant Comparator, Article 6, T-653.2 Rectified Current, Article 7, T-754

Procedure, Article 6, T-621 Surface Conditioning, Article 7, T-741

Penetrant Application, Article 6, T-671 Yoke Technique, Article 7, T-776

Penetrant Materials, Article 6, T-631 Application, Article 7, T-776.1

Penetration Time, Article 6, T-672 Magnetizing Procedure, Article 7, T-776.2

580

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

INDEX

RADIOGRAPHIC EXAMINATION, Article 2 Double-Wall Viewing, Article 2, T-275.2

Backscatter Radiation, Article 2, T-223 Maps, Article 2, T-275.3

Excessive Backscatter, Article 2, T-284 Single-Wall Viewing, Article 2, T-275.1

Castings (Examination), Article 3 Either side Markers, Article 2, T-275.1(c)

Densitometer Calibration, Article 2, T-262 Film Side Markers, Article 2, T-275.1(b)

Density Limitations, Article 2, T-282.1 Source Side Markers, Article 2, T-275.1(a)

Monitoring Density Limitations, Article 2, T-225 Penetrameters (see Image Quality Indicators)

Density Variation, Article 2, T-282.2 Pipe or Tube Weld Technique Sketches, Article 2,

Digital Image Acquisition, Display, and Storage, Article 2, Nonmandatory Appendix A

Mandatory Appendix III Procedure Requirements, Article 2, T-281

Interpretation, Evaluation, and Disposition, Article 2, Quality of Radiographs, Article 2, T-281

Mandatory Appendix IV Radiographic Technique, Article 2, T-271

Direction of Radiation, Article 2, T-273 Real-Time Radioscopic Examination, Article 2,

Documentation, Article 2, T-290 Mandatory Appendix II

Double-Wall Technique, Article 2, T-271.2 Sensitivity, Article 2, T-283

Double-Wall Viewing, Article 2, T-271.2(b) Single-Wall Technique, Article 2, T-271.1

Single-Wall Viewing, Article 2, T-271.2(a) Source Size Determination, Article 2, T-261.2

Energy of Radiation, Article 2, T-272 Source Size Verification, Article 2, T-261.1

Gamma Radiation, Article 2, T-272.2 Step Wedge Film Density Verification, Article 2, T-262

X-Radiation, Article 2, T-272.1 Surface Preparation, Article 2, T-222

Equipment and Materials, Article 2, T-230 Materials, Article 2, T-222.1

Evaluation, Article 2, T-280 Surface Finish, Article 2, T-222.3

By Manufacturer, Article 2, T-292 Welds, Article 2, T-222.2

Film Processing, Article 2, T-231.2

Film Selection, Article 2, T-231.1

Film Viewing Facilities, Article 2, T-234 ULTRASONIC EXAMINATION METHODS FOR

Geometric Unsharpness, Article 2, T-274 INSERVICE INSPECTION, Article 4

Limitations, Article 2, T-285 Amplitude Control Lenearity, Article 4, T-461.2 and

Glossary of Terms, Article 2, Mandatory Appendix V Mandatory Appendix II

Identification System, Article 2, T-224 Angle Beam Calibrations (General Techniques), Article 4,

Image Quality Indicators (Penetrameters) Nonmandatory Appendix B

Design, Article 2, T-233 Basic Calibration Block, Article 4, T-435 and

Equivalent Sensitivity, Article 2, Nonmandatory Appendix J

Nonmandatory Appendix B Block Selection, Article 4, Nonmandatory Appendix J,

Number, Article 2, T-277.2 J-10(a)

Multiple Penetrameters, Article 2, T-277.2(a) Block Quality, Article 4, Nonmandatory Appendix J,

Special Cases, Article 2, T-277.2(b) J-10(e)

Placement, Article 2, T-277.1 Clad, Article 4, Nonmandatory Appendix J, J-10(b)

Film Side, Article 2, T-277.1(b) Heat Treatment, Article 4, Nonmandatory Appendix J,

