Escolar Documentos

Profissional Documentos

Cultura Documentos

Riprap Desing NY

Enviado por

suman59Descrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Riprap Desing NY

Enviado por

suman59Direitos autorais:

Formatos disponíveis

STANDARD AND SPECIFICATIONS

FOR

ROCK OUTLET PROTECTION

Design Criteria

The design of rock outlet protection depends entirely on the

location. Pipe outlet at the top of cuts or on slopes steeper

than 10 percent, cannot be protected by rock aprons or

riprap sections due to re-concentration of flows and high

velocities encountered after the flow leaves the apron.

Many counties and state agencies have regulations and

design procedures already established for dimensions, type

and size of materials, and locations where outlet protection

is required. Where these requirements exist, they shall be

followed.

Tailwater Depth

Definition

The depth of tailwater immediately below the pipe outlet

A section of rock protection placed at the outlet end of the must be determined for the design capacity of the pipe. If

culverts, conduits, or channels. the tailwater depth is less than half the diameter of the

outlet pipe, and the receiving stream is wide enough to

Purpose accept divergence of the flow, it shall be classified as a

Minimum Tailwater Condition; see Figure 5B.12 on page

The purpose of the rock outlet protection is to reduce the 5B.25 as an example. If the tailwater depth is greater than

depth, velocity, and energy of water, such that the flow will half the pipe diameter and the receiving stream will

not erode the receiving downstream reach. continue to confine the flow, it shall be classified as a

Maximum Tailwater Condition; see Figure 5B.13 on page

Scope 5B.26 as an example. Pipes which outlet onto flat areas

with no defined channel may be assumed to have a

This standard applies to the planning, design, and Minimum Tailwater Condition; see Figure 5B.12 on page

construction of rock riprap and gabions for protection of 5B.25 as an example.

downstream areas. It does not apply to rock lining of

channels or streams. Apron Size

Conditions Where Practice Applies The apron length and width shall be determined from the

curves according to the tailwater conditions:

This practice applies where discharge velocities and

energies at the outlets of culverts, conduits, or channels are Minimum Tailwater – Use Figure 5B.12 on page 5B.25

sufficient to erode the next downstream reach. This applies Maximum Tailwater – Use Figure 5B.13 on page 5B.26

to:

If the pipe discharges directly into a well defined channel,

1. Culvert outlets of all types. the apron shall extend across the channel bottom and up the

channel banks to an elevation one foot above the maximum

2. Pipe conduits from all sediment basins, dry storm water tailwater depth or to the top of the bank, whichever is less.

ponds, and permanent type ponds.

The upstream end of the apron, adjacent to the pipe, shall

3. New channels constructed as outlets for culverts and have a width two (2) times the diameter of the outlet pipe,

conduits. or conform to pipe end section if used.

August 2005 Page 5B.21 New York Standards and Specifications

For Erosion and Sediment Control

Bottom Grade density of at least 150 pounds per cubic foot, and does not

have any exposed steel or reinforcing bars.

The outlet protection apron shall be constructed with no

slope along its length. There shall be no overfall at the end Filter

of the apron. The elevation of the downstream end of the

apron shall be equal to the elevation of the receiving A filter is a layer of material placed between the riprap and

channel or adjacent ground. the underlying soil surface to prevent soil movement into

and through the riprap. Riprap shall have a filter placed

Alignment under it in all cases.

The outlet protection apron shall be located so that there are A filter can be of two general forms: a gravel layer or a

no bends in the horizontal alignment. plastic filter cloth. The plastic filter cloth can be woven or

non-woven monofilament yarns, and shall meet these base

Materials requirements: thickness 20-60 mils, grab strength 90-120

lbs; and shall conform to ASTM D-1777 and ASTM D-

The outlet protection may be done using rock riprap, 1682.

grouted riprap, or gabions.

Gravel filter blanket, when used, shall be designed by

Riprap shall be composed of a well-graded mixture of stone comparing particle sizes of the overlying material and the

size so that 50 percent of the pieces, by weight, shall be base material. Design criteria are available in Standard and

larger than the d50 size determined by using the charts. A Specification for Riprap Slope Protection on page 5B.57.

well-graded mixture, as used herein, is defined as a mixture

composed primarily of larger stone sizes, but with a Gabions

sufficient mixture of other sizes to fill the smaller voids

between the stones. The diameter of the largest stone size Gabions shall be made of hexagonal triple twist mesh with

in such a mixture shall be 1.5 times the d50 size. heavily galvanized steel wire. The maximum linear

dimension of the mesh opening shall not exceed 4 ½ inches

Thickness and the area of the mesh opening shall not exceed 10 square

inches.

