Escolar Documentos

Profissional Documentos

Cultura Documentos

Supply Chain Process of Jeans

Enviado por

Samarth TuliDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Supply Chain Process of Jeans

Enviado por

Samarth TuliDireitos autorais:

Formatos disponíveis

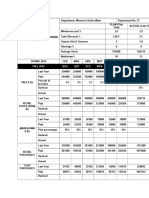

Supply chain for Mens Denim Jeans

Natural Eco- Systems Disrupted

Water Intensive Process Workers: Working Conditios(Chemicals Exposed)

Fossil Fuels For Farm Equipment

Cotton Growm( Raw Pesticides Chemical Fertilizer

Material Collection)

Energy

Workers ( Exposure To Cehmical Dust from Pesticide Residue)

Waste can be: Composed, or used as soil nutrients)

Refine Raw Cotton (

Process Cotton Gin)

Fabric s are treated with synthetic dyes such as sulfur and other chemicals

Dying mills use energy to process the chemicals

Waste such as excess water used in the process is disposed off

Cotton Raw Material Working Conditions: Workers are Once again Expoesed to Chemicals

Transprted to Dyeing

Mills

Figure A: Supply Chain- Raw material procurement to factory transportation

Fabric is then woven in the factory

Organic Pollutants produced are disposed off

Dyed Fabric

Woven

Fabric Rolls are sent to the cutting department wherein the fabric is cut based on markers

provided in the tech pak

Cut fabrics are bundled and segretated according to shade and are then sent to the sewing

Dyed Fabric ( department

Cutting Excess waste in the form of scraps are disposed off and stored away in case of order shortage

Department)

Tailors follow a progressive bundling system wherein each part is stitched and sent along the

line.

At the same time PP samples are made and sent for size set approval from technical managers in

the company and approval of the buyer

Bundled fabrics Juki machines are used for the stitching process.

are sent to the Waste such as excess water used in the process is disposed off

(sewing section) Organic Pollutants: Solid Waste

Copper Rivets: Cotton Thread

Bundled fabrics (Stitched) are washed according to the washing recipe as specified in the tech

pak

Stitched Fabrics Washing manager also makes sure garment is dryed before moving it on to the finisieding

sent (Washing department

Section)

Chemical sandblasting is done on the denim using silica

Waste is produced in the form of silica, pumice sandpaper etc.

Jeans Distressed

(Finishing_

Labels are attached to the stitched garment

Resources used- labels, buttons, washing labels etc.

Trims attached & Waste produced: excess plasti containers for the garment

packaging of Garment packed size wize/ratio wise as specified by the buyer and transported to warehouse

stitched garment

(finishing-2)

Figure B: Supply Chain- Process flow chart in the factory

Finished garment sent to warehouses via shipping or other means of transport

Transportation

(Finished garment

to warehouse)

Goods are transferred from warehouses to various intermediaries such as retailers

Second/third grade garments are shipped off to other countries or are sold whrough

Warehouse wholesalers/ factory outlets

transportation to

various

intermiediaries))

Some garments produced are donated to charities, churches to generate goodwill for the

brand

Donations to social

needs group/

As the garment enters it penultimate phase in the life cycle, it may be recycled for making

into a new product, prior to which it is dispoed off at a landfill

Recycle garments/ It may also be recycled into a new product after waste is procured from landfill.

Reuse garments

Figure C: Supply Chain- Process flow chart in the from warehouse to decline phase in product life cycle

Você também pode gostar

- KBC Nano in English PDFDocumento57 páginasKBC Nano in English PDFBHUKKAD BOX100% (1)

- Durex CondomsDocumento37 páginasDurex CondomsAlexandra VamanuAinda não há avaliações

- K. Deergha Rao - Signals and Systems (2018, Birkhäuser) - 2Documento434 páginasK. Deergha Rao - Signals and Systems (2018, Birkhäuser) - 2Eugenie medaAinda não há avaliações

