Escolar Documentos

Profissional Documentos

Cultura Documentos

Characterization of Methyl Ester Compound of Biodiesel From Industrial Liquid Waste of Crude Palm Oil Processing

Enviado por

rahmanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Characterization of Methyl Ester Compound of Biodiesel From Industrial Liquid Waste of Crude Palm Oil Processing

Enviado por

rahmanDireitos autorais:

Formatos disponíveis

Kelompok 8 (Kelas C Kamis Pagi)

Anggota Kelompok :

Lisa Adrina Pratiwi (21030117120046)

Muhammad Miftahur Rahman (21030117120055)

Belly Purgito (21030117130122)

Dio Dwi Saputra (210301371

Characterization of methyl ester compound of biodiesel from industrial liquid waste of crude

palm oil processing

The need for fuels increases along with the development of industry and population in

Indonesia. The greates fuel consumption in the sector of transportation. But, the use of fossil based

fuel is not considered environmentally friendly because it boosts the concentration of carbon dioxide (

CO2). This gas triggers greenhouse effect that contributions of global warming. For these reason, the

development of alternative energy resources should be carried out to substitute diesel- based fuel. One

alternative energy resource which is widely developed is biodiesel. Biodiesel ( methyl ester ) is an

option proposed to substitute fuel based fuel because it is vegetable oil- based fuel which is renewable

and environmentally friendly. Compared to other fuel, biodiesel is biodegradable and non toxic; it

also has low CO2 emission and sulfuric gas content.

Liquid waste of palm oil is one of the renewable raw materials of biodiesel. The great amount

of palm oil liquid waste within palm oil processing is considered as environmental pollution; inspite

of that fact, it is a quite potential raw material to be processed as vegetable based fuel which is

economical in price and sumptuous in supply. Direct use of vegetable oil as the fuel of dielsel

( biodiesel) still exhibits a weakness in term of its higher viscosity than diesel petroleum. This high

viscosity of vegetable oil disturbs the process of injection and atomization of fuel. To overcome these

problems, the process of converting vegetable oil into methy - ester through the transesterification

prosess with catalyst should be carried out.

Transesterification process can be carried out by using homogenous, heterogeneous, or

enzymatic catalyst. Homogenous catalyst is a catalyst with the same phase as its catalyst reagent,

while the heterogeneous catalyst is a catalyst with different phase to its reagent. The iseof

homogenous catalyst such as sodium hydroxide (NaOH) and potassium hydroxide (KOH) is more

effective than heterogeneous catalyst. In addition to that, liquid catalyst used to produce biodiesel is

corrosive and not reusable.

Enzymatic catalyst in transesterification is one of the alternative methods since enzyme can

broaden the reaction rate than the usual reaction. Transesterification reaction makes use of an enzyme

that can work in low temperature and produce high, environmentally friendly methyl ester yield.

Enzymatic catalyst is used in esterification and transesterification to produce methyl ester. Many

recent researches use heterogeneous catalyst since it is more economical, easily separated, reusable,

and non corrosive.

Potassium oxide (CaO) catalyst is an alkaline earth metaloxide catalyst which is quite

potential to be developed because it has good activities and produces an optimal yield of biodiesel

in soy oil. Therefore, this study attempted to process liquidwaste of palm oil through the esterification

process using sulfuricacid (H2SO4) and transesterfication process using CaO catalyst.

It is advised to do further research about the content of the palm oil waste in order to produce

a high quality methyl ester product, a while using a more efficient catalyst.

Você também pode gostar

- Physical and Chemical Equilibrium For Chemical Engineers - N. de NeversDocumento197 páginasPhysical and Chemical Equilibrium For Chemical Engineers - N. de NeversWilliamAinda não há avaliações

- Production of Biodiesel From Used Cooking OilDocumento7 páginasProduction of Biodiesel From Used Cooking OilDennis OrlandoAinda não há avaliações

- Introduction To Petroleum Refinery OperationsDocumento12 páginasIntroduction To Petroleum Refinery Operationsvinhlhd83% (6)

- Biodiseal Cooked OilDocumento4 páginasBiodiseal Cooked OildineshlathiaAinda não há avaliações

- (BP Process Safety Series) BP Safety Group-Safe Furnace and Boiler Firing-Institution of Chemical Engineers (IChemE) (2005)Documento86 páginas(BP Process Safety Series) BP Safety Group-Safe Furnace and Boiler Firing-Institution of Chemical Engineers (IChemE) (2005)William Villarreal100% (6)

