Escolar Documentos

Profissional Documentos

Cultura Documentos

Ci3307scanlon 896 PDF

Enviado por

Assefa NigussieTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Ci3307scanlon 896 PDF

Enviado por

Assefa NigussieDireitos autorais:

Formatos disponíveis

Estimating Two-Way

Slab Deflections

Spreadsheet includes construction load effects

by Andrew Scanlon and Bruce A. Suprenant

M any studies have shown that the service behaviors

of two-way slab systems are sensitive to the

effects of construction loading.1 Because construction

a slab during construction wconst can be estimated as

wconst = k1k2Rwslab (1)

loads can approach or even exceed service level

design loads, shoring and reshoring must be used where k1 is a factor to allow for variations in slab stiffness, k2

to meet safety and serviceability requirements per is a factor to account for weight of formwork, R is a factor

ACI 318-08.2 Sustained, early-age loading can also (commonly called a load ratio) that varies with the number

have a significant impact on long-term deflections. of levels of shoring and reshoring in the system,1, 5-7 and

Even if the shoring and reshoring schedules meet wslab is the self-weight of the slab; k1 and k2 typically have

recommendations in ACI 347-043 or ACI 347.2R-05,4 assigned values of 1.1.

unanticipated deflections can damage nonstructural An example of a load history for a slab with one level

items or require remedial measures. of shores and two levels of reshores is shown in Fig. 1. On

This article provides a simplified calculation method removal of shoring at time ts, the slab carries wslab. Reshoring

for estimating deflections of two-way slabs in multi-story is then installed before the shoring for the next level is

buildings. Early-age loading and its effects on concrete installed. When the new slab is cast at time tstart, the slab

properties (elastic and creep behaviors) are incorporated. in question is loaded by wconst per Eq. (1). At time tend, the

The method is implemented in a spreadsheet format, load on the slab drops as the slab no longer supports

allowing users to investigate the effects of slab dimensions, reshores. The slab carries its own weight and any

design loads, and shoring/reshoring scenarios on long- superimposed loads during the subsequent construction

term deflections. The method is shown to provide good process. This load is termed wsus.

agreement with data from laboratory tests of slabs. During the period tstart to tend, short-duration construction

live loads will be applied to the hardened slab during the

Construction Loading subsequent placements. These loads will increase the

For the common case where individual slabs in a shored/ likelihood of cracking in the slab. At time tinst, nonstructural

reshored system are of equal thickness, the load carried by elements such as partition walls, doors, and windows are

installed—adding dead load to the slabs. Between tend

Download the spreadsheet described here at the and tinst, loads can include temporary storage of

ACI Concrete Knowledge Center at www.concrete.org.

construction materials.

Concrete international / July 2011 29

For most deflection calculations, the slab is assumed to K w n 4 (2)

δ=

carry its own weight, the design superimposed dead load, 384 Ec I e

and a sustained portion of live load after tend. The sustained

live load is usually taken as 10% of the design live load, and where K is a factor to account for span boundary conditions

the remaining portion of live load can be applied at any and can be taken as 1.4 for interior panels and 2.0 for

time during the service life. For the spreadsheet described exterior panels without edge beams, w is a uniformly

in this article, the live load is assumed to be applied as a distributed load, ℓn is the clear span, Ec is the modulus

short-term load at 5 years. For simplicity, the same level of of elasticity of concrete, and Ie is the effective moment

sustained load is assumed to be present before and after of inertia. Additional time-dependent deflection

the installation of nonstructural elements. under sustained load can be estimated by applying a

long-term load multiplier λ(ti, tj), based on the ACI 209

Deflection Calculations creep coefficient,10 a correction factor accounting for

ACI 435R-957 summarizes methods for calculating concrete age at loading,1 and the creep factor provided

deflections of two-way slabs. These include methods by ACI 3182

based on the crossing beam analogy in which the mid-

(ti − t j )0.6 ξ

panel deflection is calculated as the sum of a unit-width λ (ti , t j ) = × kj × (3)

