Escolar Documentos

Profissional Documentos

Cultura Documentos

Alignment Tolerance Table

Enviado por

Alagar Samy ADireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alignment Tolerance Table

Enviado por

Alagar Samy ADireitos autorais:

Formatos disponíveis

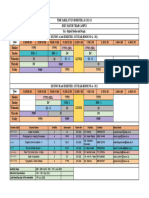

Machinery Alignment Tolerance Tables

The suggested alignment tolerances shown here are general values based upon experience and

general industry standards and should not be exceeded. (Note: If a manufacturer of a machine or

coupling requires tighter alignment tolerances, those should be used)

Consider all values listed to be the maximum allowable deviation from the alignment target, be it

zero, or some desired value to compensate for thermal growth. In most cases, a quick glance at

the table will tell whether coupling misalignment is allowable or not. Metric tolerances are given

for machines with a 50Hz supply running at multiples/fractions of 3000 RPM. Imperial tolerances

are given for machines with a 60 Hz supply running at multiples/fractions of 3600 RPM. Angularity

is usually measured in terms of gap width at the edge of the coupling. For a given amount of

angularity, the larger the diameter requires the wider the gap at the coupling edge. The table lists

values for coupling diameters of 100 mm or 10". If actual coupling diameter is required, multiply

the value from the table by the appropriate factor.

(RPM) metric (mm) inch (mils)

Align machine to within Soft foot any 0.06mm 2.0 mils

“Acceptable” tolerances based

upon coupling type and RPM Short "flexible"

couplings Excellent Excellent

Acceptable Acceptable

600 9.0 5.0

750 0.19 0.09

Offset

1500 0.09 0.06

1800 3.0 2.0

3000 0.06 0.03

Compliments of Pruftechnik, dB 3600 1.5 1.0

“There Is A Better Way” 6000 0.03 0.02

7200 1.0 0.5

Angularity

(gap difference at 600 15.0 10.0

coupling edge per 100 750 0.13 0.09

millimeters diameter 1500 0.07 0.05

1800 5.0 3.0

3000 0.04 0.03

3600 3.0 2.0

6000 0.03 0.02

7200 2.0 1.0

Spacer shafts and

membrane (disk)

For spacer shafts, the couplings Offset

corresponding table gives the (per 100 millimeters

600 3.0 1.8

maximum allowable offset for spacer length or per 750 0.25 0.15

each 100 mm or inch of spacer inch of spacer length) 1500 0.12 0.07

1800 1.0 0.6

shaft length. 3000 0.07 0.04

3600 0.5 0.3

6000 0.03 0.02

7200 0.3 0.2

"Acceptable" limits are calculated from sliding velocity of lubricated steel on steel, using a

conservative value of 12 mm/sec. (0.5 In/Sec) for allowable sliding velocity. These values also

coincide with those derived from elastomer shear rates, so they also apply to short couplings with

flexible elements.

The "excellent" values draw on vibration observations made upon a wide variety of industrial

machines to determine the critical misalignment for vibration; however, compliance with these

tolerance values does not guarantee vibration-free operation of a particular machine. Rigid

couplings have no tolerance for misalignment; they should be aligned as accurately as possible.

Você também pode gostar

- Alignment ProcedureDocumento31 páginasAlignment ProcedurekuldipsinhAinda não há avaliações

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreAinda não há avaliações

- PACCAR MX-13 EPA2013 Diagnostic Manual - P062A To P1223 - WK 11 2015Documento440 páginasPACCAR MX-13 EPA2013 Diagnostic Manual - P062A To P1223 - WK 11 2015Ariel SanchezAinda não há avaliações

- Overhauling TP800C Gbox ME-810cDocumento10 páginasOverhauling TP800C Gbox ME-810cwasay0% (1)

- Shaft Alignment ManualDocumento76 páginasShaft Alignment Manualmjerkan100% (11)

- Sleeve Vs Antifriction Bearings Selection of The Optimal BearingDocumento13 páginasSleeve Vs Antifriction Bearings Selection of The Optimal BearingKamal Arab0% (1)

- Turbine AlignmentDocumento3 páginasTurbine AlignmentParmasamy SubramaniAinda não há avaliações

- Vibration Analysis For Machinery Health Diagnosis: Emerson SumicoDocumento1 páginaVibration Analysis For Machinery Health Diagnosis: Emerson SumicoTeguh SAinda não há avaliações

