Escolar Documentos

Profissional Documentos

Cultura Documentos

4 Panel Saw PDF

Enviado por

Turijan MxTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

4 Panel Saw PDF

Enviado por

Turijan MxDireitos autorais:

Formatos disponíveis

Plans N O W

w w w. P l a n s N O W. c o m

shop-built

PANEL SAW

P anel saws are impressive. They make it

easy for one person to cut a plywood sheet.

But the high price of a store-bought model

has always kept me from adding this tool to my

shop. So I decided to build my own version with

saw 90, and push the workpiece through the

blade. To provide additional support when rip-

ping a full sheet of plywood, I added two remov-

able wings to the sides of the saw.

MOBILE. Since the Panel Saw is about 10

the features that I like. feet long (with the wings), I attached casters

VERTICAL BED. To prevent twist and warp, I to roll it around. When Im done cutting, the

used sturdy, 3/4" birch plywood to create a vertical Panel Saw folds up flat and rolls against the wall

A-frame bed. And for the support rails, I used a for storage.

strong Douglas fir for added strength. DESIGN OPTION. This plan includes an

RIPPING. The Panel Saw can also be used for optional design for adding a router carriage for

ripping. Just lock the carriage in place, rotate the cutting grooves and dadoes in sheet goods.

From ShopNotes magazine page 1 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

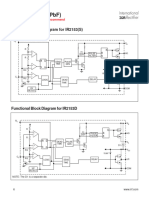

EXPLODED VIEW

OVERALL DIMENSIONS:

1163/8W x 271/4D x 767/8H

1!/2" SLIDING GLASS

DOOR WHEEL

PULLEY S PULLEY BASE PLATE

SUPPORT T

D TOP RAIL

TOP BRACE

PLATE EDGE

G RAIL 1!/2" EMT CONDUIT

C

COUNTER-

%/16" WEIGHT L CARRIAGE

PLASTIC #/32"

T-KNOB WIRE

ROPE

K INSERT

BRACE B

F CENTER

RAIL

BOTTOM

BRACE

PLATE

G MATERIAL

REST EXTENSION

FOOT EXTENSION

BACK Q

H A A P

BED PIECE

BASE

PIECE

I R

LIP

EXTENSION

N

MATERIAL

REST LIP

M

3" BUTT MATERIAL

HINGE O REST

EXTENSION

E SUPPORT

BOTTOM 1!/2"

RAIL CONDUIT

THREADED STRAP

STAR KNOB

MATERIALS LIST

WOOD

A Bed Pieces (2) 3/ ply - 36 x 72 T Pulley Support (1) 3/ ply - 2 x 6 (1) 5/16" x 2" - 31/4" square U-bolt

4 4

B Center Rails (2) 11/2 x 3 - 72 U Pipe Cap (1) 3/ x 21/ -dia. rough

4 2 (1) 5/16" lock nut w/ nylon insert

C Edge Rails (2) 11/2 x 3 - 78 (4) 5/16" x 21/4" threaded star knobs

D Top Rail (1) 11/2 x 23/8 - 305/8 HARDWARE SUPPLIES (4) 5/16" T-nuts

E Bottom Rail (1) 11/2 x 23/8 - 777/8 (100) No. 8 x 11/2" Fh woodscrews (1) 5/16" x 11/2" eye bolt

F Braces (2) 11/2 x 3 - 48 (16) No. 8 x 11/4" Fh woodscrews (8) 3/8" x 5" lag bolts

G Top/Btm. Br. Plt. (1) 3/ ply - 6 x 151/ (7) 1/4" x 3/4" threaded round knobs (8) 3/8" washers

4 2

H Foot (1) 3/ ply - 3 x 8 (7) 1/4" T-nuts w/ brad holes (34) 1/2" nylon spacers -.375 x .562

4

I Base Pieces (2) 3/ ply - 193/ x 32 rgh. (8) 1/4" x 11/2" lag bolts (5) 7/8" nail-on plastic glides

4 4

J Turnbuttons (2) 3/ x 11/ - 31/ (18) 1/4" washers (2) 11/2" x 72" EMT conduit

4 2 2

K Insert (1) 1/ hdbd. - 73/ x 113/ (4) 1/4" x 11/4" fender washers (4) 11/2" conduit straps

4 4 4

L Carriage (2) 1/ hdbd. - 153/ x 19 (1) 1/4" x 4" hex bolt (2) 11/2" sliding glass door wheels

2 4

M Material Rest (2) 11/4 x 2 - 331/4 (2) 1/4" x 11/2" hex bolts (1) No. 6 x 11/2" S-hook

N Matl. Rest Lips (2) 1/ hdbd. - 21/ x 253/ (3) 1/4" hex nuts (2) 2" swivel casters

4 2 4

O Ext. Supports (2) 3/ ply - 7 x 48 (2) 5/16" x 3" hanger bolts (8) 3" butt hinges w/ screws

4

P Ext. Back (2) 3/ ply - 77/ x 24 (3) 5/16" plastic T-knobs (1) 3" x 13" PVC pipe

