Escolar Documentos

Profissional Documentos

Cultura Documentos

GMAW Manual ME 374 Lab

Enviado por

Ajay KotwalDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

GMAW Manual ME 374 Lab

Enviado por

Ajay KotwalDireitos autorais:

Formatos disponíveis

Metal Inert Gas (MIG) Welding

Instructions:

1. Shoes are mandatory for the laboratory.

2. Report for laboratory to be submitted on the same day.

3. Carry a printout of this manual, writing sheets, 3 graph sheets, 1 transparency sheet and

a CD marker for this laboratory.

Aim:

To study the influence of process parameters on weld geometry and melting efficiency in

GMAW with DCEP polarity.

Apparatus to be used:

1. DC GMAW power source

2. Electrode feeder and electrode wire spool

3. Flexible air-cooled welding torch

4. Inert Gas Cylinder

5. Workpiece (150 x 100 x 10 mm)

Procedure:

1. Produce weld bead-on-plate at 4 different power settings for DCEP polarity.

2. Observe the mode of metal transfer.

3. Record the mean voltage (V) and current (I) for each setting.

4. Cut transverse section on each weld sample.

5. Etch exposed section with nital (5% nitric acid and ethanol) solution; measure bead

width (w), penetration (p) and reinforcement height (h).

6. Calculate approximate cross sectional area, A, of the weld (mm2)

7. Plot p, w, h, A and melt as a function of I for DCEP polarity.

8. Prepare in tabular format the results as:

Welding Velocity (v) (mm/s) =_________________

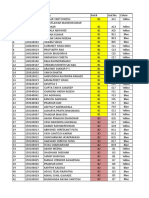

Sr. Volt, V Current, I p w h A R T

No (V) (A) (mm) (mm) (mm) mm

melt (mm) (K)

1

2

3

4

Calculation Procedure:

Ein = Effective energy input

process V I (1)

where, process = 0.60, V= measured voltage (V); I = measured current (A)

Eutilized = Effective energy utilized in melting electrode and base material

m1C1( TMelt

1

TAmb ) m2C2 ( TMelt

2

TAmb ) m1 L1 m2 L2

(2)

( m1 m2 ) C( TMelt TAmb ) ( L )

( m1 m2 ) Av (3)

where

m1 = Rate of melting of mass of base material (kg/s)

m2 = Rate of melting of electrode mass (kg/s)

L1 = L2 = L = Latent heat of melting (~ 2.65 x 105 J/kg for steel)

C1 = C2 = C = Specific heat (~ 622 J/kg.K for steel)

1

TMelt TMelt

2

TMelt = Melting temperature of base material and electrode (~ 1800 K)

TAmb = Ambient temperature (~ 300 K)

= 8000 kg / m3

Next,

Eutilized = melt * Ein (4)

Further, the temperature (T) at any point (x, y, z) at a distance R from the center (xc, yc, zc) of

the weld pool during linear welding can be calculated analytically as,

E 1 vR

T T Amb in exp (5)

2k R 2 k

C

where

k = Thermal conductivity (~ 60 W/m.K for steel)

R= ( x xc ) 2 ( y y c ) 2 ( z z c ) 2

Plots:

1. p, w, h v/s I.

2. A v/s I.

3. melt v/s I.

Você também pode gostar

- Chapter 2 Heat ConductionDocumento26 páginasChapter 2 Heat ConductionFarooq AhmadAinda não há avaliações

- Modul 2. Perpindahan Panas Konduksi Unsteady StateDocumento45 páginasModul 2. Perpindahan Panas Konduksi Unsteady StatefiAinda não há avaliações

- HEat Transfer DPP 46Documento46 páginasHEat Transfer DPP 46Dev PancholiAinda não há avaliações

- S 7 - Heat Transfer LabDocumento30 páginasS 7 - Heat Transfer LabKiran Madhavan100% (2)

- Heat Transfer Lab ManualDocumento52 páginasHeat Transfer Lab ManualDivyamAinda não há avaliações

- Problem Solutions in Heat TransferDocumento31 páginasProblem Solutions in Heat TransferAngelica Joyce BenitoAinda não há avaliações

- Department of Chemical & Biomolecular Engineering The National University of SingaporeDocumento6 páginasDepartment of Chemical & Biomolecular Engineering The National University of SingaporeHaha WoNgAinda não há avaliações

- Composite Wall Apparatus (Bihar Communications)Documento12 páginasComposite Wall Apparatus (Bihar Communications)infoAinda não há avaliações