Hole-Type Penetrameters, Article 2, T-277.1(c) J-10(c)

Materials Other Than Welds, Article 2, T-277.1(e) Reflectors, Article 4, Nonmandatory Appendix J, J-20

Sketches, Article 2, Nonmandatory Appendix C Diameters Greater Than 20 Inches, Article 4,

Source Side, Article 2, T-277.1(a) Nonmandatory Appendix J, J-10(e)

Wire Type Penetrameters, Article 2, T-277.1(d) Diameters 20 Inches and Less, Article 4,

Selection, Article 2, T-276 Nonmandatory Appendix J, J-10(f)

Dissimilar Material Welds, Article 2, T-276.3 Surface Finish, Article 4, Nonmandatory Appendix J,

Material, Article 2, T-276.1 J-10(d)

Size, Article 2, T-276.2 Beam Angle, Article 4, Nonmandatory Appendix I, I-20

Shims Under Hole-Type Penetrameters, Article Beam Spread Measurements, Article 4, T-434.1

2,T-277.3 Bolts and Studs (Inservice Examination), Article 4,

In-Motion Radiography, Article 2, Mandatory Appendix I Nonmandatory Appendix L

Intensifying Screens, Article 2, T-232 Calibration, Article 4, T-460

Location Markers, Article 2, T-275 System, Article 4, T-462

581

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

2004 SECTION V

Computerized Imaging Techniques, Article 4, T-436 and Pipe, Article 5, T-542.8.1.2

Nonmandatory Appendix E Surface Finish, Article 5, T-542.2.1.1(d)

Equipment, Article 4, T-430 Beam Angle, Article 5, T-542.6.1.4 and T-542.8.2.2

Evaluation, Article 4, T-480 Bolts and Studs (Inservice Examination), Article 5,

Examination Coverage, Article 4, T-424.1 T-541.5.3

Glossary of Terms, Article 5, Mandatory Appendix III Bolting Material (Examination), Article 5, T-541.5

Instrument Requirements, Article 4, T-431 Calibration (General), Article 5, T-534

Nozzle Examination, Article 4, Nonmandatory Appendix F Calibration (Welds), Article 5,T-542.2

Nozzle Inner Radius and Inner Corner Region Calibration Check, Article 5, T-542.4.6 to T-542.4.8

Examinations, Article 4, T-442 DAC Correction, Article 5, T-542.5.2

Personnel Requirements, Article 4, T-422 Pipe, Article 5, T-542.8.1

Pumps and Valves (Including Welds), Article 4, T-444 Angle Beam, Article 5, T-542.8.2

Rate of Search Unit Movements, Article 4, T-424.2 Straight Beam, Article 5, T-542.8.2.5

Scanning Sensitivity Level, Article 4, T-424.3 System, Article 5, T-542.4

Records, Article 4, T-490 Angle Beam, Article 5, T-542.4.4

Planar Reflectors Straight Beam, Article 5, T-542.4.5

Data Record Example, Article 4, Sweep Range Correction, Article 5, T-542.5.1

Nonmandatory Appendix D Cladding (Examination), Article 5, T-543

Recording Angle Beam Examination Data, Article 4, Equipment and Supplies, Article 5, T-530

Nonmandatory Appendix H Evaluation, Article 5, T-580

Recording Straight Beam Examination Data, Article Examination Coverage, Article 5, T-523.1

