Escolar Documentos

Profissional Documentos

Cultura Documentos

Astm C 704 PDF

Enviado por

JeganeswaranTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Astm C 704 PDF

Enviado por

JeganeswaranDireitos autorais:

Formatos disponíveis

Designation: C704/C704M 12

Standard Test Method for

Abrasion Resistance of Refractory Materials at Room

Temperature1

This standard is issued under the fixed designation C704/C704M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon () indicates an editorial change since the last revision or reapproval.

1. Scope C865 Practice for Firing Refractory Concrete Specimens

1.1 This test method covers the determination of relative C1036 Specification for Flat Glass

abrasion resistance of refractory brick at room temperature. C1054 Practice for Pressing and Drying Refractory Plastic

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

This test method can also be applied to castable refractories and Ramming Mix Specimens

(see Metric Dimensions, Practice C861 and Practice C865) and D4285 Test Method for Indicating Oil or Water in Com-

plastic refractories (see Practice C1054). pressed Air

1.2 UnitsWhen values are stated in both SI and inch- 2.2 American Society of Mechanical Engineers (ASME)

pound units, the units are to be regarded separately as standard. Standard:

The values stated in each system may not be exact equivalents; B40.100 Pressure Gauges and Gauge Attachments

therefore, use each system independently of the other. Com- 2.3 ASTM Adjuncts:

bining values from the two systems may result in non- Abrasion Tester (1 dwg)3

conformance with the standard. Several values are stated only 3. Summary of Test Method

in SI units as a matter of convention and to permit comparison

of results. Included are the abrading media weight (grams), 3.1 This test method measures the volume of material in

specimen weight (grams), specimen weight loss due to abra- cubic centimeters abraded from a flat surface at a right angle to

sion (grams), and the resultant volume loss (cubic centimeters). a nozzle through which 1000 g of size-graded silicon carbide

1.3 This standard does not purport to address all of the grain is blasted by air at a prescribed air pressure.

safety concerns, if any, associated with its use. It is the 4. Significance and Use

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 4.1 This test method measures the relative abrasion resis-

bility of regulatory limitations prior to use. tance of various refractory samples under standard conditions

at room temperature.

2. Referenced Documents 4.2 The abrasion resistance of a refractory material provides

2.1 ASTM Standards:2 an indication of its suitability for service in abrasive environ-

A681 Specification for Tool Steels Alloy ments.

C134 Test Methods for Size, Dimensional Measurements, 4.3 The results obtained by this test method could be

and Bulk Density of Refractory Brick and Insulating different than those obtained in service because of the different

Firebrick conditions encountered.

C179 Test Method for Drying and Firing Linear Change of 5. Interferences (Factors known to Affect Results)

Refractory Plastic and Ramming Mix Specimens

C861 Practice for Determining Metric Dimensions of Stan- 5.1 During development, a ruggedness test was performed

dard Series Refractory Brick and Shapes using 114 by 114 by 12.7 mm [412 by 412 by 12 in.] float glass

C862 Practice for Preparing Refractory Concrete Speci- plates conforming to Specification C1036. Several factors were

mens by Casting found to cause statistically significant effects on measured

results (see Section 10).

5.1.1 Nozzle Tube Inside DiameterVariation in the inside

1

This test method is under the jurisdiction of ASTM Committee C08 on diameter of the flint glass nozzle tube statistically affected the

Refractories and is the direct responsibility of Subcommittee C08.03 on Physical

Properties. abrasion values obtained on the glass plate. Ideal glass tube

Current edition approved March 1, 2012. Published April 2012. Originally

approved in 1972. Last previous edition approved in 2009 as C704 09 . DOI:

10.1520/C0704_C0704M-12.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Detailed prints for the construction of the test chamber are available at a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM nominal cost from ASTM International Headquarters. Order Adjunct No.

Standards volume information, refer to the standards Document Summary page on ADJC0704. An acceptable test chamber can be made from a weatherproof electrical

the ASTM website. switch box.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International

Provided by IHS under license with ASTM

1Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

inside diameter is 4.8 mm. Glass tube lots purchased as 7 mm which the abrading media enters the nozzle in the venturi

outside diameter tube with a nominal 1.1 mm wall thickness chamber is inserted into a 15.9 mm [58 in.] outside diameter,

can have inside diameters ranging from 4.6 mm to 5.0 mm. For 6.4 mm [14 in.] inside diameter rubber grommet with a

the ruggedness test, flint glass tube inside diameters of 4.7 mm thickness of 4.75 to 6.4 mm [316 to 14 in.]. The glass tube is

and 4.9 mm were used. Take the statistically significant effect placed through the sleeve in the tubing nut, compressing the

of this small tube inside diameter variation into consideration. grommet within the nut. The nut is attached to the gun. Fit the

Individually measure and choose all nozzle tubes to conform to nozzle tightly into the grommet in order to achieve adequate

a specified 4.8 mm inside diameter. vacuum (see 8.6). The glass tube is then positioned at a

5.1.2 Air PressureVariation in the test air pressure statis- distance of 2 mm [0.08 in.] from the air-generator nozzle. This

tically affected the abrasion values obtained on the glass plate. is done by using a brass rod, 4.5 mm [0.175 in.] in diameter

Air pressure as specified in this test method is 448 kPa [65 psi] with a shoulder 7.9 mm [516 in.] in diameter, 117 mm [4.59 in.]

measured by a gauge capable to 6 6.9kPa [6 1 psi]. For the from the tip and inserting this rod into the glass tube. This will

ruggedness test, air pressure was maintained at values of 441 allow the operator to push the glass tubing up until the rod

kPa [64 psi] and 455 kPa [66 psi] by the use of a calibrated touches the venturi, ensuring a 2 mm [0.08 in.] gap between the

master series pressure gauge. Take the statistically significant venturi and the glass tubing.