- Modelling, Simulation and Identification of Heat Loss Mechanisms For Parabolic Trough Receivers Installed in Concentrated Solar Power PlantsDocumento6 páginasModelling, Simulation and Identification of Heat Loss Mechanisms For Parabolic Trough Receivers Installed in Concentrated Solar Power PlantsAriefful CiezboyAinda não há avaliações

- Electric Discharge Machining (EDM)Documento52 páginasElectric Discharge Machining (EDM)MaheshAinda não há avaliações

- Ieee80 Step and Touch CalculationDocumento24 páginasIeee80 Step and Touch Calculationwaleed.liaquat.kkAinda não há avaliações

- Heat Transfer EquationDocumento2 páginasHeat Transfer EquationNatol MidegsaAinda não há avaliações

- Problem SheetDocumento2 páginasProblem SheetUsman FarooqAinda não há avaliações

- February 14 Homework Solutions: Mechanical Engineering 375 Heat TransferDocumento5 páginasFebruary 14 Homework Solutions: Mechanical Engineering 375 Heat TransferYuvaperiyasamy MayilsamyAinda não há avaliações

- Multi-Layer Transient Heat Conduction Using Transition Time ScalesDocumento11 páginasMulti-Layer Transient Heat Conduction Using Transition Time ScalesGabriel SaavedraAinda não há avaliações

- Thermal Conductvity Matal RodDocumento7 páginasThermal Conductvity Matal RodTheOPGarriXAinda não há avaliações

- Forced Convection Heat TransferDocumento6 páginasForced Convection Heat TransferHani BanatAinda não há avaliações

- Iec 60853 PDFDocumento5 páginasIec 60853 PDFprathap394Ainda não há avaliações

- Heat TransferDocumento9 páginasHeat Transferdeme2411Ainda não há avaliações

- DENGS Volume 8 Issue 1 Pages 64-82Documento19 páginasDENGS Volume 8 Issue 1 Pages 64-82Arjun KoduriAinda não há avaliações

- Answer (Three) Questions OnlyDocumento7 páginasAnswer (Three) Questions Onlyنهاد نهادAinda não há avaliações

- Thermal Stability and Anti-Corrosion Analysis of Alloy Coatings On Overhead Ground WiresDocumento7 páginasThermal Stability and Anti-Corrosion Analysis of Alloy Coatings On Overhead Ground WiresKedar BhaveAinda não há avaliações

- HMT DAVV PracticalDocumento21 páginasHMT DAVV PracticalNarendraAinda não há avaliações

- Persamaan Konduksi & Kasus - Bag 1Documento25 páginasPersamaan Konduksi & Kasus - Bag 1ArdanAinda não há avaliações

- Btech Me 5 Sem Heat and Mass Transfer Eme504 2020Documento2 páginasBtech Me 5 Sem Heat and Mass Transfer Eme504 2020SuryaAinda não há avaliações

- Formulae For Injection MoldingDocumento13 páginasFormulae For Injection MoldingFatih Mehmet CetinAinda não há avaliações

- Convection Concentric Annulus Vertical Cylinders Filling Porous MediaDocumento17 páginasConvection Concentric Annulus Vertical Cylinders Filling Porous MediakarthikeyanAinda não há avaliações

- Heat Transfer Quiz (1) MB - SolveDocumento5 páginasHeat Transfer Quiz (1) MB - Solveعبدالله حامد الرفاعيAinda não há avaliações

- Cryogenic EDM, Abhinav SharmaDocumento7 páginasCryogenic EDM, Abhinav Sharmaabhinav sharmaAinda não há avaliações

- Determination OF THE Band-Gap OF THE Semiconductor Using The Four Probe MethodDocumento3 páginasDetermination OF THE Band-Gap OF THE Semiconductor Using The Four Probe MethodJø Ñń ÝAinda não há avaliações

- Fe Heat TransferDocumento6 páginasFe Heat Transfervzimak2355Ainda não há avaliações

- Temperature Distributions in Solids and in Laminar FlowDocumento4 páginasTemperature Distributions in Solids and in Laminar FlowSambasiva Rao KaturiAinda não há avaliações

- Laser Beam MachiningDocumento25 páginasLaser Beam Machiningdataentry1442Ainda não há avaliações

- JPCS M5Or1B-06 V4-FinalDocumento9 páginasJPCS M5Or1B-06 V4-FinalMohammed FouaidyAinda não há avaliações

- Thermoelectric Power Generation: Converting Low-Grade Heat Into ElectricityDocumento3 páginasThermoelectric Power Generation: Converting Low-Grade Heat Into ElectricityBurak PalaAinda não há avaliações

