Escolar Documentos

Profissional Documentos

Cultura Documentos

Conbextra EP10

Enviado por

ganmosesTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Conbextra EP10

Enviado por

ganmosesDireitos autorais:

Formatos disponíveis

Fosroc Conbextra EP10 constructive solutions

High strength, low viscosity epoxy resin grout

Uses Properties

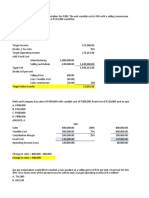

Provides a free flowing grout, for use where physical Pot life : 90 min. @ 20C

properties and chemical resistance of the hardened grout 40 min. @ 35C

are of utmost importance. It is suitable for a wide range of Density : approx. 1050 kg/m3

heavy duty applications including : Tensile strength : 26 N/mm2 @ 7 days

Flexural strength : 63 N/mm2 @ 7 days

! Underplate grouting to structural elements.

Compressive strength : 57 N/mm2 @ 1 day

! Base plate grouting in dynamic load situations such as 66 N/mm2 @ 3 days

turbines and other reciprocating machinery. 93 N/mm2 @ 7 days

! Heavy industrial applications in steelworks, refineries

Instructions for use

chemical plants and electroplating works.

Preparation

! Structural infill where very high strength is required.

Underplate grouting

! Rail track applications, to support heavy cranes, or on

transporter rails. The unrestrained surface area of the grout must be kept to a

minimum. Generally, the gap between the perimeter formwork

Advantages and the plate edge should not exceed 75 mm on the pouring

side and 25 mm on the opposite side. Formwork on the flank

! Excellent durability - high compressive, flexural and

sides should be kept tight to the plate edge. Air pressure

tensile strengths ensure a long working life.

relief holes should be provided to allow venting of any isolated

! Cost effective - high early strength gain promotes high spots.

minimum downtime and early commissioning of plant.

Formwork

! User friendly - simple, full pack mixing to ensure that the

The formwork should be constructed to be leak proof as

performance characteristics are achieved.

Conbextra EP10 is a free flow grout. This can be achieved by

! Versatile - suitable for a wide range of loading situations using foam rubber strip or mastic sealant beneath the

including repetitive dynamic loads. constructed formwork and between joints.

! Excellent in service performance - non-shrink capability For free flow grout conditions, it is essential to provide a

ensures full surface to surface contact. hydrostatic head of grout. To achieve this a feeding hopper

should be used - please consult your local Fosroc office for

Description more details.

Conbextra EP10 is a solvent free epoxy resin grout designed Foundation surface

for grouting of gap widths of 0.25 to 10mm. It is an all liquid

This must be free from oil, grease, or any loosely adherent

system consisting of base and hardener. The components

material. If the concrete surface is defective or has laitence,

are supplied in the correct mix proportions designed for

it must be cut back to a sound base. Bolt holes or fixing

whole pack mixing on site.

pockets must be blown clean of any dirt or debris.

Specification Base plate

Where shown on the contract documents, the epoxy grout If delay is likely before placing steel base plates, it is

shall be Conbextra EP10 supplied by Fosroc. When tested recommended that the underside and edges are coated with

at 7 days it shall provide compressive strength greater than Nitoprime 25* to prevent rust formation and ensure bonding

90, Tensile strength greater than 25 & Flexural strength with the Conbextra EP10 grout. All metal surfaces should be

greater than 60. It shall also provide good chemical cleaned to a bright finish in accordance with Swedish

Conbextra EP10

resistance. Standard SA 2 or equal. Nitoprime 25 can be applied directly

onto newly cleaned steel surfaces even if they are damp.

Fosroc Conbextra EP10

Mixing Limitation

The entire contents of the hardener can should be poured - For underplate grouting, failure to adhere to Instructions

into the base container and mixed for 2-3 minutes or until for use, may result in cracking & edge uplifting.

uniform colour is achieved. Once mixed, the material must

be used within the specified pot life (see under Properties). Estimating

After this time, unused material will have stiffened and should

Supply

be discarded.

Conbextra EP10 : 1 litre pack

Note: Immediately prior to placement, all surfaces must be Nitoprime 25 : 1 and 4 litre packs

dry. Fosroc Solvent 102 : 5 litre packs

Placing Coverage

Nitoprime 25 : 4.0 to 5.0 m2/litre

Ensure that the grout can be placed within its pot life.

Continuous grout flow is essential. Sufficient grout must be

Storage

available prior to starting and the time taken to pour a batch

must be regulated to the time taken to prepare the next one. When stored in warehouse conditions below 35C,

Pouring should be from one side of the void to eliminate air Conbextra EP10 will have a shelf life of 12 months.

entrapment. The hydrostatic head must be maintained at all

times so that a continuous grout front is achieved. Precautions

Cleaning Health and safety

All tools and equipment should be cleaned immediately after Some people are sensitive to epoxy resin so gloves and a

use with Fosroc Solvent 102*. barrier cream such as Kerodex 71, Rozalex 9, Debba-Wet

Work or similar should be used when handling these products.