4 8

Q Matl. Rest Ext. (2) 11/4 x 2 - 22 (4) 5/16" x 2" - 31/4" U-bolts (7 ft.) 3/32" wire rope

R Lip Extensions (2) 1/ hdbd. - 21/ x 22 (18) 5/16" hex nuts (2) 3/32" crimp-on clips

4 2

S Pulley Base Plate (1) 3/ ply - 6 x 9 (18) 5/16" washers (16 lbs.) Lead weight (will vary with saw)

4

From ShopNotes magazine page 2 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

CUTTING DIAGRAM BED

#/4" BIRCH PLYWOOD - 48 x 96 #/4" BIRCH PLYWOOD - 24 x 48

I started on the Panel Saw by making the

O

bed. The bed is built in two sections. Each

I O

A section consists of a triangular piece of

G G S plywood with one edge rail and one center

I H rail screwed to the long edges of each bed

T

piece (Fig. 1).

A !/4" TEMPERED HARDBOARD - 24 x 48

P CUT PIECES. To make the bed sections,

N R

start by cutting two bed pieces (A) from a

P

L L

K blank of 3/4" plywood (Fig. 1). To do this,

NOTE: ALSO NEED FOUR

I first raised the plywood off the floor with

96" PIECES 2x8 DOUGLAS FIR some scrap 2x4s. Then I clamped another

2x4 diagonally across the workpiece to

act as a straightedge for the saw. Next, cut

1 the center and edge rails (B, C) to length

NOTE: EDGE AND CENTER

RAILS ARE 1!/2"-THICK STOCK. (Fig. 1). Note: The edge rails are cut 6"

BED PIECES ARE #/4" PLYWOOD

11&/8 longer than the center rails (Fig. 1). I used

78

C EDGE RAIL

straight-grained 2x8s for both the center

and edge rails. I ripped them to a finished

width of 3".

ATTACH RAILS. With all of the rails cut

B A 3 to size, they are ready to be clamped and

CENTER RAIL BED PIECE screwed to the bed pieces. The edge rails (C)

72 need to extend past the bottom edge of the

bed. They will become two of the feet for

BED a. EDGE b. the panel saw (Fig. 1b). To ensure that both

RAIL

EDGE EXTENDS feet extend an equal distance on both sides,

RAIL #8 x 1!/2" Fh PAST BED EDGE just position the top inside corner of each

A WOODSCREW 36 RAIL

TOP INSIDE C edge rail flush with the top of the bed (Fig.

CORNER IS C BED A 1a). The center rails (B) are left flush with

FLUSH WITH

BED the bottom edge of the bed.

CONNECT SECTIONS. After the two

sections are complete, theyre connected

2 THIRD: with a top and bottom rail (D, E) (Fig. 2).

D LAG BOLT ENDS I used the remainders of the 2x8s to make

TOP RAIL (SEE DETAIL a)

(2#/8" x 30%/8") the rails, but this time the rails are ripped to

a finished width of 23/8".

CUTTING TROUGH. To prevent the cir-

SECOND: cular saw from cutting into the bed, a space

SCREW BED

TO RAILS (cutting trough) is left between the two sec-

tions (Fig. 2). I used a piece of 6"-long scrap

NOTE: WASHER 2x4 as the spacer to get both sections into

RAILS ARE

1!/2"-THICK place before screwing the bed pieces to the

STOCK

rails (Fig. 2). Note: This scrap spacer will

a. be used later to position the guide tubes. For

added strength, I secured the ends of the

#8 x 1!/2" Fh edge and center rails to the top and bottom

FIRST: WOODSCREW

#/8" USE 6" LONG rails with lag bolts (Fig. 2a).

WASHER SPACER TO POSITION E

BED SECTIONS ON RAILS BOTTOM RAIL CASTERS. Finally, to roll the saw around

#/8" x 5" the shop, I screwed a pair of 2" swivel casters

LAG BOLT

b. under the bottom rail (Fig. 2b).

77&/8

BOTTOM

BED RAIL BACK SUPPORT

2#/8

EDGE

RAIL EDGE Once the bed is complete, the next step is

RAIL

to make the folding back support. In the

BOTTOM down position, it holds the bed upright.

RAIL #8 x 1!/2" Fh

2" SWIVEL CASTER WOODSCREW

CASTER

From ShopNotes magazine page 3 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

The back support consists of two main 3

parts: a brace assembly and two plywood a. %/16" x 3"

HANGER BOLT

base pieces (Fig. 3).To move the Panel

NOTE:

Saw, the back support folds up, and the TOP BRACE LOCATE

PLATE HANGER

saw can be rolled around on the casters. G BOLTS 46"

The back support consists of two FROM

%/16" PLASTIC

BOTTOM OF

main parts: a brace assembly and two CENTER RAIL T-KNOB

plywood base pieces (Fig. 3). F

BRACE ASSEMBLY. The brace is a B BRACE G

CENTER TOP BRACE

simple wood frame (Fig. 4). The braces BRACE J

RAIL PLATE

(F) are 11/2"-thick stock cut to a finished F TURNBUTTON

(#/4" STOCK -

length of 48". Complete the frame by 1!/2" x 3!/2")

screwing a 3/4" plywood top and bottom b. BOTTOM

BRACE

plate (G) to the braces (Fig. 4). CENTER RAIL PLATE

To secure the brace assembly to the BRACE G

F

vertical bed, cut slots in the top plate

(Fig. 4a). The slots fit over hanger bolts

installed in the center rails (Fig. 3a). BOTTOM 3" BUTT

BASE BRACE HINGE

Tightening a plastic T-knob (or wing nut) PIECE PLATE

FOOT

locks the bed in place. I G H

Note: A counterbore at the end of the H FOOT

slot prevents the knob from sliding as its I BASE PIECE

tightened (Figs. 3a and 4a).

