Escolar Documentos

Profissional Documentos

Cultura Documentos

Capacity Control For 3D Compressors

Enviado por

Humaid ShaikhTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Capacity Control For 3D Compressors

Enviado por

Humaid ShaikhDireitos autorais:

Formatos disponíveis

AE21-1278 R5

AE21-1278 R5 February 1997

Reformatted November 2010

Moduload Capacity Control for 3D Compressors

On refrigeration and air conditioning applications The unloading hardware consists of a spring and

where the refrigeration load may vary over a wide plunger assembly for each cylinder housed in a chamber

range, some means of compressor capacity control is mounted on top of the valve plate. See Figure 1.

often desirable for optimum system performance and

control. In addition, compressor capacity modulation In the fully loaded operating mode (with the solenoid

can reduce power and energy consumption, provide valve de-energized), the solenoid needle valve is seated

better dehumidification, reduce compressor cycling, in the upper port, and the top of the unloading piston is

and decrease the starting electrical load. exposed to discharge pressure through the discharge

pressure port. The high pressure discharge gas on top

In order to achieve the above objectives, Emerson of the unloader piston forces it to remain seated in the

Climate Technologies has developed Moduload, a Discus valve.

unique and highly efficient method for unloading small

Discus Copelametic compressors. When unloaded operation is required, the solenoid

valve is energized. The needle valve seats in the

Moduload will, for the first time, permit efficient unloading lower port, and the unloading piston chamber (above

on Copeland compressors with less than 4 cylinders the unloading piston) is exposed to suction pressure

for high, medium, and low temperature applications. through the suction port. With suction pressure on top

Moduload assures smooth, vibrationfree operation in of the piston, the spring force underneath the piston is

the unloaded mode by unloading all cylinders equally. sufficient to move the piston to the top of the chamber.

In this position, the unloader piston opens a passage

Theory of Operation in the center of the Discus valve through which high-

Moduload compressors unload by allowing compressed pressure gas enters the expansion chamber during the

gas to fill a storage chamber above each cylinder and compression stroke. During the suction stroke, the gas

re-expand back into the cylinder during the suction contained in the unloading chamber re-expands through

stroke. As the gas re-expands, both volumetric the passage into the cylinder thus reducing capacity.

efficiency and compressor capacity are reduced.

The energy consumed during compression is almost Moduload Performance

completely recovered during re-expansion, resulting in When operating unloaded, the percent of full load

high efficiency in the unloaded mode. capacity is a function of operating compression ratio.

The higher the ratio, the greater the capacity reduction.

Moduload uses a piston, cylinder, and spring To determine actual performance at specific operating

mechanism which are solenoid actuated. All cylinders conditions, use Figures 2 through 5.

are unloaded equally, thus providing well-balanced

operation at all times. Example:

Determine part load performance of a 3DF3-0900

Since compressed gas is re-expanded to obtain operating unloaded at -25F evaporating and 110F

unloading, the percent capacity reduction is a function condensing for R-502.

of operating compression ratio. The higher the

compression ratio, the greater the percent capacity Answer:

reduction during unloading. (Using Discus sales catalog for the 3DF3- 0900)

Fully loaded performance at -25/110F is 38,400

Capacity Control Valve Construction Btu/hr and 7510 watts. For the unloaded capacity

The unloading assembly is considerably different in and power, use Figure 5. Compressor capacity is

design from either the blocked suction unloading used 54 percent of fully loaded capacity or .54 x 38,400

on Copeland 4, 6, and 8 cylinder compressors or the = 20,700 Btu/hr. Power is 60 percent of full load

external type unloading (hot gas bypass) used on 9R power or .60 x 7510 = 4506 watts.

or 9D 3 cylinder compressors.

2010 Emerson Climate Technologies 1

Printed in the U.S.A.

AE21-1278 R5

NORMAL OPERATING CONDITIONS

VALVE DE-ENERGIZED

HIGH SIDE PRESSURE FORCING

UNLOADING PISTONS DOWN

Figure 1

2010 Emerson Climate Technologies 2

Printed in the U.S.A.

AE21-1278 R5

APPLICATION Wiring

Control The capacity control valve is in the loaded position

When an unloading valve is switched from the loaded when de-energized and in the unloaded position when

to the unloaded position, or vice versa, a new system energized. The solenoid valve may be energized either

balance takes place; i.e., evaporating and condensing by means of a reverse-acting low pressure control or a

temperatures will change slightly. In aircooled systems, temperature-control thermostat.

unloading will normally cause the suction pressure to Although the leak-back rate when the coil is energized

rise and the condensing pressure to drop. In water- during a compressor off cycle is minimal, to prolong the

cooled systems, the suction pressure will rise, but the solenoid coil life it is recommended that the capacity

condensing pressure will normally remain substantially control solenoid valve be de-energized when the

the same. compressor is not operating.

