Escolar Documentos

Profissional Documentos

Cultura Documentos

Sl5ds2 Switch and Check Valve

Enviado por

Hassan ShathakDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Sl5ds2 Switch and Check Valve

Enviado por

Hassan ShathakDireitos autorais:

Formatos disponíveis

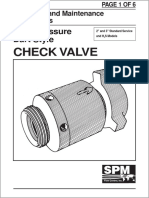

SD-06-1804

Bendix SL-5 Stop Light Switch & Bendix DS-2 Combined

Stop Light Switch & Double Check Valve

LEAF

SPRING TERMINAL

RIVET

FULCRUM

PISTON

CONTACT DIAPHRAGM

STRIP

SHUTTLE

DS-2 VALVE SL-5

VALVE SHORTING (CHECK STOP

BAR VALVE) LIGHT

SWITCH

INLET

PORT

INLET PORT

OUTLET PORT

FIGURE 1 - DS-2 COMBINED STOP LIGHT SWITCH & DOUBLE CHECK VALVE SECTIONAL

DESCRIPTION The stoplight switch is not a serviceable item; and if found

defective in either device, the complete unit must be replaced.

The Bendix SL-5 stop light switch is an electro-pneumatic

5 psi non-grounded switch that operates in conjunction with The shuttle valve in the DS-2 valve is serviceable and may

the brake valve and stop lights by completing the electrical be replaced.

circuit and lighting the stop lights when a brake application

Both the SL-5 switch and the DS-2 valve have been tested

is made.

and meet the requirements of FMVSS 121.

The DS-2 combined stop light switch and double check

valve, as the name implies, combines a SL-5 stop light OPERATION

switch with a DC-4 double check valve to perform the The stop switch mechanism is identical in the SL-5 switch

function of both. It operates in conjunction with the brake and the DS-2 valve.

valve and hand control valve by directing the flow of air from

whichever delivers the higher pressure into a common delivery When a brake application is made, air pressure from the

line and to the stop light switch, closing the electrical circuit brake valve enters the cavity below the diaphragm. The air

to the stop lamps. pressure below the diaphragm moves the piston until it

contacts the leaf spring. The leaf spring travels past a fulcrum

The stop light switch can be used with either 12 or 24 volt at which point the leaf springs snaps a shorting bar which

systems. mates with the contact strips. The stop light electrical circuit

1

Downloaded from www.Manualslib.com manuals search engine

is completed, lighting the stop lights before the brake INSTALLING

application pressures reach 6 psi. 1. Replace the SL-5 switch or DS-2 valve in the port

The snap action spring design minimizes arcing. from which it was removed. Do not install with the

terminals pointing down.

The double check valve is activated by air being introduced 2. Secure electrical connections.

through either of the two (2) inlet ports. The greater pressure

pushes the shuttle along its guides and closes the opposite 3. Reinstall air line connections to DS-2 valve.

inlet port. The air is then directed out the common delivery DISASSEMBLY (Double Check Valve)

line and to the stop light switch. 1. Remove three cap screws and cap.

PREVENTIVE MAINTENANCE 2. Remove o-ring seal from cap.

3. Remove shuttle valve.

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty CLEANING AND INSPECTION

may be voided if intrusive maintenance is performed during 1. Blow dust or other foreign material out of body. Do not

the warranty period. immerse in cleaning fluid.

No two vehicles operate under identical conditions; as a 2. Inspect shuttle valve and o-rings for excessive wear or

result, maintenance intervals may vary. Experience is a deterioration. Inspect valve seats for nicks or burrs.

valuable guide in determining the best maintenance interval Replace all parts that were discarded and any parts not

for air brake system components. At a minimum, the founds to be serviceable during inspection, using only

DS-2/SL-5 valve should be inspected every 6 months or genuine Bendix replacement parts.

1500 operating hours, whichever comes first, for proper

operation and electrical connections. Should the DS-2/ ASSEMBLY

SL-5 valve not meet the elements of the operational tests Before assembling the DS-2 double check valve, lubricate

noted in this document, further investigation and service of all o-rings and o-ring grooves with Bendix silicone lubricant

the valve may be required. (Pc. No. 291126) or equivalent.