The minimum thickness of the riprap layer shall be 1.5

times the maximum stone diameter for d50 of 15 inches or Gabions shall be fabricated in such a manner that the sides,

less; and 1.2 times the maximum stone size for d50 greater ends, and lid can be assembled at the construction site into a

than 15 inches. The following chart lists some examples: rectangular basket of the specified sizes. Gabions shall be

of single unit construction and shall be installed according

Minimum to manufacturers recommendations.

D50 dmax Blanket Thickness

(inches) (inches) (inches) The area on which the gabion is to be installed shall be

4 6 9 graded as shown on the drawings. Foundation conditions

shall be the same as for placing rock riprap, and filter cloth

6 9 14 shall be placed under all gabions. Where necessary, key, or

9 14 20 tie, the structure into the bank to prevent undermining of the

main gabion structure.

12 18 27

15 22 32 Maintenance

18 27 32 Once a riprap outlet has been installed, the maintenance

21 32 38 needs are very low. It should be inspected after high flows

for evidence of scour beneath the riprap or for dislodged

24 36 43 stones. Repairs should be made immediately.

Stone Quality

Design Procedure

Stone for riprap shall consist of field stone or rough unhewn

quarry stone. The stone shall be hard and angular and of a 1. Investigate the downstream channel to assure that

quality that will not disintegrate on exposure to water or nonerosive velocities can be maintained.

weathering. The specific gravity of the individual stones

shall be at least 2.5. 2. Determine the tailwater condition at the outlet to

establish which curve to use.

Recycled concrete equivalent may be used provided it has a 3. Enter the appropriate chart with the design discharge to

New York Standards and Specifications Page 5B.22 August 2005

For Erosion and Sediment Control

determine the riprap size and apron length required. It is Apron width, W = conduit width + (6.4)(La) = 10 + (0.4)

noted that references to pipe diameters in the charts are (40) = 26 ft.

based on full flow. For other than full pipe flow, the Example 3: Open Channel Flow with Discharge to

parameters of depth of flow and velocity must be used to Unconfined Section

adjust the design discharges.

Given: A trapezoidal concrete channel 5 ft. wide with 2:1

4. Calculate apron width at the downstream end if a flare side slopes is flowing 2 ft. deep, Q = 180 cfs (velocity = 10

section is to be employed. fps) and the tailwater surface downstream is 0.8 ft.

(minimum tailwater condition).

Examples

Find: Using similar principles as Example 2, compute

Example 1: Pipe Flow (full) with discharge to unconfined equivalent discharge for a 2 foot, using depth as a diameter,

section. circular pipe flowing full at 10 feet per second.

Given: A circular conduit flowing full. Velocity:

Q = 280 cfs, diam. = 66 in., tailwater (surface) is 2 ft. Q = π (2ft)2 x 10 fps = 31.4 cfs

above pipe invert (minimum tailwater condition). 4

Find: Read d50 = 1.2 and apron length (La) = 38 ft. At intersection of the curve, d = 24 in. and Q = 32 cfs, read

d50 = 0.6 ft.

Apron width = diam. + La = 5.5 + 38 = 43.5 ft.

Then reading the d = 24 in. curve, read apron length (La) =

Use: d50 = 15”, dmax = 22”, blanket thickness = 32” 20 ft.

Example 2: Box Flow (partial) with high tailwater Apron width, W = bottom width of channel + La = 5 + 20 =

25 ft.

