Escolar Documentos

Profissional Documentos

Cultura Documentos

Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1

Enviado por

rohitkushTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1

Enviado por

rohitkushDireitos autorais:

Formatos disponíveis

Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1

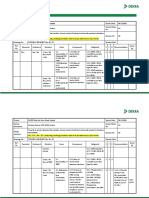

HEM Two Phase Method

Calculation Sheet

Job No. 3963 Calculation No. Rev. 0 Page No. 1

Customer QATAR PETROLEUM

Name:

Contracto CHINA PETROLEUM ENGINEERING AND CONSTRUCTION CORPORATION

r Name:

Ref. Calculation Rev.

Two-Phase Flow Relief based on Homogenous Equilibrium Model (HEM ) Method

The two phase fluid is flashed at constant entropy using Hysys Simulation Software at various pressures.

The pressure is varied from the relieving pressure to the PSV throat pressure.

The two phase fluid is assumed to be at its bubble point at the PSV inlet (ie. Vapor Pressure = Inlet Pressure).

Total Two Phase Required Relief Rate = 44,815 kg/h

Total No. of Operating PSVs = 1

Individual PSV Two Phase Required Relief Rate = 44,815 kg/h

Set Pressure ( barg) 17.7

% Overpressure 10

Relief Pressure bar(g) 19.47

Relief Temperature (oC) 60

Liquid 2 Phase

Gas Liquid Mas Specific Specific Gas Mass Liq Mass

Step Pressure Density Density Fraction Volume Sum Qn Mass Flux Flow Flow Remarks

bara kg/m3 kg/m3 m3/kg m2/s2 kg/m2/s kg/h kg/h

1 20.483 19.35 773.6 0.83692 0.00951 7,309 37,506 At PSV Inlet Pressure

2 19.537 18.50 775.0 0.83541 0.00997 921 4,304 7,376 37,439

3 18.592 17.65 776.4 0.83386 0.01049 1,889 5,861 7,446 37,369

4 17.646 16.80 777.8 0.83225 0.01106 2,908 6,897 7,518 37,297

5 16.700 15.95 779.3 0.83059 0.01169 3,983 7,635 7,592 37,223

6 15.754 15.09 780.8 0.82886 0.01240 5,123 8,162 7,670 37,145

7 14.809 14.24 782.4 0.82706 0.01320 6,334 8,523 7,750 37,064

8 13.863 13.38 784.0 0.82518 0.01412 7,626 8,747 7,835 36,980

9 12.917 12.52 785.7 0.82321 0.01517 9,011 8,851 7,923 36,892

10 11.971 11.66 787.5 0.82114 0.01638 10,503 8,846 8,016 36,799

11 11.025 10.79 789.4 0.81895 0.01781 12,120 8,742 8,114 36,701

12 10.080 9.93 791.5 0.81662 0.01950 14,175 8,633 8,218 36,597

13 9.134 9.06 793.6 0.81414 0.02155 16,117 8,331 8,329 36,486

14 8.188 8.18 795.9 0.81147 0.02407 18,274 7,943 8,449 36,366

15 7.242 7.30 798.5 0.80857 0.02725 20,701 7,468 8,579 36,236

16 6.296 6.41 801.2 0.80538 0.03138 23,473 6,906 8,722 36,093

17 5.351 5.51 804.4 0.80183 0.03696 26,704 6,253 8,881 35,934

18 4.405 4.60 807.9 0.79780 0.04493 30,577 5,504 9,062 35,753

19 3.459 3.68 812.2 0.79308 0.05721 35,407 4,651 9,273 35,541

20 2.513 2.74 817.5 0.78730 0.07864 41,831 3,678 9,532 35,283 At PSV Outlet Pressure

2

Maximum Specific Mass Flux = 8,851 kg/m /s

(From Above Table)

