Escolar Documentos

Profissional Documentos

Cultura Documentos

12P1892F

Enviado por

Saad BroDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

12P1892F

Enviado por

Saad BroDireitos autorais:

Formatos disponíveis

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA REV F

Class I Div. 2 with Class I, II, III Div. I Page 1 of 8

Field Circuits Installation Instructions

Drawn By: PAL Date: 27 Apr 99

Checked By: WCM Date: 15 May 99

Approved By: PAL Date: 15 May 99

Revised By: AFF Date: 10 Oct 11

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 2 of 8

Field Circuits Installation Instructions

1. SCOPE

This document provides guidelines for the installation of DeltaVTM Scalable Process System with Intrinsically Safe

Field Circuits in a Class1 Division 2 Group A, B, C, D Hazardous Location. Installation shall be in accordance with

Article 500 of the National Electrical Code 4, ANSI/NFPA-70.

2. APPLICATION

System components intended for use in a Class1 Division 2, Groups A,B,C,D have been evaluated to Factory

Mutual Class Number 3611. Approved components are labeled per the Factory Mutual requirements.

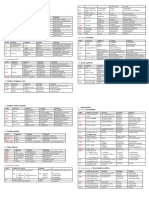

See Note 7 See Note 8

See Note 6 18 - 36 V dc

Control Network

Um1 Um2 I/O Modules

IS-Series Additional I/O IS Power

See Note 13

(A) Modules Supply

POWER I/O KJ4110-EB1 (See Notes

SUPPLY

CONTROLLER

MODULES See Notes 4, 5

KJ4110X1-EA1

3,9,10,11,12) (F)

IS Power Supply

See Notes 4 (D) (C) (E)

IS Term Block

(See Notes

3,9,10,11,12)

(B) (C)

Intrinsically

Non-Incendive or

Safe Field

Non-Arcing

Circuits

Field Circuits Only

See Notes 9

Installation - Ordinery location or where applicable, Installation - Class 1, Division 2,

Class 1, Division 2, field circuits - class 1, Division 2 Field Circuits - Classes I, II, III, Division 1

(See Notes 1 & 5) (See Notes 1, 5 & 14)

Figure 1.

NOTES:

1. The components shown in Figure 1, defines the interface between, equipment which may comprise of

Unspecified Ordinary Location or Class 1, Division 2 Groups A, B, C, D hazardous area location components

and components equipped with intrinsically safe field circuits. This system will include a single Localbus

isolator, I.S. I/O Cards and all other necessary apparatus such as power supplies, carriers, carrier extenders, etc..

2. The details of this system involve:

(A) 8-way I/O Carriers, and up to eight I/O Cards per carrier. Where applicable, these products are approved

for installation in, and connection to, circuits in Class 1, Division 2 Hazardous Locations, refer to FRS

drawing (12P1293).

(B) A Localbus Isolator type KJ4110X1-EB1 (with its associated carrier KJ4101X1-BB1) which provide an

isolation interface between (A) above and all other parts of the system. Non-I.S. components are located to

the left of the Localbus Isolator and I.S. components are located to the right of the Localbus Isolator.

(C) A DC/DC Power Supply Type (KJ4110X1-EA1) which is a source of supply for

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 3 of 8

Field Circuits Installation Instructions

i) the Localbus Isolator JK4110X1-EB1, and

ii) I/O Cards with I.S. Field circuits:

Note: The system may include up to eleven System Power supplies, including one for redundancy

depending on number and type of I/O Cards, individual field circuit loading and ambient temperature.

(D) Up to eight I/O Carriers in the DeltaV IS-I/O system.

(E) If required, Carrier Extenders KJ4110X1-CA1 and KJ4110X1-CB1, IS extenders, Right Hand and Left

hand respectively, together with associated cables:

(F) At present the following extension cables exist as pairs ( a carrier cable and a power cable):

Description: Carrier Cable (Note 15) Power Cable (Note 16)

Cable assembly 0.35 meters KJ4110X1- DA1 KJ4110X1-DB1

Cable assembly 0.85 meters KJ4110X1- DC1 KJ4110X1-DD1

Cable assembly 1.20 meters KJ4110X1- DE1 KJ4110X1-DF1

Cable assembly 2.0 meters KJ4110X1- DG1 KJ4110X1-DH1

3. Each I/O Card interfaces the field through a Terminal Block Assembly. The IS-I/O Cards are designed to allow

removal and insertion of the cards on the carriers without the need to remove power from the Localbus.