- Shaft Alignment Excel SheetDocumento5 páginasShaft Alignment Excel Sheetpollekeshooter100% (1)

- Troubleshooting VTP Vertical Turbine PumpDocumento20 páginasTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- Maintenance Guidelines: 8. 1 Centrifugal Pumps Fits and Clearance Checklist. Basic Data No: Measurement ToleranceDocumento2 páginasMaintenance Guidelines: 8. 1 Centrifugal Pumps Fits and Clearance Checklist. Basic Data No: Measurement Tolerancedave381dAinda não há avaliações

- Balancing Fundamentals SchenckDocumento15 páginasBalancing Fundamentals SchenckChoochart Thongnark0% (1)

- Alignment CourseDocumento167 páginasAlignment Coursedennis_packiaraj3063100% (20)

- Rotor Axial Movement IdentificationDocumento14 páginasRotor Axial Movement IdentificationisidoroAinda não há avaliações

- NATCOM Alignment TrainingDocumento133 páginasNATCOM Alignment TrainingMohamed M. AfifiAinda não há avaliações

- Computational Flexible Multibody Dynamics: Bernd SimeonDocumento254 páginasComputational Flexible Multibody Dynamics: Bernd SimeonSergio Quisbert P.100% (1)

- Bearing Instal at Ion and Maintenance GuideDocumento130 páginasBearing Instal at Ion and Maintenance GuideTeodoru Horia Adrian75% (4)

- Reverse and Rim and Face AlignmentDocumento37 páginasReverse and Rim and Face AlignmentvenkeekuAinda não há avaliações

- SKF Spherical Roller Bearing ClearanceDocumento2 páginasSKF Spherical Roller Bearing ClearanceKumaran GopalAinda não há avaliações

- Shaft AlignmentDocumento44 páginasShaft Alignmentrodolfosti100% (1)

- Seminar On ABRO BalancingDocumento62 páginasSeminar On ABRO BalancingJora Saragi100% (2)

- Rim and Face - Alignment KnowledgeDocumento19 páginasRim and Face - Alignment Knowledgevj kumarAinda não há avaliações

- Centrifugal Comp. Alignment-PDocumento7 páginasCentrifugal Comp. Alignment-PvinothenergyAinda não há avaliações

- Transient Vibration Analysis Dec07 HandoutDocumento24 páginasTransient Vibration Analysis Dec07 HandoutsandragoncAinda não há avaliações

- Pump AlignmentDocumento1 páginaPump AlignmentSanjoy Kr. Dey100% (1)

- Alignment Procedure PDocumento8 páginasAlignment Procedure PvinothenergyAinda não há avaliações

- AlignmentDocumento35 páginasAlignmentdf100% (1)

- Alignment PDFDocumento61 páginasAlignment PDFSumedh SinghAinda não há avaliações

- Gear Box OverhaulingDocumento41 páginasGear Box OverhaulingMahmoud Mohammad50% (2)

- PDMS Balance 0512 - Field BalancingDocumento83 páginasPDMS Balance 0512 - Field Balancingramnadh803181100% (1)

- Alignment Face and Rim MethodDocumento3 páginasAlignment Face and Rim MethodAbd Elrahman Abd Rabouh100% (2)

- Field Application Note: Reverse Dial Indicator Alignment RdiaDocumento7 páginasField Application Note: Reverse Dial Indicator Alignment RdiaYasir BhattiAinda não há avaliações

- Pump Alignment.Documento3 páginasPump Alignment.sen_subhasis_58100% (1)

- Rotating Machinery Reliability for Technicians and EngineersNo EverandRotating Machinery Reliability for Technicians and EngineersAinda não há avaliações

- Vibration Cat II Practise ExamDocumento3 páginasVibration Cat II Practise Examalxmaas91% (11)

- FlenderDocumento384 páginasFlenderAnis Kurniawati100% (1)

- Installation & Alignement of Rotating DrumsDocumento9 páginasInstallation & Alignement of Rotating Drumsguilanya100% (1)

- Rotating EquipmentDocumento2 páginasRotating EquipmentHasen Bebba100% (1)

- Soft Foot CorrectionDocumento1 páginaSoft Foot CorrectionJaime Berry100% (2)

- Mtce AlignmentDocumento44 páginasMtce AlignmentDin UdinAinda não há avaliações

- Specifications Standards For Shafts Alignment PDFDocumento18 páginasSpecifications Standards For Shafts Alignment PDFDelfinshAinda não há avaliações