0.6

column-strip deflection and a unit-width middle-strip (10 + (ti − t j ) ) (1 + 50ρ′ )

deflection (Fig. 2). Results obtained using this analogy

have been shown to compare favorably with those from where tj is the age of the concrete when load is applied, ti is

finite element analyses.8,9 The instantaneous column- and the age of the concrete at which deflection is calculated, ξ

middle-strip immediate deflections δc and δm can be is a creep factor (generally taken as 2.0 unless specific

calculated using standard beam deflection equations information is available on the creep characteristics of

the concrete), and ρ′ is the reinforcing ratio for the

compression bars at midspan. The factor kj accounts for

concrete age at loading1

k j = 2.3t −j 0.25 ≤ 1.75 (4)

Generalizing the principle of creep superposition11 to

the superposition of deflections due to a series of load

increments, deflection at time ti can be calculated as

K 4n i Δw(t j )(1 + λ (ti , t j )) (5)

Δ (ti ) = ∑

384 I e j =1 Ec (t j )

Fig. 1: Schematic load history for a slab in a multi-story building where Δw(tj) is an increment of load applied at time tj and

constructed using one level of shoring and two levels of reshoring Ec is a function of fc′, which is also a function of time.10

The modulus of elasticity at time ti is obtained from

Ec = 57,000 (ti ( ati + b)) fc′, psi (with f ′ in psi) or (6)

c

Ec = 4700 (ti (ati + b)) fc ′ , MPa (with f ′ in MPa).

c

For fc′ specified at 3 days, the coefficients a = 0.63 and

b = 1.11 are used. For fc′ specified at 28 days, the coefficients

a = 0.85 and b = 4 are used.

Deflections can thus be computed at a series of times ti

to provide the desired deflection-time history. The

time-dependent modulus of elasticity is based on the

compressive strength at the time of load application.

Bažant12 points out that the principle of superposition

predicts too much recovery on unloading by as much as

twice the observed amount. To account for the fact that

Fig. 2: Crossing beam analogy based on Reference 7 creep deformations are not completely recoverable, a

30 July 2011 / Concrete international

factor of one-half is applied to the multiplier for load approximation appears to give reasonable results

reductions (negative load increments). considering the extent of uncertainties involved regarding

For a uniformly distributed load, the moments in environmental conditions, material properties, and load

column strips are higher than the moments in middle history. We obtained similar levels of agreement for

strips. Based on the distributions of moments between Slabs S3 through S7 in the test series.

column and middle strips prescribed in ACI 318, the

uniformly distributed load wUDL is adjusted as follows for Examples to Illustrate use of the

use in Eq. (5): Spreadsheet

for the column-strip equivalent load The spreadsheet is implemented with a 7-day cycle

time. The concrete age at stripping can be taken as 1, 3,

wcol = 1.35wUDL (7) or 5 days. Construction loading is determined using

Eq. (1), with R assigned as 1.33 for one level of shores and

and for the middle-strip equivalent load two levels of reshores (1S + 2R), 1.25 for one level of

shores and three levels of reshores (1S + 3R), and 1.20 for

wmid = 0.65wUDL (8) one level of shores and four levels of reshores (1S + 4R).

The spreadsheet can be easily modified for other shoring/

For rectangular panels, a further adjustment is made to reshoring scenarios or for an arbitrary load history. The

the middle-strip load to account for the fact that the middle spreadsheet computes the deflection-time history for

strip in the short direction is wider than the column strip. column-strip, middle-strip, and midpanel locations. An

The effective moment of inertia is used to account for example of the output is shown in Fig. 4.

cracking in the slab. As a first approximation, Ie is respec-

tively taken as 40% and 80% of the gross moment of inertia

for the column strips and middle strips. These values reflect

the fact that column strips with higher moment intensities,

particularly in the vicinity of columns, are more likely to be

cracked than middle strips. The approximate values are

similar to the assumptions proposed by Rangan.13

Comparison with Measured

Deflections

To evaluate the validity of the proposed simplified method

for estimating slab deflections under time-dependent loads,

calculated values were compared with test results reported

by Gilbert and Guo.14 For each slab, Ec was based on the (a)

reported 28-day values for fc′. Long-term multipliers of 2.0 for

Slab S1 and 2.5 for Slab S2 were used based on reported

creep data. Calculated and measured deflection-time

histories are shown in Fig. 3. The deflections are overesti-

mated in the initial loading stages for Slab S1; however, the

comparison between calculated and measured values

improves at later age. For Slab S2, calculated values at early

age are again slightly greater than measured values, although

the measured values overtake the calculated values at about

60 days. A sudden decrease in measured deflection occurred

at about 100 days due to unintended wetting of the slab

surface caused by rain. Eventually, the measured deflections

again overtake the calculated values.