CAUTION: Carriers, Extenders, Extension Cables must NOT be unplugged unless either

a) the System has been de-energized, or

b) the area is known to be non-hazardous.

4. The Controller communicates with the I/O cards by means of the Localbus, which runs through all the carriers,

connected to it.

5. The System may comprise up to 64 I/O cards and has a maximum length of 6.8m (including carriers extenders and

extension cables). The Localbus Isolator KJ4110X1-EB1 is transparent and the number of I/O card left and right

is dependent entirely on the requirements of the system.

6. The voltage source to this power supply must not generate or contain in both normal or abnormal operation, a

source of potential in excess of 250 Vrms or DC.

7. The Control Network connected to the DeltaV Controller must not be connected to a supply, which generates or

contains, under normal or abnormal conditions, a source of potential in excess of 250 Vrms or DC.

8. The IS-card Power Supply, KJ4110X1-EA1, must not be connected to a source of power, which contains or

generates, under normal or abnormal conditions, a source of potential in excess of 250 Vrms or DC.

9. The field outputs of all DeltaV IS-System Cards having a label as such are intrinsically safe, but may have

different entity parameter and different number of channels. Each I/O card interfaces with the field though a

Terminal Block Assembly. All IS-I/O cards in this system may be removed and inserted onto the carrier while

the carrier remains energized. Only one I/O card may be removed or inserted at a time.

10. Field Terminals may be left in place during insertion and removal. The possibility of inserting an I/O Card with

incorrect entity parameters or different channel output connections into a Field Terminal is prevented by means

of a rotary Keying system.

11. Refer to Figure 2, for details of the I/O Card and Termination Block rotary Keys. The Keys fitted to I.O Cards

are factory set (Ultrasonic welding), while the Keys fitted to the Termination Block are adjustable and are set to

match those of a chosen I/O Card at the time of installation.

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 4 of 8

Field Circuits Installation Instructions

12. Table 1, shows the detail of the I/O Card in the DeltaV Process System. Note, that there are no keying

arrangements given to other components such as power supplies and Localbus isolators but their individual

unique connector arrangement ensure that they can only be installed on their respective carriers.

13. A Card Blanking Cover KJ4001X1-FA1 should be fitted to any permanently unoccupied location on an I/O

Card Carrier. (Permanently unoccupied implies no Field Terminal Assembly and no I/O card are intended for

the particular location).

14. All apparatus forming part of a single system must be housed within the same enclosure. Enclosures must meet

the requirements of ANSI/ISA S82.01 and S82.03.

ASSIGNMENT OF I/O KEY POSITIONS

Card No. Description of Letter Number

Field Terminals Key Position Key Position

KJ3101X1-BA1 25V, 110mA, 0.69W B 5

KJ3101X1-BB1 10.5V, 14mA, 0.04W B 1

KJ3102X1-BA1 28V, 93mA, 0.65W A 1

KJ3102X1-BB1 23.3V, 88mA, 0.65W A 4

KJ3102X1-BB2 24.6V, 93mA, 0.57W A 4

KJ3102X1-BE1 24.6V, 93mA, 0.57W A 4

Table 1.

A-F 1-6

A-F 1-6

A 1

F B 6 2

Intrinsically Safe E C 5 3

D 4 Module Key

Field Teminal Block

Figure 2.

15. This cable is comprised of a 19-twisted-pair multicore cable covered by a layer of heatshink sleeving. The

combined thickness of insulation provided by the multicore and heatshrink sleeve is greater than or equal to

1.0mm, each component providing a minimum of 0.33mm. The heatshrink sleeve is applied over the whole

length of the multicore, to within 10mm of the connector at each end. These cables do not need to carry FM

approval markings.

16. This cable is comprised of up to six separately insulated cores, covered by a layer of heatshrink sleeving. The

combined thickness of insulation of any core and the heatshrink sleeve is greater than or equal to 1.0mm, each

component providing a minimum of 0.33mm. The heatshrink sleeve is applied over the whole length of the

insulated cores, to within 20mm of the connector at each end. These cables do not need to carry FM approval

markings.

