Escolar Documentos

Profissional Documentos

Cultura Documentos

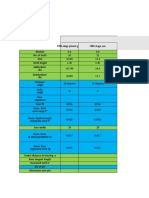

Tedata: Programm Benutzer Datum Kunde Proj. NR

Enviado por

Jason CanoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Tedata: Programm Benutzer Datum Kunde Proj. NR

Enviado por

Jason CanoDireitos autorais:

Formatos disponíveis

Tedata

Programm : MDESIGN Benutzer : Kunde :

Version : 1.1.2 Datum : 29.10.2017 Proj. Nr :

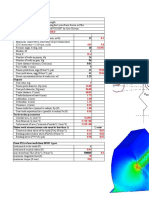

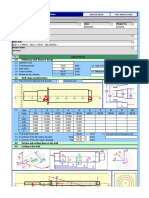

Helical Gearing

Eingabedaten:

= 25

Pdn = 9 teeth/in

F = 1.652 in

P = 25 hp

np = 139 rpm

Np = 21

ng = 69 rpm

L = 20000 h

q = 1

Rim thickness of pinion tr = 1 1 in

and gear

Bending geometry factor of J = 0.45 0.98

pinion and gear

I = 0.201

Cp = 2300

Ko = 2

SF = 1

Ch = 1

Kr = 1

Results

Diametral pitch Pd = 8.157 teet h/in

Transverse pressure angle t = 21.880

Actual output speed ng = 69.500 rpm

Actual number of gear teeth Ng = 42

Gear ratio mg = 2.000

Qualty number Qv = 7.000

Geometry parameters

Pinion Gear

Pitch diameter D = 2.575 5.149 in

Outside diameter Do = 2.820 5.394 in

HELI 2.XML 29.10.2017 20:25:38 Seite 1/3

Tedata

Programm : MDESIGN Benutzer : Kunde :

Version : 1.1.2 Datum : 29.10.2017 Proj. Nr :

Helical Gearing

Root diameters Dr = 2.268 4.843 in

Base circle diameter Db = 2.389 4.778 in

Addendum a = 0.123 in

Dedendum b = 0.153 in

Clearance c = 0.028 in

Circular pitch p = 0.385 in

Normal circular pitch Pn = 0.349 in

Axial pitch Px = 0.826 in

Whole depth ht = 0.276 in

Working depth hk = 0.245 in

Tooth thickness t = 0.175 in

Center distance C = 3.862 in

Fillet radius in basic rack rf = 0.037 in

Force and speed factors

Pitch line speed vt = 93.688 ft/min

Tangential force Wt = 8802.270 lbf

Normal force Wn = 10335.540 lbf

Radial force Wr = 3534.963 lbf

Axial force Wx = 4104.566 lbf

Size factor Ks = 1.000

Load distribution factor Km = 1.200

Dynamic factor Kv = 1.107

Face width/Axial pitch F/Px = 2.000

Pinion Gear

Rim thickness factor Kb = 1.000 1.000

Number of load cycle Nc = 1.7e+008 8.3e+007

Bending stress cycle factor Yn = 0.968 0.980

Pitting stress cycle factor Zn = 0.937 0.952

Expected bending stress St = 2.566e+005 1.178e+005 psi

Expected contact stress Sc = 3.804e+005 3.804e+005 psi

Allowable bending stress number Sat = 2.651e+005 1.202e+005 psi

Allowable contact stress number Sac = 4.058e+005 3.994e+005 psi

Note

After computing the values for allowable bending stress number and for

allowable

contact stress number, you should go to the data in AGMA Standard 2001-C95,

to

HELI 2.XML 29.10.2017 20:25:38 Seite 2/3

Tedata

Programm : MDESIGN Benutzer : Kunde :

Version : 1.1.2 Datum : 29.10.2017 Proj. Nr :

Helical Gearing

select a suitable material. Consider first whether the material should be

steel,

cast iron, bronze, or plastic. Then consult the related tables of data.

For instance use through-hardened steel with hardness, HB

Pinion Gear

Grade 1 3263.605 2438.006

Grade 2 1389.732 1046.139

Note

The hardness cannot be greater than 400 HB for through-hardened steel.

Consider using case hardened steel.