FOOT. Now all that needs to be done

to complete the brace assembly is to 4 SCREW TOP AND BOTTOM

screw a plywood foot (H) to the bottom TOP BRACE PLATE G BRACE PLATES FLUSH

WITH ENDS AND EDGES BOTTOM

plate (Fig. 4). With the ends of the two OF BRACES BRACE PLATE

edge rails, this foot creates a tripod that NOTE: BRACES G

#8 x 1!/2" Fh

stabilizes the Panel Saw. ARE 1!/2"-THICK STOCK. WOODSCREW

PLATES AND FOOT

BASE. The last step is to build the ARE #/4" PLYWOOD 6

base. The base is just two triangular- F 15!/2

shaped pieces of plywood that keep the

BRACE F

Panel Saw from racking (Fig. 5).

The base pieces (I) are hinged to

the bed and braces (Fig. 5). Start by a. FIRST: DRILL 1" 48

screwing the brace assembly to the base COUNTERBORE !/8" DEEP

pieces. But to allow the back support to 4!/4

easily fold up, I left 1/4" clearance between NOTE: H

TOP EXTEND FOOT 3 FOOT

the base pieces and the center rails. 1

PLATE 2" PAST BOTTOM (3" x 8")

Note: To keep everything straight, BRACE PLATE

SECOND:

screw the hinges to the bases first. Attach CUT #/8"-WIDE SLOT TO

END OF COUNTERBORE #8 x 1!/4" Fh

the back support with screws to the bed. WOODSCREW

TURNBUTTON. Finally, screw a

turnbutton (J) to each center rail to

secure the back support in the up

position (Fig. 3).

5 POSITION EDGE OF

BASE PIECE !/4" FROM

CENTER RAIL a. 32

2 BASE PIECE

I

I

19#/4

3" BUTT HINGES

NOTE:

WOODSCREW BRACE BASE PIECE

ASSEMBLY IS #/4" PLYWOOD

BASE PIECE 3!/2

I

From ShopNotes magazine page 4 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

6 !/4" x #/4" THREADED

ROUND KNOB a. .375 I.D. x .562

!/4" x 1!/4" INSERT GUIDE O.D. - !/2"-LONG

%/16" x 2" - 3!/4" FENDER K TUBE NYLON SPACERS

U-BOLT W/ PLATE WASHER

CUT ONE 1!/2"

NYLON SPACER IN HALF THIN WALL

SPACERS %/16" TO FILL U-BOLT ELECTRICAL

WASHER CONDUIT

%/16"

T-KNOB

&/8" NAIL-ON

!/4" PLASTIC CUT ENDS OF

T-NUT FURNITURE BOLT FLUSH

%/16" GLIDE WITH NUT TRIM FLUSH

HEX NUT

NOTE: SQUARE

b. 19

!/2

CARRIAGE

L U-BOLT LOCKS

SAW IN POSITION

%/16" LOCK NUT FOR RIPPING

W/ NYLON INSERT (SEE PAGE 97)

!/2

%/16" x 2" - 3!/4" CL

SQUARE U-BOLT L

W/ STRAP

CL 15#/4

c. BEARING RIDES

ON TOP EDGE

d. CREATE 2!/4

LIP BY #/8

OF GUIDE STRIP REMOVING

WASTE WITH

RECESS JIG SAW

GUIDE ROUT !/4"-

STRIP DEEP RECESSES

#/8

2!/4

CARRIAGE

CARRIAGE WASTE

DRILL #/64"-DIA. HOLES

!/2" PATTERN BIT FOR FURNITURE GLIDES

7 THIRD: DRILL

CARRIAGE ASSEMBLY

FIRST: LOCATE AND HOLES AND CUT SLOT

DRILL THREE %/16" HOLES

IN BASE OF SAW SLOT IN INSERT a. ADJUSTING The heart of this Panel Saw is the car-

SAW HOLE

BASE riage assembly. This versatile assembly

DRILL provides an easy way to mount the saw.

%/16"

BLADE

HOLE Plus, it allows you to easily rotate the saw

OPENING for accurate crosscutting or ripping. The

carriage assembly is built from three

b. !/4" THREADED

11#/4 ROUND main parts: an insert attached to the base

K INSERT KNOB

INSERT !/4 of the circular saw, a sliding carriage to

7#/4 SECOND:

CENTER SAW BASE hold the insert, and a pair of metal guide

PIVOT ON INSERT AND SAW tubes that the carriage slides on.

