Escolar Documentos

Profissional Documentos

Cultura Documentos

Double Angle Bar

Enviado por

Shadin Asari ArabaniDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Double Angle Bar

Enviado por

Shadin Asari ArabaniDireitos autorais:

Formatos disponíveis

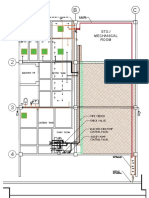

midas Gen Steel Checking Result

Company PMENG'G TECHNIC INC. Project Title

Author Shadz File Name C:\...\Desktop\FLATFORM.mgb

z

1. Design Information

0.0047625

Design Code : AISC(13th)-LRFD05

y

0.0508

Unit System : kN, m

Member No :1

Material : A36 (No:1) 0.0047625

(Fy = 248211, Es = 199948024) 0.0508

Section Name : 2L2X2X3/16X3/8 (No:1)

(Rolled : 2L2X2X3/16X3/8).

Member Length : 1.30000

2. Member Forces Depth 0.05080 Web Thick 0.00476

Axial Force Fxx = 0.00000 (LCB: 1, POS:J) Flg Width 0.05080 Flg Thick 0.00476

BTB Spacing 0.00952

Bending Moments My = -1.1971, Mz = 0.00000

Area 0.00093 Asz 0.00032

End Moments Myi = -1.1971, Myj = -1.1971 (for Lb) Qyb 0.00066 Qzb 0.00129

Iyy 0.00000 Izz 0.00000

Myi = -1.1971, Myj = -1.1971 (for Ly) Ybar 0.05556 Zbar 0.03655

Mzi = 0.00000, Mzj = 0.00000 (for Lz) Syy 0.00001 Szz 0.00001

ry 0.01554 rz 0.02456

Shear Forces Fyy = 0.00000 (LCB: 1, POS:I)

Fzz = 5.52517 (LCB: 1, POS:J)

3. Design Parameters

Unbraced Lengths Ly = 1.30000, Lz = 1.30000, Lb = 1.30000

Effective Length Factors Ky = 1.00, Kz = 1.00

Moment Factor / Bending Coefficient

Cmy = 1.00, Cmz = 1.00, Cb = 1.00

4. Checking Results

Slenderness Ratio

L/r = 83.6 < 300.0 (LCB: 1)............................................. O.K

Axial Strength

Pr/Pc = 0.000/207.536 = 0.000 < 1.000 ...................................... O.K

Bending Strength

Mry/Mcy = 1.19712/1.37643 = 0.870 < 1.000 ................................... O.K

Mrz/Mcz = 0.00000/2.29144 = 0.000 < 1.000 ................................... O.K

Combined Strength (Tension+Bending)

Pr/Pc = 0.00 < 0.20

Rmax = Pr/(2*Pc) + [Mry/Mcy + Mrz/Mcz] = 0.870 < 1.000 ............................ O.K

Shear Strength

Vry/Vcy = 0.000 < 1.000 ...................................................... O.K

Vrz/Vcz = 0.085 < 1.000 ...................................................... O.K

Modeling, Integrated Design & Analysis Software Print Date/Time : 10/10/2017 16:23

Você também pode gostar

- Axle Design For Trolley CartDocumento2 páginasAxle Design For Trolley CartHailemariam WeldegebralAinda não há avaliações

- Equal angle steel profiles data sheetDocumento2 páginasEqual angle steel profiles data sheetGalih PutraAinda não há avaliações

- SloshingDocumento36 páginasSloshingVicky GautamAinda não há avaliações

- Bore Pile Design in SandDocumento4 páginasBore Pile Design in SandsyakirohAinda não há avaliações

- RF Prope Way Pauri 1602669219Documento49 páginasRF Prope Way Pauri 1602669219Agnichandra SubediAinda não há avaliações

- 70R_TRACKED LOAD DISPERSION CALCULATIONSDocumento17 páginas70R_TRACKED LOAD DISPERSION CALCULATIONSHimal KafleAinda não há avaliações

- Iitk Rdso 19-07-10Documento165 páginasIitk Rdso 19-07-10Ashok ChaudharyAinda não há avaliações

- Foundation Design f1Documento2 páginasFoundation Design f1Sampath Kumar KandasamyAinda não há avaliações

