Escolar Documentos

Profissional Documentos

Cultura Documentos

Small Drip Legs Cause Big Problem

Enviado por

John0 notas0% acharam este documento útil (0 voto)

14 visualizações1 páginaSmall Drip Legs Cause Big Problem (1)

Título original

Small Drip Legs Cause Big Problem (1)

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoSmall Drip Legs Cause Big Problem (1)

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

14 visualizações1 páginaSmall Drip Legs Cause Big Problem

Enviado por

JohnSmall Drip Legs Cause Big Problem (1)

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 1

Carefully designed drip legs enable steam traps to

properly drain condensate from mains

stream as it forms on pipe walls. These water able to use a steam separator to provide flow

droplets are carried along, mixed with steam, reduction, and drain with an adequate drip

at velocities that can exceed 100 mph. To sep- leg.

arate the condensate from high-velocity If condensate accumulates in the flowing

steam, the drip leg must be large enough to steam, it reduces steam quality. This reduces

provide expansion in the flow area, reducing the amount of heat transferred from the steam

gas velocity and allowing condensate to drop delivered downstream and increases operat-

out. If the drip leg is not large enough, the ing costs. The erosive force of condensate

pressure drop created at the interface of the droplets being whipped along at 100 mph is

steam line and the drip leg draws condensate roughly analogous to a major hurricane. As

out of the drip leg and steam trap. In applica- pipe walls and heat exchanger surfaces are

tions where dry steam is essential, it is prefer- eroded by the water blast, they begin to leak

or fail. Control valves, ends of mains, and

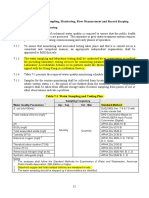

Recommended Steam Main and expansion loops also become eroded and

Branch Line Drip Leg Sizing eventually fail when subjected to these forces.

M D H Drip Leg Design

-- ~ ,: Oflfi~C~g:~r;~nQth_,-;:-_-~J~~, :J.J1-~: Given these three flow dynamics, it is

Steam Main Drip '-~g Supervi$ed Automatic · obvious that, to be effective, a drip leg must

Size, in.··.. Dic:tmeter, in. Warlll-Up Warm-.Up be as carefully designed as the rest of the

steam system. Following a few simple sizing

~ 10 28 guidelines enables the steam trap to drain

% 10 28 condensate from the main throughout the

1 10 28 operating cycle of any steam system.

2 2 10 28 In general, for steam mains up to 4 in. in

10 28

diameter, the drip leg should be constructed

3 3

from the same size pipe as the main. For

4 4 10 28 steam mains larger than 4 in., the drip leg

6 4 10 28 should be half the diameter of the main but

8 4 12 28 never less than 4 in. The distance from the

10 6 15 28 bottom of the main to the top of the trap, in

12 6 18 28 inches, divided by 28 yields the amount of sta-

14 8 21 28 tic head, in psi, available to push condensate

Fig. 4. Drip legs 16 8 24 28 through the trap on startup. The accompany-

must be large 18 10 27 28 ing table gives recommendations for sizing of

enough to allow 20 10 30 30 steam mains and branch drip legs when the

condensate to drop trap discharges to a gravity return.

out of the stream at 24 12 36 36 On automatic startup, when return lines are

the pipe bottom. elevated or pressurized, special precautions

should be taken to prevent flooding. The best

method is to collect the trap discharge in a

Effect Of Drip Leg Size nonpressurized receiver and use a pump or a

pumping trap to raise condensate or overcome

back pressure.

The best way to trap drip legs is by using an

inverted bucket (LB.) steam trap. This trap

effectively handles accumulations of dirt and

slugs of condensate. The I.B. trap drains con-

densate as it forms, has low maintenance

requirements, and has a long operating life. If

the trap does fail, it usually fails open, pre-

cluding system flooding and dangerous water

hammer.