POINT HOLE TRANSFER HOLES

!/4" T-NUT BASE INSERT. The base of the circular

saw is attached to an insert (K) made of

1/ " hardboard that fits into a recessed

4

opening in the carriage (Fig. 6).

8 FIRST: SECOND: THIRD: MOUNTING HOLES. The saw is then

GLUE UP TWO CENTER INSERT POSITION GUIDE

PIECES OF !/4" ON CARRIAGE STRIPS AROUND mounted to the hardboard insert with 1/4"

HARDBOARD EDGES OF

INSERT

threaded knobs and T-nuts. This means

youll first have to drill three holes in the

saw base (Fig. 7).

INSERT After drilling the holes, center the saw

K base on the insert, and transfer the loca-

GUIDE

a. !/4" HARDBOARD

tion of the holes and the blade opening

STRIP

onto the insert. Now you can drill the

#/4"

PLY holes and cut the slot in the insert.

GUIDE 1

ADJUSTMENT. Next, to provide a

L

CARRIAGE way to adjust the saw, enlarge the two

CARPET 3 holes at the end of the insert (Fig. 7a).

TAPE

The single hole at the other end of the

insert will be used later as a pivot point

to help position the saw blade.

From ShopNotes magazine page 5 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

CARRIAGE 9 SECOND:

SLIDE CARRIAGE TO TOP

OF GUIDE TUBES

Just as its name implies, the carriage NOTE: SEE THE

carries the saw up and down the guide TOP RAIL SHOP TIP BELOW

1!/2" ON HOW TO

tubes on the Panel Saw. Depending on CONDUIT MAKE THE TUBES

STRAP ADJUSTABLE

whether youre ripping or crosscutting !/4" x 1!/2"

LAG BOLT GUIDE

a panel, the insert fits into one of the two TUBE

(1!/2" CONDUIT)

recessed openings. To make the carriage

THIRD:

(L), start by gluing together two pieces LAG BOLT

of 1/4" hardboard (Figs. 6 and 6b). CONDUIT

STRAPS FIRST:

Creating the recessed openings is a SPACER CLAMP SPACER

FOURTH: TO BACK OF

simple two-step process. First, a 1/4"-deep REPEAT PROCESS

BLOCK

CARRIAGE

recess is routed in the carriage to match AT THE BOTTOM

OF PANEL SAW

the shape of the insert (Fig. 6c). Then a

lip is created by removing the waste with

a jig saw (or coping saw) (Fig. 6d).

The trick to making the recess is to

10

use the insert as a template and rout the

THREADED

recess with a pattern bit. First, center the KNOB

insert on the carriage (Fig. 8). Then, to

guide the router, tape strips around the

a. !/4" THREADED KNOB

edges of the insert with carpet tape.

ROUT RECESS. Now you can remove FENDER

WASHER

the insert and rout one recess (Fig. 6c). HOLDS INSERT

IN PLACE

Then repeat the process, and rout a CARRIAGE

second recess 90 to the first (Fig. 6b). INSERT

LIP. To complete the openings and INSERT

CARRIAGE

form the lip for the insert, remove the FENDER

WASHER

waste with a jig saw (Fig. 6d). !/4" T-NUT

HARDWARE. All thats left is to drill

holes and install hardware onto the car-

riage. To help the carriage slide smoothly the guide tubes and the carriage, I added INSTALL TUBES. Now the top and

without a lot of play, I slipped nylon nail-on plastic furniture glides between bottom ends of the guide tubes can be

spacers over the four U-bolts. Just slide the ends of each U-bolt. secured with the straps and lag bolts

them over the bolts like you would when (Fig. 9). But first, slot the holes in the

lacing beads on a necklace. GUIDE TUBES ears of the conduit straps (see the Shop

Note: You may need to cut one of the Tip at left). Next, place a square U-bolt

spacers in half to completely cover the The next step in assembling the car- and a locking knob on the carriage. This

U-bolt and surround the tube (Fig. 6a). riage is to use conduit straps to attach U-bolt is used to lock the carriage in place

Finally, to reduce the friction between the carriage guide tubes to the top and (see the Technique on page 97).

bottom rails. (The tubes are just 6-foot ATTACH INSERT. Finally, attach the

long pieces of 11/2" thin wall electrical insert to the carriage with knobs and

conduit.) T-nuts (Fig. 10a). The knobs tighten

MOUNT CARRIAGE. Before attaching against fender washers, holding the

the guide tubes, slide the ends of the insert in place.

Enlarge Holes tubes through the carriage U-bolts. Now

To make the guide tubes adjust- the carriage assembly can be slid over

able, I enlarged the holes in the the top and bottom rails.

ears of the conduit straps. The key is to center the carriage

on the cutting trough and position the

guide tubes parallel with each other.

An easy way to do this is to use the

same spacer that was used earlier to

ENLARGE form the cutting trough. Just clamp the

HOLE

spacer so its centered on the back of

the carriage and extends into the cut-

ting trough (Fig. 9). Thanks to a pair of recesses placed per-

As you slide the carriage to the top and pendicular to each other, the insert can be

bottom of the tubes, the spacer centers rotated 90 for crosscutting or ripping.

the carriage on the cutting trough, posi-

tioning the tubes parallel to each other.