- Pin Base ModuleDocumento16 páginasPin Base ModuleMd Ahsanul KabirAinda não há avaliações

- Braking Test: Vehicle Laboratory 2Documento20 páginasBraking Test: Vehicle Laboratory 2Steven SullivanAinda não há avaliações

- Steel Grating AnalysisDocumento17 páginasSteel Grating AnalysisDhanraj VasanthAinda não há avaliações

- Disclosure To Promote The Right To InformationDocumento22 páginasDisclosure To Promote The Right To InformationjanidevangAinda não há avaliações

- M3D - SampleProblemSet ACI PDFDocumento6 páginasM3D - SampleProblemSet ACI PDFasaisenthilAinda não há avaliações

- Is SP 34 1987Documento19 páginasIs SP 34 1987ankitAinda não há avaliações

- Gusset BaseDocumento2 páginasGusset Basemanish mehtaAinda não há avaliações

- Lateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Documento8 páginasLateral Pile Capacity Caculation Using Broms's Method (Free Head Type)Mohammad Tawfiq WaraAinda não há avaliações

- Base Plate BiaxilDocumento19 páginasBase Plate BiaxilGunjan KolarkarAinda não há avaliações

- Soil Details: ResultsDocumento3 páginasSoil Details: ResultsGhanaam LilaAinda não há avaliações

- For Maximum Load (Normal Case) : From Staad From STAAD With ImpactDocumento4 páginasFor Maximum Load (Normal Case) : From Staad From STAAD With ImpactVasu Deva Rao ChilukuriAinda não há avaliações

- Chequred Plate CheckDocumento2 páginasChequred Plate Check_jessecaAinda não há avaliações

- Punching Shear design and reinforcement calculationDocumento4 páginasPunching Shear design and reinforcement calculationMohafisto SofistoAinda não há avaliações

- Verification of Lifting Lug (As Per OVS For MPD, P-III) : y All VDocumento4 páginasVerification of Lifting Lug (As Per OVS For MPD, P-III) : y All VGohar ZamanAinda não há avaliações

- Live Load CalculationDocumento1 páginaLive Load CalculationSuman NakarmiAinda não há avaliações

- Summary of IS 3370 Detailing RequirementsDocumento2 páginasSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethAinda não há avaliações

- Amendment IS 1893 Part 2Documento14 páginasAmendment IS 1893 Part 2write2souravdAinda não há avaliações

- Idn - 4Documento5 páginasIdn - 4Anh KyAinda não há avaliações

- XyzDocumento64 páginasXyzP S HARSHITAAinda não há avaliações

- CEMENT CONCRETE PAVEMENT DESIGN FOR 150 CVPDDocumento3 páginasCEMENT CONCRETE PAVEMENT DESIGN FOR 150 CVPDSatish BhairanattiAinda não há avaliações

- 1.2 B-001 - Master Template Without MedianDocumento7 páginas1.2 B-001 - Master Template Without MediankanagarajodishaAinda não há avaliações

- Design of Biaxial ColumnDocumento5 páginasDesign of Biaxial ColumndineshAinda não há avaliações

- Base Plate Design - Rev-0Documento8 páginasBase Plate Design - Rev-0KINGSUK PALAinda não há avaliações

- Examples 8.3 and 8.4Documento12 páginasExamples 8.3 and 8.4itissa INGENIERIAAinda não há avaliações

- Design of Slab Bs-2 Calculation of Crack WidthDocumento2 páginasDesign of Slab Bs-2 Calculation of Crack WidthD SRINIVASAinda não há avaliações

- Construction of Road Linking Thalian to New Islamabad AirportDocumento8 páginasConstruction of Road Linking Thalian to New Islamabad AirportyasirAinda não há avaliações

- Apsara BorderDocumento15 páginasApsara BorderskumarsrAinda não há avaliações

- 4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Documento27 páginas4.3 Design of Base Plate W STIFFENER (Feb 21 2015)Jair llacuachaqui villalvaAinda não há avaliações

- Dynamic Earth PressureDocumento2 páginasDynamic Earth PressureMahadev D. BhandareAinda não há avaliações