Gilbert and Guo14 reported that Slab S1 was initially

uncracked, whereas some shrinkage restraint cracking

was evident in Slab S2 from the time of initial loading. In (b)

both cases, time-dependent cracking was observed and

attributed to the development of shrinkage restraint Fig. 3: Calculated deflections compared with measured deflections

from Reference 14. Measured values are the average of the

stresses. To simplify the calculation procedure, cracking deflections measured at the four midpanel points: (a) Slab S1;

is assumed at all load stages, as outlined previously. This and (b) Slab S2 (dimensions in mm) (1 mm = 0.04 in.)

Concrete international / July 2011 31

To illustrate the use of the spreadsheet, an example is

presented of a typical interior panel of a flat plate. The

analysis is performed for three construction loading cases:

1S + 2R, 1S + 3R, and 1S + 4R. In each case, a 7-day cycle is

assumed with stripping at 3 days. It was assumed that the

concrete strength at 3 days was fc′ and the load during

shoring and reshoring did not exceed the design dead plus

live load. The age-at-loading correction factor (Eq. (4))

varied from 1.75 at 1 to 3 days to 1.0 at 28 days.

Analyses are also performed for Case 1S + 2R with a

7-day cycle and 1-, 3-, and 5-day stripping times. The

results (Fig. 5) show that deflection is not very sensitive to

the number of levels of reshores for the range considered

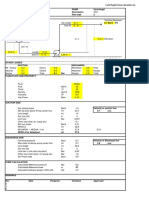

Fig. 4: Example of spreadsheet output. Inputs include: slab but is sensitive to the age at stripping.

spans, slab thickness, superimposed dead load, live load,

sustained live load, 3-day compressive strength, and long-term

multiplier (1 psf = 0.05 kPa; 1 psi = 6.9 kPa; 1 in. = 25 mm) Conclusion

Slab deflections, as affected by the construction

process (particularly for multi-story buildings), can have a

significant impact on serviceability. Although it’s well

known that slab deflections are highly variable and cannot

be predicted very accurately, a reasonable estimate of

expected time-dependent deflection magnitudes can be

obtained using the described calculation procedure. The

procedure takes into account the construction loading

history, time-dependent concrete properties, and effects of

cracking. The results can assist engineers in the evaluation

of proposed shoring and reshoring schemes as well as the

effect of slab thickness on time-dependent deflections. The

spreadsheet can also be used at the design stage to give an

indication of potential deflection problems related to the

construction process and provide an opportunity to

modify the design as needed.

The method has been shown to produce reasonable

(a) agreement with results from test slabs made with 28-day

compressive strengths around 4000 to 6000 psi (28 to

41 MPa). For higher-strength concretes, the modulus of

Will the spreadsheet results match those

of structural design software?

Probably not. The dead-load deflections calculated

by structural design programs typically:

■■ Use a moment of inertia based on the effects of dead

load alone, not dead plus construction load;

■■ Don’t include the effects of shrinkage and temperature

cracking; and

■■ Don’t include the effects of early-age prolonged

loading.

The spreadsheet is calibrated against measured actual

deflections, and it includes the effects of construction

(b) loads, cracking due to shrinkage and temperature change,

and early prolonged loadings. The latter consideration is

particularly important, as shoring/reshoring effects are

Fig. 5: Example plots of deflection histories: (a) case study

showing effects of reshoring schemes; and (b) case study likely to last about 1 month.

showing the effect of age of concrete at stripping (1 in. = 25 mm)

32 July 2011 / Concrete international

elasticity versus time function and the long-term multiplier Hills, MI, 1995, 89 pp.

may require adjustment. 8. Scanlon, A., and Murray, D.W., “Practical Calculation of Two-Way

Slab Deflections,” Concrete International, V. 4, No. 11, Nov. 1982, pp. 43-50.

References 9. Chang, K.Y., and Hwang, S.J., “Practical Estimation of Two-Way

1. Ghosh, S.K., “Construction Loading in High-Rise Buildings,” Slab Deflections,” Journal of Structural Engineering, ASCE, V. 122,

Concrete Construction Engineering Handbook, second edition, E.G. No. 2, 1996, pp. 150-159.