The unloading control (whether based on suction Note: As with any unloading compressor it is

pressure or case temperature) should be set for as wide recommended the unloader solenoid be de-energized

a differential as necessary to prevent rapid cycling of before pumping down the low side. Operating in the

the unloading valve. A wider differential will normally unloaded mode will greatly increase the time period

be required with the pressure control method than for pumpdown.

the temperature control method because of the large

thermal mass of the cooled medium. Actual system In control circuits operating at line voltage, the solenoid

operation should determine the final control setting. valve and control can be connected to the load side of

the contactor as in Figure 6. The unloader solenoid

Operating Envelope valve will then be de-energized and closed when the

Low temperature as well as high and medium compressor is not operating.

temperature applications are approved for Moduload

unloading because of reductions in compressor On large installations, the control circuit may have a

operating temperatures due to Discus valving and power source independent of the compressor power

improved internal gas flow. The boundaries of Figures supply. In such cases, the unloading solenoid valve

2 through 5 provide the operating envelope (loaded and control may be connected as shown in Figure 6 or

and unloaded) for stable and safe operation for all they may be connected in parallel with the compressor

applications. contactor coil as in Figure 7.

Depending upon the exact hardware configuration, Piping

tolerances, and spring force, stable operation of the A very important factor to be considered in the design of

Moduload unloader requires a minimum of 60 to 70 psi any refrigerant system equipped with an unloading-type

differential between suction and discharge pressure compressor is gas velocity in refrigerant-system piping.

in order for the discharge pressure acting on top of This is especially true for low and medium temperature

the unloader piston to overcome the upward forces of single-compressor systems. Gas velocity must be

the unloader spring and cylinder pressure. Differential maintained at a sufficiently high level to ensure oil return

pressures encountered in medium temperature R-12 to the compressor when it is unloaded. To ensure oil

floating head applications occasionally do not meet this return when an unloading-type compressor is employed

criteria. Because of this, use of Moduload for medium on a single evaporator with a single suction line, it may

temperature R-12 applications should be limited to be necessary to employ double risers constructed as

floating head applications where the evaporating shown in Figure 8. Where oil return is marginal, use

temperature is low enough that the discharge pressure of an oil separator and float system is recommended.

never falls below a pressure corresponding to 70 psi

above suction pressure, or to fixed head pressure and If an unloading-type compressor is to be installed on a

water-cooled applications where discharge pressure system employing multiple evaporators with solenoid

never falls below a pressure corresponding to 70 psi valves to control the flow of refrigerant to the individual

above suction pressure. evaporators, a separate suction line should be run

from each evaporator to the machine room and then

Cooling Requirements connected into a common suction line, which should

Head cooling fans are required when the saturated slope downward toward the compressor to ensure

suction temperature is at or below 0F for both the adequate oil return.

loaded and unloaded mode.

2010 Emerson Climate Technologies 3

Printed in the U.S.A.

AE21-1278 R5

Expansion valves for systems with unloading New HFC models have an alternate seal material

compressor must be sized to be able to control the (HSN) that is compatible; however, it cannot be used

refrigerant flow while the compressor is unloaded as well with CFC or HCFC refrigerants. This issue becomes

as loaded. Expansion valves should not be oversized very important when retrofitting and may necessitate

since they usually cannot control well when operating replacing Moduload assemblies.

25-35 percent below their rated capacity.

Table 1 lists the model nomenclature for the appropriate

For a detailed discussion of system piping 3D Models for use with both HFC and CFC refrigerants.

recommendations, consult the ASHRAE Manual

(Systems Volume 1984) or Emerson Climate Field Service and Conversion

Technologies Refrigeration Manual, Part 5. Moduload may be added to standard 3D compressors

by means of the appropriate conversion kit (Consult

HFC Refrigerants factory for kit numbers or Parts List PS-1260).

HFC's are not compatible with the seal material (viton)

used in the standard Moduload cylinders.

2010 Emerson Climate Technologies 4

Printed in the U.S.A.

Printed in the U.S.A.

2010 Emerson Climate Technologies

5

Figure 2

Moduload Discus 3D Compressors

Tpical Unloader Performance Factors

R404A & R-502 Low Temperature Applications

AE21-1278 R5

Printed in the U.S.A.