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 5 of 8

Field Circuits Installation Instructions

I.S. I/O Card assemblies:

Hazardous Location Class I, Division 2

Class I, Division 1, Groups A,B,C,D

Groups A,B,C,D

Class II, Division 1,

Groups E,F,G I/O Module

Class III See Note 5

See Note 1

Intrinsically Safe Field Circuits (x4, x8, x16)

See Note 4

See Notes 4, 6, and 7

1 3 5 7 9 11 13 15

See Notes 2 & 3

2 3 6 8 10 12 14 16

Figure 3.

Notes:

1. The IS I/O cards may only be mounted on an IS-I/O card carrier KJ4101X1-BA1.

2. The IS I/O cards may be used in conjunction with the KJ4110X1-BA1, -BB1, or -BC1 Terminal Block

Assemblies. Refer to Table 2 for permissible I/O card and Terminal Block combinations.

3. Each of the field channels of the IS I/O cards use one pair of terminals of the above Terminal Block

Assemblies. Please refer to Table 2, for terminal entity parameters.

4. Each channel of the IS-I/O cards may be connected to apparatus which does not generate or store more than

1.2V, 0.1A, 25mW or 40 J, such as switches, thermocouples, LEDs and RTD devices, provided cable

parameters meet the following criteria:

A. Ca Capacitance of cable

B. La Inductance of cable

Alternatively, each channel of the IS-I/O card, may be connected to FM Approved intrinsically safe apparatus

suitable for use in Division 1 hazardous location, in accordance with the following criteria:

Voc Apparatus Vmax

Isc Apparatus Imax

Ca Ci + Capacitance of cable

La Li + Inductance of cable

5. The IS-I/O cards may be inserted onto, or removed from the IS-carrier while the system remains energized. It is

preferable removal and insertion is done when the area is known to be non-hazardous. Only one I/O card may

be removed or inserted at a time.

6. Each of the field devices, and associated wiring, connected to the IS-I/O cards, shall satisfy the 500 VDC

insulation test to field devices connected to any other DeltaV IS-I/O card, forming part of the same installation.

7. Field wiring devices must be installed in accordance with the requirements of ANSI/ISA RP12.6

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 6 of 8

Field Circuits Installation Instructions

8. The AO Card KJ3102X1-BB1 was superceded by AO Card KJ3102X1-BB2 in 2003, but details are included

for information.