- T (z, t) = T T is amplitude of the oscillating temperature, z the depth below the surface, λ is theDocumento7 páginasT (z, t) = T T is amplitude of the oscillating temperature, z the depth below the surface, λ is theyansyahprasetyoAinda não há avaliações

- Patidar PaperDocumento6 páginasPatidar Papertiffany.rusu85Ainda não há avaliações

- New Method For Calculating The Heating of ConductorDocumento15 páginasNew Method For Calculating The Heating of ConductorBrent M. GannonAinda não há avaliações

- Uch402 PDFDocumento2 páginasUch402 PDFAdityaAinda não há avaliações

- Assignment 1Documento5 páginasAssignment 1Miriam NagyAinda não há avaliações

- Part - A (Physics) : J J J JDocumento5 páginasPart - A (Physics) : J J J Jsusheel_uiitshimlaAinda não há avaliações

- 3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Documento3 páginas3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Carlos CastilloAinda não há avaliações

- 2015 Heat TransferDocumento4 páginas2015 Heat TransferJitendra Kumar BiswasAinda não há avaliações

- Heat Transfer Lab ManualDocumento44 páginasHeat Transfer Lab ManualNaveen luckyAinda não há avaliações

- Activation Energy of Thermistor KKDocumento5 páginasActivation Energy of Thermistor KKKush SharmaAinda não há avaliações

- P Ch-11 Thermal+Properties+of+Matter PDFDocumento5 páginasP Ch-11 Thermal+Properties+of+Matter PDFlaksh jainAinda não há avaliações

- Calculo Radiación TérmicaDocumento9 páginasCalculo Radiación TérmicamarcmanichAinda não há avaliações

- Lab Sheet Trif SuspensionDocumento4 páginasLab Sheet Trif SuspensionHUMAID SIDDIQUIAinda não há avaliações

- sm3 023Documento2 páginassm3 023Sadie HnatowAinda não há avaliações

- HW 01 SolutionDocumento6 páginasHW 01 SolutionPotatoes123Ainda não há avaliações

- NEET 2016 Question Paper Phase 2 Code DD SS ZZDocumento19 páginasNEET 2016 Question Paper Phase 2 Code DD SS ZZShobhit JainAinda não há avaliações

- TALAT Lecture 2503: Calculation Methods For Fire DesignDocumento31 páginasTALAT Lecture 2503: Calculation Methods For Fire DesignCORE MaterialsAinda não há avaliações

- Inductive Heating of A Copper Cylinder: Created in COMSOL Multiphysics 5.4Documento10 páginasInductive Heating of A Copper Cylinder: Created in COMSOL Multiphysics 5.4Jaime FalaganAinda não há avaliações

- Chapter 3 - TutorialDocumento4 páginasChapter 3 - TutorialDavidAinda não há avaliações

- PRGRN603: Module 5: Stationary CollectorsDocumento18 páginasPRGRN603: Module 5: Stationary CollectorsRony Bou cheblAinda não há avaliações

- Solution of Transient 2D Heat Conduction Problem Using Freefem++Documento4 páginasSolution of Transient 2D Heat Conduction Problem Using Freefem++Chicca PantanoAinda não há avaliações

- EAT 339 Jan 2023 TCT QuestionsDocumento10 páginasEAT 339 Jan 2023 TCT QuestionsOji Ifeanyi0% (1)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1No EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Ainda não há avaliações

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3No EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Nota: 3 de 5 estrelas3/5 (2)

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresNo EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresNota: 4 de 5 estrelas4/5 (1)

- Fluid MechanicsDocumento2 páginasFluid MechanicsAjay KotwalAinda não há avaliações

- Course Outline 2018Documento1 páginaCourse Outline 2018Ajay KotwalAinda não há avaliações

- HW1 TorsionThinSectionsDocumento1 páginaHW1 TorsionThinSectionsAjay KotwalAinda não há avaliações

- Tutorial Batch Seat NosDocumento3 páginasTutorial Batch Seat NosAjay KotwalAinda não há avaliações

- Tail Design Team RAKSHAK, IIT Bombay: Prashant Kumar Jaspreet Singh Sai ThejaDocumento4 páginasTail Design Team RAKSHAK, IIT Bombay: Prashant Kumar Jaspreet Singh Sai ThejaAjay KotwalAinda não há avaliações

- Tut 09 2016 PDFDocumento1 páginaTut 09 2016 PDFAjay KotwalAinda não há avaliações

- RMRS Construction Equipment MODU FOP EngDocumento416 páginasRMRS Construction Equipment MODU FOP EngDesedentAinda não há avaliações