- Datasheet Industrial 501 Kb7sDocumento2 páginasDatasheet Industrial 501 Kb7sNebojsa100% (1)

- Api RP 5a3Documento4 páginasApi RP 5a3maruc08100% (1)

- 01 TK 205 Process Flow Diagram 01Documento15 páginas01 TK 205 Process Flow Diagram 01rahman100% (1)

- A Second Generation Biofuel PDFDocumento11 páginasA Second Generation Biofuel PDFNoviAinda não há avaliações

- Eastman Gasification OverviewDocumento64 páginasEastman Gasification OverviewAdy PrasetyoAinda não há avaliações

- LC-MAX and Other LC-FINING Process Enhancements to Extend Conversion and On-stream FactorDocumento16 páginasLC-MAX and Other LC-FINING Process Enhancements to Extend Conversion and On-stream FactorMarisol OjedaAinda não há avaliações

- INGAA - Natural Gas Pipelines Briefing BookDocumento164 páginasINGAA - Natural Gas Pipelines Briefing Bookmacen23Ainda não há avaliações

- Conversion of Waste Cooking Oil To Biodiesel: Chemistry Department, SMDRSD College Pathankot, 145001, IndiaDocumento14 páginasConversion of Waste Cooking Oil To Biodiesel: Chemistry Department, SMDRSD College Pathankot, 145001, Indiaferry merryAinda não há avaliações

- Applied Energy: Fengxian Qiu, Yihuai Li, Dongya Yang, Xiaohua Li, Ping SunDocumento6 páginasApplied Energy: Fengxian Qiu, Yihuai Li, Dongya Yang, Xiaohua Li, Ping Sunsureshm_raj5434Ainda não há avaliações

- Optimization of Biodiesel Production From Palm OilDocumento3 páginasOptimization of Biodiesel Production From Palm OilNthabiseng Mo MalukeAinda não há avaliações

- Biodiesel Production from Waste Cooking OilDocumento6 páginasBiodiesel Production from Waste Cooking OilSaya Redha100% (1)

- Conversion of Waste Cooking Oil Into BiodieselDocumento48 páginasConversion of Waste Cooking Oil Into BiodieselMUHAMMAD ADNANAinda não há avaliações

- Optimization of Biodiesel Synthesis Using Membrane Reactive DistillationDocumento5 páginasOptimization of Biodiesel Synthesis Using Membrane Reactive DistillationGanesh ShindeAinda não há avaliações

- Analytical Chemistry Research: Maulidiyah, Muhammad Nurdin, Fetty Fatma, Muh. Natsir, Dwiprayogo WibowoDocumento9 páginasAnalytical Chemistry Research: Maulidiyah, Muhammad Nurdin, Fetty Fatma, Muh. Natsir, Dwiprayogo WibowoOnime No IchinoseAinda não há avaliações

- Palm Oil 2Documento1 páginaPalm Oil 2rahmanAinda não há avaliações

- Talha Dan Sulaiman 2016Documento10 páginasTalha Dan Sulaiman 2016Alexander LiangAinda não há avaliações

- Bio-Diesel An Alternative Fuel For Compression Ignition Engines R MohantyDocumento6 páginasBio-Diesel An Alternative Fuel For Compression Ignition Engines R MohantyA S M Younus Bhuiyan SabbirAinda não há avaliações

- Solid Catalysts and Their Application in Biodiesel ProductionDocumento8 páginasSolid Catalysts and Their Application in Biodiesel ProductionUli AsariAinda não há avaliações

- Solid Catalyst Mat2012Documento8 páginasSolid Catalyst Mat2012pramuda sirodzAinda não há avaliações

- Comparison of Two Different Processes To SynthesizeDocumento6 páginasComparison of Two Different Processes To SynthesizeNestor Armando Marin SolanoAinda não há avaliações

- Biodiesel Refers To A Vegetable Oil-Or Animal Fat-Based Diesel Fuel Consisting of Long-Chain AlkylDocumento12 páginasBiodiesel Refers To A Vegetable Oil-Or Animal Fat-Based Diesel Fuel Consisting of Long-Chain AlkylClaroslava FrancoAinda não há avaliações

- Upgrading of Waste Oils Into Transportation Fuels Using Hydrotreating TechnologiesDocumento3 páginasUpgrading of Waste Oils Into Transportation Fuels Using Hydrotreating TechnologiesMarcelo MisutsuAinda não há avaliações

- Bio Diesel BuetDocumento7 páginasBio Diesel BuetTanjina azadAinda não há avaliações

- Biodiesel Production Research PaperDocumento8 páginasBiodiesel Production Research Paperafeawckew100% (1)

