Escolar Documentos

Profissional Documentos

Cultura Documentos

Vaporizers Theory and Types: Thermal Design of Shell and Tube Exchangers: Aspen Hetran

Enviado por

Consuelo VelandiaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Vaporizers Theory and Types: Thermal Design of Shell and Tube Exchangers: Aspen Hetran

Enviado por

Consuelo VelandiaDireitos autorais:

Formatos disponíveis

Thermal Design of Shell/Tube Exchangers:Aspen Hetran Vaporizers: Theory and Type

Vaporizers

Theory and Types

Thermal Design of Shell and Tube Exchangers:

Aspen Hetran

© 2002 AspenTech. All rights reserved.

Vapor Generation Bubble growth from cavity

Surface

Cavity in surface

• Vapor growth takes place from preexisting vapor or inert gases i n the small cavities

• Boiling occurs from reentrant cavities on the surface. A reentrant cavity has a small

opening, which allows an interface to be retained even if there is no preexisting

vapor or inert gas. Such surfaces are basis for enhanced boilin g surfaces

• Boiling can occur from cavities that are activated during boilin g from adjacent

cavities. Bubble growth on the surface fills adjacent cavities with vapor, some of

which retained after the bubble departs

© 2002 AspenTech. All rights reserved.

© 2002 AspenTech. All Rights Reserved. 5–1 Aspen Technology, Inc.

Thermal Design of Shell/Tube Exchangers:Aspen Hetran Vaporizers: Theory and Type

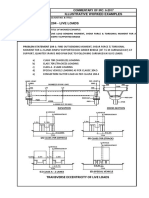

Nucleate and Film Boiling

Heating Bubbles grow

but do not detach

Bubbles Bubbles so

increase, numerous they

detach coalesce

and condense to form continuous

in liquid vapor layer

• The process in which vapor generation occurs by nucleation at the

surface is known as nucleate boiling

• Ultimately the bubbles become so numerous that they coalesce to

form a continuous vapor layer on the surface. The heat transfer

coefficient decreases and the tubes may become very hot. This is

film boiling

© 2002 AspenTech. All rights reserved.

© 2002 AspenTech. All Rights Reserved. 5–2 Aspen Technology, Inc.

Você também pode gostar

- Reading Exercises For Units 1 and 2Documento6 páginasReading Exercises For Units 1 and 2Consuelo VelandiaAinda não há avaliações

- SD ArticleDocumento16 páginasSD ArticleConsuelo VelandiaAinda não há avaliações

- Introduction To Aspen B-JACDocumento76 páginasIntroduction To Aspen B-JACConsuelo VelandiaAinda não há avaliações

- Perceptions of Group Music Therapy Among Elderly Nursing Home Residents in TaiwanDocumento6 páginasPerceptions of Group Music Therapy Among Elderly Nursing Home Residents in TaiwanConsuelo VelandiaAinda não há avaliações

- Comparing The Effects of Music and Exercise With Music For Older Adults With InsomniaDocumento7 páginasComparing The Effects of Music and Exercise With Music For Older Adults With InsomniaConsuelo VelandiaAinda não há avaliações

- Musictherapy DementiaDocumento16 páginasMusictherapy DementiaConsuelo VelandiaAinda não há avaliações

- Arts and The Quality of Life An Exploratory StudyDocumento50 páginasArts and The Quality of Life An Exploratory StudyConsuelo VelandiaAinda não há avaliações

- Arts and The Quality of Life An Exploratory StudyDocumento50 páginasArts and The Quality of Life An Exploratory StudyConsuelo VelandiaAinda não há avaliações

- A Quantitative Study of Choral Singing and (Canadian)Documento18 páginasA Quantitative Study of Choral Singing and (Canadian)Consuelo VelandiaAinda não há avaliações

- I Dont Want To Miss A Thing PDFDocumento4 páginasI Dont Want To Miss A Thing PDFWell Fran Cius SianturiAinda não há avaliações

- US Visa Appointment InstructionsDocumento3 páginasUS Visa Appointment InstructionsConsuelo VelandiaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- SFD & BMDDocumento44 páginasSFD & BMDAltaf Hossain100% (2)

- Re 79093Documento4 páginasRe 79093Anonymous lIJl27QBXLAinda não há avaliações

- PDF The 2017 Aisi Cold Formed Steel Design Manual - CompressDocumento11 páginasPDF The 2017 Aisi Cold Formed Steel Design Manual - Compressfreddy noya plata0% (1)