Ch. Terminals Entry parameters, Groups A, B Groups C, E Groups D,F,G

Permissible Field No. each channel

Terminal Blocks

AI card, KJ4110X1-BA1 1 1&2 Voc 28Vdc Ca 0.14F Ca 0.43F Ca 1.14F

KJ3102X1-BA1: KJ4110X1-BB1 2 3 &4 Isc 93mA La 4.38mH La 17.2mH La 34.2mH

3 5&6 Po 0.65W

4 7&8

5 9 &10

6 11 & 12

7 13 & 14

8 15 & 16

AO card, KJ4110X1-BA1 1 1&2 Voc 23.8Vdc Ca 0.21F Ca 0.64F Ca 1.70F

KJ3102X1-BB1: KJ4110X1-BB1 2 3 &4 Isc 90mA La 4.67mH La 18.3mH La 36.5mH

3 5&6 Po 0.54W

4 7&8

5 9 &10

6 11 & 12

7 13 & 14

8 15 & 16

AO card, KJ4110X1-BA1 1 1&2 Voc 24.6Vdc Ca 0.116F Ca 0.87F Ca 3.12F

KJ3102X1-BB2: KJ4110X1-BB1 2 3 &4 Isc 93mA La 4.3mH La 17.7mH La 36.02mH

3 5&6 Po 0.57W

4 7&8

5 9 &10

6 11 & 12

7 13 & 14

8 15 & 16

AO card, w/HART KJ4110X1-BA1 1 1&2 Voc 24.6Vdc Ca 0.116F Ca 0.87F Ca 3.12F

KJ3102X1-BE1 KJ4110X1-BB1 2 3 &4 Isc 93mA La 4.3mH La 17.7mH La 36.02mH

3 5&6 Po 0.57W

4 7&8

5 9 &10

6 11 & 12

7 13 & 14

8 15 & 16

DO card, KJ4110X1-BA1 1 1&3 Voc 25Vdc Ca 0.19F Ca 0.56F Ca 1.51F

KJ3101X1-BA1: KJ4110X1-BB1 2 5&7 Isc 110mA La 3.15mH La 12.5mH La 24.5mH

3 9 & 11 Po 0.69W

4 13 & 15

DI card, KJ4110X1-BC1 1 1&2 Voc 10.5Vdc Ca 2.67F Ca 8.00F Ca 21.3F

KJ3101X1-BB1: 2 3 &4 Isc 14mA La 176mH La 633mH La 1000mH

3 5&6 Po 0.04W

4 7&8

5 9 &10

6 11 & 12

7 13 & 14

8 15 & 16

9 17 & 18

10 19 & 20

11 21 & 22

12 23 & 24

13 25 & 26

14 27 & 28

15 29 & 30

16 31 &32

I.S. I/O Card Parameters, Table 2.

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 7 of 8

Field Circuits Installation Instructions

Model KJ4110X1-EB1, Localbus Isolator:

KJ4101-BB1

See Note 4

See Note 1 KJ4110X1-EB1

See Note 3 See Note 2

CON 4

CON 1

Class I, Division 2 Hazardous Location

Figure 4.

Notes:

1. The Localbus Isolator KJ4110X1-EB1, may only be used in conjunction with the Localbus Isolator Carrier

KJ4101X1-BB1.

2. (CON 1) of the Localbus Isolator Carrier may only be connected to the following DeltaV Series products:

Product Description

KJ4101X1-BA1 IS, 8-Wide carrier

KJ4101X1-CA1 IS extender right-hand

KJ4101X1-BC1 IS System Power Supply carrier

Connection to any of these items in an energized system ensures that the value of Um2 (18VDC max) of the

Localbus Isolator, KJ4110X1-EB1 is not exceeded.

3. (CON 4) of the Localbus Isolator Carrier may only be connected to the following DeltaV series products:

Product Description

KJ4001X1-BA2 2-Wide Carrier

KJ4001X1-BB1 8-Wide Carrier with out Shield bar

KJ4001X1-BE1 8-Wide Carrier with Shield bar

KJ4001X1-HA1 Left hand connector of Local bus extender

Any supply system used to energize the above must not generate or store potentials in excess of 250 Vrms or

DC, in both normal and abnormal condition of operation.

4. The Localbus Isolator may be inserted onto, or removed from the Localbus carrier while the system remains

energized. It is preferable if removal and insertion is done when the area is known to be non-hazardous.

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

FRSI DeltaV TM Scalable Process System 12P1892

Austin, TX USA Class I Div. 2 with Class I, II, III Div. I REV F

Page 8 of 8

Field Circuits Installation Instructions

Model KJ4110X1-EA1, IS System Power supply:

18-36 VDC

Input Supply

connector

See Note 3

KJ4101X1-BC1

See Note 1

KJ4110X1-EA1

See Note 4

See Note 2 See Note 2

CON 3

CON 1

Class I, Division 2 Hazardous Location

Figure 5.

Notes:

1. The IS System Power Supply, KJ4110X1-EA1, may only be used in conjunction with the IS System Power

Supply Carrier, KJ4101X1-BC1.

2. CON 1 and CON 3 of the KJ4110X1-EA1 may only be connected to the following DeltaV Series products:

Product Description Permissible Connector(s)

KJ4101X1-BA1 IS, 8-Wide Carrier Con1 or Con3

KJ4110X1-CA1 IS, extender, Right-hand Con1 only

KJ4110X1-CB1 IS, extender, Left-hand Con3 only

KJ4101X1-BB1 Localbus Isolator Carrier Con3 only

3. The input supplies to the KJ4110X1-EA1 in the range of 18-36VDC. This supply must not contain or generate

potentials in excess of 250 Vrms or DC in both normal and abnormal conditions of operation.

4. The IS System Power Supply may be removed from or inserted onto the IS System Power Supply carrier while

the system to which it is connected remains energized, but only with the following provisions AND in the order

given:

A) the input supply must be de-energized, and

B) the input supply connector must be removed from the IS System Power Supply

It is preferable if removal and insertion is done when the area is known to be non-hazardous.