effect of this small air pressure variation into consideration and 6.1.3 VenturiThe air generator nozzle dimensions are an

use only gauges as specified in 6.1.5. It is also recommended inlet inside diameter of 2.84 to 2.92 mm [0.112 to 0.115 in.]

that air gauges be recalibrated at frequent intervals. and an outlet inside diameter of 2.36 to 2.44 mm [0.093 to

5.2 Factors that were found to be rugged during the test 0.096 in.]. Inspect the air generator nozzle for wear before any

method evaluation were: (1) particle size variation of the test series and replace as necessary. The maximum inside

silicon carbide grain between sizings of grain composed of diameter of the venturi chamber is 10 mm [38 in.]. Check the

25% 20 mesh by 30 mesh and 75% 30 mesh by 50 mesh silicon inside diameter periodically for wear (Fig. 4).

carbide to one composed of 15% 20 mesh by 30 mesh and 85% 6.1.4 Air SupplySupply the abrasion gun with clean dry

30 mesh by 50 mesh silicon carbide sizing, (2) nozzle to air in accordance with Test Method D4285. The use of

sample distance varying between 200 mm [7 78 in.] to 206 mm appropriate drying equipment is necessary in order to achieve

[818 i.n], (3) silicon carbide grit amount between 995 g and consistent results. Ensure that the air supply is able to supply

1005 g, and (4) test operator. an adequate volume of air such that the air pressure does not

6. Apparatus fluctuate during the test run. If the air supply is also connected

to other equipment, ensure that the air supply is able to

6.1 Abrasion Tester, used for measuring the abrasion resis- maintain consistent pressure throughout the test run, even

tance of refractory specimens, consisting of the following (Fig. when other equipment connected to the supply is operated.

1 and Fig. 2): Consultation with an industrial professional in compressed air

6.1.1 Blast Gun (Leitch Carco Gun Model LC-CG)4, modi- systems is recommended in setting up the air supply for the

fied for this equipment as shown in Fig. 3. Other sand blast gun abrasion tester.

models or types may affect test results.

6.1.5 Air Supply Pressure Gauge Affix a dial or digital

6.1.2 NozzleMake the nozzle from a piece of flint-glass

test pressure gauge meeting the requirements of ASME

tubing, 115 mm [4 12 in.] long, 7 mm [0.276 in.] 6 0.12 mm

B40.100, accuracy grade 3A, 60.25% of the span, to a fitting

[0.005 in.] outside diameter, with a 1.1 mm [0.043 in.] 6 0.03

on top of the gun as shown on Fig. 1. Dial to have a mirrored

mm [0.001 in.] wall thickness. When the Carco Blast Gun is

band for knife-edged pointer tip reflection to prevent parallax

used, this will replace the steel nozzle supplied with the gun.

error. The minimum recommended diameter for dial type is

Cleanly cut the ends of the glass tube and do not fire polish

114 mm [4.5 in]. Recommended span is 0/1000 kPa [0/100

them. Check the length and diameter of each tube prior to use.

psig] based on an anticipated air supply pressure of 455 kPa

The diameter may be checked by the use of a gage consisting

[65 psig].

of a tapered stainless steel rod with the 4.8 mm (316 in.)

diameter marked on the rod. The glass tubing is held in place 6.1.6 Abrading MediaNew (unused), sharp (angular, jag-

by a 70 mm (234 in.) long piece of stainless steel or copper ged edged grains), No. 36 grit silicon carbide containing

tubing with an inside diameter of 7.15 to 7.75 mm [932 to 58 minimal foreign material and having a screen analysis as

in.] and an outside diameter of 9.53 mm [38 in.]. Flare the shown in Table 1. Verify the sizing of the grit by either user

tubing at one end to sit snugly inside a 9.53 mm [38 in.] tubing confirmation of the screen analysis or a certificate of confor-

nut. This sleeve is glued or soldered in place inside the 9.53 mance from the supplier. Take care to avoid segregation in

mm [38 in.] tubing nut, and is used primarily to hold the glass large containers of abrading media. Splitting (possibly with use

tubing perpendicular to the test sample, ensuring a proper of a riffler) or another similar procedure and reblending may be

vacuum within the gun. The end of the glass tube through necessary to obtain a grit sample conforming to the required

screen analysis.

6.1.7 Feeding MechanismTwo acceptable mechanisms

4

The sole source of supply of the apparatus known to the committee at this time for feeding the abrading media are shown in Fig. 5. The feed

is Leitch & Company, 106 Abram Court, San Leandro, CA 64577. If you are aware

of alternative suppliers, please provide this information to ASTM International

funnel contains a suitable orifice to obtain a flow time of 450

Headquarters. Your comments will receive careful consideration at a meeting of the 6 15 s while delivering 1000 g of abrading media into the gun

responsible technical committee,1 which you may attend. supply funnel. Metal, glass, or plastic orifices may be used to

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

2Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

NOTEIdentified by number in this figure are: (1) cabinet pressure manometer, (2) dust collector vent, (3) test pressure gage, (4) grit feed tunnel, and (5) vacuum gage.

FIG. 1 Abrasion Tester

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

regulate the flow. Provide an air gap between the orifice and the gun such that the downward stream of abrading media will

gun supply funnel to allow secondary air to enter with the travel 203 mm [8 in.] from the glass nozzle tip to the test

abrading media. specimen. Equip the test chamber with a 52 mm [2116 in.]

6.1.8 Test ChamberA tightly sealed closure with a door to exhaust with a butterfly valve to regulate the cabinet pressure.

permit ready access for mounting and removing the test Fig. 1 and Fig. 2show the design of an acceptable chamber.3

specimens. Cut a 13-mm [12 in.] mounting hole in the top of 6.1.8.1 Dust CollectorA dust-collecting cloth or paper

the test chamber to permit the vertical mounting of the blast bag of adequate capacity may be used on the exhaust port of

Copyright ASTM International

Provided by IHS under license with ASTM

3Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

NOTEIdentified by number in this figure are: (1) sand blast gun, (2) air pressure regulator, (3) glass tube and metal stabilizing sleeve, (4) test sample, and (5) adjustable

platform.