2010 Emerson Climate Technologies

6

Figure 3

Moduload Discus 3D Compressors

Typical Unloader Performance Factors

R404A & R-502 Medium Temperature Application

AE21-1278 R5

Printed in the U.S.A.

2010 Emerson Climate Technologies

7

Figure 4

Moduload Discus 3D Compressors

Typical Unloader Performance Factors

R-22 High Temperature Applications

AE21-1278 R5

Printed in the U.S.A.

2010 Emerson Climate Technologies

8

Figure 5

Moduload Discus 3D Compressors

Typical Unloader Performance Factors

R-12 Medium and High Temperature Applica

AE21-1278 R5

AE21-1278 R5

Figure 6

Typical Control Circuit for Compressor with Unloading Valve

Figure 7

Typical Control Circuit for Compressor with Unloading Valve

and Separate Power Source Control Circuit

2010 Emerson Climate Technologies 9

Printed in the U.S.A.

AE21-1278 R5

Figure 8

Installation

The Moduload valve and coil assembly (240 volt) is

included in the Moduload model standard -200 bill of

material as a ship remote item. The Moduload model

compressor can be operated without the unloading valve

and coil installed, if desired for any reason. It is critical

for the gasket to be matched to intended usage before

starting the compressor, per the following instructions.

020-0783-00

Figure 10

Unloading Valve Gasket. Use this gasket when

installing the Moduload solenoid valve & coil. The

compressor will run unloaded when the solenoid is

energized, and will be fully loaded when the solenoid

is de-energized.

020-0931-00

Figure 9

Shipping Gasket. This gasket is under the shipping

plate covering the Moduload mounting pad on the

cylinder head, as shipped from the Emerson factory.

Replace it with the appropriate gasket (Figure 10 or

11) before operating the compressor. If not replaced,

the compressor will run unloaded.

020-0745-00

Figure 11

Full Load Gasket. Use this gasket with the shipping

plate if the solenoid valve & coil are not installed.

Compressor will run only fully loaded.

2010 Emerson Climate Technologies 10

Printed in the U.S.A.

AE21-1278 R5

Table 1

Moduload Model Nomenclature

CFC/HCFC HFC

Loaded Unloaded Loaded Unloaded

Ref Ref

Model No. Model No. Model No. Model No.

R-12 HT 3DB3-0750 3DP3-0750

R-12 HT 3DF3-0900 3DK3-0900

R-12 HT 3DS3-1000 3DL3-1000

R-12 LT 3DA3-0500 3DE3-0500

R-12 LT 3DB3-0500 3DP3-0500

R-12 LT 3DF3-0750 3DK3-0750

R-12 LT 3DS3-0750 3DT3-0750

R-22 MT 3DA3-0750 3DE3-0750 404A MT 3DA3-075E 3DEH-075E

R-22/502 MT 3DB3-1000 3DP3-1000 404A MT 3DB3-100E 3DPH-100E

R-22 MT 3DF3-1200 3DK3-1200 404A MT 3DF3-120E 3DKH-120E

R-22/502 MT 3DS3-1500 3DT3-1500 404A MT 3DS3-150E 3DTH-150E

R-22/502 MT 3DA3-0750 3DE3-0750

R-502 LT 3DA3-0600 3DH3-0600 404A LT 3DA3-060E 3DHH-060E

R-502 LT 3DB3-0750 3DJ3-0750 404A LT 3DB3-075E 3DJH-075E

R-502 LT 3DF3-0900 3DG3-0900 404A LT 3DF3-090E 3DGH-090E

R-502 LT 3DS3-1000 3DR3-1000 404A LT 3DS3-100E 3DRH-100E

2010 Emerson Climate Technologies 11

Printed in the U.S.A.

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocumento3 páginasTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocumento3 páginasTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- Testing and Commissioning of Water Supply Piping System Network PDFDocumento4 páginasTesting and Commissioning of Water Supply Piping System Network PDFHumaid ShaikhAinda não há avaliações

- Testing and Commissioning of Fire Fighting System Hosereel and Sprinkler SystemDocumento4 páginasTesting and Commissioning of Fire Fighting System Hosereel and Sprinkler SystemHumaid ShaikhAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocumento2 páginasProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhAinda não há avaliações

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELDocumento2 páginasPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT FOR FIRE HOSE RACKS and FIRE HOSE REELHumaid ShaikhAinda não há avaliações