From ShopNotes magazine page 6 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

MATERIAL REST CHAMFER EDGES. To prevent sheet rest. This will help to track workpieces

goods from catching on the material along the material rest (Fig. 11).

The Panel Saw is designed with a mate- rest, the top edge of each opening is Note: Cut the lip shorter than the rest

rial rest to support sheet goods during chamfered (see Shop Tip on this page). to allow clearance for the carriage.

a cut. Why not just use the bottom rail I also chamfered the edges of the bed ATTACH REST. The last step is to

as a rest? Because the carriage would next to the cutting trough. clamp and screw the material rest to the

bottom out on the rail before the saw LIP. Before attaching the material rest bed (Fig. 11a). The key here is to posi-

could cut all the way through a work- to the bed piece, glue a 1/4" hardboard lip tion the pieces so the top edges are level

piece. (N) flush with the ends of the material and are 90 to the cutting trough.

The material rest (M) is made of two

11/4"-thick blanks (one for each half of 11 CHAMFER EDGES

the bed) (Fig. 11). A number of deep (SEE SHOP TIP

AT LEFT)

SCREW MATERIAL

REST TO BED WITH

dadoes create openings in the rest that MATERIAL #8 x 1!/2" Fh

allow sawdust to fall through. REST WOODSCREWS

M

LOCATE

BOTTOM

OF MATERIAL

Eased Edges 2!/2

33!/4 REST 7" FROM

BOTTOM RAIL

To allow workpieces to slide easily

2

on the material rest, rout or file a

chamfer on the top edges of each

N

opening and the edge of the bed MATERIAL 25#/4

next to the cutting trough. REST LIP

(!/4" HARDBOARD)

GLUE END OF LIP

MATERIAL

a. REST M FLUSH WITH END

OF MATERIAL REST

FILE FILE

TOP EDGES BED

EDGE TOP VIEW

OF

BED

b.

2!/2 2 1#/4 2

2!/2

M 2

1!/4 M

NOTE: DADOES

ALLOW DUST N LIP

LIP N !/4 TO FALL THROUGH

12 CUT END OF EXTENSION TO

MATCH OUTSIDE EDGE OF BED

a. P EXTENSION

Q

3 R

24

#8 x 1!/2" Fh

P WOODSCREW

EXTENSION 2

21 BACK %/16"

THREADED T-NUT

KNOB #8 x 1!/4" Fh

WOODSCREW

7&/8

MATERIAL

REST

EXTENSION O

Q EXTENSION

SUPPORT %/16" x 2!/4" O 3!/2

(7" x 48") THREADED

OVERLAP KNOB

BY 2"

2

NOTE:

CHAMFER

TOP EDGE FOR BED

NOTE:

R DUST RELIEF EXTENSION

22 BACK AND

LIP SUPPORT BOTTOM

EXTENSION GLUE LIP TO ARE #/4" PLYWOOD RAIL

(!/4" HARDBOARD) MATERIAL REST

2!/2

From ShopNotes magazine page 7 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

WINGS

To provide extra support when ripping, I port. To hold the shot in the pipe, I cut a An S-hook in one loop hooks into an

built two wings. Each wing consists of 3/ " hardwood pipe cap (U) to fit snugly eye bolt that is installed on the carriage

4

an extension support (O) and an exten- inside the end of the pipe (Fig. 15b). (Fig. 14). (I cut off the exposed, threaded

sion back (P) (Fig. 12). WIRE CABLE. After the counter- end of the eye bolt for clearance.) The

The support is ripped to width from a weight was done, I ran a 7-foot length other end slips over a bolt which passes

48"-long piece of plywood to fit between of wire cable over the pulleys to con- through the top of the pipe (Fig. 15a).

the material rest and the bottom rail. nect the pipe to the carriage. Each end Note: To keep the loop from slipping

Next, I cut the extension back to of the cable has a loop made with a to one side of the bolt, I filed a small notch

match the diagonal edges of the vertical crimp-on clip. in the middle of the bolt (Fig. 15a).

bed, and screwed the pieces together

(Fig. 12a). To make the wings remov-

able for storage, I drilled two holes for 13

threaded knobs, T-nuts, and washers in #8 x 1!/2" Fh

a. CENTER PULLEY

WOODSCREW 1!/2"

each of the extension supports. !/2 #/4

PULLEY

T SUPPORT PULLEY ON LENGTH

!/4" OF BASE

MATERIAL REST. Finally, build a HEX NUT PLATE

material rest extension from 11/2" stock PULLEY

(Q) and a hardboard lip extension (R) for BASE PLATE

each wing (Fig. 12). S

!/4" x 1!/2" 2

HEX BOLT

PULLEY SYSTEM #/4 1

6

All thats left to complete the Panel Saw

CL

is to add a pulley system and counter- S

weight. The idea here is for the carriage 9

NOTE: #8 x 1!/2" Fh

to return easily to the top of the guide FRONT EDGES OF CENTER WOODSCREW

tubes when you finish a cut. BASE AND RAIL RAIL

ARE FLUSH

The pulley system consists of three TOP RAIL

parts: a pulley base plate (S), a pulley

support (T), and a couple of 11/2" wheels 14 FORM LOOP AND %/16"

used for sliding glass doors (Fig. 13). CRIMP ON #/32" CLIP HEX NUT a. CRIMP CLIP