Given: A box conduit discharging under partial flow

conditions. A concrete box 5.5 ft. x 10 ft. flowing 5.0 ft. Example 4: Pipe flow (partial) with discharge to a

deep, confined section

Q = 600 cfs and tailwater surface is 5 ft. above invert (max. Given: A 48 in. pipe is discharging with a depth of 3 ft.

tailwater condition). Q = 100 cfs, and discharge velocity of 10 fps (established

from partial flow analysis) to a confined trapezoidal channel

Since this is not full pipe and does not directly fit the with a 2 ft. bottom, 2:1 side slopes, n = .04, and grade of

nomograph assumptions of Figure 7B.13 substitute depth as 0.6%.

the diameter, to find a discharge equal to full pipe flow for

that diameter, in this case 60 inches. Calculation of the downstream channel (by Manning’s

Equation) indicates a normal depth of 3.1 ft. and normal

Since, Q = AV and A = π D2 velocity of 3.9 fps.

4

Since the receiving channel is confined, the maximum

First, compute velocity: tailwater condition controls.

V = (Q/A) = (600/(5) (10)) = 12 fps Find: discharge using previous principles:

Then substituting: Q = π (3ft)2 x 10 fps = 71 cfs

4

Q = π D2 x V = 3.14 (5 ft)2 x 12 fps = 236 cfs

4 4 At the intersection of d = 36 in. and Q = 71 cfs, read d50 =

0.3 ft.

At the intersection of the curve d = 60 in. and Q = 236 cfs, Reading the d = 36” curve, read apron length (La) = 30 ft.

read d50 = 0.4 ft.

Since the maximum flow depth in this reach is 3.1 ft., that is

Then reading the d = 60 in. curve, read apron length (La) = the minimum depth of riprap to be maintained for the entire

40 ft. length.

August 2005 Page 5B.23 New York Standards and Specifications

For Erosion and Sediment Control

Construction Specifications

1. The subgrade for the filter, riprap, or gabion shall be

prepared to the required lines and grades. Any fill

required in the subgrade shall be compacted to a

density of approximately that of the surrounding

undisturbed material.

2. The rock or gravel shall conform to the specified

grading limits when installed respectively in the riprap

or filter.

3. Filter cloth shall be protected from punching, cutting,

or tearing. Any damage other than an occasional small

hole shall be repaired by placing another piece of cloth

over the damaged part or by completely replacing the

cloth. All overlaps, whether for repairs or for joining

two pieces of cloth shall be a minimum of one foot.

4. Stone for the riprap or gabion outlets may be placed by

equipment. Both shall each be constructed to the full

course thickness in one operation and in such a manner

as to avoid displacement of underlying materials. The

stone for riprap or gabion outlets shall be delivered and

placed in a manner that will ensure that it is reasonably

homogenous with the smaller stones and spalls filling

the voids between the larger stones. Riprap shall be

placed in a manner to prevent damage to the filter

blanket or filter cloth. Hand placement will be required

to the extent necessary to prevent damage to the

permanent works.

New York Standards and Specifications Page 5B.24 August 2005

For Erosion and Sediment Control

Figure 5B.12

Outlet Protection Design—Minimum Tailwater Condition

(Design of Outlet Protection from a Round Pipe Flowing Full,

Minimum Tailwater Condition: Tw < 0.5Do) (USDA - NRCS)

August 2005 Page 5B.25 New York Standards and Specifications

For Erosion and Sediment Control

Figure 5B.13

Outlet Protection Design—Maximum Tailwater Condition

(Design of Outlet Protection from a Round Pipe Flowing Full,

Maximum Tailwater Condition: Tw ≥ 0.5Do) (USDA - NRCS)

New York Standards and Specifications Page 5B.26 August 2005

For Erosion and Sediment Control

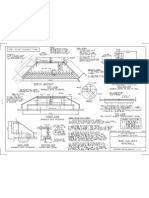

Figure 5B.14

Riprap Outlet Protection Detail (1)

August 2005 Page 5B.27 New York Standards and Specifications

For Erosion and Sediment Control

Figure 5B.15

Riprap Outlet Protection Detail (2)

New York Standards and Specifications Page 5B.28 August 2005

For Erosion and Sediment Control

Figure 5B.16

Riprap Outlet Protection Detail (3)

August 2005 Page 5B.29 New York Standards and Specifications

For Erosion and Sediment Control

This Page Intentionally Left Blank

New York Standards and Specifications Page 5B.30 August 2005

For Erosion and Sediment Control

Você também pode gostar

- Sewage Disposal Works: Their Design and ConstructionNo EverandSewage Disposal Works: Their Design and ConstructionAinda não há avaliações