- Shams Ma'An Solar PV Power Plant Project (50MW) : 14 July 2014 Rev - 0Documento13 páginasShams Ma'An Solar PV Power Plant Project (50MW) : 14 July 2014 Rev - 0MohamedAinda não há avaliações

- Konan Gbamélé Elisée: Konan - Elisee@univ-Na - CiDocumento12 páginasKonan Gbamélé Elisée: Konan - Elisee@univ-Na - CiGbamélé Elisée KonanAinda não há avaliações

- Bakhtar Bastan Solar Wind CompanyDocumento3 páginasBakhtar Bastan Solar Wind Companygraceenggint8799Ainda não há avaliações

- Renewable Energy-DigitalDocumento33 páginasRenewable Energy-DigitalMubeen NavazAinda não há avaliações

- Hydropower 97 - ProcedingsDocumento173 páginasHydropower 97 - ProcedingsEdward Hcr100% (3)

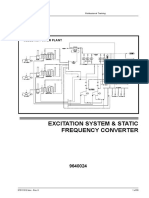

- Excitation Sys & SFCDocumento55 páginasExcitation Sys & SFCABVSAI100% (1)

- Neutral GroundingDocumento9 páginasNeutral Groundingmspd2003Ainda não há avaliações

- AFE Active Front EndDocumento28 páginasAFE Active Front Endshaikhsajid242Ainda não há avaliações

- Energy Efficiency in Household Appliances and LightingDocumento864 páginasEnergy Efficiency in Household Appliances and LightingMemoonaAinda não há avaliações

- EX Solar ModuleDocumento2 páginasEX Solar ModuleBuwana luhurAinda não há avaliações

- Dual-Fuel ARTEMIS CaseStud eDocumento17 páginasDual-Fuel ARTEMIS CaseStud etorjaniceAinda não há avaliações

- EEE259 Electrical Drives and Controls QBDocumento10 páginasEEE259 Electrical Drives and Controls QBkannanchammyAinda não há avaliações

- CDM Project On Briquettes ManufacturingDocumento2 páginasCDM Project On Briquettes ManufacturingShanky JainAinda não há avaliações

- h8103 M PDFDocumento28 páginash8103 M PDFMiltonAinda não há avaliações

- SEAOC PV2-2012 Wind Design For Low-Profile Solar PV Arrays On Flat RoofsDocumento38 páginasSEAOC PV2-2012 Wind Design For Low-Profile Solar PV Arrays On Flat RoofsJennifer Alfsen Castillo100% (1)

- Thermoelectric Generator 1Documento14 páginasThermoelectric Generator 119wh1a0437 Gurrala PriyankaAinda não há avaliações

- Thermo 1 - Mid TermDocumento4 páginasThermo 1 - Mid TermMohammad Faiz AkbarAinda não há avaliações

- Tidal Energy: by Lori DeleonDocumento9 páginasTidal Energy: by Lori DeleonAbigail AmorAinda não há avaliações

- Rosa de Viento - CochasDocumento1 páginaRosa de Viento - CochasLore Muñoz MaraviAinda não há avaliações

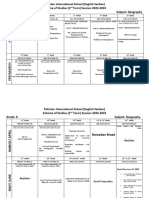

- Geography Grade 8 2nd Term SOS - 2022-23Documento2 páginasGeography Grade 8 2nd Term SOS - 2022-23mohammad abdurehmanAinda não há avaliações

- KearneyDocumento20 páginasKearneyoscar vascoAinda não há avaliações

- Ball and Tube Mill OpnDocumento5 páginasBall and Tube Mill OpnDevendra PrasadAinda não há avaliações

- A Common MetricsDocumento12 páginasA Common MetricsDorina PllumbiAinda não há avaliações

- Exec SummDocumento19 páginasExec Summroland jeminoAinda não há avaliações

- Main Catalogue 9 Transformerer Power SupplyDocumento12 páginasMain Catalogue 9 Transformerer Power SupplyRadu Fabian FishyAinda não há avaliações

- L&T Construction Commissions India's First 765kV Gas Insulated SubstationDocumento1 páginaL&T Construction Commissions India's First 765kV Gas Insulated SubstationChandru SAinda não há avaliações

- Design Calculation Sheet - Cable Trench RecalcsDocumento4 páginasDesign Calculation Sheet - Cable Trench RecalcsAmol ChavanAinda não há avaliações

- Study of Various Parameters On Design of Compressor ShelterDocumento4 páginasStudy of Various Parameters On Design of Compressor Shelterpiv0ter_betterAinda não há avaliações

- Combined Heat and Power Design GuideDocumento370 páginasCombined Heat and Power Design GuideTrong Hieu Nguyen100% (3)