- PDF/ajassp 2011 804 809Documento6 páginasPDF/ajassp 2011 804 809Nadia Shahira Bt SaidiAinda não há avaliações

- Modeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking OilDocumento10 páginasModeling, Analysis and Optimization For The Biodiesel Production Process From Waste Cooking OilAdhisya Salma KhairunnisaAinda não há avaliações

- TK4104 Perancangan Produk KimiaDocumento3 páginasTK4104 Perancangan Produk Kimiaaridhiena nurbanieAinda não há avaliações

- Prodcciond e Biodiesel A Partir de Aceites Conn Altos Contenidos de Grasas SaturadasDocumento9 páginasProdcciond e Biodiesel A Partir de Aceites Conn Altos Contenidos de Grasas SaturadasNicolas LutkensAinda não há avaliações

- 2013 Optimization of Biodiesel ProductionDocumento7 páginas2013 Optimization of Biodiesel ProductionJ VAinda não há avaliações

- Varanda, Pinto, Martins - 2011 - Life Cycle Analysis of Biodiesel ProductionDocumento8 páginasVaranda, Pinto, Martins - 2011 - Life Cycle Analysis of Biodiesel ProductionJalcamAinda não há avaliações

- Solid Catalyst in Esterification and Transesterification Reactions For Biodiesel Production: A ReviewDocumento7 páginasSolid Catalyst in Esterification and Transesterification Reactions For Biodiesel Production: A ReviewMuhammad Husein HizbullahAinda não há avaliações

- Sdarticle6 With Cover Page v2Documento13 páginasSdarticle6 With Cover Page v2Tarun UppalaAinda não há avaliações

- Biodiesel Separation and Purification ReviewDocumento7 páginasBiodiesel Separation and Purification ReviewKarla SotoAinda não há avaliações

- Journal of The Taiwan Institute of Chemical EngineersDocumento7 páginasJournal of The Taiwan Institute of Chemical EngineersDian Rahmat YuneriAinda não há avaliações

- Solid Acid Catalyzed Biodiesel Production From Waste Cooking OilDocumento6 páginasSolid Acid Catalyzed Biodiesel Production From Waste Cooking OilMáximo Décimo MeridioAinda não há avaliações

- Utilization of Karanja Oil for Biodiesel ProductionDocumento5 páginasUtilization of Karanja Oil for Biodiesel ProductionMithila AkterAinda não há avaliações

- 2001 Canakci Biodiesel ProductionDocumento10 páginas2001 Canakci Biodiesel ProductionLeanne MartinAinda não há avaliações

- Production of Biodiesel From Waste Cooking Oil and Factors Affecting Its Formation: A ReviewDocumento7 páginasProduction of Biodiesel From Waste Cooking Oil and Factors Affecting Its Formation: A ReviewShashikanth MohrirAinda não há avaliações

- Geothermal Sludge Catalyst BiodieselDocumento3 páginasGeothermal Sludge Catalyst BiodieselReza Hendy DjoerkaeffAinda não há avaliações

- 1 s2.0 S0016236112002736 MainDocumento9 páginas1 s2.0 S0016236112002736 MainRiandy PutraAinda não há avaliações

- History and Production of BiodieselDocumento10 páginasHistory and Production of BiodieselgoddieAinda não há avaliações

- Research Proposal Computer - WORD-1Documento11 páginasResearch Proposal Computer - WORD-1Allycel ChiucoAinda não há avaliações

- Electro-Catalysis System For Biodiesel Synthesis From Palm Oil Over Dielectric-Barrier Discharge Plasma ReactorDocumento10 páginasElectro-Catalysis System For Biodiesel Synthesis From Palm Oil Over Dielectric-Barrier Discharge Plasma ReactorppnAinda não há avaliações

- Coconut Oil Biodiesel: Renewable Alternative Fuel for Diesel EnginesDocumento5 páginasCoconut Oil Biodiesel: Renewable Alternative Fuel for Diesel EnginesAde HadyAinda não há avaliações

- Literature Review On Production of BiodieselDocumento8 páginasLiterature Review On Production of Biodieselaixgaoqif100% (1)

- Producing Biodiesel from Avocado SeedsDocumento6 páginasProducing Biodiesel from Avocado SeedsAdilla PratiwiAinda não há avaliações

- Eng-Investigation On Biofuel Production Using Two-Ayoola AyodejiDocumento6 páginasEng-Investigation On Biofuel Production Using Two-Ayoola AyodejiImpact JournalsAinda não há avaliações