1999-2011 Fisher-Rosemount Systems, Inc. All Rights reserved. Filename: 12P1892F.doc

10/24/2011

Você também pode gostar

- 12P1990EDocumento6 páginas12P1990ESaad BroAinda não há avaliações

- Vinafix - VN Qlm00 La-7841p r05 MB ST 02 Dell Xps14Documento65 páginasVinafix - VN Qlm00 La-7841p r05 MB ST 02 Dell Xps14Jonatas Coronado StambouliAinda não há avaliações

- 12P1990EDocumento6 páginas12P1990ESaad BroAinda não há avaliações

- S-Series Hardware InstallDocumento76 páginasS-Series Hardware InstallSaad BroAinda não há avaliações

- A Guide To The Preparation of Civil Engineering Drawing PDFDocumento186 páginasA Guide To The Preparation of Civil Engineering Drawing PDFEraj100% (3)

- Data Structures and AlgorithmsDocumento45 páginasData Structures and AlgorithmsKeith Tanaka MagakaAinda não há avaliações

- 12P1293AHDocumento19 páginas12P1293AHSaad BroAinda não há avaliações

- Technical Specifications AdaniDocumento30 páginasTechnical Specifications Adanishahnawaz1709Ainda não há avaliações

- KDL-32R413 Chassis Itc3Documento21 páginasKDL-32R413 Chassis Itc3nnovik1Ainda não há avaliações

- D D D D D: SN74LVC1G86 Single 2-Input Exclusive-Or GateDocumento6 páginasD D D D D: SN74LVC1G86 Single 2-Input Exclusive-Or GateJose M PeresAinda não há avaliações

- 12P6123EDocumento3 páginas12P6123EMalik HamzaAinda não há avaliações

- Mil S 19500J PDFDocumento170 páginasMil S 19500J PDFYoon Seung WookAinda não há avaliações

- CSEZEN-F100x-V2 CatalogDocumento48 páginasCSEZEN-F100x-V2 CatalogPrasenjit MaityAinda não há avaliações

- BombardierDocumento46 páginasBombardierАльмир Зиннатуллин100% (1)

- 0450 - Volume V.4Documento47 páginas0450 - Volume V.4Billy MakoyAinda não há avaliações

- b522f Compal LA-8581P PDFDocumento60 páginasb522f Compal LA-8581P PDFluix101Ainda não há avaliações

- M09 Avia / Maybach DIS: Compal ConfidentialDocumento63 páginasM09 Avia / Maybach DIS: Compal ConfidentialMauro CamiloAinda não há avaliações

- LA-5811P Dell AlienwareDocumento59 páginasLA-5811P Dell AlienwaregkyankielAinda não há avaliações

- TB 1-1500-346-20Documento17 páginasTB 1-1500-346-20SiviAinda não há avaliações

- Functional Testing of Iec 61850 Based SubstationDocumento6 páginasFunctional Testing of Iec 61850 Based Substationasi midobarAinda não há avaliações

- ADM3065EDocumento18 páginasADM3065Emiri10861Ainda não há avaliações

- TLP293 4 Datasheet en 20190520-1916320Documento13 páginasTLP293 4 Datasheet en 20190520-1916320moacirmenezes51Ainda não há avaliações

- 1515-WME-ELE-SPE-260512 - Electrical Materials and MethodsDocumento12 páginas1515-WME-ELE-SPE-260512 - Electrical Materials and MethodsdendincAinda não há avaliações

- Micom P141, P142, P143, P144, P145: Technical Data SheetDocumento80 páginasMicom P141, P142, P143, P144, P145: Technical Data SheetEverton Klinger Sousa Silva100% (1)

- v2500 Ts PDFDocumento18 páginasv2500 Ts PDFGioVanni LorizioAinda não há avaliações

- Power Supply EmersonDocumento20 páginasPower Supply Emersonindra gunawanAinda não há avaliações

- Hammond Service Manual A A-100 BA BC BCV BV B2 B3 C CV C2 C2 TextDocumento220 páginasHammond Service Manual A A-100 BA BC BCV BV B2 B3 C CV C2 C2 Textbubbapebi100% (3)

- Ic DatasheetDocumento19 páginasIc DatasheetAmin UdinAinda não há avaliações

- Scds 137Documento22 páginasScds 137Katvia LiannaAinda não há avaliações

- Bionics IFM-500 - Test ReportDocumento74 páginasBionics IFM-500 - Test ReportRomário CaribéAinda não há avaliações