Nawy, ed., CRC Press, Boca Raton, FL, 2008, pp. 8.1-8.60. 10. ACI Committee 209, “Prediction of Creep, Shrinkage, and

2. ACI Committee 318, “Building Code Requirements for Structural Temperature Effects in Concrete Structures (ACI 209R-92),”

Concrete (ACI 318-08) and Commentary,” American Concrete American Concrete Institute, Farmington Hills, MI, 1992, 47 pp.

Institute, Farmington Hills, MI, 2008, 473 pp. 11. McHenry, D., “A New Aspect of Creep in Concrete and its

3. ACI Committee 347, “Guide to Formwork for Concrete (ACI Application to Design,” ASTM Proceedings, V. 43, 1943, pp. 1069-1086.

347-04),” American Concrete Institute, Farmington Hills, MI, 2004, 32 pp. 12. Bažant, Z.P., “Mathematical Models for Creep and Shrinkage

4. ACI Committee 347, “Guide to Shoring/Reshoring of Concrete of Concrete,” Creep and Shrinkage in Concrete Structures, John Wiley

Multistory Buildings (ACI 347.2R-05),” American Concrete Institute, & Sons, Inc., 1982, pp. 163-256.

Farmington Hills, MI, 2005, 18 pp. 13. Rangan, B.V., “Prediction of Long-Term Deflections of Flat

5. Grundy, P., and Kabaila, A., “Construction Loads on Slabs with Plates and Slabs,” ACI JOURNAL, Proceedings V. 73, No. 4, Apr. 1976,

Shored Formwork in Multi-Story Buildings,” ACI JOURNAL, Proceedings pp. 223-226.

V. 60, No. 12, Dec. 1963, pp. 1729-1738. Also published as part of the 14. Gilbert, R.I., and Guo, X.H., “Time-Dependent Deflection and

Landmark Series, Concrete International, V. 26, No. 7, July 2004, Deformation of Reinforced Concrete Slabs—An Experimental Study,”

pp. 99-112. ACI Structural Journal, V. 102, No. 3, May-June 2005, pp. 363-373.

6. Gardner, N.J., “Shoring, Reshoring, and Safety,” Concrete

International, V. 7, No. 4, Apr. 1985, pp. 28-34. Received and reviewed under Institute publication policies.

7. ACI Committee 435, “Control of Deflection in Concrete

Structures (ACI 435R-95),” American Concrete Institute, Farmington

Will structural design software predict A

Q

U

actual deflections?

EXCELLENCE

I

T

Y C O R P O R AT I O N

® Environmentally Safe VpCI ®/MCI ® Technologies

Probably not. As the introduction to ACI 435R-95,

“Control of Deflection in Concrete Structures,”7 states:

…the magnitude of actual deflection in concrete

structural elements, particularly in buildings,

which are the emphasis and the intent of this

Report, can only be estimated within a range of

20-40 percent accuracy.

It’s likely the structural engineer’s design program Cortec® MCI® used on Pentagon Repair Project as featured in Concrete Repair Bulletin Sept./Oct. 2010 Issue.

will underestimate the actual dead load deflection Cracked Beam Testing of Surface Treatments. Details: www.CortecMCI.com

because it fails to account for cracking due to construction

Total Corrosion, Coulombs

loads, cracking due to shrinkage and temperature • Control

change, or creep effects due to early and prolonged

loadings. • Aminoalcohol

It’s also important to note that measured elevations • MCI®-2020

Amine Carboxylate

may not provide true indicators of dead load deflections.