HELI 2.XML 29.10.2017 20:25:38 Seite 3/3

Você também pode gostar

- Involute Spur Gear Geometry Calculations: Input DataDocumento11 páginasInvolute Spur Gear Geometry Calculations: Input DataNILESH YADAVAinda não há avaliações

- T M B D Z M: Pitting StrengthDocumento6 páginasT M B D Z M: Pitting StrengthprasannaAinda não há avaliações

- Design ShaftDocumento10 páginasDesign Shaftทนงศักดิ์ วิไลพันธ์Ainda não há avaliações

- OMDocumento16 páginasOMLiviu AndreiAinda não há avaliações

- Example DIN743 Bbl1Documento7 páginasExample DIN743 Bbl1dd hhAinda não há avaliações

- 4.2 Method of Measurement With Overballs OrRollers TechnicalData KGSTOCKGEARSDocumento6 páginas4.2 Method of Measurement With Overballs OrRollers TechnicalData KGSTOCKGEARSAna Gabriela OjedaAinda não há avaliações

- Table For Gear DrawingDocumento1 páginaTable For Gear DrawingprasannaAinda não há avaliações

- Bearing Stress AnalysisDocumento7 páginasBearing Stress Analysisrahulmenon995030Ainda não há avaliações

- GdaDocumento3 páginasGdareinaldosidejuniorAinda não há avaliações

- Shaft StabilityDocumento2 páginasShaft StabilityPradeep SarodeAinda não há avaliações

- Measuring Helix Angle of GearsDocumento6 páginasMeasuring Helix Angle of Gearsdarshan.hegdebAinda não há avaliações

- Trocoide Thurman PDFDocumento4 páginasTrocoide Thurman PDFmgualdiAinda não há avaliações

- Shaft - Axial - Xls Radius Transition or Undercut Between Diameters?Documento2 páginasShaft - Axial - Xls Radius Transition or Undercut Between Diameters?Pradeep SarodeAinda não há avaliações

- Spur & Helical Backlash ChartDocumento2 páginasSpur & Helical Backlash ChartRaji SuriAinda não há avaliações

- Mode Shape Frequency (HZ.) Speed (RPM)Documento3 páginasMode Shape Frequency (HZ.) Speed (RPM)tooocooolAinda não há avaliações

- Norma de Tallado y Acanalado de EngranajesDocumento7 páginasNorma de Tallado y Acanalado de EngranajesJohn Walter RodriguezAinda não há avaliações

- Gear Design CalcDocumento2 páginasGear Design Calcomprakashd4196Ainda não há avaliações

- Machine Design & Drawing - II - GEARSDocumento12 páginasMachine Design & Drawing - II - GEARSSenthil KumarAinda não há avaliações

- Smoothing Properties of Convex Functions: Time Varying DemandDocumento16 páginasSmoothing Properties of Convex Functions: Time Varying DemandMichaelAinda não há avaliações

- Shaft DesignDocumento2 páginasShaft DesignRamji RaoAinda não há avaliações

- Brake Calculation SheetDocumento2 páginasBrake Calculation SheetvijayAinda não há avaliações

- Tolerance SheetDocumento76 páginasTolerance SheetprasannaAinda não há avaliações

- RP11LDocumento18 páginasRP11Lمحمد جوادAinda não há avaliações

- Fatica Oligociclica PDFDocumento116 páginasFatica Oligociclica PDFPaoloPetraglia100% (1)

- Shaft Design - Overheads PDFDocumento20 páginasShaft Design - Overheads PDFRyan BaleAinda não há avaliações

- A Procedure To Determine The Unknown Geometry of External Cylindrical Gears - Gear Solutions Magazine Your Resource To The Gear IndustryDocumento11 páginasA Procedure To Determine The Unknown Geometry of External Cylindrical Gears - Gear Solutions Magazine Your Resource To The Gear IndustryChetan PrajapatiAinda não há avaliações

- Cycloid Drive - Replaced by Planocentric Involute GearingDocumento6 páginasCycloid Drive - Replaced by Planocentric Involute GearingMax GrandeAinda não há avaliações

- Equations For The Design of Standard Sprocket TeethDocumento4 páginasEquations For The Design of Standard Sprocket TeethvanjaurkeAinda não há avaliações

- Spur Gear, Helical Gear Design Step Final1Documento2 páginasSpur Gear, Helical Gear Design Step Final1Venkadesh ShanmugamAinda não há avaliações

- Design of Bevel GearDocumento9 páginasDesign of Bevel GearMarkHualdaAinda não há avaliações

- On Shrink Fit Analysis and DesignDocumento10 páginasOn Shrink Fit Analysis and DesignParag NaikAinda não há avaliações