- Riprap Slope and Outlet ProtectionDocumento10 páginasRiprap Slope and Outlet ProtectionMAZIGHIAinda não há avaliações

- Outlet ProtectionDocumento6 páginasOutlet ProtectionalikoleiniAinda não há avaliações

- Riprap Shear Stress DesignDocumento5 páginasRiprap Shear Stress DesignphatmatAinda não há avaliações

- S Telp RDB 1046898Documento6 páginasS Telp RDB 1046898Manikanta Sai KumarAinda não há avaliações

- Natural Resources Conservation Service Conservation Practice StandardDocumento6 páginasNatural Resources Conservation Service Conservation Practice StandardManikanta Sai KumarAinda não há avaliações

- Design of Dams and Bridges Training ProgrammeDocumento44 páginasDesign of Dams and Bridges Training ProgrammeMuralikrishna Baduru100% (1)

- Module-2: 3.1.1. Design Criteria of Earthen DamDocumento9 páginasModule-2: 3.1.1. Design Criteria of Earthen DamsakshiAinda não há avaliações

- ESCHandbook Chapter3 3.18Documento12 páginasESCHandbook Chapter3 3.18Larry Wayne Sumpter, JrAinda não há avaliações

- Dewatering Revised Oct 98Documento11 páginasDewatering Revised Oct 98Mahmoud BreamaAinda não há avaliações

- Energy DissipationDocumento26 páginasEnergy Dissipationwinzo01Ainda não há avaliações

- Pipeline Stream Crossings.: A. GeneralDocumento8 páginasPipeline Stream Crossings.: A. GeneralAlejandro GuerreroAinda não há avaliações

- River Protection Design GuideDocumento13 páginasRiver Protection Design GuideEm MarAinda não há avaliações

- Riprap DesignDocumento20 páginasRiprap DesignAnonymous e3ajjitjNAinda não há avaliações

- Sedimentation Trap (Basin) BMP 38: DescriptionDocumento7 páginasSedimentation Trap (Basin) BMP 38: DescriptionjamilthaljiAinda não há avaliações

- Small Earth Fill Dams: Planning, Design, Construction and MaintenanceDocumento4 páginasSmall Earth Fill Dams: Planning, Design, Construction and MaintenanceEli WallachAinda não há avaliações

- SILT CURTAIN - FLOATING TEMPORARY SEDIMENT BARRIERDocumento5 páginasSILT CURTAIN - FLOATING TEMPORARY SEDIMENT BARRIERMohamed ElfawalAinda não há avaliações

- Seepage Mitigation MeasuresDocumento20 páginasSeepage Mitigation MeasuresFaran AssifAinda não há avaliações

- Slopeprot PDFDocumento9 páginasSlopeprot PDFasnawi89Ainda não há avaliações

- Piping Embankment DamDocumento5 páginasPiping Embankment DamNathan TaylorAinda não há avaliações

- Well DesignDocumento17 páginasWell DesignabdulazizAinda não há avaliações

- Ten Rules of Thumb For Culvert Crossings Storm WaterDocumento1 páginaTen Rules of Thumb For Culvert Crossings Storm WaterJulio Cesar ChiaAinda não há avaliações

- Chap 5Documento26 páginasChap 5LauraAinda não há avaliações

- Small Earthfill DamDocumento4 páginasSmall Earthfill DamMaged HusseinAinda não há avaliações

- Iowa Stormwater Culvert Design ManualDocumento31 páginasIowa Stormwater Culvert Design ManualKok WaiAinda não há avaliações

- Drainage and Slope Protection PDFDocumento6 páginasDrainage and Slope Protection PDFAngelo Mike John JavinezAinda não há avaliações

- Culvert and Bridge Material - 1 and 2Documento116 páginasCulvert and Bridge Material - 1 and 2Tulu SenaAinda não há avaliações

- Guidelines For Design of Earth DamsDocumento13 páginasGuidelines For Design of Earth Damsrvkumar3619690100% (1)

- Seepage On Dams PDFDocumento12 páginasSeepage On Dams PDFAbera MamoAinda não há avaliações

- Earth Dams Unit - IIIDocumento54 páginasEarth Dams Unit - IIIvixivi6780Ainda não há avaliações