PSV Choke Pressure = 12.9 bara

3

Gas Density at Maximum Specific Mass Flux = 12.5 kg/m

3

Liq Density at Maximum Specific Mass Flux = 785.7 kg/m

Two-phase Discharge Coefficient, C = 0.85

Two-phase Back Pressure Factor, Kb = 1.0

Required Relief Valve Orifice Area = 1654.7 mm2 PSV Spring Material

Carbon SteelSteel

Carbon

Selected Relief Valve Orifice Area = 1841 mm2

Orifice Designation

At PSV Choke Pressure Required Rated L

Gas Mass Flow 7,923 8,813 kg/h

Liq Mass Flow 36,892 41,036 kg/h PSV Inlet by Outlet Size

3" x 4"

Você também pode gostar

- HP Fuel Gas SystemDocumento8 páginasHP Fuel Gas SystemAnonymous QSfDsVxjZAinda não há avaliações

- 2-Phase Omega PSV SizingDocumento2 páginas2-Phase Omega PSV SizingABULARA2K6Ainda não há avaliações

- SP 1125Documento12 páginasSP 1125Venkat RanganAinda não há avaliações

- Sizing For Two PhaseDocumento6 páginasSizing For Two PhaseKong LingweiAinda não há avaliações

- 3443-SZ-RT-101 - 04 Attachment 15Documento8 páginas3443-SZ-RT-101 - 04 Attachment 15tak-1963Ainda não há avaliações

- Distillation Theoretical Stages CalculatorDocumento1.557 páginasDistillation Theoretical Stages Calculatorgautam_96948069Ainda não há avaliações

- Unlock Separator SizingDocumento42 páginasUnlock Separator SizingmortezasabetiAinda não há avaliações

- Rigorous Method For Fire CaseDocumento4 páginasRigorous Method For Fire CaseFlorin Daniel AnghelAinda não há avaliações

- Tube Rupture (Two Phase-Omega Method) PDFDocumento1 páginaTube Rupture (Two Phase-Omega Method) PDFAmin RoisAinda não há avaliações

- Solving Vessel Equations PDFDocumento5 páginasSolving Vessel Equations PDFNaturasfera Suplementos AlimenticiosAinda não há avaliações

- Emergency ShutingdownDocumento11 páginasEmergency ShutingdownOsama OmayerAinda não há avaliações

- Vent To Flare 1683883352Documento31 páginasVent To Flare 1683883352saheem_783617392Ainda não há avaliações

- High Fidelity Dynamic Simulation of Compressor SystemsDocumento9 páginasHigh Fidelity Dynamic Simulation of Compressor SystemsTrần Quang ThắngAinda não há avaliações

- Sonic VelocityDocumento2 páginasSonic Velocityganeshdhage100% (1)

- PSV Calculation and PhilosophyDocumento33 páginasPSV Calculation and PhilosophysbmmlaAinda não há avaliações

- Interface Level Measurement Displacer and DP TransmitterDocumento4 páginasInterface Level Measurement Displacer and DP TransmitterBobismy Alterego Bob100% (2)

- R1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0ADocumento4 páginasR1111-DSH-PL-00-021 - DATA SHEET FOR PIG LAUNCHER-Rev 0AAHMED AMIRAAinda não há avaliações

- Liquid Line SizingDocumento8 páginasLiquid Line Sizingsamuad59Ainda não há avaliações

- Heating and Cooling of Batch ProcessesDocumento40 páginasHeating and Cooling of Batch Processesjdgh1986100% (1)

- Process Design Basis: Doc. No.: DB-SP2021ON-PR-103-P312-0201Documento19 páginasProcess Design Basis: Doc. No.: DB-SP2021ON-PR-103-P312-0201mohsen ranjbarAinda não há avaliações

- PSV Sizing - Two Phase (Two-Points)Documento2 páginasPSV Sizing - Two Phase (Two-Points)Saeid Rahimi MofradAinda não há avaliações

- Distillation1 AdeyabDocumento17 páginasDistillation1 AdeyabSrihari Kodimela0% (1)

- PSSCV ZixxingDocumento2 páginasPSSCV ZixxingShashi Kant KumarAinda não há avaliações

- Impact of Emergency Shutdown Devices On Relief System Sizing and Design PDFDocumento21 páginasImpact of Emergency Shutdown Devices On Relief System Sizing and Design PDFB rgAinda não há avaliações

- PSV Sizing (Two Phase - HEM)Documento1 páginaPSV Sizing (Two Phase - HEM)Saeid Rahimi MofradAinda não há avaliações