- Design Aids of Flexural Members and Beam Columns Based On Limit State Method PDFDocumento16 páginasDesign Aids of Flexural Members and Beam Columns Based On Limit State Method PDFscshekarAinda não há avaliações

- GratingDocumento8 páginasGratingGhanshyam PandeyAinda não há avaliações

- 3 5mDocumento8 páginas3 5mSanjay sharmaAinda não há avaliações

- Design of 75Kl Zinc Alume (Znal) Elevated Water Storage TankDocumento26 páginasDesign of 75Kl Zinc Alume (Znal) Elevated Water Storage TankSmit PatelAinda não há avaliações

- Haufe GISSMODocumento48 páginasHaufe GISSMOGoncharik DmitryAinda não há avaliações

- Structural Design Basis Report FOR Project "Proposed Industrial Building For M/S Sudhir Enterprises" AT TumkurDocumento19 páginasStructural Design Basis Report FOR Project "Proposed Industrial Building For M/S Sudhir Enterprises" AT TumkurANIL KUMAR H CAinda não há avaliações

- CV DM 001 100dpiDocumento58 páginasCV DM 001 100dpighazi andonoAinda não há avaliações

- Ficha Técnica - ArmourJoint PDFDocumento2 páginasFicha Técnica - ArmourJoint PDFDiego BarretoAinda não há avaliações

- Rectangular BasePlate DesignDocumento13 páginasRectangular BasePlate DesignMuhammad HasanAinda não há avaliações

- Hilti Profis Anchor calculation for M10 anchor in cracked concreteDocumento7 páginasHilti Profis Anchor calculation for M10 anchor in cracked concreteDr RajeevAinda não há avaliações

- RCC Design Sheets 1Documento437 páginasRCC Design Sheets 1Bang JoyAinda não há avaliações

- Wind Design - ASCE 7-16Documento22 páginasWind Design - ASCE 7-16Nguyen Tan PhatAinda não há avaliações

- Bolt Design & Development LengthDocumento3 páginasBolt Design & Development LengthShamik ChowdhuryAinda não há avaliações

- Calculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDocumento2 páginasCalculation of Base Shear (Ubc-1997) Location: Rancakusumba SubstationDS IchaqueAinda não há avaliações

- DesignDocumento25 páginasDesignMelchorRdzAinda não há avaliações

- AASHTO Shear Calculator, No Stirrups: Code Values of Beta and ThetaDocumento6 páginasAASHTO Shear Calculator, No Stirrups: Code Values of Beta and ThetaNuttasak AriyapurkAinda não há avaliações

- For Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Documento43 páginasFor Axial Compressive Load & Biaxial Bending Moments, Including Slenderness Effect, As Per Is:456-2000Mohan BhalmeAinda não há avaliações

- Influencelines Lineas de InfluenciaDocumento6 páginasInfluencelines Lineas de InfluenciaMarlon MartinezAinda não há avaliações

- Gardez - Khost Bridge No. 5 I - GIRDER 0.600 X 1.450 X 25.700 MDocumento5 páginasGardez - Khost Bridge No. 5 I - GIRDER 0.600 X 1.450 X 25.700 MBrian UrciaAinda não há avaliações

- Wind Pressure Calculation For 3 Sec Gust Extreme StormDocumento5 páginasWind Pressure Calculation For 3 Sec Gust Extreme StormChinnaraja GandhiAinda não há avaliações

- Diagonal Web Member PDFDocumento1 páginaDiagonal Web Member PDFJohn Edrick TanAinda não há avaliações

- Midas Gen: 1. Design InformationDocumento6 páginasMidas Gen: 1. Design InformationChristian Jeremiah TevesAinda não há avaliações

- DB16 MMDocumento1 páginaDB16 MMGooddayBybsAinda não há avaliações

- Construction Estimate BreakdownDocumento46 páginasConstruction Estimate BreakdownShadin Asari ArabaniAinda não há avaliações

- Summary Sheet: Shieham Construction and EnterprisesDocumento26 páginasSummary Sheet: Shieham Construction and EnterprisesShadin Asari ArabaniAinda não há avaliações

- Summary Sheet: Shieham Construction and EnterprisesDocumento13 páginasSummary Sheet: Shieham Construction and EnterprisesShadin Asari ArabaniAinda não há avaliações

