Escolar Documentos

Profissional Documentos

Cultura Documentos

Pipes. Maxi 1

Enviado por

Nasrul Adli0 notas0% acharam este documento útil (0 voto)

26 visualizações1 páginaThe document summarizes the method for determining the length between pipe supports using the maximum bending stress method.

1) It calculates the concentrated and distributed loads on the pipe.

2) It then sets up an equation to calculate the maximum allowable length using the loads and the material properties.

3) The calculated length is then selected as the length between pipe supports.

Descrição original:

PIPE

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe document summarizes the method for determining the length between pipe supports using the maximum bending stress method.

1) It calculates the concentrated and distributed loads on the pipe.

2) It then sets up an equation to calculate the maximum allowable length using the loads and the material properties.

3) The calculated length is then selected as the length between pipe supports.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

26 visualizações1 páginaPipes. Maxi 1

Enviado por

Nasrul AdliThe document summarizes the method for determining the length between pipe supports using the maximum bending stress method.

1) It calculates the concentrated and distributed loads on the pipe.

2) It then sets up an equation to calculate the maximum allowable length using the loads and the material properties.

3) The calculated length is then selected as the length between pipe supports.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

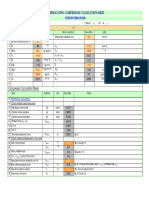

Determination of the length

between pipe supports by Requirements Pipe yield st

the method of the "Maximum Ref. 2a. Tabl

Bending Stress" [1] The ratio Lenght/deflection t =

is defined with a minimum

Data value of Pipe basic al

Nominal pipe size (NPS) (L/y)min = 600 given tempe

dn = 300 mm Ref. 2a. Tabl

Material: A 312 TP316L Maximum bending stress t=

Pipe pressure and temperature ratio allow =

P= 20 bar b/allow = 0.3 allow =

t= 22 C b : Maximum allowed

Pipe filled with water bending stress Maximum b

allow : Pipe allowed stress b =

It will be considered the weight in tension according B31.3 allow =

of two men at the center of Table A-1 b =

the pipe. b =

Concentrated weight The lenght is designed for the

mc = 200 kg pipe working with the Steel elastic

wc = 1961 N maximum allowed bending Sheet SS 316

Pipe insulation weigth stress b. E=

wi = 0 N/m

Pipe shedule is to be determined

Water load Concentrated weight

ww = w * g * V wc = 1961 N

w = 1000 kg/m

V= 0.072971 m/m Pipe length (eq. (h)

ww = 715.6 N/m Lcalc = (-b + (b^2

w 2 wc I

L + L- b = 0 (h)

16 8 d b=

Pipe load (steel) a=

wp = p*g*(/4)*(de^2-di^2) a= w/16 c=

(from sheet SS 316) w= 1453 N/m Lcalc =

p = 8000 kg/m a= 90.8 Let

de = 0.324 m Lselected =

di = 0.305 m b= wc /8

Você também pode gostar

- Presure Regulator Calculate PDFDocumento5 páginasPresure Regulator Calculate PDFGorast KolevAinda não há avaliações

- Chimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficeDocumento1 páginaChimney Draught Calculations: //vboxsrv/conversion - Tmp/scratch - 4/195995390.xls - Ms - OfficemohdnazirAinda não há avaliações

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocumento6 páginasSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareAinda não há avaliações

- Heat Balance Calculation Sheet - Part ADocumento1 páginaHeat Balance Calculation Sheet - Part AFer VFAinda não há avaliações

- Copie de LeastSquaresDocumento25 páginasCopie de LeastSquaresbelazouzboualemAinda não há avaliações

- Chapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallDocumento4 páginasChapter 11: Refrigeration Rules of Thumb For Chemical Engineers, 5th Edition by Stephen HallReza SaeeAinda não há avaliações

- PSYCH v10Documento9 páginasPSYCH v10Daniel Puello RodeloAinda não há avaliações

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocumento5 páginasGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Heat CalcDocumento13 páginasHeat Calciese027Ainda não há avaliações

- Compressor Settle-Out CalculationDocumento4 páginasCompressor Settle-Out CalculationWickyAinda não há avaliações

- Desuperheater Flow CalculationDocumento1 páginaDesuperheater Flow CalculationMechanicalVee18Ainda não há avaliações

- SFW - FV Flash Steam and Flash Vessel CalculationDocumento2 páginasSFW - FV Flash Steam and Flash Vessel CalculationjnmanivannanAinda não há avaliações