FIG. 2 Abrasion Tester

the chamber. Alternate dust handling systems such as venting npt(f) connection in the top portion of the test chamber for the

to the outside are acceptable as long as the chamber pressure is chamber pressure connection.

maintained at the desired level. 6.1.9 Vacuum GaugeDial or digital test gauge meeting the

6.1.8.2 Chamber Pressure ManometerWater manometer, requirements of ASME B40.100 accuracy grade 3A, 60.25%

digital manometer, or magnehelic gauge with a span of 0 to 80 of the span. Dial to have a mirrored band for knife-edged

mm (0 to 3 in.) water based on an operating pressure of 32 mm pointer tip reflection to prevent parallax error. The minimum

(114 in.) water with an accuracy of 62% of span. Install a 14 recommended diameter for dial type is 114 mm [4.5 in.]. The

Copyright ASTM International

Provided by IHS under license with ASTM

4Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

NOTEIdentified by number in this figure are: (1) glass tube adjustment rod, (2) metal stabilizing sleeve, (3) glass tube with grommet, and (4) sand blast gun.

FIG. 3 Modified Blast Gun Breakdown

FIG. 4 Venturi Nozzle

recommended span is 100/0 kPa (30/0 in. Hg). Connect the

vacuum gauge to a T-fitting in the abrasive supply line.

Copyright ASTM International

Provided by IHS under license with ASTM

5Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

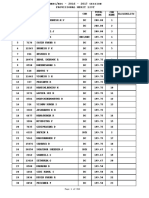

TABLE 1 Screen Analysis for Abrading Media supply funnel and read the vacuum gauge. If the vacuum gauge

ASTM Standard

Opening, m Retained, %

does not show a minimum vacuum of 380 mm (15 in.) of

Sieve No. mercury, check the position of the glass tubing or the condition

20 850 trace of the air-generator nozzle.

30 600 20 6 2

50 300 80 6 3

8.7 After obtaining the proper vacuum pressure, unplug the

70 212 2 max gun supply funnel and recheck the cabinet pressure before

Pass No. 70 ... trace placing 1000 6 5 g of dry abrading media in the main supply

funnel. Do not completely fill or flood the gun supply funnel

with material. When connected with the abrasion tester, ensure

6.2 Balance, capable of weighing the sample to an accuracy that the feed mechanism delivers the abrading media in the

of 60.1 g. Used for weighing the abrading media and test specified time of 450 6 15 s.

specimens. Typically a 2000 to 3000 g capacity balance is 8.8 Use the silicon carbide abrading media only once and

required. then discard.

8.9 Remove the refractory specimens from the test chamber,

7. Test Specimens blow off the dust, and immediately weigh to the nearest 0.1 g.

7.1 Cut 100 by 100 by 25 mm [4 by 4 by 1 in.] or 114 by 114 If the samples are allowed to sit before being weighed, they

by 65 or 76 mm [4.5 by 4.5 by 2.5 or 3 in.] test specimens from may pick up moisture resulting in an inaccurate test result. In

refractory brick or shapes or mold them from monolithic this case, dry the sample as in 8.1 prior to measuring.

refractory materials. Only the most abrasion resistant materials

can be 25 mm [1 in.] thick since the test is invalid if a hole is 9. Calculation and Report

eroded completely through the specimen. 9.1 From the initial weight and volume, calculate the bulk

7.2 Mold castable refractories in accordance with Practice density of the specimens in g/cm3.

C862. Fire specimens to the anticipated service temperature or 9.2 Calculate the amount of abrasion loss from each speci-

a higher temperature, if specified, in accordance with Practice men in cm3, A, to the nearest 0.1 cm3 as follows:

C865. One 100 by 100 mm (4 by 4 in.) or 114 by 114 mm (4.5

A 5 [~M1 2 M2! / B] 5 M / B

by 4.5 in.) face of each specimen is a free (not troweled,

molded, or cut) face. where:

7.3 Mold plastic refractories and fire the specimens to the B = bulk density, g/cm3(to the nearest 0.1 g/cm3),

anticipated service temperature or a higher temperature, if M1 = weight of specimen before testing, g (to the nearest

specified, in accordance with Test Method C179 (see the 0.1 g),

sections on apparatus and test specimens). One 100 by 100 mm M2 = weight of specimen after testing, g (to the nearest 0.1

(4 by 4 in.) or 114 by 114 mm (4.5 by 4.5 in.) face of each g), and

specimen is a free (not troweled, molded, or cut) face. M = weight loss of specimen, g (to the nearest 0.1 g).

9.3 Report the average of the individual results as the

8. Procedure abrasion loss for that sample.

8.1 Dry the test specimens to a constant weight at 105 to 9.4 Record and report the time required for 1000 g of

110C [220 to 230F] before testing. abrading media to flow through the gun.

8.2 Weigh the specimens to the nearest 0.1 g. Determine the 9.5 Report which surface was abraded.

volume of the specimens by measurement of length, width, and 9.6 If the test results in a hole completely through the

thickness to the nearest 0.5 mm [0.02 in.] in accordance with sample, the test results are not valid. Report the results as a

the apparatus section of Test Methods C134. hole through the specimen.