- Dokumen - Tips - Gpsa 13 Ed Separation PDFDocumento48 páginasDokumen - Tips - Gpsa 13 Ed Separation PDFNovi WulansariAinda não há avaliações

- Tube Rupture. Dynamic SimulationDocumento5 páginasTube Rupture. Dynamic SimulationAbbasAinda não há avaliações

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Documento26 páginasSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801Ainda não há avaliações

- Introduction For Test Separator: CNPCIC Field ProductionDocumento18 páginasIntroduction For Test Separator: CNPCIC Field Productionsalahadine maideAinda não há avaliações

- Gas Flowmeter SizingDocumento1 páginaGas Flowmeter SizingtungluongAinda não há avaliações

- Gas Liquid Seperation by VesselsDocumento2 páginasGas Liquid Seperation by VesselszapspazAinda não há avaliações

- Control Valve Sizing PDFDocumento5 páginasControl Valve Sizing PDFsivaAinda não há avaliações

- Steam Condensate Pot SizingDocumento1 páginaSteam Condensate Pot SizingmaniazharAinda não há avaliações

- 2 Phase Relief Calculations Spreadsheet: Basis General DataDocumento1 página2 Phase Relief Calculations Spreadsheet: Basis General DataAffian WidjanarkoAinda não há avaliações

- Design Practices - SVsDocumento12 páginasDesign Practices - SVsagarwalashwin32Ainda não há avaliações

- HYSYS PROII Converter - V1.5 PDFDocumento28 páginasHYSYS PROII Converter - V1.5 PDFzubair1951Ainda não há avaliações

- RD 810Documento73 páginasRD 810Ashish MishraAinda não há avaliações

- AR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFDocumento6 páginasAR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFYaakoubi FethiAinda não há avaliações

- Calculate The Relieving Temperature Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Method PDFDocumento3 páginasCalculate The Relieving Temperature Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Method PDFDjamel Ait MohamedAinda não há avaliações

- Total Control Controllers: Owner'S ManualDocumento22 páginasTotal Control Controllers: Owner'S ManualPluot1Ainda não há avaliações

- Line ListDocumento1 páginaLine Listهيمنت بيلودياAinda não há avaliações

- PSV Load Calculation For Gas Expantion Fire Case PDFDocumento2 páginasPSV Load Calculation For Gas Expantion Fire Case PDFAnonymous V5UYBUMaAinda não há avaliações

- Significance of 3% PSV Inlet Line Pressure LossDocumento8 páginasSignificance of 3% PSV Inlet Line Pressure LossKannanGKAinda não há avaliações

- Savvy Separator: The Ghosts of Separators Past, Present, and FutureDocumento7 páginasSavvy Separator: The Ghosts of Separators Past, Present, and FutureDeepblue09100% (1)

- Working Principle of TEG RegenerationDocumento3 páginasWorking Principle of TEG RegenerationAzhar AhmadAinda não há avaliações

- HYSYS Stream Reporter Utility Version 1.1, User GuideDocumento5 páginasHYSYS Stream Reporter Utility Version 1.1, User GuideMikhail LópezAinda não há avaliações

- Refrigerated Gas Plant Hysys SimulationDocumento6 páginasRefrigerated Gas Plant Hysys SimulationOsas UwoghirenAinda não há avaliações

- FlareTot - Total Flare AnalysisDocumento8 páginasFlareTot - Total Flare AnalysisArjun KapoorAinda não há avaliações

- Flare Sweep GasDocumento5 páginasFlare Sweep GasChem.EnggAinda não há avaliações

- Teg ContactorDocumento4 páginasTeg ContactorrepentinezAinda não há avaliações

- PSV Sizing (Two-Phase Flow)Documento19 páginasPSV Sizing (Two-Phase Flow)D K S100% (1)

- Simulation, System and Analytical: Lainnya Blog Berikut Buat Blog MasukDocumento8 páginasSimulation, System and Analytical: Lainnya Blog Berikut Buat Blog MasukIkhsanudin AbdullahAinda não há avaliações

- Validated SheetDocumento12 páginasValidated SheetrohitkushAinda não há avaliações