4, Nonmandatory Appendix K

Forgings and Bars (Examination), Article 5, T-541.2

Screen Height Linearity, Article 4, T-461.1 and

Frequency (Instrument), Article 5, T-531

Mandatory Appendix I

Search Unit, Article 5, T-542.6.1.3 and T-542.8.2.1

Straight Beam Calibrations (General Techniques), Article

Glossary of Terms, Article 5, Mandatory Appendix III

4, Nonmandatory Appendix C

Plate (Examination), Article 5, T-541.1

Vessel Examinations, Article 4, T-441

Rate of Search Unit Movement, Article 5, T-523.2

Welds, Article 4, T-471

Recording Sensitivity Level, Article 5, T-523.3

Examination Using Angle Beam Search Units, Article

Reports and Records, Article 5, T-590

4, Nonmandatory Appendix I

Screen Height Linearity, Article 5, T-532 and

--`,,```,,,,````-`-`,,`,,`,`,,`---

Surface Preparation, Article 4, T-471.1.2

Mandatory Appendix I

Vessel Reference Points (Layout), Article 4,

Search Units, Article 5, T-535

Nonmandatory Appendix A

Thickness Measurement, Article 5, T-544

Written Procedure Requirements, Article 4, T-450

Tubular Products (Examination), Article 5, T-541.3

Welds (Examination), Article 5, T-542

ULTRASONIC EXAMINATION METHODS FOR Austenitic and High Nickel Alloy Welds, Article 5,

MATERIALS AND FABRICATION, Article 5 T-542.8.5

Alternate Calibration Block Configuration, Article 5, Ferritic Welds in Ferritic Pipe, Article 5, T-542.8

Nonmandatory Appendix II Evaluation, Article 5, T-542.8.4.3

Amplitude Control Linearity, Article 5, T-533 and Scanning, Article 5, T-542.8.4

Mandatory Appendix A Surface Preparation, Article 5, T-542.8.3.1

Basic Calibration Block (Welds), Article 5, T-542.2.1 Wrought and Cast Ferritic Product Forms (Excluding

Block Selection, Article 5, T-542.2.1(a) Pipe), Article 5, T-542.6

Block Quality, Article 5, T-542.2.1.1(e) Evaluation, Article 5, T-542.7.2.5

Clad, Article 5, T-542.2.1.1(b) Scanning, Article 5, T-542.7.2

Heat Treatment, Article 5, T-542.2.1.1(c) Surface Preparation, Article 5, T-542.7.1

Material, Article 5, T-542.2.1.1 Written Procedure Requirements, Article 5, T-522

Pipe, Article 5, T-542.8.1.1

Reflectors, Article 5, T-542.3

Diameters Greater Than 20 Inches, Article 5, VISUAL EXAMINATION, Article 9

T-542.3.4 Applications, Article 9, T-951

Diameters 20 Inches and Less, Article 5, T-542.3.5 Direct Visual Examination, Article 9, T-952

582

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

INDEX

Evaluation, Article 9, T-980 Records/Reports, Article 9, T-990

Glossary of Terms, Article 9, Mandatory Appendix I Remote Visual Examination, Article 9, T-953

Personnel Requirements, Article 9, T-942 Translucent Visual Examination, Article 9, T-954

Procedure Technique, Article 9, T-950 Written Procedure Requirements, Article 9, T-941

583

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

584

--`,,```,,,,````-`-`,,`,,`,`,,`---

Copyright ASME International

Provided by IHS under license with ASME

No reproduction or networking permitted without license from IHS Not for Resale

Você também pode gostar

- Measurement While Drilling: Signal Analysis, Optimization and DesignNo EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignAinda não há avaliações

- Asme Sec V A-12Documento16 páginasAsme Sec V A-12AL DOMAAinda não há avaliações

- Technical Specification - BPI - Rev-00Documento2 páginasTechnical Specification - BPI - Rev-00Om SaxenaAinda não há avaliações

- KSEA JeppesenDocumento49 páginasKSEA Jeppesenmk45a100% (1)

- GRMP 1Documento19 páginasGRMP 1dhinakaranAinda não há avaliações

- Fdocuments - in KJFK ChartsDocumento32 páginasFdocuments - in KJFK ChartsFercho Anaya MAinda não há avaliações

- Areva P139 Vol.2Documento534 páginasAreva P139 Vol.2Dayann Soares FroesAinda não há avaliações

- HR3000 GEMSpecVer06Documento91 páginasHR3000 GEMSpecVer06Fiona Zhang100% (1)