- C1 W12x65 Full CalculationDocumento5 páginasC1 W12x65 Full CalculationShadin Asari ArabaniAinda não há avaliações

- Product Data Sheet: Sika® Anchorfix-3001Documento7 páginasProduct Data Sheet: Sika® Anchorfix-3001Shadin Asari Arabani100% (1)

- C1 W12x65 Summary CalculationDocumento2 páginasC1 W12x65 Summary CalculationShadin Asari ArabaniAinda não há avaliações

- 1 Identification of The Substance/preparation and of The Company/undertakingDocumento7 páginas1 Identification of The Substance/preparation and of The Company/undertakingShadin Asari ArabaniAinda não há avaliações

- Sample Grouted Riprap EstimateDocumento2 páginasSample Grouted Riprap EstimateShadin Asari ArabaniAinda não há avaliações

- Budget Allocation ControlDocumento11 páginasBudget Allocation ControlShadin Asari ArabaniAinda não há avaliações

- C1 W12x65 Full CalculationDocumento5 páginasC1 W12x65 Full CalculationShadin Asari ArabaniAinda não há avaliações

- Builderware Price List 5Documento38 páginasBuilderware Price List 5Jongson Dantes RodriguezAinda não há avaliações

- Eastwest Mastercard Interest Computation SampleDocumento1 páginaEastwest Mastercard Interest Computation SampleArjay PlautaAinda não há avaliações

- C1 W12x65 Summary CalculationDocumento2 páginasC1 W12x65 Summary CalculationShadin Asari ArabaniAinda não há avaliações

- Injection System PDFDocumento20 páginasInjection System PDFb4rfAinda não há avaliações

- Wilo Pump DataDocumento58 páginasWilo Pump Datapolaris100% (1)

- Basic Soil and Rock CharacteristicsDocumento31 páginasBasic Soil and Rock CharacteristicsShadin Asari ArabaniAinda não há avaliações

- 2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsDocumento26 páginas2D Frame Analysis: Analysis of A 2D Frame Subject To Distributed Loads, Point Loads and MomentsShadin Asari ArabaniAinda não há avaliações

- Baggage General Rules As of 04jul17 PDFDocumento32 páginasBaggage General Rules As of 04jul17 PDFjrAinda não há avaliações

- Standards For 7-Day and 28-Day Strength Test Results PDFDocumento2 páginasStandards For 7-Day and 28-Day Strength Test Results PDFShadin Asari ArabaniAinda não há avaliações

- A 00Documento1 páginaA 00Shadin Asari ArabaniAinda não há avaliações

- For Layout PDFDocumento1 páginaFor Layout PDFShadin Asari ArabaniAinda não há avaliações

- Bid Form: Civil / Structural / Architectural WorksDocumento54 páginasBid Form: Civil / Structural / Architectural WorksShadin Asari ArabaniAinda não há avaliações

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocumento4 páginasPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniAinda não há avaliações

- 19 372 Degic TunnelDocumento4 páginas19 372 Degic TunnelShadin Asari ArabaniAinda não há avaliações

- Beam CheckingDocumento5 páginasBeam CheckingShadin Asari ArabaniAinda não há avaliações

- Analysis of Raft Foundation Using Finite Element ApproachDocumento15 páginasAnalysis of Raft Foundation Using Finite Element ApproachShadin Asari ArabaniAinda não há avaliações

- Construction of Multi-Level ParkingDocumento13 páginasConstruction of Multi-Level Parkingdunknown15Ainda não há avaliações

- ScaffoldDocumento2 páginasScaffoldShadin Asari ArabaniAinda não há avaliações

- Analysis of Raft Foundation Using Finite Element ApproachDocumento15 páginasAnalysis of Raft Foundation Using Finite Element ApproachShadin Asari ArabaniAinda não há avaliações

- Load TabulationDocumento4 páginasLoad TabulationShadin Asari ArabaniAinda não há avaliações

- Concrete and asphalt aggregate element chartDocumento4 páginasConcrete and asphalt aggregate element chartsaber2s22ahmadAinda não há avaliações

- Polyester Resin For Laminating 1Documento13 páginasPolyester Resin For Laminating 1Kelvin XuAinda não há avaliações