- IND 5000 Inst. ManualDocumento10 páginasIND 5000 Inst. ManualmglemAinda não há avaliações

- mPRO-100 Motor Protection Relay GuideDocumento18 páginasmPRO-100 Motor Protection Relay GuideAmol BhaleraoAinda não há avaliações

- XF105 System and Component Information DtcoDocumento28 páginasXF105 System and Component Information DtcoAnd Dron100% (1)

- Generic EICRDocumento6 páginasGeneric EICRKuljinder VirdiAinda não há avaliações

- CR1700r2 (Rel-15) R3-194756Documento4 páginasCR1700r2 (Rel-15) R3-194756prateekiitkAinda não há avaliações

- Hig - Ie SW Al10m 8TX 2GC - V1.1 - 2020 12 29Documento2 páginasHig - Ie SW Al10m 8TX 2GC - V1.1 - 2020 12 29isaacsavioAinda não há avaliações

- TN1002 OdDocumento1 páginaTN1002 Odgaetan.boehlyAinda não há avaliações

- Vs-G20Edg/Ek/Em/Eo/Eoh: Schematic Diagrams and PC BoardsDocumento62 páginasVs-G20Edg/Ek/Em/Eo/Eoh: Schematic Diagrams and PC BoardsattiAinda não há avaliações

- FW50+ Produktpass Ift 10027203 e Ift 2004-11-17 PDFDocumento6 páginasFW50+ Produktpass Ift 10027203 e Ift 2004-11-17 PDFMaties Ionut CiprianAinda não há avaliações

- SD969-2 With BCM (ETACS) - Display (2/4) A/V & NavigationDocumento1 páginaSD969-2 With BCM (ETACS) - Display (2/4) A/V & NavigationDhashana MoorthyAinda não há avaliações

- Protection ChecklistDocumento5 páginasProtection ChecklistkaranAinda não há avaliações

- IEC 61850 Disturbance Recording Standard ImpactDocumento12 páginasIEC 61850 Disturbance Recording Standard ImpactpavanAinda não há avaliações

- 12P5403GDocumento16 páginas12P5403GMalik HamzaAinda não há avaliações

- SCC PIW SD PE Taman Salmon SG BulohDocumento4 páginasSCC PIW SD PE Taman Salmon SG BulohJohan RamliAinda não há avaliações

- CAN connection points and voltages of EAS-2 unitDocumento62 páginasCAN connection points and voltages of EAS-2 unitBranko Andric100% (2)

- 155MAT00008 Manuel Technique DreamStar enDocumento66 páginas155MAT00008 Manuel Technique DreamStar enNattawut ZuesatAinda não há avaliações

- Ewis Job CardDocumento4 páginasEwis Job CardNikolaos KechagiasAinda não há avaliações

- Compal LA - C771P Rev 1 SchematicDocumento34 páginasCompal LA - C771P Rev 1 Schematicbong bernalbongAinda não há avaliações

- Overheating and RBS 6102 Internal RoutingDocumento8 páginasOverheating and RBS 6102 Internal RoutingDavid51100% (1)

- 1839 - SEC (III) - Khaadi Gujrat - BOQ - 000 (Updated)Documento13 páginas1839 - SEC (III) - Khaadi Gujrat - BOQ - 000 (Updated)Kashan ShoukatAinda não há avaliações

- Intelligent Measuring and Protection Device CSENEX-IDocumento25 páginasIntelligent Measuring and Protection Device CSENEX-Ivasu100% (1)

- 93L34 8-Bit Addressable Latch: General Description FeaturesDocumento9 páginas93L34 8-Bit Addressable Latch: General Description Featuresparvalhao_Ainda não há avaliações

- Ios 1028 Ag enDocumento4 páginasIos 1028 Ag enJORGE ALOR RODRIGUEZAinda não há avaliações

- Mod-Itp-Ll - 010 - String Inverters Electrical InstallationDocumento2 páginasMod-Itp-Ll - 010 - String Inverters Electrical InstallationalejandroAinda não há avaliações

- TCP Walfish-Ikegami Model Strippad ADocumento6 páginasTCP Walfish-Ikegami Model Strippad AWaqas AhmedAinda não há avaliações