- Pneumatic Systems: Aircraft High-Pressure Pneumatic SystemsDocumento14 páginasPneumatic Systems: Aircraft High-Pressure Pneumatic SystemsAndreas.G100% (1)

- Park Brake Recall ActionDocumento13 páginasPark Brake Recall Actionrobocop81Ainda não há avaliações

- CHP 4 - 4.3 Determinate Structural AnalysisDocumento57 páginasCHP 4 - 4.3 Determinate Structural Analysismhazarath murariAinda não há avaliações

- Steam System Properties and Energy SavingsDocumento34 páginasSteam System Properties and Energy SavingsArnav KothiyalAinda não há avaliações

- 2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualDocumento382 páginas2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualShelli Godfrey100% (1)

- Aerodynamics Prelim Lecture PDFDocumento4 páginasAerodynamics Prelim Lecture PDFelle liAinda não há avaliações

- Two Rotor CDocumento3 páginasTwo Rotor CmuralidharanAinda não há avaliações

- Illustrative Worked Examples: Commentary of Irc: 6-2017Documento4 páginasIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singla100% (1)

- SYIL 7 Epoxy Granite Small Milling CenterDocumento2 páginasSYIL 7 Epoxy Granite Small Milling CenterXi FengAinda não há avaliações

- Bajaj 4s ct100 Platina Boxer - XLSX 0 PDFDocumento7 páginasBajaj 4s ct100 Platina Boxer - XLSX 0 PDFgurubalaji15Ainda não há avaliações

- Safe Work Method Statement For Welding of Pipes WPS PQR PDFDocumento3 páginasSafe Work Method Statement For Welding of Pipes WPS PQR PDFDeepak RajanAinda não há avaliações

- Mccauley Constant Speed Propellers: Threaded Series Threadless Series Retention Nut Split Retainer RingDocumento10 páginasMccauley Constant Speed Propellers: Threaded Series Threadless Series Retention Nut Split Retainer Ringcam cotAinda não há avaliações

- The New Mercedes Arocs BrochureDocumento77 páginasThe New Mercedes Arocs Brochureislamafash100% (1)

- Morgana Digifold Service ManualDocumento55 páginasMorgana Digifold Service Manualpfequip100% (1)

- 455zx - Brochure PDFDocumento16 páginas455zx - Brochure PDFDhru Ti100% (1)

- M10S Ball Valve DN " To DN2 ": Full BoreDocumento4 páginasM10S Ball Valve DN " To DN2 ": Full BoreTsion GtatiosAinda não há avaliações

- Connection HCS PDFDocumento25 páginasConnection HCS PDFPranay UpadhyayAinda não há avaliações

- Din 6914-10.9 PDFDocumento2 páginasDin 6914-10.9 PDFvpjagannaathAinda não há avaliações

- Greenstar 25Si/30Si: User Instructions & Customer Care GuideDocumento20 páginasGreenstar 25Si/30Si: User Instructions & Customer Care GuideJBAinda não há avaliações

- Quadracci Pavilion - Hind Bitar PDFDocumento10 páginasQuadracci Pavilion - Hind Bitar PDFHeind BitarAinda não há avaliações

- CG AlternatorsDocumento23 páginasCG AlternatorsHitesh Shinde100% (2)

- New Developments in Pavement Design - Some IssuesDocumento45 páginasNew Developments in Pavement Design - Some IssuesSalam FaithAinda não há avaliações

- ROV and MOVDocumento1 páginaROV and MOVnewprocessAinda não há avaliações

- Technical Data Sheet FFBDocumento4 páginasTechnical Data Sheet FFBvenkiram88Ainda não há avaliações

- Kobelco 70SR: The Most Awesome 7-Ton Excavator Under 40 CharactersDocumento16 páginasKobelco 70SR: The Most Awesome 7-Ton Excavator Under 40 Charactershaiccdk6Ainda não há avaliações

- Ra92060 2006-12 PDFDocumento36 páginasRa92060 2006-12 PDFabdelrhmangbr86Ainda não há avaliações

- Aquatech B Series Operators ManualDocumento169 páginasAquatech B Series Operators ManualJader Leyva100% (2)