NOTE: When using pipe thread sealant during assembly

OPERATING AND LEAKAGE TEST and installation, take particular care to prevent the

1. Install an accurate air gauge in the service line (or brake sealant from entering the valve itself. Apply the

chamber). Apply brake valve gradually. Stop lamps should sealant beginning with the second thread back from

light at 6 psi or less and go out after the brake application the end.

is released. This checks the electrical function of the

stop light switch in either the SL-5 switch or DS-2 TEST

valve. Repeat Operating and Leakage Test.

2. (DS-2 valve only) Apply the foot valve and coat the

WARNING! PLEASE READ AND FOLLOW

exhaust port of the hand valve (or other alternate source).

Reverse the above, applying the hand valve or other THESE INSTRUCTIONS TO AVOID

alternate source and coat the exhaust port of the foot PERSONAL INJURY OR DEATH:

valve. In either mode a leakage of not more than a 1

bubble in 5 seconds is permissible. When working on or around a vehicle, the following

general precautions should be observed at all times.

3. (SL-5 switch or DS-2 valve) When pressurized, no

leakage is permitted from the body of the valve or switch. 1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

If the SL-5 switch or DS-2 valve does not function as Always wear safety glasses.

described above or if leakage is excessive, the valve or switch 2. Stop the engine and remove ignition key when

should be replaced with a new unit or in the case of the working under or around the vehicle. When

double check portion of the DS-2 valve repaired with genuine working in the engine compartment, the engine

Bendix parts. should be shut off and the ignition key should be

removed. Where circumstances require that the

REMOVING AND INSTALLING engine be in operation, EXTREME CAUTION should

REMOVING be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

1. Block vehicle wheels or hold by means other than vehicle

electrically charged components.

service brakes.

3. Do not attempt to install, remove, disassemble or

2. Disconnect electrical connections from terminal screws. assemble a component until you have read and

3. (SL-5 switch) Remove the switch using a wrench on thoroughly understand the recommended

the hex portion of the body. procedures. Use only the proper tools and observe

4. (DS-2 valve) Disconnect air lines and remove the DS-2 all precautions pertaining to use of those tools.

valve.

2

Downloaded from www.Manualslib.com manuals search engine

4. If the work is being performed on the vehicles air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturers

recommended procedures, deactivate the electrical

system in a manner that safely removes all

electrical power from the vehicle.

6. Never exceed manufacturers recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp shoud be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

Downloaded from www.Manualslib.com manuals search engine

4 BW1594 2006 Bendix Commercial Vehicle Systems LLC All rights reserved. 7/2006 Printed in U.S.A.

Downloaded from www.Manualslib.com manuals search engine

Você também pode gostar

- Sl3sl4 Stop Light SwitchDocumento4 páginasSl3sl4 Stop Light SwitchHassan ShathakAinda não há avaliações

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGAinda não há avaliações

- Pressure MechanicalDocumento67 páginasPressure MechanicalDian PramadiAinda não há avaliações

- Dv-2 Drain Valve Installation 001Documento4 páginasDv-2 Drain Valve Installation 001AriesAinda não há avaliações

- Service Data 2020Documento8 páginasService Data 2020Hec NandoAinda não há avaliações

- C15 & C20 Series Inline Flow Switch: FeaturesDocumento2 páginasC15 & C20 Series Inline Flow Switch: FeaturesJavier AffifAinda não há avaliações

- Simplified Valve Circuit GuideDocumento28 páginasSimplified Valve Circuit GuideAlamin SiddiqueAinda não há avaliações

- Integrated Deluge Skid: Model: Sd-Dsk-Ad, Sd-Dsk-Aw Sd-Dpack-Ad, Sd-Dpack-Aw Sd-Dvch2, Sd-Dvch3Documento4 páginasIntegrated Deluge Skid: Model: Sd-Dsk-Ad, Sd-Dsk-Aw Sd-Dpack-Ad, Sd-Dpack-Aw Sd-Dvch2, Sd-Dvch3boxyfunAinda não há avaliações