- Presented By: Rohan.J BFT/15/314: Project-Quality Control in Sewing Department by Increasing Pass Percentage of GarmentsDocumento55 páginasPresented By: Rohan.J BFT/15/314: Project-Quality Control in Sewing Department by Increasing Pass Percentage of GarmentsRohan JetlingAinda não há avaliações

- Plant Layout - IDocumento16 páginasPlant Layout - ITanya rajAinda não há avaliações

- Understanding The Global Apparel Manufacturing ProcessDocumento18 páginasUnderstanding The Global Apparel Manufacturing Processyasin husen100% (1)

- # What Is Industrial Engineering ?Documento27 páginas# What Is Industrial Engineering ?Shahin MahmudAinda não há avaliações

- Denim Bottom: Textile Merchadising and Marketing Akmal JavedDocumento9 páginasDenim Bottom: Textile Merchadising and Marketing Akmal JavedAkmal JavedAinda não há avaliações

- National Institute of Fashion Technology: HyderabadDocumento40 páginasNational Institute of Fashion Technology: HyderabadGreeshmaAinda não há avaliações

- Apparel Quality ManagementDocumento24 páginasApparel Quality ManagementManish GuptaAinda não há avaliações

- Industrial EngineeringDocumento32 páginasIndustrial Engineeringpradeep_vsp1077100% (1)

- Productivity in Apparel ManufacturingDocumento7 páginasProductivity in Apparel ManufacturingAmar Nath PrasadAinda não há avaliações

- Product Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem ViiDocumento29 páginasProduct Analysis and Developement: Presented by Parul Vashist Divya Rani DFT Sem Viimaduvats100% (1)

- Time and Action CalendarDocumento6 páginasTime and Action CalendarnidhisanjeetAinda não há avaliações

- AQM II Nikita (BFT17143)Documento42 páginasAQM II Nikita (BFT17143)Shivani JayanthAinda não há avaliações

- Factory Report 2Documento6 páginasFactory Report 2Chen Wei Sassei-KetsuAinda não há avaliações

- Standardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Documento8 páginasStandardization of Apparel Manufacturing Industry Focusing On "Cutting Section"Anish RajAinda não há avaliações

- Advanced Apparel Manufacturing ManagementDocumento27 páginasAdvanced Apparel Manufacturing ManagementPrachi YashAinda não há avaliações

- Fast React Evolve Case Study MaduraDocumento2 páginasFast React Evolve Case Study MaduraNt93100% (1)

- Arvind Limited, Electronic City, Bangalore: Nift KolkataDocumento50 páginasArvind Limited, Electronic City, Bangalore: Nift KolkataDurbar DasguptaAinda não há avaliações

- General Steucture of Denim Garment UnitDocumento17 páginasGeneral Steucture of Denim Garment UnitumairvmdAinda não há avaliações

- Apparel Industrial EngineeringDocumento4 páginasApparel Industrial EngineeringkbalabalaAinda não há avaliações

- Session 2 - Apparel Production SystemsDocumento25 páginasSession 2 - Apparel Production SystemsPuja PrasadAinda não há avaliações

- Mesauring EfficiencyDocumento7 páginasMesauring EfficiencySaurabh SumanAinda não há avaliações

- TLS PDFDocumento36 páginasTLS PDFAmrita KhatriAinda não há avaliações

- Calendar Plan For An Export HouseDocumento8 páginasCalendar Plan For An Export HouseAditi JindalAinda não há avaliações

- IE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoDocumento3 páginasIE SOP - Standard Operating Procedure of Industrial Engineering Department - Garments-InfoSayed Aasim JawaidAinda não há avaliações

- Pre-Production Process Production Process Post-Production ProcessDocumento2 páginasPre-Production Process Production Process Post-Production ProcessDevjyoti ShawAinda não há avaliações

- Production Planning 18 StepsDocumento19 páginasProduction Planning 18 StepsFaraz AliAinda não há avaliações

- Plant Layout Assignment 1Documento12 páginasPlant Layout Assignment 1Debdeep GhoshAinda não há avaliações

- Thread Consumption MethodsDocumento5 páginasThread Consumption MethodsRejaal100% (1)