- GRMP 2Documento18 páginasGRMP 2dhinakaranAinda não há avaliações

- Jeppview For Windows: List of Pages in This Trip KitDocumento76 páginasJeppview For Windows: List of Pages in This Trip KitSamuel AlmecigaAinda não há avaliações

- Media 1930835 D104531 REFDocumento3 páginasMedia 1930835 D104531 REFmicrajacutAinda não há avaliações

- APN-59 2 of 10Documento27 páginasAPN-59 2 of 10sameeramendis100% (1)

- Modern Coach Factory Raebareli आधुनि क रेल नि ब्बा क रेख़ा रे यबारेलDocumento2 páginasModern Coach Factory Raebareli आधुनि क रेल नि ब्बा क रेख़ा रे यबारेलRahul Sarwan RajputAinda não há avaliações

- 0183 Advancements Nmea Oct 1 2010Documento49 páginas0183 Advancements Nmea Oct 1 2010Ferdy Fer DAinda não há avaliações

- Jeppview For Windows: List of Pages in This Trip KitDocumento90 páginasJeppview For Windows: List of Pages in This Trip Kitandika aditamaAinda não há avaliações

- ITP-Line Hardware - Sample Test PDFDocumento3 páginasITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- Astor Accreditation Certificate 2022 (Id 1361648)Documento6 páginasAstor Accreditation Certificate 2022 (Id 1361648)Dalibor84Ainda não há avaliações

- KJFKDocumento29 páginasKJFKSridhar Eswaran100% (1)

- SM15 RS16Documento30 páginasSM15 RS16jackcastelAinda não há avaliações

- Mm-7911 A0 - Obc 12 Transceiver.Documento26 páginasMm-7911 A0 - Obc 12 Transceiver.Ambudhi ShuklaAinda não há avaliações

- L9235F - Car Alternator Voltage RegulatorDocumento11 páginasL9235F - Car Alternator Voltage Regulatorlongtrandang5867Ainda não há avaliações

- Rips Battery SN 001768Documento4 páginasRips Battery SN 001768vinayak ShajiAinda não há avaliações

- TESP11919R3Documento46 páginasTESP11919R3Nabeel ZahidAinda não há avaliações

- 4.kanoria Trafo Setting PDFDocumento5 páginas4.kanoria Trafo Setting PDFA SharmaAinda não há avaliações

- Easergy Micom P139: Feeder Management and Bay ControlDocumento516 páginasEasergy Micom P139: Feeder Management and Bay ControlMarian VinatoruAinda não há avaliações

- How To Test Distance Relay 7SA522Documento55 páginasHow To Test Distance Relay 7SA522Said Wahdan89% (18)

- STep&TouchDocumento17 páginasSTep&TouchjoseAinda não há avaliações

- STC AltitudeDocumento17 páginasSTC Altitudedianavg.9319Ainda não há avaliações

- 01 B01961150-02 Rev.C DME TheoryDocumento48 páginas01 B01961150-02 Rev.C DME TheoryKial YoucefAinda não há avaliações

- Tec37681911 PDFDocumento30 páginasTec37681911 PDFAnkitAinda não há avaliações

- 7SA611 SettingDocumento10 páginas7SA611 SettingcuamiAinda não há avaliações

- RCTPDocumento49 páginasRCTP蔡雨澄Ainda não há avaliações

- Print - Contents: Larkana City / Folder / LRK City - LRK New-II / 7SA522 V4.6Documento8 páginasPrint - Contents: Larkana City / Folder / LRK City - LRK New-II / 7SA522 V4.6cuamiAinda não há avaliações

- Overcurrent ProtectionDocumento61 páginasOvercurrent Protectionalimaghami67% (3)

- EGLLDocumento78 páginasEGLLSebastian RomeroAinda não há avaliações

- Gmdss Radio InsatallationDocumento8 páginasGmdss Radio InsatallationHoàng VũAinda não há avaliações