8.3 Place the nominal 100 by 100 mm (4 by 4 in.) or 114 by

114 mm [4.5 by 4.5 in.] face of the test specimens at a 90 10. Precision and Bias 5

angle to the glass nozzle with the surface to be abraded 203 10.1 Interlaboratory Test DataAn interlaboratory study

mm [8 in.] from the tip of the glass nozzle. For brick samples was completed among eight laboratories in 1999. Five different

test an unbranded surface. For monolithic refractory speci- types of refractories, along with a float glass plate standard,

mens, test the surface (that is, top free face or bottom mold were tested for abrasion resistance by each laboratory. The five

face) that most accurately reflects the actual field situation. types of refractories were a high-alumina brick, a silica brick,

Normally, the free surface is the most appropriate test surface. an abrasion-resistant castable, a super-duty fire brick, and a

Position the specimen such that the abrasion pattern is centered conventional high-cement castable. All specimens were 4.5 by

on the surface of the plate. 4.5 in. in cross section. Additionally, both castables were fired

8.4 Turn on the air pressure. Regulate the air pressure to 448 to 1500F. Prior to testing, bulk density and sonic velocity were

kPa [65 psi]. Check the air pressure before and after the measured on all specimens to ensure uniformity. Specimens

abrading media is run through the system. were then randomly selected for distribution to the participat-

8.5 Measure the cabinet pressure using the manometer and ing laboratories.

maintain the pressure in the chamber at 31.8mm [114 in.] of

water by means of the butterfly valve in the exhaust vent.

8.6 After the air pressure to the gun and the chamber 5

Supporting data have been filed at ASTM International Headquarters and may

pressure have been adjusted, plug the opening of the gun be obtained by requesting Research Report RR:C08-1019.

--``,,,`,,``,,`,``,,,,,,`,

Copyright ASTM International

Provided by IHS under license with ASTM

6Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

NOTEIdentified by number in this figure are: (1) main supply funnel with metering insert, (2) gun supply funnel, (3) main supply funnel, (4) metering funnel, and (5) gun

supply funnel.

FIG. 5 Feeding Mechanisms

10.2 PrecisionTable 2 contains the precision statistics for ability interval (% r). The 95 % repeatability intervals are given

the abrasion resistance results. in Table 2. Two test results that do not differ by more than the

10.2.1 RepeatabilityThe maximum permissible difference repeatability interval shall be considered to be from the same

due to test error between two test results obtained by one population; conversely, two test results that do differ by more

operator on the same material using the same test equipment is than the repeatability interval shall be considered to be from

given by the repeatability interval (r) and the relative repeat- different populations.

Copyright ASTM International

Provided by IHS under license with ASTM

7Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

TABLE 2 Precision Statistics for Abrasion Resistance

Standard Standard Coefficient Coefficient

Average Deviation Deviation Repeat- Reproduc- of Varia- of Varia- Relative Relative

Material Volume Within Between ability bility tion Within tion Between Repeat- Reproduc-

Loss, cm3 Labora- Labora- Interval, r Interval, R Labora- Labora- ability, %r ibility, %R

tories, Sr tories, SR tories, Vr tories, VR

High-alumina brick 4.19 0.39 0.71 1.08 1.98 9.22 16.85 25.80 47.19

Silica brick 22.17 2.64 4.62 7.40 12.95 11.91 20.86 33.36 58.41

Abrasion-resistant castable 8.36 0.87 1.89 2.42 5.29 10.35 22.59 28.99 63.24

Super-duty firebrick 25.48 4.25 7.81 11.90 21.86 16.68 30.64 46.70 85.80

Conventional high-cement castable 10.89 2.12 3.02 5.94 8.45 19.48 27.71 54.54 77.59

Plate glass standard 9.28 0.34 1.51 0.95 4.23 3.66 16.27 10.24 45.58

10.2.2 ReproducibilityThe maximum permissible differ- 10.3 BiasNo justifiable statement can be made on the bias

ence due to test error between two test results obtained by two of this test method because the value of the volume loss can be

operators in different laboratories on the same material using defined only in terms of a test method.

the same test equipment is given by the reproducibility interval

(R) and the relative reproducibility interval (% R). The 95 % 11. Keywords

reproducibility intervals are given in Table 2. Two test results

that do not differ by more than the reproducibility interval shall 11.1 abrasion resistance; blasted by air; castable refracto-

be considered to be from the same population; conversely, two ries; glass plate; flat surface; monolithic refractory materials;

test results that do differ by more than the reproducibility refractory brick or shape; room temperature

interval shall be considered to be from different populations.

SUPPLEMENTARY REQUIREMENTS

S1. Highly Abrasion Resistant Materials S1.3.4 Feeding Mechanism (Replaces 6.1.7)Use a two

S1.1.1 The requirements of this supplement apply only when funnel feeding mechanism to supply the abrading media to the

specified in the purchase order. gun as shown on the left side of Fig. 5. Ensure that the main

supply funnel has sufficient volume to hold the required 1000

S1.1.2 These requirements are designed for applications

g of silicon carbide abrading medium. Provide an orifice

where increased precision is necessary for the abrasion resis-

approximately 4.5 mm (0.18 in.) in diameter to control the flow

tance of the refractory material in order to reduce the variabil-

of silicon carbide. Size the orifice so that 1000 g of the

ity of results obtained using the standard test procedure.

abrading media flows through the funnel in 450 6 15 s. Equip

S1.1.3 The requirements of this supplement modify or the gun supply funnel with a 4.06 mm [0.16 in.] inside

augment the requirements of Test Method C704/C704M. diameter, 6.35 mm [0.25 in.] outside diameter hose fitting to

Follow all requirements of the supplement. connect to the feed line. Provide a gap between the two funnels

S1.1.4 Do not compare test results using the supplementary to allow for air to be introduced to the particle stream. Connect

requirements to results obtained using the standard testing the lower funnel to the feed inlet of the blast gun with clear

procedures. flexible poly(vinyl chloride) tubing with an inside diameter of

S1.2 Interferences (Factors Known to Affect Results) 6.35 mm [0.25 in.].