- V1 Chap4 6 Sediment Control FBDocumento10 páginasV1 Chap4 6 Sediment Control FBMohamed ElfawalAinda não há avaliações

- New PK Weirs Triple Spillway DischargeDocumento2 páginasNew PK Weirs Triple Spillway DischargeCarlos AndresAinda não há avaliações

- River Banks Design PDFDocumento15 páginasRiver Banks Design PDFpk100% (1)

- Well Design ConsiderationsDocumento30 páginasWell Design ConsiderationsarytriAinda não há avaliações

- Drainage Design Manual Final Nov13-4Documento100 páginasDrainage Design Manual Final Nov13-4sir zhangAinda não há avaliações

- Channel Drop StructureDocumento39 páginasChannel Drop StructurechanakawidAinda não há avaliações

- Build small dams safelyDocumento4 páginasBuild small dams safelyMetuq Tudela QuispeAinda não há avaliações

- Controlling Beaver Flooding at Wetland Restoration ProjectsDocumento8 páginasControlling Beaver Flooding at Wetland Restoration ProjectschaitanyahegdegrAinda não há avaliações

- FDDocumento74 páginasFDShita AlemieAinda não há avaliações

- Under-Drainageoflinedcanals-Codeofpractice /: Indian StandardDocumento8 páginasUnder-Drainageoflinedcanals-Codeofpractice /: Indian StandardAnonymous oVmxT9KzrbAinda não há avaliações

- Unit1 PPT 4Documento23 páginasUnit1 PPT 4Ayushi AgarwalAinda não há avaliações

- Earthfilled DamDocumento5 páginasEarthfilled DamTakchandra JaikeshanAinda não há avaliações

- Principles of Design of RockfilldamsDocumento20 páginasPrinciples of Design of Rockfilldamsumairfarooq2Ainda não há avaliações

- 2008-Prefabricated Vertical Drain - The Squeeze Is On-Wick Drain (PVD)Documento3 páginas2008-Prefabricated Vertical Drain - The Squeeze Is On-Wick Drain (PVD)Tato Del AguilaAinda não há avaliações

- Spillway NOTEDocumento74 páginasSpillway NOTEMūssā Mūhābā ZēĒthiopiāAinda não há avaliações

- Infiltration Trench Fact SheetDocumento8 páginasInfiltration Trench Fact SheetFani Septiana Nilam SariAinda não há avaliações

- Sediment Basin: (No.) Code 350Documento7 páginasSediment Basin: (No.) Code 350Quicksilver 1975Ainda não há avaliações

- 3-Row 1-Meter Dia Hume Pipe Culvert Design and Cost AnalysisDocumento18 páginas3-Row 1-Meter Dia Hume Pipe Culvert Design and Cost AnalysisChaitanya KumbharAinda não há avaliações

- MWMH Fact Sheet 5Documento5 páginasMWMH Fact Sheet 5Shailesh AtkariAinda não há avaliações

- 10 Farm Dam ConstructionDocumento3 páginas10 Farm Dam ConstructionOluwaseyi AdegokeAinda não há avaliações

- Culvert Maintenance & Replacement: BMP Factsheet #11Documento4 páginasCulvert Maintenance & Replacement: BMP Factsheet #11Anjali SharmaAinda não há avaliações

- Chapter 8Documento10 páginasChapter 8bini1221Ainda não há avaliações

- Well FoundationDocumento126 páginasWell Foundationjoshjeth0% (1)

- Standards for Slope Protection StructuresDocumento8 páginasStandards for Slope Protection StructuresNasir ZakiAinda não há avaliações

- Check Dam Design Manual Chapter 7EDocumento4 páginasCheck Dam Design Manual Chapter 7ESulistyo WidodoAinda não há avaliações

- Proposed Storm Water OutfallDocumento60 páginasProposed Storm Water OutfallLauro F. Dupra Jr.Ainda não há avaliações

- Standard and Specifications FOR Check Dam: Size (NYS - DOT Light Stone Fill Meets TheseDocumento2 páginasStandard and Specifications FOR Check Dam: Size (NYS - DOT Light Stone Fill Meets TheseKA25 ConsultantAinda não há avaliações

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionAinda não há avaliações

- 2020 West Mountain Winter ClinicsDocumento2 páginas2020 West Mountain Winter Clinicssuman59Ainda não há avaliações