- 7SJ612Documento6 páginas7SJ612Afsar AliAinda não há avaliações

- Ei 734-031-0029R01 PDFDocumento14 páginasEi 734-031-0029R01 PDFOscar RochaAinda não há avaliações

- KJFK ChartsDocumento32 páginasKJFK ChartsA340_600100% (1)

- EnerVista 469 Setup Active ScreDocumento5 páginasEnerVista 469 Setup Active ScreJosue CardosoAinda não há avaliações

- AT155 ManualDocumento27 páginasAT155 ManualGeorge Cunha LimaAinda não há avaliações

- Power Supply Operation Manual - Rev1.04Documento17 páginasPower Supply Operation Manual - Rev1.04Soy JeanAinda não há avaliações

- EDDT Page 13,14 BerlinDocumento21 páginasEDDT Page 13,14 BerlinUmer CheemaAinda não há avaliações

- Double TMADocumento10 páginasDouble TMASDCGranomAinda não há avaliações

- Radio Site Installation Documentation 1200logement: Project Phase: MOUHOUM (51 Sites)Documento19 páginasRadio Site Installation Documentation 1200logement: Project Phase: MOUHOUM (51 Sites)mehdi berenjiAinda não há avaliações

- RFP 132kV CTsDocumento24 páginasRFP 132kV CTsOm SaxenaAinda não há avaliações

- Red670 Distance Line DifferentialDocumento23 páginasRed670 Distance Line DifferentialRatheesh KumarAinda não há avaliações

- OptimDocumento10 páginasOptimPablo GomsaAinda não há avaliações

- TIA SS7 TT SSN Website Repository Proc TablesDocumento5 páginasTIA SS7 TT SSN Website Repository Proc TablesjjagdishhAinda não há avaliações

- TM 11-809-20 - Radio - Transmitters - T-368 - 1958 PDFDocumento54 páginasTM 11-809-20 - Radio - Transmitters - T-368 - 1958 PDFWurzel1946Ainda não há avaliações

- Site Name Site ID Site Type BSC 104 Tower Type GBT PM Report PM DateDocumento6 páginasSite Name Site ID Site Type BSC 104 Tower Type GBT PM Report PM DateRahul SharmaAinda não há avaliações

- T8 B15 Hijacked Airplaner 2 of 3 FDR - AA 77 - DOT FAA Report of Aircraft Accident and Daily Record of Facility OperationDocumento8 páginasT8 B15 Hijacked Airplaner 2 of 3 FDR - AA 77 - DOT FAA Report of Aircraft Accident and Daily Record of Facility Operation9/11 Document Archive100% (1)

- Mines 1Documento12 páginasMines 1Anand AgrawalAinda não há avaliações

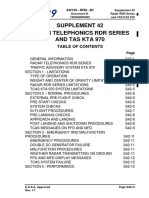

- Supplement 42 Radar Telephonics RDR Series and Tas Kta 970Documento14 páginasSupplement 42 Radar Telephonics RDR Series and Tas Kta 970dugiAinda não há avaliações

- 11DQ06 Schottky DiodeDocumento5 páginas11DQ06 Schottky DiodeMohd Najib Mohd HussainAinda não há avaliações

- Calculo TérmicoDocumento6 páginasCalculo Térmicopasheff shookoffAinda não há avaliações

- Auxiliary Relay - AR111Documento2 páginasAuxiliary Relay - AR111Santhosh Kumar VinayagamAinda não há avaliações

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersNo EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersNota: 5 de 5 estrelas5/5 (2)

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964No EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryAinda não há avaliações

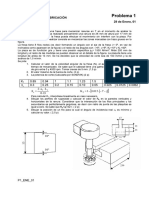

- (Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodDocumento4 páginas(Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodMauricio Esteban Fernandez RamirezAinda não há avaliações

- 7hfqrorjtdgh) Deulfdflyq 3ureohpdv KrudvDocumento5 páginas7hfqrorjtdgh) Deulfdflyq 3ureohpdv KrudvMauricio Esteban Fernandez RamirezAinda não há avaliações