Hot weather working

If contact with the resin occurs, it must be removed before it

Whilst the performance of Conbextra EP10 at elevated hardens with a resin removing cream such as Kerocleanse

temperatures is assured, application under such conditions 22 or Rozalex 42. Follow by washing with soap and water.

can sometimes be difficult. It is therefore suggested that, for Do not use solvent. The use of goggles is recommended but

temperatures above 35C, the following guidelines are used: should accidental eye contamination occur, wash thoroughly

with plenty of clean water and seek medical treatment

(i) Store unmixed materials in a cool (preferably temperature

immediately.

controlled) environment, avoiding exposure to direct

sunlight. Fire

(ii) Keep mixing and placing equipment cool, arranging Nitoprime 25 and Fosroc Solvent 102 are flammable.

shade protection if necessary. It is especially important

to keep cool those surfaces of the equipment which will Flash points

come into direct contact with the material itself. Nitoprime 25 : 39C

Fosroc Solvent 102 : 33C

(iii) Try to eliminate application in the middle of the day, and

certainly avoid application in direct sunlight.

(iv) Ensure that there are sufficient operatives available to * Denotes the trademark of Fosroc International Limited

complete application within the materials pot life.

See separate data sheet

Important note

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for

the Supply of Goods and Service. All Fosroc datasheets are updated on a regular basis. It is the users responsibility to

obtain the latest version.

Head Office

telephone: (+9714) 2039699 fax: (+9714) 2859649 email: agf@fosroc.com

Al Gurg Fosroc LLC

Regional offices

Post Box 657, Dubai Abu Dhabi, Al Gurg Fosroc telephone: 673 1779 fax: 673 1449 email: abudhabi@fosroc.com

United Arab Emirates Bahrain, YBA Kanoo telephone: 17738200 fax: 17732828 email: bahrain@fosroc.com

Kuwait, Boodai telephone: 4817618 fax: 4832124 email: kuwait@fosroc.com

www.fosroc.com

Oman, Al Amana telephone: 24815080 fax: 24817554 email: oman@fosroc.com

Qatar, Tadmur telephone: 4432365 fax: 4419517 email: qatar@fosroc.com

UAE/0324/07/D

Você também pode gostar

- A4 80Documento2 páginasA4 80alwezalokAinda não há avaliações

- Arihant - Mat Solvedpaper 2012Documento26 páginasArihant - Mat Solvedpaper 2012Extra MarksAinda não há avaliações

- Specifications Part1Documento3 páginasSpecifications Part1ganmosesAinda não há avaliações

- IC - B1 - SW - SP03 - v1.0 - Week 3Documento4 páginasIC - B1 - SW - SP03 - v1.0 - Week 3ganmoses100% (2)

- Geogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFDocumento115 páginasGeogroup Company, Soil Investigation, Geogroup Laboratory, Soil Mechanics Testing PDFChan Hoi KitAinda não há avaliações

- Admixtures in ConcreteDocumento15 páginasAdmixtures in ConcreteSundara LingamAinda não há avaliações

- 002 Waterstop FactsDocumento0 página002 Waterstop FactsganmosesAinda não há avaliações

- Soil Compaction Earthworks - Notes PDFDocumento47 páginasSoil Compaction Earthworks - Notes PDFGnabBangAinda não há avaliações

- Road Geometric Design Manual PDFDocumento690 páginasRoad Geometric Design Manual PDFganmosesAinda não há avaliações

- 316 316L Data SheetDocumento2 páginas316 316L Data SheetHanna ChanAinda não há avaliações

- Heavy PlatesDocumento41 páginasHeavy PlatesganmosesAinda não há avaliações

- Angle of Repose & Angle of FrictionDocumento4 páginasAngle of Repose & Angle of Frictionganmoses50% (2)

- SSINA - Designer's Handbook - Stainless Steel FastenersDocumento23 páginasSSINA - Designer's Handbook - Stainless Steel FastenersSerguei DobrinAinda não há avaliações

- A4 80Documento2 páginasA4 80alwezalokAinda não há avaliações

- Aalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFDocumento3 páginasAalco Metals LTD - Aluminium Alloy 6063 T6 Extrusions - 158 PDFganmosesAinda não há avaliações

- Admixtures For ConcreteDocumento4 páginasAdmixtures For ConcreteMuhammad Shahbaz KhokharAinda não há avaliações

- Epoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidDocumento4 páginasEpoxy or Polyurethane Foam?: Stories and Photos by Jay SchmidganmosesAinda não há avaliações

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 316 316L Data Bulletin PDFDocumento0 página316 316L Data Bulletin PDFRKLNAinda não há avaliações

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDocumento1 páginaGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesAinda não há avaliações

- DCL Test ChargesDocumento1 páginaDCL Test ChargesganmosesAinda não há avaliações

- Underpass DWGDocumento1 páginaUnderpass DWGganmosesAinda não há avaliações

- SpeedyDocumento4 páginasSpeedyBudhi KurniawanAinda não há avaliações

- GeoMatt Datasheet TB11 Ed1 2017 ASTM ADDocumento1 páginaGeoMatt Datasheet TB11 Ed1 2017 ASTM ADganmosesAinda não há avaliações