- My Math Path Program Overview NationalDocumento24 páginasMy Math Path Program Overview Nationalsuman59Ainda não há avaliações

- Design Guidelines For Drinking Water SystemsDocumento311 páginasDesign Guidelines For Drinking Water SystemsJason LeBlancAinda não há avaliações

- 630ch15 PDFDocumento29 páginas630ch15 PDFBernard OwusuAinda não há avaliações

- A Guide to Statistical Methods for Hydrology AnalysisDocumento27 páginasA Guide to Statistical Methods for Hydrology AnalysisJohn E Cutipa LAinda não há avaliações

- Riprap Desing NYDocumento10 páginasRiprap Desing NYsuman59Ainda não há avaliações

- Can Cisec 2014 ManualDocumento204 páginasCan Cisec 2014 Manualsuman59Ainda não há avaliações

- Statistical Tools for Hydrologic AnalysisDocumento44 páginasStatistical Tools for Hydrologic Analysissuman59Ainda não há avaliações

- A Guide to Statistical Methods for Hydrology AnalysisDocumento27 páginasA Guide to Statistical Methods for Hydrology AnalysisJohn E Cutipa LAinda não há avaliações

- Guidelines for Designing Water Storage FacilitiesDocumento230 páginasGuidelines for Designing Water Storage Facilitiessuman59Ainda não há avaliações

- Erosion and Sediment Control Guidelines, 2006 PDFDocumento153 páginasErosion and Sediment Control Guidelines, 2006 PDFManimaran PAinda não há avaliações

- 2010rev Chapter 5 Hydrologic Analysis DesignDocumento58 páginas2010rev Chapter 5 Hydrologic Analysis Designsuman59Ainda não há avaliações

- SCS HydrologyDocumento2 páginasSCS Hydrologysuman59Ainda não há avaliações

- 630ch15 PDFDocumento29 páginas630ch15 PDFBernard OwusuAinda não há avaliações

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocumento2 páginasYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printersuman59Ainda não há avaliações

- Foundation Drain GuidelineDocumento7 páginasFoundation Drain Guidelinesuman59Ainda não há avaliações

- Frequency Analysis in HydrologyDocumento24 páginasFrequency Analysis in Hydrologysuman59Ainda não há avaliações

- SCS HydrologyDocumento2 páginasSCS Hydrologysuman59Ainda não há avaliações

- Flood RoutingDocumento68 páginasFlood Routingsuman59100% (1)

- Rainfall Analysis 1Documento64 páginasRainfall Analysis 1jojo3jAinda não há avaliações

- Civil3dpedia Pond RampDocumento3 páginasCivil3dpedia Pond Rampsuman59Ainda não há avaliações

- 12 How To Analyse Rainfall DataDocumento40 páginas12 How To Analyse Rainfall DataSagar Jss100% (1)

- Statistics in HydrologyDocumento28 páginasStatistics in Hydrologysuman590% (1)

- 12 How To Analyse Rainfall DataDocumento40 páginas12 How To Analyse Rainfall DataSagar Jss100% (1)

- Low Impact Development: JANUARY 2005Documento0 páginaLow Impact Development: JANUARY 2005suman59Ainda não há avaliações

- Civil 3D TutorialsDocumento840 páginasCivil 3D TutorialsRebecca ZodinpuiiAinda não há avaliações

- Design StormsDocumento35 páginasDesign Stormssuman59Ainda não há avaliações

- General Income Tax and Benefit Guide: Canada Revenue AgencyDocumento63 páginasGeneral Income Tax and Benefit Guide: Canada Revenue AgencyvolvoproAinda não há avaliações

- General Income Tax and Benefit Guide: Canada Revenue AgencyDocumento63 páginasGeneral Income Tax and Benefit Guide: Canada Revenue AgencyvolvoproAinda não há avaliações

- Culvert Design and Operation CIRIA C689Documento104 páginasCulvert Design and Operation CIRIA C689MohammedAmjid100% (1)

- QCS 2014 Road Works Section Setting Out and Existing LevelsDocumento412 páginasQCS 2014 Road Works Section Setting Out and Existing Levelsjawadka100% (1)

- Mvuc Revised Final 02Documento7 páginasMvuc Revised Final 02Dexter G. BatalaoAinda não há avaliações