- 3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghDocumento4 páginas3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghMauricio Esteban Fernandez RamirezAinda não há avaliações

- 3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghDocumento3 páginas3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 K Gh6HswlhpeuhghMauricio Esteban Fernandez RamirezAinda não há avaliações

- (Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodDocumento4 páginas(Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodMauricio Esteban Fernandez RamirezAinda não há avaliações

- 3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 KP GH (QhurDocumento3 páginas3ureohpd: 7 (&12/2 Ë$6' $%5,&$&,Ï1 KP GH (QhurMauricio Esteban Fernandez RamirezAinda não há avaliações

- 7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7lhpsrgxudflyqk 6hswlhpeuhghDocumento3 páginas7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7lhpsrgxudflyqk 6hswlhpeuhghMauricio Esteban Fernandez RamirezAinda não há avaliações

- Diurno1trans PDFDocumento10 páginasDiurno1trans PDFMauricio Esteban Fernandez RamirezAinda não há avaliações

- (Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodDocumento4 páginas(Vfxhod 6xshulru GH, Qjhqlhurv, Qjhqldulhq RL 0dlodnr (VnrodMauricio Esteban Fernandez RamirezAinda não há avaliações

- XsxsDocumento6 páginasXsxsMauricio Esteban Fernandez RamirezAinda não há avaliações

- 7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7Lhpsrk GH) HeuhurDocumento4 páginas7hfqrorjtdvgh) Deulfdflyq 3ureohpd: 7Lhpsrk GH) HeuhurMauricio Esteban Fernandez RamirezAinda não há avaliações

- F I / D I D I U UDocumento4 páginasF I / D I D I U UMauricio Esteban Fernandez RamirezAinda não há avaliações

- Cuaderno 2Documento10 páginasCuaderno 2Mauricio Esteban Fernandez RamirezAinda não há avaliações

- Cuaderno 1Documento10 páginasCuaderno 1Mauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Seamless Medium-Carbon Steel Boiler and Superheater TubesDocumento4 páginasSpecification For Seamless Medium-Carbon Steel Boiler and Superheater TubesMauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesDocumento6 páginasSpecification For Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesMauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Carbon Steel Forgings, For General-Purpose PipingDocumento6 páginasSpecification For Carbon Steel Forgings, For General-Purpose PipingMauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes Nps 16 and Over)Documento6 páginasSpecification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes Nps 16 and Over)Mauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-Finished, General Requirements ForDocumento26 páginasSpecification For Steel Bars, Carbon and Alloy, Hot-Wrought and Cold-Finished, General Requirements ForMauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Carbon Steel Forgings For Piping ApplicationsDocumento10 páginasSpecification For Carbon Steel Forgings For Piping ApplicationsMauricio Esteban Fernandez RamirezAinda não há avaliações

- Ayudantía Diseño - 20171011231336Documento3 páginasAyudantía Diseño - 20171011231336Mauricio Esteban Fernandez RamirezAinda não há avaliações

- Specification For Carbon Structural Steel: SA-36 /SA-36MDocumento6 páginasSpecification For Carbon Structural Steel: SA-36 /SA-36MMauricio Esteban Fernandez RamirezAinda não há avaliações

- 1.3.3 1.3.4 1.3.5 Input, Output & Storage Devices Workbook by Inqilab Patel PDFDocumento173 páginas1.3.3 1.3.4 1.3.5 Input, Output & Storage Devices Workbook by Inqilab Patel PDFRayyan MalikAinda não há avaliações

- 103-Article Text-514-1-10-20190329Documento11 páginas103-Article Text-514-1-10-20190329Elok KurniaAinda não há avaliações

- Amberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerDocumento2 páginasAmberjet™ 1500 H: Industrial Grade Strong Acid Cation ExchangerJaime SalazarAinda não há avaliações

- Din 48204Documento3 páginasDin 48204Thanh Dang100% (4)