- Distilled Water From Dirty Water SolarDocumento3 páginasDistilled Water From Dirty Water SolarbatcavernaAinda não há avaliações

- Sika® Microcrete®-218: Product Data SheetDocumento3 páginasSika® Microcrete®-218: Product Data SheetthowchinAinda não há avaliações

- Catalogo Yz65 2023Documento55 páginasCatalogo Yz65 2023diego vazAinda não há avaliações

- Storage Tank Test & Inspection Report enDocumento10 páginasStorage Tank Test & Inspection Report enMarketing CTNAinda não há avaliações

- Gabion & Mattress Construction SpecificationDocumento8 páginasGabion & Mattress Construction SpecificationAkmarn Makmur100% (1)

- Design of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorDocumento31 páginasDesign of Masonry Structures: Dr. Ratnesh Kumar Associate ProfessorArunsai GillaAinda não há avaliações

- Bilaga 3 ReservdelsprislistaDocumento856 páginasBilaga 3 ReservdelsprislistaMarlon OliveiraAinda não há avaliações

- Chapter 2Documento11 páginasChapter 2Melvin EsguerraAinda não há avaliações

- Cet201 Mos Module 1Documento27 páginasCet201 Mos Module 1Sidhartha Krishna TAinda não há avaliações

- Kohinoor Case Syudy PDFDocumento7 páginasKohinoor Case Syudy PDFPUJIAinda não há avaliações

- Imbinari Teava Fibra de Sticla PDFDocumento1 páginaImbinari Teava Fibra de Sticla PDFplex015Ainda não há avaliações

- MOS DrainageDocumento16 páginasMOS DrainageMohammad Hadoumi Saldan100% (1)

- Manage Noise & Vibration from ConstructionDocumento18 páginasManage Noise & Vibration from ConstructionCarl WilliamsAinda não há avaliações

- Innovative Design and Construction Methods For CFRDDocumento11 páginasInnovative Design and Construction Methods For CFRD191162100% (1)

- Refrigerant-Piping Design Guide-McquayDocumento91 páginasRefrigerant-Piping Design Guide-Mcquayapi-19789368100% (4)

- MDD FormatDocumento6 páginasMDD FormatEngineeri TadiyosAinda não há avaliações

- Module 2 Filler SlabDocumento19 páginasModule 2 Filler SlabShahnaaz SyediAinda não há avaliações

- Combi 200Documento3 páginasCombi 200arunradAinda não há avaliações

- Brushbond Ultraflex BFLDocumento2 páginasBrushbond Ultraflex BFLpeashAinda não há avaliações

- Fire Alarm System Maintenance 2Documento3 páginasFire Alarm System Maintenance 2renvAinda não há avaliações

- Arch 001 Architectural Design 01 Introduction of Design Ar, Ryan BakingDocumento12 páginasArch 001 Architectural Design 01 Introduction of Design Ar, Ryan BakingZendrick EspartinezAinda não há avaliações

- Basic Design Study - Meru Water SupplyDocumento79 páginasBasic Design Study - Meru Water SupplyKip Rotich100% (1)

- Aircraft Fastener NotesDocumento76 páginasAircraft Fastener NotesHarimau Merah100% (2)

- Impact of Fire On Steel Reinforcement of R.C.C StructuresDocumento18 páginasImpact of Fire On Steel Reinforcement of R.C.C StructuresLayali90Ainda não há avaliações

- TRAFFIC SIGNS, MARKINGS & OTHER ROAD APPURTENANCESDocumento2 páginasTRAFFIC SIGNS, MARKINGS & OTHER ROAD APPURTENANCESRajkumar Sagar100% (1)

- MADE EASY Editorial Board - SSC JE (Objective) - Civil Engineering-MADE EASY Publications (2018)Documento433 páginasMADE EASY Editorial Board - SSC JE (Objective) - Civil Engineering-MADE EASY Publications (2018)Sourabh Raj DesaiAinda não há avaliações

- Grounding and Bonding in Data CenterDocumento3 páginasGrounding and Bonding in Data CenterLuis Ivan Moreno ParraAinda não há avaliações

- CRSI Manual To Design RC Diaphragms - Part22Documento4 páginasCRSI Manual To Design RC Diaphragms - Part22Adam Michael GreenAinda não há avaliações