ACI 117 allows a ±3/4 in. (±19 mm) tolerance for the

formed slab bottom surface and finished slab top Cycle Number

surface, both to be measured when the forms and Cortec’s Migrating Corrosion Inhibitors (MCI®) offer superior corro-

shores are still in place. An elevation that is 3/4 in. sion protection for new and existing structures. Proven to penetrate

(19 mm) lower than the design elevation might simply to embedded reinforcement, MCI® can reduce corrosion rates as

much as 80%. This offers an economical solution to more expensive

be the result of an initially low (yet within tolerance)

cathodic protection systems used for concrete. For more informa-

slab elevation. It’s also important to note that if the tion, including testing and case histories, please visit our newly up-

slab surface elevations were not taken when the forms dated website:

and shores were in place, the datum for slab deflections w w w. C o r t e c M C I . c o m

should be the elevation of the slab surface at the 1-800-4-CORTEC

Info@CortecVCI.com

columns, not the design elevation. St. Paul, MN 55110 USA

© Cortec Corporation 2011

Concrete international / July 2011 33

The practical problem: The 3- to 9-month dead load deflection in two-way slabs

The construction sequence for buildings with two-way slabs is generally as follows:

■■ Erect shores and forms;

■■ Place and cure the slab concrete;

■■ When a specified concrete strength is reached, remove shores and replace with reshores;

■■ Continue this process until the slab is no longer supported by reshores;

■■ Install mechanical, plumbing, electrical, masonry, and interior wall framing; and

■■ Finally, at 3 to 9 months, install cabinets, molding, and floor coverings.

When the final finish trades start their work, they sometimes find that the floors are sagging too much to allow

a good fit of the interior finishes. The owner or construction manager may then claim that the problem stems

from inappropriate construction practices and use this as justification for requiring the concrete contractor to

provide supplemental fill to bring the slab surface closer to level. On one multi-story building, for which the

second author was a consultant, the cost of extra fill approached $1 million—this is too large a cost to ignore.

Because of this, engineers, construction managers, and owners need to understand that if the dead-load

deflection at the time of finish installation is controlled by tolerances for finishes, the tighter tolerances must be

considered in the design, specification, and construction process.

Designing in accordance with building code requirements for deflection is not a solution to this issue. Table 9.5(c)

in ACI 318-082 includes minimum thicknesses of two-way slabs without interior beams that can be used without

providing deflection calculations. These thicknesses are intended to provide some control of deflection. The

commentary states:

R9.5.3.2—The minimum thicknesses in Table 9.5(c) are those that have been developed through the years.

Slabs conforming to those limits have not resulted in systematic problems related to stiffness for short- and

long-term loads. These limits apply to only the domain of previous experience in loads, environment, materials,

boundary conditions, and spans.

Based on the second author’s experience in the past 5 years, the owner’s, architect’s, or construction manager’s

expectations for slab deflections have changed and the expected deflections may be outside the domain of

previous experience.

ACI 318-082 also allows the designer to use a smaller value for the thickness than prescribed by Table 9.5(c)

if deflection calculations are performed. Table 9.5(b) gives limitations for maximum permissible computed

deflections based on two criteria:

■■ Immediate deflection due to live load; and

■■ That part of total deflection occurring after attachment of nonstructural elements.

There are no criteria for the $1 million issue—deflection prior to installation of the nonstructural elements. If

this deflection is limited to a very small value by tight tolerances for finish work, the designer needs to take that

into account. For instance, if a 10 in. (250 mm) thick slab is required by Table 9.5(c) and the designer chooses an

8 in. (200 mm) thick slab based on calculated deflection, the gross moment of inertia is about halved and the

deflections may increase by a factor of two. Such additional deflection may meet the requirements in ACI 318-082

but still result in the need for costly repairs to allow the finishes to fit properly.

Andrew Scanlon, FACI, is a Professor of civil Bruce A. Suprenant, FACI, is President of

engineering at The Pennsylvania State Concrete Engineering Specialists, Boulder,

University, University Park, PA. He is Chair CO. He is a member of ACI Committees 117,

of ACI Committee 435, Deflection of Tolerances; 222, Corrosion of Metals in

Concrete Building Structures, and a Concrete; 228, Nondestructive Testing of

member of ACI Committees 224, Cracking, Concrete; 301, Specifications for Concrete;

and 348, Structural Reliability and Safety. and 302, Construction of Concrete Floors.

His research interests include safety and

serviceability of concrete structures.