- 5 I.E - Problems & SolutionsDocumento29 páginas5 I.E - Problems & Solutionsghosh71Ainda não há avaliações

- Cut Order PlanningDocumento2 páginasCut Order Planningarunkadve100% (1)

- Aqm Case StudyDocumento10 páginasAqm Case StudyrishiAinda não há avaliações

- Section - I Company Overview: Aquarelle India Pvt. LTDDocumento79 páginasSection - I Company Overview: Aquarelle India Pvt. LTDShivasrri SethuramanAinda não há avaliações

- Fashion Merchandising: Orient Craft Limited, ManesarDocumento10 páginasFashion Merchandising: Orient Craft Limited, Manesarjawed_akhtar100% (3)

- H and M Quality Standards and RequiremenDocumento16 páginasH and M Quality Standards and RequiremenAmisha SinghAinda não há avaliações

- Spreading and Cutting - Material PDFDocumento27 páginasSpreading and Cutting - Material PDFSowmya50% (4)

- Diploma in Apparel Merchandising (LANKA CLOTHING)Documento23 páginasDiploma in Apparel Merchandising (LANKA CLOTHING)shahdhk100% (1)

- Knit Asia Operation ProcessDocumento12 páginasKnit Asia Operation ProcessParvezMridhaAinda não há avaliações

- Apparel Internship atDocumento32 páginasApparel Internship atdipalimodiAinda não há avaliações

- Preparatory Apparel Production ProcessDocumento151 páginasPreparatory Apparel Production ProcessNesar Ahmad Shaown100% (1)

- Sewing Defects in Apparel IndustryDocumento3 páginasSewing Defects in Apparel IndustryMadhavi Ajay NagarAinda não há avaliações

- Product Analysis and Development Assignment 1Documento33 páginasProduct Analysis and Development Assignment 1yaswanthAinda não há avaliações

- Cutting Room Planning: ATDC, BhubaneswarDocumento37 páginasCutting Room Planning: ATDC, BhubaneswarBinoy MundaAinda não há avaliações

- Garment ProcessingDocumento35 páginasGarment ProcessingKeshav Dhawan0% (1)

- 18.estimating Thread ConsumptionDocumento4 páginas18.estimating Thread ConsumptionSugar Lipss0% (1)

- Chapter One PDFDocumento24 páginasChapter One PDFKibromGereAinda não há avaliações

- Marketing Activities of MerchandiserDocumento49 páginasMarketing Activities of MerchandiserzahidAinda não há avaliações

- Apparel Manufacturing - An Overview OverviewDocumento16 páginasApparel Manufacturing - An Overview Overviewmmiks2008Ainda não há avaliações

- Naisargi SCAP End TermDocumento11 páginasNaisargi SCAP End TermNaisargiAinda não há avaliações

- Sampling DepttDocumento72 páginasSampling DepttAron SolankiAinda não há avaliações

- Wip PDFDocumento29 páginasWip PDFEruAinda não há avaliações

- Production Planning and Control in GarmentsDocumento2 páginasProduction Planning and Control in Garmentskbalabala100% (1)

- Implementation of Lean Manufacturing Tools in Garment Manufacturing Process Focusing Sewing Section of Men's ShirtDocumento80 páginasImplementation of Lean Manufacturing Tools in Garment Manufacturing Process Focusing Sewing Section of Men's ShirtAdnan HameedAinda não há avaliações

- Sample Room DepartmentDocumento5 páginasSample Room DepartmentRajib DasAinda não há avaliações

- Knitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1Documento25 páginasKnitwear Technology (Cutting & Sewing) - APM 7402 - Note Book-1shahinrezaAinda não há avaliações

- 1c. Cutting TrainingDocumento1 página1c. Cutting Trainingjahazi1Ainda não há avaliações

- Spreading and Cutting HandoutDocumento7 páginasSpreading and Cutting HandoutAlemu HaileAinda não há avaliações

- Carr and Latham's Technology of Clothing ManufactureNo EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerNota: 4 de 5 estrelas4/5 (1)