- Renewable Energy: SciencedirectDocumento8 páginasRenewable Energy: SciencedirectVignesh WarAinda não há avaliações

- 9 Art 9 PDFDocumento10 páginas9 Art 9 PDFVinoth Kumar VinsAinda não há avaliações

- 2 131 Acpi 2 (1) 2012 PDocumento7 páginas2 131 Acpi 2 (1) 2012 PBreKB MéndezAinda não há avaliações

- 1827 ApprovedpaperDocumento20 páginas1827 ApprovedpaperMahtab SajnaniAinda não há avaliações

- 29 Kapilan Natesh 1-3 (278-282)Documento5 páginas29 Kapilan Natesh 1-3 (278-282)Fitriani Indah LestariAinda não há avaliações

- Use of Waste Vegetable Oil As BiodieselDocumento11 páginasUse of Waste Vegetable Oil As BiodieselSherwin B. LutapAinda não há avaliações

- Seminar ReportDocumento15 páginasSeminar ReportDepepanshu MahajanAinda não há avaliações

- Thesis Biodiesel ProductionDocumento7 páginasThesis Biodiesel ProductionKelly Lipiec100% (2)

- Production of Biodiesel from Avocado Seed OilDocumento6 páginasProduction of Biodiesel from Avocado Seed OilKhairi Maulida AzhariAinda não há avaliações

- Biomass Conversion Routes: Seminar Course On Bioenergy (ESQ306)Documento12 páginasBiomass Conversion Routes: Seminar Course On Bioenergy (ESQ306)Ayush ChoubeyAinda não há avaliações

- ESD 1 Joprv22dec10-Puah1Documento7 páginasESD 1 Joprv22dec10-Puah1Kavi PriyanAinda não há avaliações

- MBTC 2092Documento44 páginasMBTC 2092clintoncAinda não há avaliações

- Lca For Palm BiodieselDocumento7 páginasLca For Palm BiodieselLai Mei EeAinda não há avaliações

- Biodiesel Assisnment Intro and Method..2Documento3 páginasBiodiesel Assisnment Intro and Method..2Paris RiazAinda não há avaliações

- Study On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDocumento7 páginasStudy On Biodiesel From Cotton Seed Oil by Using Heterogeneous Super Acid Catalyst So /zroDyshelly Nurkartika PascapurnamaAinda não há avaliações

- Accepted Manuscript: Chemical Engineering JournalDocumento43 páginasAccepted Manuscript: Chemical Engineering JournalRyan Eka JuniawanAinda não há avaliações

- Biodiesel Production from Used Cooking Oil: Business Advice & Training, #4No EverandBiodiesel Production from Used Cooking Oil: Business Advice & Training, #4Ainda não há avaliações

- New Doc 2018-12-06Documento11 páginasNew Doc 2018-12-06rahmanAinda não há avaliações

- Daftar Buku Kumpulan Buku Teknik KimiaDocumento2 páginasDaftar Buku Kumpulan Buku Teknik KimiarahmanAinda não há avaliações

- Daftar Buku Pustaka Ebook 2Documento4 páginasDaftar Buku Pustaka Ebook 2rahmanAinda não há avaliações

- Spray DryerDocumento1 páginaSpray DryerrahmanAinda não há avaliações

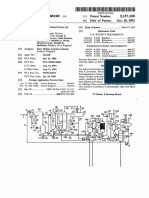

- Narrow distribution ethoxylated alcohols patentDocumento7 páginasNarrow distribution ethoxylated alcohols patentrahmanAinda não há avaliações

- US5157168 (Patent Fatty Alcohol)Documento29 páginasUS5157168 (Patent Fatty Alcohol)rahmanAinda não há avaliações

- RK RahmanDocumento1 páginaRK RahmanrahmanAinda não há avaliações

- Palm Oil 2Documento1 páginaPalm Oil 2rahmanAinda não há avaliações

- Msds Etanol 2005Documento7 páginasMsds Etanol 2005Puput Trisnayanti Inanto PutriAinda não há avaliações

- 2639 - Rekap Nilai TotalDocumento7 páginas2639 - Rekap Nilai TotalrahmanAinda não há avaliações

- Tugas Bahasa Inggris 1Documento2 páginasTugas Bahasa Inggris 1rahmanAinda não há avaliações

- 10 1016@j Cogsc 2017 03 010Documento5 páginas10 1016@j Cogsc 2017 03 010rahmanAinda não há avaliações