Reprinted from PLANT ENGINEERING September 9, 1993

© 1993 by CAHNERS PUBLISHING COMPANY

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Reciprocating Pump PratishthaDocumento13 páginasReciprocating Pump Pratishthamike rosaAinda não há avaliações

- DS EN545 Ductile Iron Pipe&Fitting CatalogueDocumento23 páginasDS EN545 Ductile Iron Pipe&Fitting CatalogueVicky Bi -Dinsen Impex CorpAinda não há avaliações

- Ersatzteilliste KolbenhubpumpeDocumento59 páginasErsatzteilliste KolbenhubpumpealiwaAinda não há avaliações

- Standard Methods For Examination of WaterDocumento2 páginasStandard Methods For Examination of Wateryiu winghungAinda não há avaliações

- Water Cooler Day 4-3Documento10 páginasWater Cooler Day 4-3Laka 98Ainda não há avaliações

- Hydraulic Study Material CompressedDocumento76 páginasHydraulic Study Material CompressedGokul Prasad ChettiAinda não há avaliações

- Computational Fluid Dynamics For Incompressible FlowsDocumento43 páginasComputational Fluid Dynamics For Incompressible Flowskushal bosuAinda não há avaliações

- Atmospheric Foam TankDocumento5 páginasAtmospheric Foam TankAndro SidhomAinda não há avaliações

- Leser Transmittal (EN)Documento1 páginaLeser Transmittal (EN)Mohamed RaafatAinda não há avaliações

- VDLSE502 - VRB2-3 - Danfoss VentiliDocumento8 páginasVDLSE502 - VRB2-3 - Danfoss VentilizigicsasaAinda não há avaliações

- Exp 1Documento4 páginasExp 1Ihsan SamohAinda não há avaliações

- Notas Ashrae HVAC Design Manual For Hospitals and Clinics 8.2 Room PressurizationDocumento2 páginasNotas Ashrae HVAC Design Manual For Hospitals and Clinics 8.2 Room PressurizationRoger PandoAinda não há avaliações

- Equipment and Materials Unit Tag Number Qty NameDocumento2 páginasEquipment and Materials Unit Tag Number Qty NameIshwar AltAinda não há avaliações

- Rying of Solids: Mohammad Hadi Usama Zulfiqar Abdullah IqbalDocumento30 páginasRying of Solids: Mohammad Hadi Usama Zulfiqar Abdullah IqbalHadi SiddiqiAinda não há avaliações

- L16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDocumento25 páginasL16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyAinda não há avaliações

- Separator SizingDocumento18 páginasSeparator SizingmkwendeAinda não há avaliações

- RheologyDocumento33 páginasRheologyLindsey Barber100% (1)

- Orange County Utilities Standards and Construction Specifications ManualDocumento3 páginasOrange County Utilities Standards and Construction Specifications ManualAssetAinda não há avaliações

- Chapter 4 PipesDocumento18 páginasChapter 4 Pipeshamadamjad047Ainda não há avaliações

- Opi Marine DDC r2021Documento9 páginasOpi Marine DDC r2021Ozan EgemenAinda não há avaliações

- MembranesionoDocumento16 páginasMembranesionoمحمد ازواديAinda não há avaliações

- Septic Tank Design ComputationDocumento1 páginaSeptic Tank Design ComputationEngilbert AragonAinda não há avaliações

- Basic Mechanical EngineeringDocumento4 páginasBasic Mechanical Engineeringalex mcraeAinda não há avaliações

- Mist Drilling: Soal-Soal PetroleagueDocumento9 páginasMist Drilling: Soal-Soal PetroleagueHeri YantoAinda não há avaliações

- 1.4 Centrifugal Compressor Structure1Documento42 páginas1.4 Centrifugal Compressor Structure1ramakrishnanAinda não há avaliações

- Oilgear Type "PVG" Pumps 150 (SERIES A1) Service InstructionsDocumento28 páginasOilgear Type "PVG" Pumps 150 (SERIES A1) Service InstructionsAngel Mendoza RodríguezAinda não há avaliações

- CN1319878C - Treating Method and Apparatus For Seawater Desalting - Google PatentsDocumento11 páginasCN1319878C - Treating Method and Apparatus For Seawater Desalting - Google Patentssahar vahdatifarAinda não há avaliações

- DataDocumento3 páginasDataEduardo Paulini VillanuevaAinda não há avaliações

- MCQ Thermal PDFDocumento6 páginasMCQ Thermal PDFpriya dharshiniAinda não há avaliações

- Water Management PosterDocumento1 páginaWater Management PosterVaishnavi SinghAinda não há avaliações