34 July 2011 / Concrete international

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- ASM Practical Fractography PDFDocumento159 páginasASM Practical Fractography PDFmarcotulio123100% (9)

- Behavior and Design of Spread Prestressed Concrete Slab Beam BridgesDocumento406 páginasBehavior and Design of Spread Prestressed Concrete Slab Beam BridgesAssefa NigussieAinda não há avaliações

- Chapter Four. Roof DesignDocumento85 páginasChapter Four. Roof DesignAssefa NigussieAinda não há avaliações

- 1ST-2ND-4TH - SLAB SsssDocumento143 páginas1ST-2ND-4TH - SLAB SsssAssefa NigussieAinda não há avaliações

- Chapter - 3 Load On Bridge.Documento13 páginasChapter - 3 Load On Bridge.Assefa NigussieAinda não há avaliações

- 1ST-2ND-4TH - SLAB SsssDocumento143 páginas1ST-2ND-4TH - SLAB SsssAssefa NigussieAinda não há avaliações

- Chapter Four. Roof Design: Wind Load AnalysisDocumento65 páginasChapter Four. Roof Design: Wind Load AnalysisAssefa NigussieAinda não há avaliações

- Slab DesignDocumento15 páginasSlab DesignLawrence Arellano FernandezAinda não há avaliações

- Thermal Energy Storage With Phase Change MaterialsDocumento217 páginasThermal Energy Storage With Phase Change MaterialsAssefa NigussieAinda não há avaliações

- Chapter Five Composite Structures (Concrete and Steel)Documento15 páginasChapter Five Composite Structures (Concrete and Steel)Assefa Nigussie100% (1)

- Design of 6 Storey Building in EtabsDocumento51 páginasDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- Strip Method2Documento42 páginasStrip Method2Assefa NigussieAinda não há avaliações

- Solution SD Test-1Documento3 páginasSolution SD Test-1Assefa NigussieAinda não há avaliações

- Plastic Analysis PDFDocumento69 páginasPlastic Analysis PDFShakeelAinda não há avaliações

- ICE Paper (Holistic Behaviour of Concrete Buildings in Fire) PDFDocumento35 páginasICE Paper (Holistic Behaviour of Concrete Buildings in Fire) PDFAssefa NigussieAinda não há avaliações

- Moreno Fib SymposiumDocumento16 páginasMoreno Fib SymposiumAssefa NigussieAinda não há avaliações

- Hawiso DargeDocumento83 páginasHawiso DargeAssefa NigussieAinda não há avaliações

- Faggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Documento17 páginasFaggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Assefa NigussieAinda não há avaliações

- MSC ProgrammebrochureDocumento5 páginasMSC Programmebrochurekanishka_gunasekara7208Ainda não há avaliações

- Faggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Documento17 páginasFaggella - Barbosa - Conte - Spacone - Restrepo - Probabilistic Seismic Response Analysis of A 3D RC Building - Struct-Safety - 2013Assefa NigussieAinda não há avaliações

- 2009 Eesd Martinelli Filippou PDFDocumento21 páginas2009 Eesd Martinelli Filippou PDFAssefa NigussieAinda não há avaliações

- 2007 SDTSB WallaceDocumento18 páginas2007 SDTSB WallaceChristian Alcedo SantiAinda não há avaliações

- PHD Baldock PDFDocumento180 páginasPHD Baldock PDFSaurabh PednekarAinda não há avaliações

- Two Way Slab DesignDocumento16 páginasTwo Way Slab Designgullipalli75% (4)

- One Way SlabDocumento12 páginasOne Way SlabJosé FerreiraAinda não há avaliações

- Stability Exam Fall-2014Documento4 páginasStability Exam Fall-2014Assefa NigussieAinda não há avaliações

- Sample Research Proposal 2Documento4 páginasSample Research Proposal 2Syamil Ahamad SabkiAinda não há avaliações

- 2 Way SlabDocumento28 páginas2 Way SlabGautam PaulAinda não há avaliações

- RC Design PDFDocumento58 páginasRC Design PDFZerihun IbrahimAinda não há avaliações

- Design of Waffle SlabDocumento4 páginasDesign of Waffle SlabAriel Mayer100% (1)

- Ci3307scanlon 896 PDFDocumento6 páginasCi3307scanlon 896 PDFAssefa Nigussie100% (1)

- Sphericaltankpresentation 1Documento72 páginasSphericaltankpresentation 1NilabhAinda não há avaliações

- Mechanical Drives 1 Lap 3Documento77 páginasMechanical Drives 1 Lap 3j.bbarnesAinda não há avaliações