S1.3.5 Test Chamber (Modifies 6.1.8)Use a 20 mm [1316

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

S1.2.1 A round robin study for these supplementary require-

ments is underway. No interference statements can be made at in.] mounting hole. Attach the blast gun to the top of the

this time. chamber through the hole in the top and secure it in place with

S1.3 Apparatus a nut. Ensure the gun is perpendicular to the specimen.

S1.3.1 Abrasion Tester (Modification of 6.1)See Fig. S1.1. S1.3.6 Vacuum Gauge (Modifies 6.1.9) Use two vacuum

gauges. If the readings on the gauges differ by more than 6.9

S1.3.2 Blast Gun (Replaces 6.1.1), machined from a block of

kPa (1 psi), recalibrate, repair, or replace the gauges. Use one

American Iron and Steel Institute (AISI) Grade A-2 (Specifi-

gauge as the primary gauge; all vacuum measurements are to

cation A681, Type A-2; UNS T30102) tool steel in accordance

be taken from that gauge. The second gauge is used only for

with Fig. S1.2.

verification. Affix the gauges to the blast gun as shown in Fig.

S1.3.3 Air Supply Pressure Gauge (Modifies 6.1.5)Use S1.1. Ensure that there are not any flow obstructions between

two pressure gauges. If the readings on the gauges differ by the gauge and the gun.

more than 6.9 kPa (1 psi), recalibrate, repair, or replace the

gauges. Use one gauge as the primary gauge; all pressure S1.4 Calibration

measurements are to be taken from that gauge. The second S1.4.1 Calibrate the abrasion tester at least once a week

gauge is used only for verification. Ensure that there are not when the tester is used. Also calibrate the abrasion tester when

any flow obstructions between the gauge and the gun. replacing the gun, venturi, or any gauge and when using a new

Copyright ASTM International

Provided by IHS under license with ASTM

8Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

NOTEIdentified by number in this figure are: (1) grit feed funnels, (2) pressure gauges, (3) blast gun, (4) vacuum gauge, (5) exhaust port, and (6) cabinet pressure

manometer.

FIG. S1.1 Modified Abrasion Tester

lot of silicon carbide or batch of glass tubes. Additionally, S1.4.2 Calibration check specimens are 114 by 114 by 12.7

calibrate the abrasion tester any time an abnormality occurs in mm [4.5 by 4.5 by 0.5 in.] float glass plates conforming to

the test such as erratic results or a hole being worn in the glass Specification C1036, with a density between 2.48 and 2.51

nozzle. g/cm3. Confirm the density of the float glass plates by testing

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

9Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

FIG. S1.2 Machined Block Blast Gun

one plate in each batch. Due to small irregularities normally S1.4.6 Run the abrasion test in accordance with 8.2-8.7 with

present in the shape of the glass plates, use of a water the exception of setting the air pressure in 8.4 to the value

immersion method is suggested. Refer to Table 2 for the obtained during the previous calibration.

acceptable precision statistics for float glass plate. S1.4.7 Weigh the plate to the nearest 0.1 g.

S1.4.2 Calibration check specimens are 114 by 114 by 12.7 S1.4.8 Calculate the glass plate abrasion loss, AG, to the

mm [4.5 by 4.5 by 0.5 in.] float glass plates conforming to nearest 0.1 cm3 as follows:

Specification C1036, with a density between 2.48 and 2.51

AG 5 [~MG1 MG2! / BG# 5 MG / 2.49

g/cm3. Confirm the density of the float glass plates by testing

one plate in each batch. Due to small irregularities normally where:

present in the shape of the glass plates, use of a water 2.49 = glass plate bulk density, g/cm3,

immersion method is suggested. Refer to Table 2 for the MG1 = weight of glass plate specimen before testing, g (to

acceptable precision statistics for float glass plate. the nearest 0.1 g),

S1.4.3 Weigh the glass plate to the nearest 0.1 g prior to MG2 = weight of glass plate specimen after testing, g (to

calibration. the nearest 0.1 g), and

MG = weight loss of glass plate specimen, g (to the

S1.4.4 Prior to running the calibration, inspect all parts of the nearest 0.1 g).

abrasion tester for wear. Replace any components that are worn

S1.4.9 The target abrasion loss of the glass plate is 9.3 6 0.3

prior to calibration.

cm3. Observe the abrasion pattern of the glass plate through the

S1.4.5 Place the glass plate into the abrasion tester in the edge of the plate. The abraded area is to be uniform and

same manner as a test specimen. Maintain the 203 mm (8 in.) symmetrical. A nonuniform, or unsymmetrical wear pattern

spacing between the end of the glass nozzle and the surface of indicates that the abrasion tester is not set up properly (for

the glass plate. This can be achieved by using a second glass example, the nozzle is not perpendicular to the specimen plate,

plate under the calibration plate as a spacer, or by adjusting the the nozzle is not securely fixed into place, the nozzle to

height of the sample holding platform. The glass plate may be specimen distance is incorrect, the air pressure is varying, etc.).

placed in the abrasion tester with either face up. Correct the problem and rerun the calibration test with a new

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International

Provided by IHS under license with ASTM

10

Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

C704/C704M 12

glass plate. If the abrasion plate results do not meet the feed line by closing the opening of the lower funnel. If the

standard, adjust the air pressure to the gun and run the vacuum gauge does not read a minimum vacuum of 380 mm

calibration procedure again using a new glass plate each time (15 in.) of mercury, then check the position of the glass nozzle

until an abrasion of 9.3 6 0.3 cm3 is achieved. in the blast gun. If correcting the position of the glass nozzle

S1.4.10 Record the result of the calibration in a calibration does not correct the problem then check the condition of the

log. Include the date of the calibration, the air pressure used, venturi, the condition of the abrading media feed lines, and the

the calibration value, and the event that triggered the calibra- blast gun. Replace any parts as necessary and calibrate the

--``,,,`,,``,,`,``,,,,,,`,`,,,,,-`-`,,`,,`,`,,`---

tion in the log entry. This log may be kept either on paper or abrasion tester in accordance with Section 7 before proceeding.