- Design Calculation For Gaseous SystemsDocumento16 páginasDesign Calculation For Gaseous Systemsshashi ranjanAinda não há avaliações

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and GreenDocumento6 páginasNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and Greensunii19847908Ainda não há avaliações

- Air CompDocumento1 páginaAir CompHsein WangAinda não há avaliações

- Design For EO & PO Scrubbing System (Rev.02) - Case2Documento70 páginasDesign For EO & PO Scrubbing System (Rev.02) - Case2Ashish PawarAinda não há avaliações

- Data Sheet: Description Unit Design DataDocumento2 páginasData Sheet: Description Unit Design DataEDUARDOAinda não há avaliações

- Cal. Dew PointDocumento1 páginaCal. Dew PointJuan Pablo ApazaAinda não há avaliações

- L.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o oDocumento9 páginasL.3.1. EVAPORATOR - 01 (EV-01) : 1 o o o omedias indah monica sariAinda não há avaliações

- Cooling Tower Calculations: I N P U TDocumento2 páginasCooling Tower Calculations: I N P U ThuangjlAinda não há avaliações

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultDocumento87 páginasAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalAinda não há avaliações

- Double FdexchangerDocumento8 páginasDouble FdexchangerBoško IvanovićAinda não há avaliações

- Center Vent & Peripheral Vent CalDocumento1 páginaCenter Vent & Peripheral Vent CalrichardchiamAinda não há avaliações

- Combustion CalculationsDocumento6 páginasCombustion CalculationsDaniel AriefinAinda não há avaliações

- C3CYCLVDocumento13 páginasC3CYCLVUok RitchieAinda não há avaliações

- Centrif Pumps1 SpreadsheetDocumento2 páginasCentrif Pumps1 SpreadsheetCast Ed Iv0% (1)

- Atmospheric Temperature, Pressure and Density As Function of The Height Above Sea LevelDocumento53 páginasAtmospheric Temperature, Pressure and Density As Function of The Height Above Sea LevelMustafa TıraşAinda não há avaliações

- Desuperheater Boiler Feed Water RequirementDocumento2 páginasDesuperheater Boiler Feed Water Requirementmehul10941Ainda não há avaliações

- Burst DiscDocumento6 páginasBurst DiscMa AlAinda não há avaliações

- Thermal InsulationDocumento27 páginasThermal Insulationmkchy12Ainda não há avaliações

- CFM and Capacity Calcs 4.9Documento14 páginasCFM and Capacity Calcs 4.9hvacrmedicAinda não há avaliações

- Process Calculation For FREYLIT CPI Oil SeparatorDocumento4 páginasProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhAinda não há avaliações

- Viscosity of Natural Gas: ParametersDocumento3 páginasViscosity of Natural Gas: Parametersprateek_bhoirAinda não há avaliações

- For Weight of PipeDocumento5 páginasFor Weight of PipekathirAinda não há avaliações

- Hydroulics Calculation and Gas PropertiesDocumento3 páginasHydroulics Calculation and Gas PropertiesSteve WanAinda não há avaliações

- Data Sheet EjectorDocumento4 páginasData Sheet EjectorGunturMudaAliAkbarAinda não há avaliações

- STEAMcalc 12.8 RupiahDocumento1.009 páginasSTEAMcalc 12.8 RupiahlightsonsAinda não há avaliações

- Perancangan CycloneDocumento20 páginasPerancangan CycloneDavid LambertAinda não há avaliações

- Heat Conduction Pipe InsulationDocumento1 páginaHeat Conduction Pipe InsulationJogender DhayalAinda não há avaliações

- R 134a ChillerDocumento48 páginasR 134a ChillerAshfaq NoorAinda não há avaliações

- XSteam Excel v2.6 USDocumento12 páginasXSteam Excel v2.6 USOnkarabile MatomeAinda não há avaliações

- BOILER CALCULATION SYSTEM REV 3-1Documento3 páginasBOILER CALCULATION SYSTEM REV 3-1Dewi FellaAinda não há avaliações

- Vent Dispersion Calc - OptionalDocumento4 páginasVent Dispersion Calc - OptionalPeddy Nesa0% (1)

- CT Blowdown PhilosophyDocumento6 páginasCT Blowdown PhilosophyzamijakaAinda não há avaliações

- 3 - Heating - Calculation - Tool - EmptyDocumento7 páginas3 - Heating - Calculation - Tool - EmptyThaigroup CementAinda não há avaliações