- Comant II A12055 C120-200G-S InstallationDocumento2 páginasComant II A12055 C120-200G-S InstallationFrank JansenAinda não há avaliações

- Ls CatalogueDocumento132 páginasLs CatalogueThe DampenerAinda não há avaliações

- D2 - START-UP (EN 115) : Face/Groups/ElevadoristasDocumento54 páginasD2 - START-UP (EN 115) : Face/Groups/ElevadoristasAnonymous 1Q3b2r100% (1)

- PPM 2017 2.0 LV System (Monthly)Documento2 páginasPPM 2017 2.0 LV System (Monthly)Nazlie NasirAinda não há avaliações

- Srs z1Documento8 páginasSrs z1TrentungcaysoBombodealopAinda não há avaliações

- StarLAN Technology ReportNo EverandStarLAN Technology ReportNota: 3 de 5 estrelas3/5 (1)

- Token Ring Technology ReportNo EverandToken Ring Technology ReportAinda não há avaliações

- CCTV Surveillance: Video Practices and TechnologyNo EverandCCTV Surveillance: Video Practices and TechnologyNota: 5 de 5 estrelas5/5 (2)

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999Ainda não há avaliações

- Musnad Ahmad Vol-3Documento606 páginasMusnad Ahmad Vol-3Saad BroAinda não há avaliações

- S-Series Interface For PROVOX IODocumento44 páginasS-Series Interface For PROVOX IOSaad BroAinda não há avaliações

- 02) CP Training-STARDOM-Overview of IEC - Programming - FuFb (With Hands-On)Documento10 páginas02) CP Training-STARDOM-Overview of IEC - Programming - FuFb (With Hands-On)Saad Bro100% (1)

- 00) CP Training-STARDOM-FCN-500 Selection GuideDocumento17 páginas00) CP Training-STARDOM-FCN-500 Selection GuideSaad BroAinda não há avaliações

- SIS InstallDocumento76 páginasSIS InstallSaad BroAinda não há avaliações

- 12P2524EDocumento21 páginas12P2524ESaad BroAinda não há avaliações

- Sirr Ul-Israr (Urdu Translation)Documento229 páginasSirr Ul-Israr (Urdu Translation)Talib Ghaffari100% (23)

- FatoohulGhaib PDFDocumento166 páginasFatoohulGhaib PDFSaad BroAinda não há avaliações

- Awarif-ul-Maarif Urdu TranslationDocumento776 páginasAwarif-ul-Maarif Urdu TranslationTalib Ghaffari97% (35)

- 12P2046AEDocumento14 páginas12P2046AESaad BroAinda não há avaliações

- 12P3292CDocumento16 páginas12P3292CSaad BroAinda não há avaliações

- SIS CHARMs Hardware ReferenceDocumento125 páginasSIS CHARMs Hardware ReferenceSaad BroAinda não há avaliações

- 12P3517CDocumento8 páginas12P3517CSaad BroAinda não há avaliações

- 12P2822EDocumento8 páginas12P2822ESaad BroAinda não há avaliações

- M Series HardwareDocumento485 páginasM Series HardwareSaad BroAinda não há avaliações

- SIS CHARMs Hardware InstallationDocumento48 páginasSIS CHARMs Hardware InstallationSaad BroAinda não há avaliações

- M-Series Interface For PROVOX IODocumento51 páginasM-Series Interface For PROVOX IOSaad BroAinda não há avaliações

- Interface For RS3 IODocumento48 páginasInterface For RS3 IOSaad BroAinda não há avaliações

- Quick Start Power and GroundingDocumento82 páginasQuick Start Power and GroundingSaad BroAinda não há avaliações

- Getting StartedDocumento173 páginasGetting StartedSaad Bro100% (1)

- Fieldbus InstallationDocumento88 páginasFieldbus InstallationSaad BroAinda não há avaliações

- Ps7swo B en-USDocumento68 páginasPs7swo B en-USSaad BroAinda não há avaliações

- PHB PCS7 eDocumento528 páginasPHB PCS7 eSaad BroAinda não há avaliações

- DS SyncServer S350Documento8 páginasDS SyncServer S350Saad BroAinda não há avaliações