- E PR 460Documento37 páginasE PR 460khorzooAinda não há avaliações

- B.G.M.U. - Referat 2 SlavkoDocumento7 páginasB.G.M.U. - Referat 2 SlavkoVioleta PopaAinda não há avaliações

- Design Option 3 1Documento7 páginasDesign Option 3 1Christian DelfinAinda não há avaliações

- Practica N°1 - Graficas y ExuacionesDocumento19 páginasPractica N°1 - Graficas y ExuacionesLopez Pedro100% (1)

- 6.4 Engine Performance Test ResultsDocumento5 páginas6.4 Engine Performance Test ResultsVarundeep Merugu NethaAinda não há avaliações

- Job Pipa KasarDocumento16 páginasJob Pipa Kasarmuhammad zulfurqanAinda não há avaliações

- (Kalibrasi 0.264)Documento19 páginas(Kalibrasi 0.264)Ahmad Mubarok FadhlullahAinda não há avaliações

- Control Valve Skid ArrangementDocumento1 páginaControl Valve Skid ArrangementrohitkushAinda não há avaliações

- J1237 Asian Paints HAZOP WSDocumento98 páginasJ1237 Asian Paints HAZOP WSrohitkushAinda não há avaliações

- Expectations For The Mi ProgramDocumento3 páginasExpectations For The Mi ProgramrohitkushAinda não há avaliações

- Wind Speed (M/S) N NE E SE SDocumento3 páginasWind Speed (M/S) N NE E SE SrohitkushAinda não há avaliações

- PSM GoalDocumento2 páginasPSM GoalrohitkushAinda não há avaliações

- Criterion For Hazard Ranking ProcedureDocumento1 páginaCriterion For Hazard Ranking ProcedurerohitkushAinda não há avaliações

- Line Sizing HYSYS PDFDocumento1 páginaLine Sizing HYSYS PDFrohitkush100% (1)

- Hydraulic Expansion (Liquid)Documento1 páginaHydraulic Expansion (Liquid)rohitkushAinda não há avaliações

- Validated SheetDocumento12 páginasValidated SheetrohitkushAinda não há avaliações

- Volume Calculation For BlowdownDocumento6 páginasVolume Calculation For BlowdownrohitkushAinda não há avaliações

- Calculation For Jet MixerDocumento3 páginasCalculation For Jet MixerrohitkushAinda não há avaliações

- Cover Sheet (West Qurna - 2 Project. Early Phase Production Stage)Documento2 páginasCover Sheet (West Qurna - 2 Project. Early Phase Production Stage)rohitkushAinda não há avaliações

- Kinetic Energy Equals: A. Mass X Velocity B. Mass X Velocity C. Mass X Acceleration D. Mass X VelocityDocumento108 páginasKinetic Energy Equals: A. Mass X Velocity B. Mass X Velocity C. Mass X Acceleration D. Mass X Velocitynathaniel villanuevaAinda não há avaliações

- Dimensioning: Bushra Fatima NED University of Engineering & TechnologyDocumento41 páginasDimensioning: Bushra Fatima NED University of Engineering & TechnologyAbdul RashidAinda não há avaliações

- Thesis SynopsisDocumento4 páginasThesis Synopsisbhavdip_shahAinda não há avaliações

- A Note On The Asymptotic Stability in The Whole of Non-Autonomous SystemsDocumento8 páginasA Note On The Asymptotic Stability in The Whole of Non-Autonomous SystemsprofjnapolesAinda não há avaliações

- 3 Fluid Heat ExchangerDocumento19 páginas3 Fluid Heat ExchangerAswini RoutAinda não há avaliações

- Water Research Volume 31 Issue 12 1997 (Doi 10.1016/s0043-1354 (97) 00161-9) I. Sholji N.M. Kazi - Kinetics of Pneumatic FlocculationDocumento10 páginasWater Research Volume 31 Issue 12 1997 (Doi 10.1016/s0043-1354 (97) 00161-9) I. Sholji N.M. Kazi - Kinetics of Pneumatic FlocculationMa'arij HarfadliAinda não há avaliações