electronically. S1.6 Calculation and Report

S1.5 Procedure S1.6.1 (Add to Section 9.) Report the calibration value of the

S1.5.1 (Replaces 8.4.) Turn on the air pressure. Regulate the glass plates, the air pressure used, and the calibration date for

air pressure to the pressure indicated by the most recent the last calibration event run prior to running the samples.

calibration of the abrasion tester. Check the air pressure before S1.7 Precision and Bias

and after the abrading media is run through the system. S1.7.1 Round robin testing for the supplementary require-

S1.5.2 (Replace 8.6.) After the air pressure to the gun and the ments is underway. No precision and bias statements can be

chamber pressure have been adjusted, plug the abrading media made at this time.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright ASTM International

Provided by IHS under license with ASTM

11Licensee=Inelectra Panama s de RL/5983191001, User=carnalla, sofia

No reproduction or networking permitted without license from IHS Not for Resale, 08/13/2013 09:52:24 MDT

Você também pode gostar

- Api 936 Practice TestDocumento9 páginasApi 936 Practice TestfraemddAinda não há avaliações

- Astm C133 PDFDocumento5 páginasAstm C133 PDFgems_gce074325Ainda não há avaliações

- Astm C 862-02Documento5 páginasAstm C 862-02Tâm NgôAinda não há avaliações

- NDT Study Material PCN UT II PDFDocumento88 páginasNDT Study Material PCN UT II PDFJeganeswaran80% (5)

- TDS R4d-IcDocumento3 páginasTDS R4d-IcRavie OuditAinda não há avaliações

- 01-ASTM C113 (2002) Test Method PDFDocumento3 páginas01-ASTM C113 (2002) Test Method PDFSreekumar K SAinda não há avaliações

- C113-14 Standard Test Method For Reheat Change of Refractory Brick PDFDocumento3 páginasC113-14 Standard Test Method For Reheat Change of Refractory Brick PDFhoangviet20006100% (1)

- Astm C-832Documento7 páginasAstm C-832Magesh KumarAinda não há avaliações

- Boiler Refractory ASTM C71Documento2 páginasBoiler Refractory ASTM C71Ujang SonjayaAinda não há avaliações

- File No. 10 - API 936Documento19 páginasFile No. 10 - API 936praveentien100% (6)

- Refractory Material SelectionDocumento7 páginasRefractory Material SelectionCristhofer HernandezAinda não há avaliações

- Monolithic Refractory Lining (Calderys)Documento16 páginasMonolithic Refractory Lining (Calderys)Nael82% (11)

- Technical Data Sheet Avikote Av 650 R PDFDocumento2 páginasTechnical Data Sheet Avikote Av 650 R PDFCIAKAinda não há avaliações

- ASTMDocumento3 páginasASTMabet_singkong8930Ainda não há avaliações

- DNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFDocumento2 páginasDNVGL-ST-F101 Submarine Pipeline Systems-415-416 PDFJeganeswaranAinda não há avaliações

- McElroy 2013 CatalogDocumento152 páginasMcElroy 2013 CatalogSulist N WahyudieAinda não há avaliações

- Plate and Frame Heat Exchangers (Amendments-Supplements To ISO 15547-1-2005)Documento16 páginasPlate and Frame Heat Exchangers (Amendments-Supplements To ISO 15547-1-2005)Jacob PhilipAinda não há avaliações

- Proceedings CIB W062 2018 SymposiumDocumento354 páginasProceedings CIB W062 2018 SymposiumdplumbingAinda não há avaliações

- Astm C704-C704M (2012)Documento11 páginasAstm C704-C704M (2012)Shiburaj SomarajanAinda não há avaliações

- Astm C 1054-03Documento3 páginasAstm C 1054-03Tâm NgôAinda não há avaliações

- Astm C133Documento6 páginasAstm C133Teddy HariyantoAinda não há avaliações

- C 133 PDFDocumento6 páginasC 133 PDFShaaf Amjad100% (1)

- Astm C16Documento5 páginasAstm C16nee2790100% (1)

- Astm C71 PDFDocumento5 páginasAstm C71 PDFclaudiaAinda não há avaliações

- Data Sheet Greencast 94: DescriptionDocumento2 páginasData Sheet Greencast 94: Descriptionmani0% (1)

- Astm C909Documento4 páginasAstm C909deivisbtsAinda não há avaliações

- API936 Effective Sheet-2020 PDFDocumento2 páginasAPI936 Effective Sheet-2020 PDFmalleshAinda não há avaliações

- C134Documento4 páginasC134maria tAinda não há avaliações

- Astm C 182-2019Documento3 páginasAstm C 182-2019Mohammed AliAinda não há avaliações

- Corot Ex ProDocumento3 páginasCorot Ex Proamk2009Ainda não há avaliações

- API 936 Quiz TestDocumento7 páginasAPI 936 Quiz TestzohirAinda não há avaliações

- File No. 7 - API 936Documento8 páginasFile No. 7 - API 936praveentien100% (1)

- File No. 6 - API 936Documento10 páginasFile No. 6 - API 936praveentienAinda não há avaliações

- API Refractory Lining and Burner Brick RequirementDocumento29 páginasAPI Refractory Lining and Burner Brick RequirementsprathAinda não há avaliações

- Refractory Repair and ProcedureDocumento3 páginasRefractory Repair and Procedureyogacruise50% (2)

- Refractory Doc JunaidDocumento3 páginasRefractory Doc JunaidAli ZamanAinda não há avaliações

- Installation Guide NUDocumento67 páginasInstallation Guide NUJorge Armando Cabrera Guaquida100% (2)

- C860Documento6 páginasC860sensaptAinda não há avaliações

- Astm C201Documento6 páginasAstm C201Cesar Bernal100% (1)