- 清单译文Documento685 páginas清单译文苏佳园Ainda não há avaliações

- Main Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFDocumento94 páginasMain Sentences - Review Report On Existing Studies - Hasang HPP Project 130225 PDFMuhammad TrayaAinda não há avaliações

- Flumes & Channel Transitions: Flume/chute On A Steep SlopeDocumento8 páginasFlumes & Channel Transitions: Flume/chute On A Steep SlopeVenance MasanjaAinda não há avaliações

- Sample Calculations (1) - Corr.Documento15 páginasSample Calculations (1) - Corr.Daniel KariukiAinda não há avaliações

- Structuran Design of Reinforced Concrete Culverts PDFDocumento48 páginasStructuran Design of Reinforced Concrete Culverts PDFflavbom95% (41)

- Design of BridgesDocumento2 páginasDesign of BridgesashokAinda não há avaliações

- Brazos County Inner Loop East Exhibit - CDocumento32 páginasBrazos County Inner Loop East Exhibit - CKBTXAinda não há avaliações

- Assignment No. 3 CIVL6785 SP 2014Documento1 páginaAssignment No. 3 CIVL6785 SP 2014Ahmad SanaAinda não há avaliações

- General Notes For Box CulvertDocumento1 páginaGeneral Notes For Box Culvertabigail0% (1)

- Irc SP 13 2004Documento154 páginasIrc SP 13 2004Anonymous ggwJDMh8Ainda não há avaliações

- Typical Box CulvertDocumento1 páginaTypical Box CulvertDeepak Pandey100% (1)

- Doug Jenkins, Interactive Design Services Pty LTD, Chris Lawson, Reinforced Earth Pty. LTDDocumento13 páginasDoug Jenkins, Interactive Design Services Pty LTD, Chris Lawson, Reinforced Earth Pty. LTDcaojin259Ainda não há avaliações

- NCHRP RPT 116 PDFDocumento168 páginasNCHRP RPT 116 PDFAnusha AravapalliAinda não há avaliações

- Indice AashtoDocumento71 páginasIndice AashtoFranklinAinda não há avaliações

- Box Culverts HumesDocumento12 páginasBox Culverts HumesawwalnafiAinda não há avaliações

- Jabatan Kerja Raya: Standard Quality Assurance/Quality Control Forms & Checklist For Construction ProjectDocumento40 páginasJabatan Kerja Raya: Standard Quality Assurance/Quality Control Forms & Checklist For Construction ProjectKelvin Lau Hin Huat100% (2)

- Reinforced Concrete Culvert PipesDocumento3 páginasReinforced Concrete Culvert PipesAbdurezak AbdurehimAinda não há avaliações

- Floodway Design GuideDocumento52 páginasFloodway Design GuideSana NeAinda não há avaliações

- NR-L3-CIV-005-3A - Railway Drainage Systems Manual Part 3a - Inspection PDFDocumento47 páginasNR-L3-CIV-005-3A - Railway Drainage Systems Manual Part 3a - Inspection PDFnigelAinda não há avaliações

- Pipe CulvertDocumento12 páginasPipe CulvertveevimalAinda não há avaliações

- HY-8 Quick Start GuideDocumento30 páginasHY-8 Quick Start Guidesach1116Ainda não há avaliações

- Deriviation of QuantitiesDocumento21 páginasDeriviation of QuantitiesDrew B MrtnzAinda não há avaliações

- 9A Toolkit (Design) For The RRAsDocumento50 páginas9A Toolkit (Design) For The RRAsyoseph dejeneAinda não há avaliações

- Method Statement For Installation of Road Culverts in Water CoursesDocumento5 páginasMethod Statement For Installation of Road Culverts in Water Coursesabsalom mkhatshwaAinda não há avaliações

- Bridge Technical Note 2018 - 016 Design of Large Box Culverts Jan 2018Documento2 páginasBridge Technical Note 2018 - 016 Design of Large Box Culverts Jan 2018plmoAinda não há avaliações

- Calculation Loose Gravel PDFDocumento114 páginasCalculation Loose Gravel PDFEE PH KHAMMAMAinda não há avaliações

- DrainageDocumento82 páginasDrainagerasheedAinda não há avaliações