- How To Program A CIP Generic Explicit Message With ControlLogix Revision 10 or 11 FirmwareDocumento4 páginasHow To Program A CIP Generic Explicit Message With ControlLogix Revision 10 or 11 FirmwareSaad BroAinda não há avaliações

- FGS ReportDocumento54 páginasFGS ReportSaad BroAinda não há avaliações

- Tips and Tricks I: Getting the Most Out of ArcGIS DesktopDocumento108 páginasTips and Tricks I: Getting the Most Out of ArcGIS Desktoptanja222Ainda não há avaliações

- c1Documento19 páginasc1vgnagaAinda não há avaliações

- Self Report QuestionnaireDocumento6 páginasSelf Report QuestionnaireMustafa AL ShlashAinda não há avaliações

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Documento1 páginaSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryAinda não há avaliações

- General 04 Fixed Flow Pump To Three TanksDocumento13 páginasGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemAinda não há avaliações

- 1.11 CHEM FINAL Chapter 11 Sulfuric AcidDocumento21 páginas1.11 CHEM FINAL Chapter 11 Sulfuric AcidSudhanshuAinda não há avaliações

- Color Order SystemsDocumento30 páginasColor Order SystemsBeyene DumechaAinda não há avaliações

- CobolDocumento224 páginasCobolrahulravi007Ainda não há avaliações

- Simultaneous EquationsDocumento11 páginasSimultaneous EquationsSaleena AurangzaibAinda não há avaliações

- Hydrogen and Its Compound.1Documento10 páginasHydrogen and Its Compound.1abhishekAinda não há avaliações

- Cold Backup and Recovery From Archivelog - OrACLE-HELPDocumento4 páginasCold Backup and Recovery From Archivelog - OrACLE-HELPadelarduarteAinda não há avaliações

- Introducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionDocumento9 páginasIntroducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionJhónatan CarranzaAinda não há avaliações

- Mathematics of Finance: Simple and Compound Interest FormulasDocumento11 páginasMathematics of Finance: Simple and Compound Interest FormulasAshekin MahadiAinda não há avaliações

- Digital Logic Design - Switch Logic & Basic GatesDocumento27 páginasDigital Logic Design - Switch Logic & Basic GatesTroon SoonAinda não há avaliações

- Pipeline Corrosion Assessment MethodsDocumento21 páginasPipeline Corrosion Assessment MethodsGilletAinda não há avaliações

- Impedance Measurement Handbook: 1st EditionDocumento36 páginasImpedance Measurement Handbook: 1st EditionAlex IslasAinda não há avaliações

- Sixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFDocumento19 páginasSixty Years of Research On Ship Rudders Effects of Design Choices On Rudder Performance PDFSunil100% (1)

- 08 Candelaria Punta Del Cobre IOCG Deposits PDFDocumento27 páginas08 Candelaria Punta Del Cobre IOCG Deposits PDFDiego Morales DíazAinda não há avaliações

- Rochor Station Pile Design CalculationsDocumento15 páginasRochor Station Pile Design CalculationsDifa LiuAinda não há avaliações

- Introduction to Continuous Optimization for Machine LearningDocumento10 páginasIntroduction to Continuous Optimization for Machine LearningMarcos OliveiraAinda não há avaliações

- Affixation (Landscape)Documento4 páginasAffixation (Landscape)difafalahudinAinda não há avaliações

- Design of Shaft Straightening MachineDocumento58 páginasDesign of Shaft Straightening MachineChiragPhadkeAinda não há avaliações

- 171 - New CAN-filter For Cran Com. SCS4 and MidrangeDocumento4 páginas171 - New CAN-filter For Cran Com. SCS4 and MidrangeMohamed ElnagdyAinda não há avaliações

- Astm D5501Documento3 páginasAstm D5501mhmdgalalAinda não há avaliações

- BetaDocumento16 páginasBetaAkshita Saxena100% (2)

- Biogen 2021Documento12 páginasBiogen 2021taufiq hidAinda não há avaliações

- Convert MBR Disk To GPT DiskDocumento5 páginasConvert MBR Disk To GPT Diskjelenjek83Ainda não há avaliações

- Scoop Atlas Wagner ST1810Documento4 páginasScoop Atlas Wagner ST1810Juan Manuel PerezAinda não há avaliações