The base plate and pulley support IN VISE

are both made from 3/4" plywood (Fig. #/32"

WIRE

NOTE:

13). After drilling holes and bolting the CABLE

CUT OFF END

#6 x 1!/2" S-HOOK OF EYE BOLT

wheels to the pulley support, the two S-HOOK

pieces can then be screwed together

to form an upside-down T-shape (Fig.

CARRIAGE

13a).

Note: Locate the pulley support so

the pulleys (not the support) are cen-

%/16"

tered on the length of the base plate. WASHER

EYE

The final step in completing the pulley %/16" x 1!/2" BOLT CARRIAGE

EYE BOLT

system is to screw the base plate to the

top rail so the pulleys are centered on the

width of the cutting trough.

15

COUNTERWEIGHT !/4" x 4"

HEX BOLT

PVC PIPE a.

With the pulley system in place, the (3" DIA. x 13" LONG) CABLE

last step is to add a counterweight. The FILE

NOTCH

secret is to make the counter weight IN BOLT

roughly equal to the combined weight !/4" HEX NUT

of your circular saw and carriage. (In my PVC PIPE

case, this was sixteen pounds.)

This lets you control the saw as it cuts CUT

a panel. And it allows the saw to travel #/4"-THICK b.

PIECE OF

easily back to the top of the tubes. STOCK

#8 x 1!/4" Fh TO FIT END

LEAD SHOT. To make the counter- WOODSCREW OF PIPE

weight, I filled a length of 3" PVC pipe U

with lead shot (Fig. 15). But concrete, FILL PIPE WITH LEAD SHOT

sand, or any other weight will work fine, TO MATCH WEIGHT OF SAW

PIPE

just as long as it clears the back sup- CAP U

(2!/2" DIA.)

From ShopNotes magazine page 8 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

SETUP . . . . . . . . . . . . . . . . . . . . Panel Saw

T aking a few minutes to tune up the

Panel Saw is the secret to making

perfect cuts. The idea is to adjust the

Next youll check the saw blade for

alignment. This is simple. Just mark

a tooth on the blades back side, then

guide tubes 90 to the material rest. rotate the saw blade forward until the

First, you need to clamp a block of same tooth aligns with the plywood edge

scrap to the carriage (Step 1). Next, again (Step 3). If there is a gap between

place a sheet of plywood (with a factory the plywood edge and the marked tooth,

square corner) on the material rest so the saw requires further adjustment.

one edge extends into the cutting trough. To make this adjustment, loosen the

Now slide the carriage along the guides, threaded knobs on each side of the insert

checking carefully for gaps. and pivot the saw. Test the adjustment

If there are gaps, youll need to adjust by rotating the blade and watching the

the guide tubes (Step 2). This is done marked tooth again (Step 4). Repeat

easily by first loosening the conduit until the marked tooth aligns with the

straps. Then place a 6"-long scrap block plywood edge. Just be sure to tighten the

between them to keep them parallel. knobs once the saw is aligned.

NOTE:

SLOTS IN STRAPS ALLOW TUBES

TO MOVE SIDE TO SIDE

CUT

BLOCK BLOCK

TO FIT

BETWEEN

GUIDE

TUBES

FACTORY EDGE

OF PLYWOOD

First, clamp a short scrap block to the carriage to align the Then, to adjust the guide tubes, first loosen the top or bottom

1 guide tubes. (This is the same scrap block you used earlier.) 2 conduit straps. Then tap the tubes into position. The slots in

Then push a sheet of plywood against the edge of the block, and the conduit straps make this easy. Cut a block to fit between the

slide the carriage up and down to check for a gap. tubes to keep them parallel while theyre adjusted.

NOTE: SECOND:

UNPLUG SAW PIVOT SAW

BEFORE

MARKING FIRST:

TOOTH LOOSEN KNOBS

MARK TOOTH

WITH FELT

TIP PEN

ROTATE BLADE SO

MARKED TOOTH

IS IN FRONT

The next step is to check the alignment of the saw blade. This If the distance between the marked tooth and the plywood

3 is a rather simple process. Just mark a tooth on the blades 4 edge varies, the saw needs to be adjusted. First you need to

back side. Then rotate the blade forward until the marked tooth loosen the knobs that hold the saw to the insert. Then pivot the

aligns with the plywood edge again. saw to align the blade.

From ShopNotes magazine page 9 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

TECHNIQUE . . . . Using the Panel Saw

T he Panel Saw is not only capable of

crosscutting, its great at ripping

large sheet goods as well. To do this,

Note: For a straight cut, its impor-

tant that the blade is perfectly aligned.