- Sss Royal Touch Laundry BrochureDocumento2 páginasSss Royal Touch Laundry BrochureMd. Badrul IslamAinda não há avaliações

- Dynamics of Glass-Forming Liquids. IX. Structural Versus Dielectric Relaxation in Monohydroxy AlcoholsDocumento7 páginasDynamics of Glass-Forming Liquids. IX. Structural Versus Dielectric Relaxation in Monohydroxy AlcoholsRaghava ParitalaAinda não há avaliações

- Heat Conduction Composite WallDocumento22 páginasHeat Conduction Composite WallMoosa NaseerAinda não há avaliações

- Nikola TeslaDocumento17 páginasNikola TeslaNicolas Glenn Pierre Borzeix-McGregorAinda não há avaliações

- DIY Temperature Controlled Solder StationDocumento6 páginasDIY Temperature Controlled Solder StationAnonymous UNG1t7lxAinda não há avaliações

- Lecture Mod 3Documento15 páginasLecture Mod 3amlan sahuAinda não há avaliações

- Free Standing Tension StructuresDocumento255 páginasFree Standing Tension StructuresJoaquin VieraAinda não há avaliações

- Design Analysis and Improvement of EOT Crane WheelDocumento4 páginasDesign Analysis and Improvement of EOT Crane WheelIJSTEAinda não há avaliações

- Determining Independent Control of Dual-Frother Systems - Gas Holdup, Bubble Size and Water Overflow RateDocumento11 páginasDetermining Independent Control of Dual-Frother Systems - Gas Holdup, Bubble Size and Water Overflow RateJose Luis Barrientos RiosAinda não há avaliações

- Large Open Pit Slope StabilityDocumento53 páginasLarge Open Pit Slope Stabilitysaifuddin_ariefAinda não há avaliações

- Spec Sheet Pegasus BT 4DDocumento2 páginasSpec Sheet Pegasus BT 4DWempic Aulia FauziAinda não há avaliações

- AMRL Soil WorksheetsDocumento88 páginasAMRL Soil WorksheetsMinh An Tran100% (1)

- Wind Turbine Power CalculationDocumento5 páginasWind Turbine Power CalculationRavi Acharya100% (2)

- Fulltext VimpDocumento117 páginasFulltext VimpmayureshAinda não há avaliações

- EPFL Lectures On Conformal Field Theory in D 3 DimensionsDocumento68 páginasEPFL Lectures On Conformal Field Theory in D 3 DimensionsMojeime Igor NowakAinda não há avaliações

- January 2015 (IAL) QP - Unit 4 Edexcel Physics A-LevelDocumento24 páginasJanuary 2015 (IAL) QP - Unit 4 Edexcel Physics A-LevelIbrahim HakamAinda não há avaliações

- Module 9 - RoboticsDocumento20 páginasModule 9 - RoboticsdharshanirymondAinda não há avaliações

- Medina 2018 J. Phys. Conf. Ser. 1065 082002Documento5 páginasMedina 2018 J. Phys. Conf. Ser. 1065 082002boborg8792Ainda não há avaliações

- Parx Plastics Successfully Adds Antimicrobial Property To BASF Terluran® GP-35 ABS Copolymer - Modern Plastics & PolymersDocumento1 páginaParx Plastics Successfully Adds Antimicrobial Property To BASF Terluran® GP-35 ABS Copolymer - Modern Plastics & PolymersParas PatelAinda não há avaliações

- Navigat X Mk1 DatasheetDocumento2 páginasNavigat X Mk1 DatasheetcristianocalheirosAinda não há avaliações

- Fiziks: Institute For NET/JRF, GATE, IIT JAM, M.Sc. Entrance, JEST, TIFR and GRE in Physics Optics JEST 2013Documento4 páginasFiziks: Institute For NET/JRF, GATE, IIT JAM, M.Sc. Entrance, JEST, TIFR and GRE in Physics Optics JEST 2013shubham varudkarAinda não há avaliações

- Coordinate Reference SystemsDocumento120 páginasCoordinate Reference SystemsBenciu Florin ValentinAinda não há avaliações

- Science States of Matter JeopardyDocumento34 páginasScience States of Matter Jeopardyapi-254830778Ainda não há avaliações