- NE/SA556: Dual TimerDocumento11 páginasNE/SA556: Dual TimerRicardo LimonAinda não há avaliações

- Fisher D4 Control Valve Assembly: FeaturesDocumento12 páginasFisher D4 Control Valve Assembly: FeaturesAlberto GuillenAinda não há avaliações

- Regulators For Gas With Filter and Safety DiaphragmDocumento11 páginasRegulators For Gas With Filter and Safety DiaphragmNhật Quang PhạmAinda não há avaliações

- ICM7555 General Purpose CMOS Timer: Description Pin ConfigurationDocumento9 páginasICM7555 General Purpose CMOS Timer: Description Pin ConfigurationkalimbaloAinda não há avaliações

- Poppet Type Directional ValvesDocumento46 páginasPoppet Type Directional ValvesdejanpecicAinda não há avaliações

- PCR Autolube Intecs PDFDocumento27 páginasPCR Autolube Intecs PDFstrong holdAinda não há avaliações

- 5266 Controls: Safety Exhaust (Dump)Documento12 páginas5266 Controls: Safety Exhaust (Dump)Julio Vazquez MorenoAinda não há avaliações

- Model G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersDocumento4 páginasModel G2 Sprinkler Guard, Model WS-2 Shield, and Model WSG-2 Sprinkler Guard With Shield Series ELO-231, ELO-231B, and ELO-231FRB SprinklersAchraf BoudayaAinda não há avaliações

- Military Refueling Nozzle: 341GF SeriesDocumento2 páginasMilitary Refueling Nozzle: 341GF SeriesCRISTIAN CMAILO CABALLEROAinda não há avaliações

- Cla-Val Electronic Control ValvesDocumento6 páginasCla-Val Electronic Control ValvesArelysSotilloAinda não há avaliações

- 1.concentric Butterfly Valve in Various ApplicationDocumento10 páginas1.concentric Butterfly Valve in Various ApplicationMaciekAinda não há avaliações

- Bk-3-Latest EIC-E-1003-0 (Solenoid Controlled Pilot Operated Directional Valves)Documento15 páginasBk-3-Latest EIC-E-1003-0 (Solenoid Controlled Pilot Operated Directional Valves)Manoj PadhiAinda não há avaliações

- RAPHAEL FP Deluge Valve, Ductile Iron, ANSI150 Flange Drilling, 240psi, Electric Actuated, UL Listed, FDV-DEODocumento7 páginasRAPHAEL FP Deluge Valve, Ductile Iron, ANSI150 Flange Drilling, 240psi, Electric Actuated, UL Listed, FDV-DEOarchiel hiponiaAinda não há avaliações

- Manual Caterpillar 992g Wheel Loader Electro Hydraulic Implement System ComponentsDocumento65 páginasManual Caterpillar 992g Wheel Loader Electro Hydraulic Implement System Componentsleaw81100% (2)

- FWD EQUIP COOLING OP TechOpsDocumento19 páginasFWD EQUIP COOLING OP TechOpsWalter Jair Rodriguez Munoz (LATAM)Ainda não há avaliações

- D D D D D D D D: DescriptionDocumento15 páginasD D D D D D D D: Descriptionbernard smithAinda não há avaliações

- Air Limit Switches: Series L-Mini ValvesDocumento2 páginasAir Limit Switches: Series L-Mini ValvesLuis Eduardo Albarracin RugelesAinda não há avaliações

- ValvulaDocumento8 páginasValvulaJose Jiimenez LopezAinda não há avaliações

- Type 128-PQC Control ValvesDocumento4 páginasType 128-PQC Control ValvesDatt NguyenAinda não há avaliações

- Applications / Markets: 50,000 Cycles For 235gfDocumento3 páginasApplications / Markets: 50,000 Cycles For 235gfalexandresjr7Ainda não há avaliações

- Dart Valves - Operating & MaintenanceDocumento6 páginasDart Valves - Operating & MaintenanceGenard Sabenacio GarciaAinda não há avaliações