If youre unsure of the alignment of the

Some older circular saws arent

equipped with lock switches. If your

saw doesnt have a lock switch, just use

the carriage needs to be locked in place, carriage, guide tubes, or saw blade, see a spring clamp to hold down the trigger

then the workpiece is pushed through the Setup article on the previous page. switch during a cut (Fig. 2).

the blade (see photo at right). Setting Then slide the carriage to the desired

up the saw for ripping from crosscutting position and lock it in place. (You should

only requires a few simple steps. be able to line the cut up by positioning

First, mount the saw in the carriage the plywood next to the saw blade.) Then,

so the blade is perpendicular to the guide just tighten the T-knob against the strap

tubes (refer to Fig. 2). on the square U-bolt (Fig. 1).

1 2

SQUARE U-BOLT

WITH STRAP

LOCK

NUT

TIGHTEN

T-KNOB TO SPRING

LOCK CARRIAGE CLAMP

Once you have the saw in position, it You will need to push the panel through,

needs to be locked into place. This is done so use the saws lock switch. If there's no

by tightening the T-knob on the U-bolt. lock, place a clamp on the trigger switch.

STORAGE

Even though the Panel Saw is a large rests on the casters (Fig. 1). Then you storing the saw, lock the braces in place

shop-built tool, I designed it so its easy to can roll the saw to another place in the by rotating the turnbuttons that are

move and store. To do this, the back sup- shop, push it out to the driveway, or store located on the center rails (Fig. 2).

port can be folded up flat into the back it flat against a wall and out of the way.

of the bed when youre finished cutting The 3/4"-thick hardwood turnbuttons

(see photo at right). are the key to moving and storing the

When its folded up, the saw lifts off Panel Saw. To hold the back support

the rear foot and the two edge rails and in an upright position when moving or

1 2

BRACE

EDGE RAIL

TURN-

BUTTON

CASTER RESTS ON GROUND

WHEN BED IS VERTICAL

The casters on the bottom rails support The turnbuttons on the center rails make

the bed when the back support is folded it easy to lock the back support in an

up and the Panel Saw is placed in a vertical upright position for storage. Just twist

position. This helps to move the saw. them to lock the support in place.

From ShopNotes magazine page 10 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

Add a base for a router and you can rout grooves and dadoes exactly where you want in either

sheet goods or large glued-up panels. A bracket locks tight to the guide tube for stopped cuts.

CONSTRUCTION NOTES:

The router base consists of a hardboard

insert with a pair of cleats that allow the

base to be locked into the carriage (L).

Hardwood spacers position the router

and the insert in the carriage so the bit

can reach the workpiece.

To build it, start by cutting the router

insert (V) from 1/4" hardboard. Its sized

to fit down through the inside edge of the

rabbet in the carriage base (Fig. 1).

Next, drill a centered hole in the insert

for the router bit. Use the manufactur-

ers base to lay out and add countersunk

shank holes for mounting the router.

Now cut the insert cleats (W) to size

from 1/4" hardboard. The cleats become

the lip that fits into the recess in the car-

riage (L).(Be sure to sand a small radius ROUTER CARRIAGE

on the corners of the cleats so they fit

snug in the carriage base.)

To complete the base, cut a pair of 3/4"-

thick hardwood spacers (X). Then the out and drill a 11/2"-dia. hole centered on MATERIALS LIST

cleat and insert are glued and screwed the width of the blank, and two shank

to the spacers (Figs. 1a and 1b). holes on each side of the center hole NEW PARTS

V Router Insert (1) 1/ hdbd. - 7 x 10

So that I could rout stopped grooves and (Fig. 2). These shank holes are for the 4

W Insert Cleats (2) 1/ hdbd. - 23/ x 73/

4 8 4

dadoes, I also made an adjustable stop. carriage bolts used to clamp the brackets X Insert Spacers (2) 3/ x 11/ - 7

4 2

The stop is just a couple of hardwood around the guide tube. Y Stop Brackets (2) 3/ x 1 - 3

4

brackets (Y) with openings that fit around Finally, rip the blank in half lengthwise

the 11/2"-dia. guide tube (Fig. 2). and cut the brackets to finished length. HARDWARE SUPPLIES

These brackets are small pieces, so Note: To create a tight grip, the gap (8) No. 8 x 3/4" Fh woodscrews

start by ripping an extra-long blank to thats cut away by the blade kerf leaves (2) 5/16" x 21/2" carriage bolts

(2) 5/16" I.D. star knobs w/ washers

rough width (21/8") from a piece of 3/4"- a half-circle that will be slightly smaller

thick stock. Now take the blank and lay than the outside of the guide tube.

INSERT CLEAT (!/4" HARDBOARD)

1 2

W a. !/4 W %/16" I.D.