- Native File For Pump (Example)Documento2 páginasNative File For Pump (Example)Venturindo SiteAinda não há avaliações

- Linear Mixing CalcDocumento12 páginasLinear Mixing CalcClarence AG YueAinda não há avaliações

- NaturalConvectionHeatTransferCoefficients SI Units Final ProtectedDocumento44 páginasNaturalConvectionHeatTransferCoefficients SI Units Final ProtectedFabio MiguelAinda não há avaliações

- G LST 001 Ab Tank Farm in ProgressDocumento270 páginasG LST 001 Ab Tank Farm in ProgressPhilippe AlexandreAinda não há avaliações

- Pressure Drop in Steam Lines CalculatorDocumento7 páginasPressure Drop in Steam Lines CalculatorHiranthaAinda não há avaliações

- Storage Tank Data SheetDocumento16 páginasStorage Tank Data SheetSalman EngineeringAinda não há avaliações

- Total Types of Wastes:: Bostik IndiaDocumento23 páginasTotal Types of Wastes:: Bostik IndiaAnonymous pVoSWn8yh0Ainda não há avaliações

- FMV Spreadsheets-Master-FMVIDocumento15 páginasFMV Spreadsheets-Master-FMVIadrianaortizv100% (1)

- AntoineDocumento64 páginasAntoinealexis19714aAinda não há avaliações

- Book 1Documento1 páginaBook 1Manju NaikAinda não há avaliações

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento62 páginasPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressArunkumar RackanAinda não há avaliações

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento64 páginasPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressselisenAinda não há avaliações

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento58 páginasPipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressJOELAinda não há avaliações

- Design Calculating For Piperack SpanDocumento3 páginasDesign Calculating For Piperack SpanMuhammad RizkyAinda não há avaliações

- 5669101-Me-Cal-010 Design Calculating For Piperack SpanDocumento3 páginas5669101-Me-Cal-010 Design Calculating For Piperack SpanMuhammad RizkyAinda não há avaliações

- Piping Engineering - Tank Nozzle Loads 1Documento1 páginaPiping Engineering - Tank Nozzle Loads 1Nasrul AdliAinda não há avaliações

- Malaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFDocumento4 páginasMalaysia Public Holidays & School Holidays 2018 CalendaR-ALL PDFNasrul AdliAinda não há avaliações

- Job Information: Engineer Checked Approved Name: Date: Structure TypeDocumento2 páginasJob Information: Engineer Checked Approved Name: Date: Structure TypeNasrul AdliAinda não há avaliações

- Exhibit II Compliance To Technical RequirementsDocumento1 páginaExhibit II Compliance To Technical RequirementsNasrul AdliAinda não há avaliações

- Asme Sect8 Div1 - SAMPLE Calculation-COVERDocumento1 páginaAsme Sect8 Div1 - SAMPLE Calculation-COVERNasrul AdliAinda não há avaliações

- B31 3 (Mygaz) - 1Documento1 páginaB31 3 (Mygaz) - 1Nasrul AdliAinda não há avaliações

- What Is Piping 2Documento1 páginaWhat Is Piping 2Nasrul AdliAinda não há avaliações

- PDMS 2Documento1 páginaPDMS 2Nasrul AdliAinda não há avaliações

- Pipes. Maxi 8 PDFDocumento1 páginaPipes. Maxi 8 PDFNasrul AdliAinda não há avaliações

- Pipes. Maxi 8 PDFDocumento1 páginaPipes. Maxi 8 PDFNasrul AdliAinda não há avaliações

- Shear Lug Verification Example 12Documento1 páginaShear Lug Verification Example 12Nasrul AdliAinda não há avaliações

- Shear Lug Verification Example 4Documento1 páginaShear Lug Verification Example 4Nasrul AdliAinda não há avaliações

- Shear Lug Verification Example 12Documento1 páginaShear Lug Verification Example 12Nasrul AdliAinda não há avaliações

- Shear Lug Verification Example 3Documento1 páginaShear Lug Verification Example 3Nasrul AdliAinda não há avaliações

- Shear Lug Verification Example 2Documento1 páginaShear Lug Verification Example 2Nasrul AdliAinda não há avaliações

- Moment of Resistance For Doubly Reinforced SectionsDocumento32 páginasMoment of Resistance For Doubly Reinforced SectionsWanda Beasley100% (3)