- Testing and Commissioning Method Statement Procedure For Argonite SystemDocumento2 páginasTesting and Commissioning Method Statement Procedure For Argonite SystemHumaid ShaikhAinda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- PRECOMMISSIONING and COMMISSIONING PROCEDURE FOR CARD ACCESS CONTROL SYSTEMDocumento3 páginasPRECOMMISSIONING and COMMISSIONING PROCEDURE FOR CARD ACCESS CONTROL SYSTEMHumaid ShaikhAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Testing and Commissioning of UPS System Method StatementDocumento3 páginasTesting and Commissioning of UPS System Method StatementHumaid Shaikh100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFDocumento2 páginasProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Testing and Commissioning Method Statement For Fire Fighting PumpsDocumento2 páginasTesting and Commissioning Method Statement For Fire Fighting PumpsHumaid Shaikh100% (1)

- Testing and Commissioning of Submain Distribution Boards SMDBsDocumento2 páginasTesting and Commissioning of Submain Distribution Boards SMDBsHumaid Shaikh0% (1)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Fire Alarm Systems CommissioningDocumento2 páginasFire Alarm Systems CommissioningHumaid ShaikhAinda não há avaliações

- Landscape Irrigation Systems CommissioningDocumento1 páginaLandscape Irrigation Systems CommissioningHumaid ShaikhAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Safe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsDocumento9 páginasSafe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsHumaid ShaikhAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Testing and Commissioning Procedure For Earthing System Method StatementDocumento2 páginasTesting and Commissioning Procedure For Earthing System Method StatementHumaid ShaikhAinda não há avaliações

- Testing and Commissioning of Motor Control Center Method StatementDocumento3 páginasTesting and Commissioning of Motor Control Center Method StatementHumaid Shaikh75% (4)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- PRECOMMISSIONING and COMMISSIONING METHOD STATEMENT PROCEDURE FOR CCTV SYSTEMDocumento2 páginasPRECOMMISSIONING and COMMISSIONING METHOD STATEMENT PROCEDURE FOR CCTV SYSTEMHumaid ShaikhAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Testing and Commissioning of Starter Panels Variable Frequency Drives VFDsDocumento3 páginasTesting and Commissioning of Starter Panels Variable Frequency Drives VFDsHumaid ShaikhAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Lighting and Control Systems CommissioningDocumento1 páginaLighting and Control Systems CommissioningHumaid ShaikhAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Fire Protection Systems CommissioningDocumento1 páginaFire Protection Systems CommissioningHumaid ShaikhAinda não há avaliações

- Indoor Environmental Quality CommissioningDocumento1 páginaIndoor Environmental Quality CommissioningHumaid ShaikhAinda não há avaliações

- Energy Monitoring and Management CommissioningDocumento1 páginaEnergy Monitoring and Management CommissioningHumaid ShaikhAinda não há avaliações

- Air-Conditioning and Ventilation Systems CommissioningDocumento2 páginasAir-Conditioning and Ventilation Systems CommissioningHumaid ShaikhAinda não há avaliações

- Telephone and Communication Systems CommissioningDocumento1 páginaTelephone and Communication Systems CommissioningHumaid Shaikh50% (2)

- Plumbing CommissioningDocumento1 páginaPlumbing CommissioningHumaid ShaikhAinda não há avaliações

- Vertical Transportation Systems CommissioningDocumento1 páginaVertical Transportation Systems CommissioningHumaid ShaikhAinda não há avaliações

- Final Commissioning PlanDocumento1 páginaFinal Commissioning PlanHumaid ShaikhAinda não há avaliações

- Electrical Power Systems CommissioningDocumento1 páginaElectrical Power Systems CommissioningHumaid ShaikhAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- On Site Energy Generation System CommissioningDocumento1 páginaOn Site Energy Generation System CommissioningHumaid ShaikhAinda não há avaliações

- Frid Ffhs26 Tech SheetDocumento2 páginasFrid Ffhs26 Tech Sheetdan themanAinda não há avaliações

- HDT ConcreteCement Brochure 05-lrDocumento8 páginasHDT ConcreteCement Brochure 05-lrDhroov SharmaAinda não há avaliações

- AcDocumento5 páginasAcDeepak GoyalAinda não há avaliações

- Hvac DuctingDocumento8 páginasHvac DuctingQuas 86Ainda não há avaliações

- Rheem Commercial Storage Tanks PDFDocumento2 páginasRheem Commercial Storage Tanks PDFcodefinderAinda não há avaliações

- Lecture 4 RefrigeratorDocumento19 páginasLecture 4 RefrigeratorNetsanet ShikurAinda não há avaliações

- Ee8015-Unit-2-Refrigeration and Air ConditioningDocumento30 páginasEe8015-Unit-2-Refrigeration and Air ConditioningS Jey RhajenAinda não há avaliações