- Calculation WorksheetDocumento1 páginaCalculation WorksheetValium MorphineAinda não há avaliações

- Elemen Mesin-AGMA-4-9-19Documento5 páginasElemen Mesin-AGMA-4-9-19M. Haekal AriandanilAinda não há avaliações

- Spur - Gears - Metric - XLS: Tooth Normal ForceDocumento5 páginasSpur - Gears - Metric - XLS: Tooth Normal ForceTigistuAinda não há avaliações

- Bearings Simply Supported ShaftDocumento8 páginasBearings Simply Supported ShaftRiyazuddin MahamadAinda não há avaliações

- Various Hardening Processes of GearsDocumento32 páginasVarious Hardening Processes of GearsYash VermaAinda não há avaliações

- M 452 ContentDocumento63 páginasM 452 ContentprasannaAinda não há avaliações

- AGMA Pitting Geometry FactorDocumento1 páginaAGMA Pitting Geometry FactormgualdiAinda não há avaliações

- LiftingLugStress Rev 1.5Documento17 páginasLiftingLugStress Rev 1.5mohdshakir bahariAinda não há avaliações

- Design Calculation of Worm and Worm Gear Endurance StrengthDocumento9 páginasDesign Calculation of Worm and Worm Gear Endurance StrengthVenkateswaran venkateswaranAinda não há avaliações

- Formulas in GearingDocumento102 páginasFormulas in GearingKeo Dính Chuột100% (1)

- 0.75kW - 1750rpmDocumento1 página0.75kW - 1750rpmanush_swaminathanAinda não há avaliações

- Optimization of Gear Reduction Unit Through Ray DiagramDocumento7 páginasOptimization of Gear Reduction Unit Through Ray Diagramأحمد دعبس100% (1)

- MItcal - Ejemplo de ClaseDocumento102 páginasMItcal - Ejemplo de ClasedaagiraldogoAinda não há avaliações

- Universidad Tecnológica Equinoccial: Facultad de Ciencias de La Ingeniería E IndustriasDocumento20 páginasUniversidad Tecnológica Equinoccial: Facultad de Ciencias de La Ingeniería E IndustriasErick DavidAinda não há avaliações

- Gorki 3Documento26 páginasGorki 3Shushay GebreyesusAinda não há avaliações

- Helical Gear Basic PDFDocumento13 páginasHelical Gear Basic PDFCarlosQuelartAinda não há avaliações

- Chiaravalli Timing Pulleys 2016 MAK PDFDocumento100 páginasChiaravalli Timing Pulleys 2016 MAK PDFer_winwibowoAinda não há avaliações

- Fuerzas de EmpotramientoDocumento2 páginasFuerzas de EmpotramientoDavid Fernando Mancilla GalánAinda não há avaliações

- Tooth ThicknessDocumento9 páginasTooth ThicknessPraveen VundrajavarapuAinda não há avaliações

- Worm GearDocumento3 páginasWorm Gearprasaad08Ainda não há avaliações

- CFturbo enDocumento184 páginasCFturbo enDefinal ChaniagoAinda não há avaliações

- TechnicalData KGSTOCKGEARS PDFDocumento171 páginasTechnicalData KGSTOCKGEARS PDFChetan PrajapatiAinda não há avaliações

- Mdesign 2016 Gears Verzahnungen en PDFDocumento86 páginasMdesign 2016 Gears Verzahnungen en PDFmgualdiAinda não há avaliações

- Design and Study of Helical Gears2Documento24 páginasDesign and Study of Helical Gears2AmjathAinda não há avaliações

- Imo - No DWT LBP LOA Beam Draft DepthDocumento42 páginasImo - No DWT LBP LOA Beam Draft DepthHimanshu RanjanAinda não há avaliações

- Tedata: Programm Benutzer Datum Kunde Proj. NRDocumento3 páginasTedata: Programm Benutzer Datum Kunde Proj. NRJason CanoAinda não há avaliações

- Caja Reductora 2da EtapaDocumento2 páginasCaja Reductora 2da EtapaEdwin Paco PovedaAinda não há avaliações

- Not For Commercial Use: TedataDocumento3 páginasNot For Commercial Use: TedataMayber DelgadoAinda não há avaliações

- Not For Commercial Use: TedataDocumento2 páginasNot For Commercial Use: Tedatawilly rojas zeballosAinda não há avaliações