- Pollution Prevention and Cleaner Technology in Textile IndustryDocumento18 páginasPollution Prevention and Cleaner Technology in Textile IndustryPratik DeogekarAinda não há avaliações

- Material SourcingDocumento16 páginasMaterial Sourcingvishnuvardhinikj0% (1)

- The Evolution of TOYOTA Production SystemDocumento21 páginasThe Evolution of TOYOTA Production SystemSamarth TuliAinda não há avaliações

- Questions - Cost of Capital - 30th Oct 2017Documento2 páginasQuestions - Cost of Capital - 30th Oct 2017Samarth TuliAinda não há avaliações

- AQM JuryDocumento12 páginasAQM JurySamarth TuliAinda não há avaliações

- Strategy Assignment - SammarthDocumento17 páginasStrategy Assignment - SammarthSamarth TuliAinda não há avaliações

- Literature ReviewDocumento4 páginasLiterature ReviewSamarth TuliAinda não há avaliações

- Fashion Merchandising A Case On Visual Merchandising The Silent Salesperson ..Documento9 páginasFashion Merchandising A Case On Visual Merchandising The Silent Salesperson ..Samarth TuliAinda não há avaliações

- CB 4Documento6 páginasCB 4Samarth TuliAinda não há avaliações

- Professional Practices Assignment - Ii: Dr. Sanjeev Sadashiv Malage Associate Professor, MFMDocumento24 páginasProfessional Practices Assignment - Ii: Dr. Sanjeev Sadashiv Malage Associate Professor, MFMSamarth TuliAinda não há avaliações

- Intellectual Property Rights Assignment 3: Department of Fashion Management StudiesDocumento11 páginasIntellectual Property Rights Assignment 3: Department of Fashion Management StudiesSamarth TuliAinda não há avaliações

- A Comparative Study of Consumer Behaviour of Factory and Exclusive Brand Outlets of NIKE in Bangalore City With Respect To FootwearDocumento2 páginasA Comparative Study of Consumer Behaviour of Factory and Exclusive Brand Outlets of NIKE in Bangalore City With Respect To FootwearSamarth TuliAinda não há avaliações

- Fit Customization-3D Body Scanning SystemDocumento5 páginasFit Customization-3D Body Scanning SystemSamarth TuliAinda não há avaliações

- 6 Month Merchandising Buiyng PlanDocumento2 páginas6 Month Merchandising Buiyng PlanSamarth TuliAinda não há avaliações

- Fashion Marketing Management, MFM - Semester - IDocumento3 páginasFashion Marketing Management, MFM - Semester - ISamarth TuliAinda não há avaliações

- Texile TestingDocumento27 páginasTexile TestingSamarth TuliAinda não há avaliações

- Critical Reasoning Lessons LearnedDocumento1 páginaCritical Reasoning Lessons LearnedSamarth TuliAinda não há avaliações

- National Institute of Fashion TechnologyDocumento4 páginasNational Institute of Fashion TechnologySamarth TuliAinda não há avaliações

- Store NameDocumento5 páginasStore NameSamarth TuliAinda não há avaliações

- Assignment For Pattern MakingDocumento8 páginasAssignment For Pattern MakingSamarth TuliAinda não há avaliações

- Adidas FinalDocumento22 páginasAdidas FinalSamarth TuliAinda não há avaliações

- Buying PlanDocumento26 páginasBuying PlanSamarth TuliAinda não há avaliações

- Session 8-Case Studies On CSR Policy and Conflicts PDFDocumento23 páginasSession 8-Case Studies On CSR Policy and Conflicts PDFSamarth TuliAinda não há avaliações

- Acknowledgements: Godrej & Boyce MFG - Co.LtdDocumento83 páginasAcknowledgements: Godrej & Boyce MFG - Co.LtdSamarth TuliAinda não há avaliações

- Demand Forecasting in The Fashion Industry: A ReviewDocumento6 páginasDemand Forecasting in The Fashion Industry: A ReviewSamarth TuliAinda não há avaliações

- Lab 1: Basic Cisco Device Configuration: Topology DiagramDocumento17 páginasLab 1: Basic Cisco Device Configuration: Topology DiagramnhiAinda não há avaliações