- Water Cooling Tower (Procedure) - Virtual Mass Transfer Lab - Chemical Engineering - IIT GUWAHATI Virtual LabDocumento2 páginasWater Cooling Tower (Procedure) - Virtual Mass Transfer Lab - Chemical Engineering - IIT GUWAHATI Virtual LabJared Philip Marquez Condez100% (1)

- 3 HvacDocumento31 páginas3 HvacFazli SubhanAinda não há avaliações

- Rittal - Thermostat - SK 3110.000Documento3 páginasRittal - Thermostat - SK 3110.000azlanAinda não há avaliações

- Pro 1000-2000Documento20 páginasPro 1000-2000cisar29Ainda não há avaliações

- Ducted Split B R22Documento2 páginasDucted Split B R22Romeo PedranoAinda não há avaliações

- An Exergy Analsysis of Various Components of Packaged Air Conditioining System To Improve Its Coefficient of PerformanceDocumento6 páginasAn Exergy Analsysis of Various Components of Packaged Air Conditioining System To Improve Its Coefficient of PerformanceIJSTEAinda não há avaliações

- Psychrometric Charts With InstructionsDocumento3 páginasPsychrometric Charts With Instructionsjebman1Ainda não há avaliações

- Chiller PDFDocumento5 páginasChiller PDFkamelAinda não há avaliações

- ESG Service Information: BackgroundDocumento6 páginasESG Service Information: BackgroundAbdulSattarAinda não há avaliações

- UBC ASHRAE Competition Report PDFDocumento34 páginasUBC ASHRAE Competition Report PDFmech118100% (1)

- Penawaran Harga COLDSTORAGEDocumento1 páginaPenawaran Harga COLDSTORAGEChannel ArifAinda não há avaliações

- Mcac TSM 2008 02Documento94 páginasMcac TSM 2008 02Eng . Moiead SlemanAinda não há avaliações

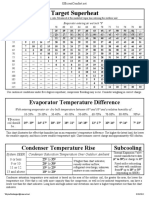

- Charging and TD Chart PlusDocumento1 páginaCharging and TD Chart PlusFaquruddin AliAinda não há avaliações

- McquayDocumento56 páginasMcquayNoushad P HamsaAinda não há avaliações

- Refrigeration & Air Conditioning: ME 170: Fundamentals of Mechanical Engineering (Model Lab)Documento52 páginasRefrigeration & Air Conditioning: ME 170: Fundamentals of Mechanical Engineering (Model Lab)Umair MueedAinda não há avaliações

- Rds+Rcun 50hz R410a r0 PDFDocumento15 páginasRds+Rcun 50hz R410a r0 PDFshahas nahasAinda não há avaliações

- 2002, Hirano Et Al.Documento9 páginas2002, Hirano Et Al.sumitAinda não há avaliações

- AMR Active Magnetic Regenerative Refrige PDFDocumento9 páginasAMR Active Magnetic Regenerative Refrige PDFsanath santhoshAinda não há avaliações

- Chapter 11 - Refrigeration CyclesDocumento25 páginasChapter 11 - Refrigeration CyclesPaul RodgersAinda não há avaliações

- SB MultiVIV HighStaticDucted ARNU363B8A4!12!15Documento2 páginasSB MultiVIV HighStaticDucted ARNU363B8A4!12!15ags387Ainda não há avaliações

- Cassette 60kbtuDocumento3 páginasCassette 60kbtuJorge TorresAinda não há avaliações

- Basement VentilationDocumento31 páginasBasement VentilationgauAinda não há avaliações

- List of Recomended ManufacturersDocumento16 páginasList of Recomended ManufacturersMostafa SalemAinda não há avaliações

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonNo EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonNota: 5 de 5 estrelas5/5 (2)

- Multiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...No EverandMultiplexed Networks for Embedded Systems: CAN, LIN, FlexRay, Safe-by-Wire...Ainda não há avaliações

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNo EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionNota: 4.5 de 5 estrelas4.5/5 (543)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNo EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tNota: 4.5 de 5 estrelas4.5/5 (27)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosNo EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosNota: 5 de 5 estrelas5/5 (1)

- Retro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsNo EverandRetro Gaming with Raspberry Pi: Nearly 200 Pages of Video Game ProjectsAinda não há avaliações

- Power System Control and ProtectionNo EverandPower System Control and ProtectionB. Don RussellNota: 4 de 5 estrelas4/5 (11)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersNo Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersNota: 5 de 5 estrelas5/5 (1)