- EF Repair en TextDocumento124 páginasEF Repair en Textronat88080Ainda não há avaliações

- Valve Trip 377 InglesDocumento20 páginasValve Trip 377 Ingleshades_x3Ainda não há avaliações

- 30 PR (D) PDFDocumento1 página30 PR (D) PDFhoussem houssemAinda não há avaliações

- Air Mantenance DeviseDocumento4 páginasAir Mantenance DeviseAhmed SolimanAinda não há avaliações

- Web Catalog PDFDocumento28 páginasWeb Catalog PDFpeter vusiAinda não há avaliações

- Pressure Switch Directional Valves: InstallationDocumento2 páginasPressure Switch Directional Valves: InstallationEliud Rodriguez100% (1)

- AR-2 Antilock Relay Valve (SD-13-4796)Documento12 páginasAR-2 Antilock Relay Valve (SD-13-4796)emmanuelAinda não há avaliações

- TBI11N02-MECH - PIP-MPA-AEI-080 - 0 MPA Vertical Float Level SwitchDocumento10 páginasTBI11N02-MECH - PIP-MPA-AEI-080 - 0 MPA Vertical Float Level Switchachmaddevy setiawanAinda não há avaliações

- m731 e K3 v04 5554 en PDFDocumento22 páginasm731 e K3 v04 5554 en PDFtsdcnAinda não há avaliações

- GF4EATDocumento112 páginasGF4EATVENDA DE PEÇAS CAMBIOAinda não há avaliações

- Differential Pressure Valve E-250-01Documento3 páginasDifferential Pressure Valve E-250-01Navin RamnauthAinda não há avaliações

- Bendix SDS-9600 Trailer Suspension Dump ValveDocumento5 páginasBendix SDS-9600 Trailer Suspension Dump ValveArcargel ArturoAinda não há avaliações

- Pribor Za Transformatore: Accessories For TransformersDocumento4 páginasPribor Za Transformatore: Accessories For TransformersTRANqAinda não há avaliações

- Jet Range PRVDocumento4 páginasJet Range PRVneiljonesAinda não há avaliações

- Na 556Documento5 páginasNa 556zperkov7Ainda não há avaliações

- Check Valve: High Pressure Dart StyleDocumento6 páginasCheck Valve: High Pressure Dart StyleGenard Sabenacio GarciaAinda não há avaliações

- MODEL: T101: 24 Hour Dial Time SwitchDocumento1 páginaMODEL: T101: 24 Hour Dial Time SwitchMarcosAinda não há avaliações

- Сигнализатор Потока Воздуха - vs5100 Om 12 RpDocumento86 páginasСигнализатор Потока Воздуха - vs5100 Om 12 RpАлександрAinda não há avaliações

- Sis 2.0Documento1 páginaSis 2.0uuganaa ugiAinda não há avaliações

- Ruelco 4222Documento6 páginasRuelco 4222khasim15Ainda não há avaliações

- D00016 Section Valve NS20 Micro SwitchDocumento1 páginaD00016 Section Valve NS20 Micro SwitchJose CienduaAinda não há avaliações

- Installation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorDocumento15 páginasInstallation, Operation and Maintenance Manual For Model WG-HLA Hydraulic ActuatorNeilton Junior100% (1)

- Reliablegatevalveswitch 2Documento3 páginasReliablegatevalveswitch 2jajakaAinda não há avaliações

- Epl 8NDocumento4 páginasEpl 8Napi-3777439Ainda não há avaliações

- XX - 374D Quick CouplerDocumento6 páginasXX - 374D Quick Couplerait mimouneAinda não há avaliações

- API 6A Gate ValveDocumento26 páginasAPI 6A Gate ValveindraAinda não há avaliações

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDocumento30 páginasE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggAinda não há avaliações

- GX 470+ride+heightDocumento5 páginasGX 470+ride+heightTimothy MartinAinda não há avaliações

- Stop Valves SVA-DL & SVA-DH 250-300: Technical BrochureDocumento8 páginasStop Valves SVA-DL & SVA-DH 250-300: Technical BrochureFernando David RamirezAinda não há avaliações