- AcousticsDocumento7 páginasAcousticscancan25Ainda não há avaliações

- Maths Grade 9 Ujian SekoahDocumento10 páginasMaths Grade 9 Ujian SekoahKopi LuwakAinda não há avaliações

- R. Angeline Prabha & J.Lavina Mary: Jacsi College of Engg. NazarethDocumento17 páginasR. Angeline Prabha & J.Lavina Mary: Jacsi College of Engg. NazarethRose EdwardAinda não há avaliações

- RKB Bearing Tolerances and Radial Internal ClearancesDocumento36 páginasRKB Bearing Tolerances and Radial Internal ClearancesCAT CYLINDERAinda não há avaliações

- Year 6 - EclipsesDocumento7 páginasYear 6 - EclipsesHani BakarAinda não há avaliações

- Projectile MotionDocumento6 páginasProjectile MotionArseniojakejr FloresAinda não há avaliações

- Stats&Prob - WEEK 1Documento3 páginasStats&Prob - WEEK 1Ji PaoAinda não há avaliações

- MAX30101 High-Sensitivity Pulse Oximeter and Heart-Rate Sensor For Wearable HealthDocumento35 páginasMAX30101 High-Sensitivity Pulse Oximeter and Heart-Rate Sensor For Wearable HealthLeonardo NiñoAinda não há avaliações

- Rabia7 Base 28.02 EmbedDocumento7 páginasRabia7 Base 28.02 EmbedvengadAinda não há avaliações

- Derrick Scott Van Heerden - Mathemagical Music Scales, 2013Documento54 páginasDerrick Scott Van Heerden - Mathemagical Music Scales, 2013Tiago Ramos100% (1)

- Pushin Fitting PDFDocumento4 páginasPushin Fitting PDFvishal.nithamAinda não há avaliações

- Zdorovye - The Means To PrepareDocumento4 páginasZdorovye - The Means To PrepareBrett DrinkwaterAinda não há avaliações

- Chapter 4 - Drains and SwalesDocumento23 páginasChapter 4 - Drains and SwalesFadhlullah Abu Bakar100% (1)

- CBSE Previous Year Question Papers Class 12 Maths Set 1 2018 Marking Scheme PDFDocumento15 páginasCBSE Previous Year Question Papers Class 12 Maths Set 1 2018 Marking Scheme PDFNavsAinda não há avaliações

- Worm GearsDocumento31 páginasWorm GearsYose MustAinda não há avaliações

- PLL - 1323 - Low Speed, High Torque Motors EatonDocumento294 páginasPLL - 1323 - Low Speed, High Torque Motors EatonWilmer Huaman PasaperaAinda não há avaliações

- PC PilesDocumento12 páginasPC PilesBobby SetiawanAinda não há avaliações

- How To Design and Build A Combat RobotDocumento14 páginasHow To Design and Build A Combat RobotBenjie Pasagdan MagallanoAinda não há avaliações

- Basic Data Viper40 15066 enDocumento10 páginasBasic Data Viper40 15066 enArmando RiveraAinda não há avaliações

- 13chapter STEEL-CONCRETE COMPOSITE STRUCTURAL MEMBERSDocumento23 páginas13chapter STEEL-CONCRETE COMPOSITE STRUCTURAL MEMBERSTarif Aziz MarufAinda não há avaliações

- BC 559 CDocumento7 páginasBC 559 CAndy SanchezAinda não há avaliações

- Chapter 4. Translational Equilibrium and Friction.: Free-Body DiagramsDocumento16 páginasChapter 4. Translational Equilibrium and Friction.: Free-Body DiagramsAlma GalvànAinda não há avaliações

- Iec 60794-1-22Documento80 páginasIec 60794-1-22Pablo DaitaAinda não há avaliações

- Lab Report Process Control - Flow Measure PDFDocumento23 páginasLab Report Process Control - Flow Measure PDFcleytonmarques1991100% (1)

- Koyo Oil SealDocumento119 páginasKoyo Oil Sealvicksgeorge100% (1)

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocumento8 páginasTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungAinda não há avaliações

- Electronic Structure of The N-V Center in Diamond: ExperimentsDocumento14 páginasElectronic Structure of The N-V Center in Diamond: Experimentspranav1999Ainda não há avaliações

- Structural DynamicsDocumento213 páginasStructural DynamicsJaime Alberto Flores PeñaAinda não há avaliações

- CompressorDocumento63 páginasCompressorRajneesh Patel100% (1)