- Analytical Chemistry Research: Maulidiyah, Muhammad Nurdin, Fetty Fatma, Muh. Natsir, Dwiprayogo WibowoDocumento9 páginasAnalytical Chemistry Research: Maulidiyah, Muhammad Nurdin, Fetty Fatma, Muh. Natsir, Dwiprayogo WibowoFirda PratiwiAinda não há avaliações

- Tugas Bahasa Inggris 1Documento2 páginasTugas Bahasa Inggris 1rahmanAinda não há avaliações

- Chem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodheaDocumento16 páginasChem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodhearahmanAinda não há avaliações

- OkeeyDocumento2 páginasOkeeyrahmanAinda não há avaliações

- Msds Etanol 2005Documento7 páginasMsds Etanol 2005Puput Trisnayanti Inanto PutriAinda não há avaliações

- Benito 2015Documento13 páginasBenito 2015rahmanAinda não há avaliações

- Tugas Bahasa InggrisDocumento3 páginasTugas Bahasa InggrisrahmanAinda não há avaliações

- Chem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodheaDocumento16 páginasChem-E-Car Sefter Conception: Muhammad Miftahur Rahman Habib Al Aziz Fitri Handayani ArcodhearahmanAinda não há avaliações

- Chem-E-Car Sefter ConceptionDocumento16 páginasChem-E-Car Sefter ConceptionrahmanAinda não há avaliações

- 0 Oil and Gas - A HistoryDocumento62 páginas0 Oil and Gas - A HistoryGabriel Alva AnkrahAinda não há avaliações

- Absorption of CO2 in Aqueous DiglycolamineDocumento10 páginasAbsorption of CO2 in Aqueous DiglycolamineLê Vinh HảoAinda não há avaliações

- South ParsDocumento10 páginasSouth ParshbatesAinda não há avaliações

- Short Notes - SNGPLDocumento15 páginasShort Notes - SNGPLRana MubasherAinda não há avaliações

- Water Determination in Gases and LPG: KF MaxDocumento4 páginasWater Determination in Gases and LPG: KF MaxMohamed MosbahAinda não há avaliações

- Bala CVDocumento3 páginasBala CVMukesh RavalAinda não há avaliações

- Lab 3 Rock Mass AssesmentDocumento15 páginasLab 3 Rock Mass AssesmentAbhishek RayAinda não há avaliações

- Conversion of Fuel Data To MWHDocumento12 páginasConversion of Fuel Data To MWHdanferreiro8318Ainda não há avaliações

- Liquid FuelsDocumento26 páginasLiquid FuelsSHANE MABUGAYAinda não há avaliações

- IELTS Writing Task 1 SimonDocumento27 páginasIELTS Writing Task 1 SimonCanttall BhejotAinda não há avaliações

- Gail Investor PresentationDocumento31 páginasGail Investor Presentationsurya167Ainda não há avaliações

- De's Technico Pvt. Ltd. Company ProfileDocumento5 páginasDe's Technico Pvt. Ltd. Company ProfileSiddharth ChaudhuryAinda não há avaliações

- International Journal of Mineral Processing: Senol Cetinkaya, Serafettin ErogluDocumento3 páginasInternational Journal of Mineral Processing: Senol Cetinkaya, Serafettin ErogluMIzan NursiadiAinda não há avaliações

- Renewable Energy Advantages and DisadvantagesDocumento7 páginasRenewable Energy Advantages and Disadvantagesvlassis BaniAinda não há avaliações

- Argus Hydrogen and Future FuelsDocumento8 páginasArgus Hydrogen and Future FuelsAgung Kus SugihartoAinda não há avaliações

- Calorific Values of Solid and GaseousDocumento2 páginasCalorific Values of Solid and GaseouslaurosaitoAinda não há avaliações

- modelDDH - BD1 - MoynoDocumento2 páginasmodelDDH - BD1 - MoynoEdgar TellezAinda não há avaliações

- The Reactivity Series PDFDocumento17 páginasThe Reactivity Series PDFVictoria KairooAinda não há avaliações

- Chayvo Field - Sakhalin-1Documento5 páginasChayvo Field - Sakhalin-1bad dabAinda não há avaliações

- 2007 California Wildfires and Fire Agencies ReportDocumento1.260 páginas2007 California Wildfires and Fire Agencies ReportcashmoneybagsAinda não há avaliações

- 1638 120123-0915 OilDocumento82 páginas1638 120123-0915 OilEugene NikolaychukAinda não há avaliações

- PPTDocumento56 páginasPPTSulman ShahzadAinda não há avaliações

- GrrtyhvhDocumento20 páginasGrrtyhvhDebolina DasAinda não há avaliações