- Relay 5Documento1 páginaRelay 5Hassan ShathakAinda não há avaliações

- Load ChartDocumento9 páginasLoad ChartHassan ShathakAinda não há avaliações

- Relay 7Documento1 páginaRelay 7Hassan ShathakAinda não há avaliações

- Hand Signal-4Documento1 páginaHand Signal-4Hassan ShathakAinda não há avaliações

- Hand Signal-6Documento1 páginaHand Signal-6Hassan ShathakAinda não há avaliações

- Hand Signal-3Documento1 páginaHand Signal-3Hassan ShathakAinda não há avaliações

- Hand Signal-5Documento1 páginaHand Signal-5Hassan ShathakAinda não há avaliações

- Tamil Nadu Loyal V 2948058aDocumento1 páginaTamil Nadu Loyal V 2948058aHassan ShathakAinda não há avaliações

- Y294093 en 000Documento2 páginasY294093 en 000Hassan ShathakAinda não há avaliações

- Hand Signal-2Documento1 páginaHand Signal-2Hassan ShathakAinda não há avaliações

- Hand Signal-1Documento1 páginaHand Signal-1Hassan ShathakAinda não há avaliações

- Tamil Nadu Loyal V 2948058a PDFDocumento10 páginasTamil Nadu Loyal V 2948058a PDFHassan ShathakAinda não há avaliações

- Tis 0012 Axle Loads and Weight Distribution Issue 1 PDFDocumento4 páginasTis 0012 Axle Loads and Weight Distribution Issue 1 PDFDon Procopio II100% (1)

- 1 Cover PageDocumento3 páginas1 Cover PageHassan ShathakAinda não há avaliações

- ResultDocumento3 páginasResultHassan ShathakAinda não há avaliações

- 4.1 Lift Force For Various GeometriesDocumento8 páginas4.1 Lift Force For Various GeometriesHassan ShathakAinda não há avaliações

- 9 ConclusionDocumento2 páginas9 ConclusionHassan ShathakAinda não há avaliações

- 1 Cover PageDocumento3 páginas1 Cover PageHassan ShathakAinda não há avaliações

- Innocent Hassan: September 20, 2013Documento53 páginasInnocent Hassan: September 20, 2013Hassan ShathakAinda não há avaliações

- 2013 Isuzu Truck: Weight Distribution ConceptsDocumento30 páginas2013 Isuzu Truck: Weight Distribution ConceptsHassan Shathak100% (1)

- 3.14. TR-069 WAN Management...Documento6 páginas3.14. TR-069 WAN Management...duculeteAinda não há avaliações

- Redesigning Boilers Solves Problems and Saves MoneyDocumento9 páginasRedesigning Boilers Solves Problems and Saves MoneyfelramAinda não há avaliações

- BPQ REV. 0 Interactive FormDocumento2 páginasBPQ REV. 0 Interactive FormcosmicbunnyAinda não há avaliações

- Glenair Connector Terms - SummaryDocumento4 páginasGlenair Connector Terms - SummarybenAinda não há avaliações

- Payment InstructionDocumento2 páginasPayment InstructionNeel PatelAinda não há avaliações

- Switch v7LAB StudentDocumento206 páginasSwitch v7LAB Studentkcf4scribdAinda não há avaliações

- Etk 001 en de PDFDocumento740 páginasEtk 001 en de PDFBinh le Thanh0% (1)

- Step-By-Step Guide - Sensors Alarms1Documento14 páginasStep-By-Step Guide - Sensors Alarms1Andy_kokoAinda não há avaliações

- Principles of Accounting, Volume 2: Managerial AccountingDocumento59 páginasPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraAinda não há avaliações

- A Practical Guide To Machine Vision Lighting - Part IIIDocumento4 páginasA Practical Guide To Machine Vision Lighting - Part IIIChai Jien WeiAinda não há avaliações

- BOQ For Interior WorkDocumento2 páginasBOQ For Interior WorkSudhanshu MandlikAinda não há avaliações