- Experiment No: - 03 Name of Experiment: - The Torsion System. ObjectivesDocumento7 páginasExperiment No: - 03 Name of Experiment: - The Torsion System. ObjectivesNewton ShikderAinda não há avaliações

- Design of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayDocumento57 páginasDesign of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayKC Paguinto100% (1)

- P - B D E R W S S L: Erformance Ased Esign of Mbedded Etaining Alls Ubjected To Eismic OadingDocumento10 páginasP - B D E R W S S L: Erformance Ased Esign of Mbedded Etaining Alls Ubjected To Eismic OadingJordan BojadzievAinda não há avaliações

- Creep in ConcreteDocumento26 páginasCreep in ConcreteheminAinda não há avaliações

- Strength of Materials-Homework3Documento3 páginasStrength of Materials-Homework3durasteelAinda não há avaliações

- Bolt Joint ReportDocumento37 páginasBolt Joint ReportNarayana Addanki Machine DesignAinda não há avaliações

- REODATA40Documento76 páginasREODATA40chanakaAinda não há avaliações

- Analysis of Roof Bolt Systems PDFDocumento8 páginasAnalysis of Roof Bolt Systems PDFjulio1051Ainda não há avaliações

- Design Coaching 1 Practice Material and LectureDocumento43 páginasDesign Coaching 1 Practice Material and LectureeklavurAinda não há avaliações

- Mesl Elements 3Documento6 páginasMesl Elements 3Backup Review Files YbanezAinda não há avaliações

- Biomaterials and Implants: School of Biomedical Engineering Jit, Jimma UniversityDocumento81 páginasBiomaterials and Implants: School of Biomedical Engineering Jit, Jimma UniversityAmirAinda não há avaliações

- Filigree Slabs TestingDocumento6 páginasFiligree Slabs Testingmulti5torpeAinda não há avaliações

- 1 - Introduction To Structural Steel Design-Chapter 1Documento3 páginas1 - Introduction To Structural Steel Design-Chapter 1Abera DeressaAinda não há avaliações

- SolidWorks Simulation PackagesDocumento4 páginasSolidWorks Simulation PackagesPhi MacAinda não há avaliações

- Supplemental Technical InformationDocumento5 páginasSupplemental Technical InformationpendexxAinda não há avaliações

- Okada 1992 BssaDocumento23 páginasOkada 1992 BssaYehezkiel HalauwetAinda não há avaliações

- Involute Gear Tooth Contact Stress AnalysisDocumento17 páginasInvolute Gear Tooth Contact Stress AnalysisCelsoAinda não há avaliações

- Problems From Design of Machine Elements V B Bhandari: Roll 17/ME/09 Sharthak GhoshDocumento5 páginasProblems From Design of Machine Elements V B Bhandari: Roll 17/ME/09 Sharthak GhoshSharthak GhoshAinda não há avaliações

- Design of Screw JackDocumento20 páginasDesign of Screw Jackchirag sanghani100% (4)

- Strain GaugesDocumento75 páginasStrain GaugesMR GOKCHENAinda não há avaliações

- Engineered System Failure AnalysisDocumento68 páginasEngineered System Failure AnalysisAdimasu AyeleAinda não há avaliações

- U.S. Army Corps of Engineers Riprap Design For Flood ChannelsDocumento9 páginasU.S. Army Corps of Engineers Riprap Design For Flood ChannelsEduardo CeceñaAinda não há avaliações

- Course Outline:: Ece 2311: Soil Mechanics IiDocumento11 páginasCourse Outline:: Ece 2311: Soil Mechanics IiSylvester WafulaAinda não há avaliações

- Manual of Cadam-AllDocumento67 páginasManual of Cadam-AllHüseyinGörenAinda não há avaliações

- 5 RC2 30 Vess JSD 95 000 0400Documento15 páginas5 RC2 30 Vess JSD 95 000 0400Shaaban Noaman100% (1)

- NCH 2369 of 2003 - Seismic Design For Industrial Structures and FacilitiesDocumento126 páginasNCH 2369 of 2003 - Seismic Design For Industrial Structures and Facilitiesoogaz2100% (2)

- Experiment I: Tension Test On Mild Steel: IdnoDocumento11 páginasExperiment I: Tension Test On Mild Steel: IdnoNavneetRaiAinda não há avaliações

- Fluid Mechanics - Resource BookDocumento167 páginasFluid Mechanics - Resource BookAkshat ModiAinda não há avaliações

- 4.project ReportDocumento38 páginas4.project ReportJagadeeshan SivanAinda não há avaliações