- 15 Oil Fired Crucible FurnaceDocumento2 páginas15 Oil Fired Crucible Furnaceudaya kumarAinda não há avaliações

- Catalogue MV 07Documento54 páginasCatalogue MV 07api-3815405100% (3)

- SFP Module PDFDocumento2 páginasSFP Module PDFMario PatarroyoAinda não há avaliações

- Aiwa RM-77 Service ManualDocumento9 páginasAiwa RM-77 Service Manualcristianhumberto_reyesaguileraAinda não há avaliações

- Guideline On Smacna Through Penetration Fire StoppingDocumento48 páginasGuideline On Smacna Through Penetration Fire Stoppingwguindy70Ainda não há avaliações

- Improvements in Offshore Pipeline Cathodic ProtectionDocumento6 páginasImprovements in Offshore Pipeline Cathodic ProtectionEddy Norman Benites DelgadoAinda não há avaliações

- ST 010 ISBT 128 Standard Product Description Code Database v6.0.0Documento34 páginasST 010 ISBT 128 Standard Product Description Code Database v6.0.0Patrick Ramos100% (1)

- History of HypnosisDocumento3 páginasHistory of Hypnosisbutterfly975k100% (1)

- TOR of The Feasibility Study of Crop RecommendationDocumento6 páginasTOR of The Feasibility Study of Crop RecommendationGangadhar ChaudharyAinda não há avaliações

- 28L059 PDFDocumento9 páginas28L059 PDFone_blanche6175Ainda não há avaliações

- Building Information Modeling BIM Systems and TheiDocumento13 páginasBuilding Information Modeling BIM Systems and Theipurvakul10Ainda não há avaliações

- ALL SYSTEMS GO by Zenovia AndrewsDocumento225 páginasALL SYSTEMS GO by Zenovia AndrewsTanya Gillie100% (3)

- Advantages of Group Decision MakingDocumento1 páginaAdvantages of Group Decision MakingYasmeen ShamsiAinda não há avaliações

- Mca Voice Morphing ReportDocumento4 páginasMca Voice Morphing Reportmango sravanreddyAinda não há avaliações

- Digital Data, Digital SignalDocumento8 páginasDigital Data, Digital SignalBastomi Adi NugrohoAinda não há avaliações

- EE 303 Tutorial 1Documento19 páginasEE 303 Tutorial 1Syama SameekshaAinda não há avaliações

- Aspect Oriented ArchitectureDocumento43 páginasAspect Oriented ArchitectureerzhanbaiAinda não há avaliações

- Petronas Technical Standards: Symbols and Identification System - MechanicalDocumento16 páginasPetronas Technical Standards: Symbols and Identification System - MechanicalUdaya Zorro100% (1)

- Chopra Scm5 Ch13Documento58 páginasChopra Scm5 Ch13Faried Putra SandiantoAinda não há avaliações

- Omni PageDocumento98 páginasOmni Pageterracotta2014Ainda não há avaliações

- Retail Generation ZDocumento24 páginasRetail Generation ZSomanAinda não há avaliações

- Guidelines For Layout and Format of The Proposal: 1. Page Margins (For All Pages) - Use A4 Size PaperDocumento3 páginasGuidelines For Layout and Format of The Proposal: 1. Page Margins (For All Pages) - Use A4 Size PaperAummy CreationAinda não há avaliações

- Iphone App DevelopmentDocumento18 páginasIphone App DevelopmentVinay BharadwajAinda não há avaliações

- CMP Tutorial PDFDocumento83 páginasCMP Tutorial PDFMax HaroutunianAinda não há avaliações

- History of Gun PowderDocumento32 páginasHistory of Gun PowderHerbert GongonAinda não há avaliações

- Pharma MarketingDocumento55 páginasPharma MarketingArpan KoradiyaAinda não há avaliações

- Void Acoustics 2017 BrochureDocumento28 páginasVoid Acoustics 2017 BrochureCraig ConnollyAinda não há avaliações