- Design A Good Road: Road Design ResourcesDocumento2 páginasDesign A Good Road: Road Design ResourcesJeremiah PAinda não há avaliações

- Guidelines For Inspection and Maintenance of Bridges Vol.2 - Minor Repairs (Recurrent Maintenance)Documento111 páginasGuidelines For Inspection and Maintenance of Bridges Vol.2 - Minor Repairs (Recurrent Maintenance)anjan luitelAinda não há avaliações

- 30 - EC210B - MCV, Válvula Lógica EmperradaDocumento4 páginas30 - EC210B - MCV, Válvula Lógica EmperradaAparecidaMarquesAinda não há avaliações

- Pipe Under Clamping ForceDocumento6 páginasPipe Under Clamping ForceJaya DiAinda não há avaliações

- Rakic - Type of Fireproofing Materials PDFDocumento3 páginasRakic - Type of Fireproofing Materials PDFbehrouzbehnam100% (1)

- DITO Tower Civil Work - Acceptance Checklist 20200521-TF - 1625704814Documento1 páginaDITO Tower Civil Work - Acceptance Checklist 20200521-TF - 1625704814bashirAinda não há avaliações

- Nicon Price List January 2021Documento12 páginasNicon Price List January 2021niket0Ainda não há avaliações

- ECOKUBO - PresentationDocumento76 páginasECOKUBO - PresentationNestor ArabejoAinda não há avaliações

- To: Project: Location Labor & Materials Total Unit Cost Total Amount Item Description QTY UnitDocumento18 páginasTo: Project: Location Labor & Materials Total Unit Cost Total Amount Item Description QTY UnitMarylan SalazarAinda não há avaliações

- Cemex Solid K4 - Raw Meal SiloDocumento3 páginasCemex Solid K4 - Raw Meal Silojoselito navarroAinda não há avaliações

- Centrifugal Pump CalculatorDocumento1 páginaCentrifugal Pump Calculatoranto3harrish3fdoAinda não há avaliações

- Adesh SurujnathDocumento3 páginasAdesh SurujnathJj DeEmpressAinda não há avaliações

- Heat Exchanger Aftercooler and SeparatorDocumento16 páginasHeat Exchanger Aftercooler and Separatorjaskaran singhAinda não há avaliações

- Building and Electrical Block C BoqDocumento40 páginasBuilding and Electrical Block C BoqAndile NtuliAinda não há avaliações

- Romanesque Architecture - PPTDocumento64 páginasRomanesque Architecture - PPTJerica YuAinda não há avaliações

- Siesmic Zone Coefficient - ValueDocumento1 páginaSiesmic Zone Coefficient - ValueMahtab HossainAinda não há avaliações

- Páginas DesdeB.H.G.brady, E.T.brown - Rock Mechanics-8Documento1 páginaPáginas DesdeB.H.G.brady, E.T.brown - Rock Mechanics-8Fredy Apaza QuispeAinda não há avaliações

- Rectangular Duct ConnectionsDocumento14 páginasRectangular Duct ConnectionsHung JPAinda não há avaliações

- Elo ( (.Ilc: Fftqffitrc./ - I&Jnqrt QRMDocumento29 páginasElo ( (.Ilc: Fftqffitrc./ - I&Jnqrt QRMAaditya AgrawalAinda não há avaliações

- Rigid Pavement Unit 4Documento76 páginasRigid Pavement Unit 4Deepak SahAinda não há avaliações

- 17cv54 ManualDocumento72 páginas17cv54 ManualUma Shankar YaligarAinda não há avaliações

- R.C.C FRAME STRUCTURE (Study Material For S.y.b.arch Students)Documento18 páginasR.C.C FRAME STRUCTURE (Study Material For S.y.b.arch Students)shrikant0% (1)

- City Block in RotterdamDocumento3 páginasCity Block in RotterdamDenisa BalajAinda não há avaliações

- Butterfield Products CatalogDocumento27 páginasButterfield Products Catalogparaschiv54Ainda não há avaliações

- Tabel Profil Konstruksi BajaDocumento26 páginasTabel Profil Konstruksi BajaAnisa FebrianaAinda não há avaliações

- Economic Considerations For Tall Multi-Use BuildingsDocumento5 páginasEconomic Considerations For Tall Multi-Use BuildingsNasim AhmadAinda não há avaliações