- Final Project Miguel Santana GallegoDocumento44 páginasFinal Project Miguel Santana GallegoDaniel PereiraAinda não há avaliações

- Pds Luxathane 5000 VocDocumento2 páginasPds Luxathane 5000 Vocmuthukumar100% (1)

- Paranormal Activity 3Documento5 páginasParanormal Activity 3alexAinda não há avaliações

- CCR Equipment ListDocumento1 páginaCCR Equipment Listbehzad parsiAinda não há avaliações

- Manto: at Work For You at Work For You at Work For You at Work For YouDocumento4 páginasManto: at Work For You at Work For You at Work For You at Work For YouHossam Eldin kamalAinda não há avaliações

- Especificaciones Tecnicas Motor 4g54 2.6ltsDocumento20 páginasEspecificaciones Tecnicas Motor 4g54 2.6ltsjr50% (2)

- Indonesia's First Maritime Service Solution Provider: Company ProfileDocumento10 páginasIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451Ainda não há avaliações

- District CoolingDocumento16 páginasDistrict Coolingmazzam75Ainda não há avaliações

- NDT NablDocumento3 páginasNDT NablPrabir KumarAinda não há avaliações

- Contactor HassDocumento1 páginaContactor Hassecaldera10Ainda não há avaliações

- GRT655 GRT655L Product Guide ImperialDocumento20 páginasGRT655 GRT655L Product Guide ImperialDanilo UrruchurtoAinda não há avaliações

- 6.hydraulic Pressure SpesificationDocumento3 páginas6.hydraulic Pressure SpesificationTLK ChannelAinda não há avaliações

- LC 2539Documento16 páginasLC 2539Kelly JonesAinda não há avaliações

- 1743 LKWActrosXXXXXX 954frDocumento4 páginas1743 LKWActrosXXXXXX 954frgeothermal3102100% (1)

- Chapter 2 A Guide To Using UnixDocumento53 páginasChapter 2 A Guide To Using UnixAntwon KellyAinda não há avaliações

- Arco Solar Inc.: Case Analysis OnDocumento12 páginasArco Solar Inc.: Case Analysis OnAnish RajAinda não há avaliações

- Poly BoreDocumento2 páginasPoly BoreMarian OpreaAinda não há avaliações

- Global Edge Interview ExperienceDocumento2 páginasGlobal Edge Interview Experienceshafi hasmaniAinda não há avaliações

- Simple Free-Energy InformationDocumento11 páginasSimple Free-Energy InformationDrago MelovAinda não há avaliações

- Chip War: The Fight for the World's Most Critical TechnologyNo EverandChip War: The Fight for the World's Most Critical TechnologyNota: 4.5 de 5 estrelas4.5/5 (82)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyNo EverandChip War: The Quest to Dominate the World's Most Critical TechnologyNota: 4.5 de 5 estrelas4.5/5 (228)

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsNo EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsNota: 5 de 5 estrelas5/5 (3)

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]No EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Nota: 5 de 5 estrelas5/5 (3)

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)No EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Nota: 5 de 5 estrelas5/5 (2)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsNo EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongAinda não há avaliações

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102No EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Nota: 5 de 5 estrelas5/5 (2)

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002No EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Nota: 5 de 5 estrelas5/5 (1)

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XNo EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XNota: 3 de 5 estrelas3/5 (2)

- Cancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionNo EverandCancer and EMF Radiation: How to Protect Yourself from the Silent Carcinogen of ElectropollutionNota: 5 de 5 estrelas5/5 (2)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNo EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsAinda não há avaliações

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideNo EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideNota: 2 de 5 estrelas2/5 (1)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingNo EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingAinda não há avaliações

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- The comprehensive guide to build Raspberry Pi 5 RoboticsNo EverandThe comprehensive guide to build Raspberry Pi 5 RoboticsAinda não há avaliações

- Advanced Production Decline Analysis and ApplicationNo EverandAdvanced Production Decline Analysis and ApplicationNota: 3.5 de 5 estrelas3.5/5 (4)

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1715193157?v=1)