STAR KNOB

W/ WASHER

!/4 NOTE: RIP

BRACKETS

2#/8 FROM OVER-

X SIZE STOCK

V 1!/2 BEFORE #/8

X CL

ROUTER V CUTTING TO

INSERT INSERT LENGTH Y

(!/4" HARDBOARD) SPACER

(#/4"-THICK %/16"

STOCK) 10 SHANK #/4" R.

b. 1#/8 HOLE

1 !/16

7

1#/8 W

#/8 Y

7#/4 STOP

1 3 BRACKET

#/4

#8 x #/4"

Fh SCREW %/16" x 2!/2"

CARRIAGE

1 BOLT

From ShopNotes magazine page 11 of 11 2007 August Home Publishing Company

www.ShopNotes.com All rights reserved

Você também pode gostar

- Cobol v1Documento334 páginasCobol v1Nagaraju BAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Isi Rumen SBG Subtitusi HijauanDocumento3 páginasIsi Rumen SBG Subtitusi HijauanBagas ImamsyahAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- SafetyRelay CR30Documento3 páginasSafetyRelay CR30Luis GuardiaAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Lightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationDocumento2 páginasLightning Arrester Lightningcontroller MC 125-B/Npe: Operation and Fields of ApplicationAnas BasarahAinda não há avaliações

- Diogenes Laertius-Book 10 - Epicurus - Tomado de Lives of The Eminent Philosophers (Oxford, 2018) PDFDocumento54 páginasDiogenes Laertius-Book 10 - Epicurus - Tomado de Lives of The Eminent Philosophers (Oxford, 2018) PDFAndres Felipe Pineda JaimesAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Design of Reinforced Cement Concrete ElementsDocumento14 páginasDesign of Reinforced Cement Concrete ElementsSudeesh M SAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- CHARACTER FORMATION 1 PrelimDocumento15 páginasCHARACTER FORMATION 1 PrelimAiza Minalabag100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Nikos MIDI Pack - Chord Progression GuideDocumento5 páginasNikos MIDI Pack - Chord Progression GuideSamuel ThompsonAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- CA21159 MG 8 Digital BookletDocumento5 páginasCA21159 MG 8 Digital BookletcantaloupemusicAinda não há avaliações

- SG110CX: Multi-MPPT String Inverter For SystemDocumento2 páginasSG110CX: Multi-MPPT String Inverter For SystemKatherine SmithAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- SPC FD 00 G00 Part 03 of 12 Division 06 07Documento236 páginasSPC FD 00 G00 Part 03 of 12 Division 06 07marco.w.orascomAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- IR2153 Parte6Documento1 páginaIR2153 Parte6FRANK NIELE DE OLIVEIRAAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Coaxial Cable Attenuation ChartDocumento6 páginasCoaxial Cable Attenuation ChartNam PhamAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Debate ReportDocumento15 páginasDebate Reportapi-435309716Ainda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- 11.3.1 Some Special CasesDocumento10 páginas11.3.1 Some Special CasesSiddharth KishanAinda não há avaliações

- Loctite 586 PDFDocumento9 páginasLoctite 586 PDForihimieAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- RARE Manual For Training Local Nature GuidesDocumento91 páginasRARE Manual For Training Local Nature GuidesenoshaugustineAinda não há avaliações

- HUMSS - Introduction To World Religions & Belief Systems CGDocumento13 páginasHUMSS - Introduction To World Religions & Belief Systems CGAliuqus SirJasper89% (18)

- Caterpillar Cat C7 Marine Engine Parts Catalogue ManualDocumento21 páginasCaterpillar Cat C7 Marine Engine Parts Catalogue ManualkfsmmeAinda não há avaliações

- Hockney-Falco Thesis: 1 Setup of The 2001 PublicationDocumento6 páginasHockney-Falco Thesis: 1 Setup of The 2001 PublicationKurayami ReijiAinda não há avaliações

- Generation III Sonic Feeder Control System Manual 20576Documento32 páginasGeneration III Sonic Feeder Control System Manual 20576julianmataAinda não há avaliações

- PostScript Quick ReferenceDocumento2 páginasPostScript Quick ReferenceSneetsher CrispyAinda não há avaliações

- APA Vs Harvard Referencing - PDFDocumento4 páginasAPA Vs Harvard Referencing - PDFTalo Contajazz Chileshe50% (2)

- The Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityDocumento7 páginasThe Effect of Co-Op Approach in Improving Visual Motor Integration Skills in Children With Learning DisabilityIJAR JOURNALAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Contemporary Strategic ManagementDocumento2 páginasContemporary Strategic ManagementZee Dee100% (1)

- Kissoft 15,69,0.4Documento10 páginasKissoft 15,69,0.4Daggupati PraveenAinda não há avaliações

- Culture 2007 2013 Projects Overview 2018-03-18Documento133 páginasCulture 2007 2013 Projects Overview 2018-03-18PontesDeboraAinda não há avaliações

- Dry Compressing Vacuum PumpsDocumento62 páginasDry Compressing Vacuum PumpsAnonymous zwSP5gvAinda não há avaliações

- Inspección, Pruebas, Y Mantenimiento de Gabinetes de Ataque Rápido E HidrantesDocumento3 páginasInspección, Pruebas, Y Mantenimiento de Gabinetes de Ataque Rápido E HidrantesVICTOR RALPH FLORES GUILLENAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDocumento30 páginasThe Checkmate Patterns Manual: The Ultimate Guide To Winning in ChessDusen VanAinda não há avaliações