- API936 Apr13Documento4 páginasAPI936 Apr13traja4Ainda não há avaliações

- Castable Refractory ConcreteDocumento23 páginasCastable Refractory Concretemnaziria6612100% (3)

- C 467 - 14 PDFDocumento2 páginasC 467 - 14 PDFAquinoAinda não há avaliações

- Protecting Your Refractory PDFDocumento33 páginasProtecting Your Refractory PDFDenzil D'SouzaAinda não há avaliações

- Catalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908Documento188 páginasCatalog of Harbison-Walker Refractories CO, Pittsburgh PA 1908iMiklaeAinda não há avaliações

- Api 936 Refractory Question BankDocumento74 páginasApi 936 Refractory Question BankAliDadKhan100% (1)

- Monolithic RefractoriesDocumento11 páginasMonolithic RefractoriesZafr Cetn100% (1)

- 2.5 Insulation & RefractoriesNDocumento43 páginas2.5 Insulation & RefractoriesNgaurang1111Ainda não há avaliações

- PDF Ce Feuerbetone e 8 2017.en.7Documento10 páginasPDF Ce Feuerbetone e 8 2017.en.7Henry SunarkoAinda não há avaliações

- WB 3 - Fireproofing IntumescentDocumento2 páginasWB 3 - Fireproofing Intumescentwafik.bassily100% (1)

- C71 12 PDFDocumento6 páginasC71 12 PDFAbdiz Engineering INCAinda não há avaliações

- How Mixing Affects The Rheology of Refractory Castables - Part IIDocumento25 páginasHow Mixing Affects The Rheology of Refractory Castables - Part IIVinh Do ThanhAinda não há avaliações

- 21-Application of Phoscst 90 RefractoryDocumento6 páginas21-Application of Phoscst 90 RefractorysonuAinda não há avaliações

- RefractoriesDocumento31 páginasRefractoriesChandra Shekar Reddy Yelety100% (2)

- SIC Refractory CastableDocumento5 páginasSIC Refractory CastableJagadeesh GuttiAinda não há avaliações

- Vacuum Pumps Common Problems and TroubleshootingDocumento18 páginasVacuum Pumps Common Problems and TroubleshootingAV kayanAinda não há avaliações

- Bull Nose Ref FailureDocumento1 páginaBull Nose Ref FailurejagrutAinda não há avaliações

- Cements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersDocumento8 páginasCements, Chemically Resistant: 1. 2. Types of Cement 2.1. Cements Containing Inorganic BindersjaimeAinda não há avaliações

- Zinc CoatingsDocumento12 páginasZinc CoatingsvvgdreamAinda não há avaliações

- Astm C704M 2015Documento12 páginasAstm C704M 2015FelixAinda não há avaliações

- C704 C704 12Documento11 páginasC704 C704 12mallesh100% (1)

- Pressing and Drying Refractory Plastic and Ramming Mix SpecimensDocumento3 páginasPressing and Drying Refractory Plastic and Ramming Mix SpecimensMahmoud HagagAinda não há avaliações

- ASTM C113 Standard Test Method For Reheat Change of Refractory BrickDocumento3 páginasASTM C113 Standard Test Method For Reheat Change of Refractory Brickjoshua johnAinda não há avaliações

- API 936 - C113-14-STM For Reheat ChangeDocumento3 páginasAPI 936 - C113-14-STM For Reheat ChangeSureshMasilamaniAinda não há avaliações

- C704C704M.cpne1983 - STM For AbrasionDocumento7 páginasC704C704M.cpne1983 - STM For AbrasionSureshMasilamaniAinda não há avaliações

- Cold Crushing Strength and Modulus of Rupture of RefractoriesDocumento6 páginasCold Crushing Strength and Modulus of Rupture of RefractoriesCristian Bianey Araque PradaAinda não há avaliações

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingNo EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingAinda não há avaliações

- NDT Sa Ut 015 Rev 1Documento22 páginasNDT Sa Ut 015 Rev 1Jeganeswaran100% (1)

- Revision of ISO 17025 (2017 Ed) PDFDocumento22 páginasRevision of ISO 17025 (2017 Ed) PDFkingstonAinda não há avaliações

- 653 10-20-2020 CertDocumento1 página653 10-20-2020 CertJeganeswaranAinda não há avaliações

- NDT AtoDocumento24 páginasNDT AtoShabbir KhanAinda não há avaliações

- Mild Steel Unequal Angle Bars (Metric Series) Size Thickness Unit Weight MM MM KG/MDocumento1 páginaMild Steel Unequal Angle Bars (Metric Series) Size Thickness Unit Weight MM MM KG/MJeganeswaranAinda não há avaliações

- Tolerante Table Groase Laminate La Cald EN 10029-2011 PDFDocumento2 páginasTolerante Table Groase Laminate La Cald EN 10029-2011 PDFDaniel C.Ainda não há avaliações

- 188ADocumento2 páginas188AJeganeswaranAinda não há avaliações

- WS-QS-FM-012 Application For Initial Examination LEVEL 3 Rev 2Documento6 páginasWS-QS-FM-012 Application For Initial Examination LEVEL 3 Rev 2JeganeswaranAinda não há avaliações

- Application Form PDFDocumento8 páginasApplication Form PDFJeganeswaranAinda não há avaliações

- Asset Care Counts - 16 - November 2012Documento2 páginasAsset Care Counts - 16 - November 2012koohestani_afshinAinda não há avaliações

- NDT Company Training ScheduleDocumento7 páginasNDT Company Training ScheduleEswaranAinda não há avaliações

- WS-QS-FM-006 Record of Pre-Certification Experience R1Documento1 páginaWS-QS-FM-006 Record of Pre-Certification Experience R1JeganeswaranAinda não há avaliações