- Nitomortar FC PDFDocumento2 páginasNitomortar FC PDFganmosesAinda não há avaliações

- Bearing Capacity of SoilsDocumento138 páginasBearing Capacity of SoilsMuqeem Khan100% (1)

- Grain Size AnalysisDocumento5 páginasGrain Size AnalysisganmosesAinda não há avaliações

- Conventional AC DesignDocumento42 páginasConventional AC Designabdikarim_omarAinda não há avaliações

- FPI FiberglassbookDocumento164 páginasFPI FiberglassbookA_ValsamisAinda não há avaliações

- DG3 Sheeting PDFDocumento8 páginasDG3 Sheeting PDFganmosesAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Intermediate Accounting Testbank 2Documento419 páginasIntermediate Accounting Testbank 2SOPHIA97% (30)

- Mosaic Maker - Instructions PDFDocumento4 páginasMosaic Maker - Instructions PDFRoderickHenryAinda não há avaliações

- Trustees Under IndenturesDocumento233 páginasTrustees Under IndenturesPaul9268100% (6)

- Lead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RDocumento189 páginasLead Magnet 43 Foolproof Strategies To Get More Leads, Win A Ton of New Customers and Double Your Profits in Record Time... (RluizdasilvaazevedoAinda não há avaliações

- Optimize Coverage and Performance with 12dB MTMA AmplifierDocumento3 páginasOptimize Coverage and Performance with 12dB MTMA AmplifierpecqueurAinda não há avaliações

- JIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test MethodsDocumento43 páginasJIS K 6250: Rubber - General Procedures For Preparing and Conditioning Test Pieces For Physical Test Methodsbignose93gmail.com0% (1)

- How To Make Pcbat Home PDFDocumento15 páginasHow To Make Pcbat Home PDFamareshwarAinda não há avaliações

- Fact Sheet Rocket StovesDocumento2 páginasFact Sheet Rocket StovesMorana100% (1)

- Lea 201 Coverage Topics in Midterm ExamDocumento40 páginasLea 201 Coverage Topics in Midterm Examshielladelarosa26Ainda não há avaliações

- UPGRADEDocumento2 páginasUPGRADEVedansh OswalAinda não há avaliações

- M Series CylindersDocumento61 páginasM Series CylindersAndres SantanaAinda não há avaliações

- Request For AffidavitDocumento2 páginasRequest For AffidavitGhee MoralesAinda não há avaliações

- Telangana Budget 2014-2015 Full TextDocumento28 páginasTelangana Budget 2014-2015 Full TextRavi Krishna MettaAinda não há avaliações

- Philippines Taxation Scope and ReformsDocumento4 páginasPhilippines Taxation Scope and ReformsAngie Olpos Boreros BaritugoAinda não há avaliações

- 2016 04 1420161336unit3Documento8 páginas2016 04 1420161336unit3Matías E. PhilippAinda não há avaliações

- Ultrasonic Examination of Heavy Steel Forgings: Standard Practice ForDocumento7 páginasUltrasonic Examination of Heavy Steel Forgings: Standard Practice ForbatataAinda não há avaliações

- Corena s2 p150 - Msds - 01185865Documento17 páginasCorena s2 p150 - Msds - 01185865Javier LerinAinda não há avaliações

- Software Engineering Modern ApproachesDocumento775 páginasSoftware Engineering Modern ApproachesErico Antonio TeixeiraAinda não há avaliações

- Book Two - 2da. EdiciónDocumento216 páginasBook Two - 2da. EdiciónJhoselainys PachecoAinda não há avaliações

- DX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Documento6 páginasDX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Welissa ChicanequissoAinda não há avaliações

- CVP Solution (Quiz)Documento9 páginasCVP Solution (Quiz)Angela Miles DizonAinda não há avaliações

- Entrepreneurship and EconomicDocumento2 páginasEntrepreneurship and EconomicSukruti BajajAinda não há avaliações

- City Gas Distribution ReportDocumento22 páginasCity Gas Distribution Reportdimple1101100% (9)

- Verifyning GC MethodDocumento3 páginasVerifyning GC MethodHristova HristovaAinda não há avaliações

- Activate Adobe Photoshop CS5 Free Using Serial KeyDocumento3 páginasActivate Adobe Photoshop CS5 Free Using Serial KeyLukmanto68% (28)

- Liability WaiverDocumento1 páginaLiability WaiverTop Flight FitnessAinda não há avaliações

- Admission Checklist (Pre-) Master September 2021Documento7 páginasAdmission Checklist (Pre-) Master September 2021Máté HirschAinda não há avaliações

- Evan Gray ResumeDocumento2 páginasEvan Gray Resumeapi-298878624Ainda não há avaliações

- NVH Analysis in AutomobilesDocumento30 páginasNVH Analysis in AutomobilesTrishti RastogiAinda não há avaliações

- Anthony Flagg's Complaint Against Eddie LongDocumento23 páginasAnthony Flagg's Complaint Against Eddie LongRod McCullom100% (1)