- SCHEMA - Amsung 214TDocumento76 páginasSCHEMA - Amsung 214TmihaiAinda não há avaliações

- 10 - SHM, Springs, DampingDocumento4 páginas10 - SHM, Springs, DampingBradley NartowtAinda não há avaliações

- English 2 Q3 Week 7 DLLDocumento7 páginasEnglish 2 Q3 Week 7 DLLEste R A BulaonAinda não há avaliações

- Final Project Synopsis 1Documento90 páginasFinal Project Synopsis 1Shyam YadavAinda não há avaliações

- Lecture Notes - Introduction To Big DataDocumento8 páginasLecture Notes - Introduction To Big Datasakshi kureley0% (1)

- Busbusilak - ResearchPlan 3Documento4 páginasBusbusilak - ResearchPlan 3zkcsswddh6Ainda não há avaliações

- PDFDocumento1 páginaPDFJaime Arroyo0% (1)

- Dashrath Nandan JAVA (Unit2) NotesDocumento18 páginasDashrath Nandan JAVA (Unit2) NotesAbhinandan Singh RanaAinda não há avaliações

- 1013CCJ - T3 2019 - Assessment 2 - CompleteDocumento5 páginas1013CCJ - T3 2019 - Assessment 2 - CompleteGeorgie FriedrichsAinda não há avaliações

- TAPPI T 810 Om-06 Bursting Strength of Corrugated and Solid FiberboardDocumento5 páginasTAPPI T 810 Om-06 Bursting Strength of Corrugated and Solid FiberboardNguyenSongHaoAinda não há avaliações

- OMN-TRA-SSR-OETC-Course Workbook 2daysDocumento55 páginasOMN-TRA-SSR-OETC-Course Workbook 2daysMANIKANDAN NARAYANASAMYAinda não há avaliações

- OMM807100043 - 3 (PID Controller Manual)Documento98 páginasOMM807100043 - 3 (PID Controller Manual)cengiz kutukcu100% (3)

- Asugal Albi 4540Documento2 páginasAsugal Albi 4540dyetex100% (1)

- SPWM Vs SVMDocumento11 páginasSPWM Vs SVMpmbalajibtechAinda não há avaliações

- Asian Paints Final v1Documento20 páginasAsian Paints Final v1Mukul MundleAinda não há avaliações

- Introduction To Soft Floor CoveringsDocumento13 páginasIntroduction To Soft Floor CoveringsJothi Vel Murugan83% (6)

- 1207 - RTC-8065 II InglesDocumento224 páginas1207 - RTC-8065 II InglesGUILHERME SANTOSAinda não há avaliações

- Starex Is BTSDocumento24 páginasStarex Is BTSKLAinda não há avaliações

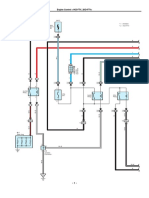

- Schematic Circuits: Section C - ElectricsDocumento1 páginaSchematic Circuits: Section C - ElectricsIonut GrozaAinda não há avaliações

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Documento222 páginasMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesAinda não há avaliações

- Rewriting Snow White As A Powerful WomanDocumento6 páginasRewriting Snow White As A Powerful WomanLaura RodriguezAinda não há avaliações

- A History of The Ecological Sciences, Part 1 - Early Greek OriginsDocumento6 páginasA History of The Ecological Sciences, Part 1 - Early Greek OriginskatzbandAinda não há avaliações

- Revised PARA Element2 Radio LawsDocumento81 páginasRevised PARA Element2 Radio LawsAurora Pelagio Vallejos100% (4)

- Tournament Rules and MechanicsDocumento2 páginasTournament Rules and MechanicsMarkAllenPascualAinda não há avaliações

- CM011l E01 Exp.3 DeJuanDocumento3 páginasCM011l E01 Exp.3 DeJuanJarell De JuanAinda não há avaliações

- Diagrama Hilux 1KD-2KD PDFDocumento11 páginasDiagrama Hilux 1KD-2KD PDFJeni100% (1)