- Welding NotesDocumento1 páginaWelding NotesJeganeswaranAinda não há avaliações

- 2 Passport PhotoDocumento1 página2 Passport PhotoJeganeswaranAinda não há avaliações

- Seamless Pipe Certificate DOC171115Documento2 páginasSeamless Pipe Certificate DOC171115JeganeswaranAinda não há avaliações

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocumento36 páginasThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaAinda não há avaliações

- Senior Welding Application Form PDFDocumento8 páginasSenior Welding Application Form PDFJeganeswaranAinda não há avaliações

- Exam - TWI (India) - 2019 Candidate ScheduleDocumento3 páginasExam - TWI (India) - 2019 Candidate ScheduleJeganeswaranAinda não há avaliações

- The Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFDocumento36 páginasThe Welding of Aluminium - Mig & Tig Fusion - Pocket Guide PDFrogersampaiocostaAinda não há avaliações

- Application Form PDFDocumento8 páginasApplication Form PDFJeganeswaranAinda não há avaliações

- Carbon Hollow Bar ST 52Documento2 páginasCarbon Hollow Bar ST 52JeganeswaranAinda não há avaliações

- Lem Tek 57Documento71 páginasLem Tek 57MohdHuzairiRusliAinda não há avaliações

- EX07 Doc 2 (Rev.4) TWI Record of Vision TestsDocumento1 páginaEX07 Doc 2 (Rev.4) TWI Record of Vision TestsJeganeswaranAinda não há avaliações

- Eddy Current Nortec-600 Manual PDFDocumento12 páginasEddy Current Nortec-600 Manual PDFEswaranAinda não há avaliações

- Mbbs Bds Meritlist TamilnaduDocumento846 páginasMbbs Bds Meritlist TamilnaduEswaranAinda não há avaliações

- 1 API 653 Memories March 2014 ExamDocumento20 páginas1 API 653 Memories March 2014 ExamHaris Khan83% (6)

- ASTM G62 87 Reapproved 1998 PDFDocumento5 páginasASTM G62 87 Reapproved 1998 PDFGuha ArnabAinda não há avaliações

- KrishnakumarDocumento1 páginaKrishnakumarJeganeswaranAinda não há avaliações

- Method Statment HDD WorksDocumento14 páginasMethod Statment HDD WorksAzimi MalekAinda não há avaliações

- Fabrication Erection and Installation Procedure For PipingDocumento35 páginasFabrication Erection and Installation Procedure For Pipingmohd as shahiddin jafri100% (1)

- E 50 Parts ManualDocumento13 páginasE 50 Parts Manualsteve@air-innovations.co.zaAinda não há avaliações

- MT-EL-004A-Back Boxes PDFDocumento88 páginasMT-EL-004A-Back Boxes PDFEslam ElsayedAinda não há avaliações

- Pipe Stress Analysis - 5Documento24 páginasPipe Stress Analysis - 5Ismail Magdy Ismail100% (1)

- Series Magnetically Driven Chemical Pump: User ManualDocumento20 páginasSeries Magnetically Driven Chemical Pump: User ManualDoanh VoAinda não há avaliações

- Mech Cat PDFDocumento169 páginasMech Cat PDFardi_a0uAinda não há avaliações

- Casing PresentationDocumento33 páginasCasing PresentationJua RulerAinda não há avaliações

- Engineer'S: Reference FolderDocumento15 páginasEngineer'S: Reference FolderG CAinda não há avaliações

- Water-Borne Intumescent Acrylic Sealant: Product InformationDocumento4 páginasWater-Borne Intumescent Acrylic Sealant: Product InformationAyman JadAinda não há avaliações

- Proposed Water Tank Design: A Solution To North Poblacion San Fernando's Inadequate Water SupplyDocumento117 páginasProposed Water Tank Design: A Solution To North Poblacion San Fernando's Inadequate Water SupplyZynne Chlyden ParinoAinda não há avaliações

- Types of Pipes and Their UsesDocumento8 páginasTypes of Pipes and Their UsesMENDOZA Marie GenielleAinda não há avaliações

- 4.SMP Boiler Feed Pump (BFP)Documento10 páginas4.SMP Boiler Feed Pump (BFP)Abdullatif umatiyaAinda não há avaliações

- By Mohamad Shahrizal Bin Alias: Cold Water SupplyDocumento18 páginasBy Mohamad Shahrizal Bin Alias: Cold Water Supplynurul atiqahAinda não há avaliações

- New Developments in Hydraulic Ram PumpingDocumento6 páginasNew Developments in Hydraulic Ram PumpingAirPop24Ainda não há avaliações

- Carbon Steel Forgings, For General-Purpose PipingDocumento3 páginasCarbon Steel Forgings, For General-Purpose PipingedwinbadajosAinda não há avaliações

- How To Prevent Control Welding DistortionDocumento2 páginasHow To Prevent Control Welding DistortionNilesh DalviAinda não há avaliações

- Binder GroupDocumento159 páginasBinder Groupvirustest99Ainda não há avaliações

- My Class Note WweDocumento607 páginasMy Class Note Wwesathiya moorthiAinda não há avaliações

- Annexure IIIa - GCH FPS Technical SpecsDocumento57 páginasAnnexure IIIa - GCH FPS Technical Specswaz ahmedAinda não há avaliações

- Trican HandbookDocumento398 páginasTrican HandbookMariaAinda não há avaliações

- 32 Samss 005Documento33 páginas32 Samss 005Selvakpm06Ainda não há avaliações

- QC InspectionDocumento18 páginasQC InspectionUNSTOPPAPAUL100% (1)

- Farm Equipment Welding Plans 1958Documento100 páginasFarm Equipment Welding Plans 1958Denis StankovićAinda não há avaliações

- SA-106 GR.BDocumento2 páginasSA-106 GR.BTree TaweeAinda não há avaliações

- SM SeriesDocumento36 páginasSM SeriesGiorgiana RosuAinda não há avaliações