- Machinery Alignment: Prepared by WADocumento23 páginasMachinery Alignment: Prepared by WAmersiumAinda não há avaliações

- SCTLK40 400 SCTLQ40 355 - 753944 768681e - Rev01Documento74 páginasSCTLK40 400 SCTLQ40 355 - 753944 768681e - Rev01CuyanausulAinda não há avaliações

- Vibxpert 2 Manual English 112010Documento170 páginasVibxpert 2 Manual English 112010santiago6767% (3)

- ROTALIGN Ultra Shaft Handbook ALI 9.855 01 12 en Web PDFDocumento176 páginasROTALIGN Ultra Shaft Handbook ALI 9.855 01 12 en Web PDFDan-jones TudziAinda não há avaliações

- 3.05 - Molecular Structure Lab Report: Determining PolarityDocumento5 páginas3.05 - Molecular Structure Lab Report: Determining PolarityMOBINA KOCHAK100% (2)

- Diatomaceous Soils A Less-Than-Cromulent Engineering MaterialDocumento8 páginasDiatomaceous Soils A Less-Than-Cromulent Engineering MaterialEsteban FinoAinda não há avaliações

- Gear Box InspDocumento19 páginasGear Box InspdombipinAinda não há avaliações

- 7300en PDFDocumento9 páginas7300en PDFWaris La Joi WakatobiAinda não há avaliações

- APHDocumento15 páginasAPHKarthi KeyanAinda não há avaliações

- Alignment TolerancesDocumento1 páginaAlignment TolerancesbederinadmlAinda não há avaliações

- Alignment For Mechanical EquipmentDocumento2 páginasAlignment For Mechanical EquipmentAzmi NordinAinda não há avaliações

- 10 Inch Coupling Diameter (Divide by 10 For Mils/1") : Acceptable Excellent Acceptable ExcellentDocumento1 página10 Inch Coupling Diameter (Divide by 10 For Mils/1") : Acceptable Excellent Acceptable ExcellentAlexis CordovaAinda não há avaliações

- TolerancesAlign PDFDocumento1 páginaTolerancesAlign PDFAlexis CordovaAinda não há avaliações

- Maximos Valores de Vibración en MotoresDocumento1 páginaMaximos Valores de Vibración en MotoresKarin FernandoAinda não há avaliações

- Tabla de Tolerancias PDFDocumento1 páginaTabla de Tolerancias PDFCesar Cedano VivarAinda não há avaliações

- Metrology ResourcesDocumento63 páginasMetrology ResourcesParkus NapsterAinda não há avaliações

- Blade DesignDocumento2 páginasBlade Designtpa1962Ainda não há avaliações

- BladedesignDocumento2 páginasBladedesigndiogenesrobertoAinda não há avaliações

- 8 Micron and Mesh RatingDocumento2 páginas8 Micron and Mesh RatingjokoAinda não há avaliações

- FJJ Llroo PDocumento294 páginasFJJ Llroo PDhaval PanchalAinda não há avaliações

- Alignment TolerancesDocumento1 páginaAlignment TolerancesMohsin MurtazaAinda não há avaliações

- Datasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Documento5 páginasDatasheet-Sandvik-Hiflex-En-V2019-06-07 14 - 59 Version 1Raja Sekaran SajjaAinda não há avaliações

- Blade Design Spreadsheet Shape: 7 2.40 2 4 0.8 6 Blue CellsDocumento2 páginasBlade Design Spreadsheet Shape: 7 2.40 2 4 0.8 6 Blue CellsOptimuz TsAinda não há avaliações

- General Tolerances DIN ISO 2768Documento4 páginasGeneral Tolerances DIN ISO 2768La Hong LeAinda não há avaliações

- BladedesignDocumento2 páginasBladedesignRaees SwatiAinda não há avaliações

- Instructions For Use Acm 631 IxDocumento17 páginasInstructions For Use Acm 631 IxAlagar Samy AAinda não há avaliações

- Know How Your Spending Are Traced by Income Tax DeptDocumento2 páginasKnow How Your Spending Are Traced by Income Tax DeptAlagar Samy AAinda não há avaliações

- 64 Interview QuestionsDocumento1.410 páginas64 Interview QuestionsAlagar Samy AAinda não há avaliações

- Turbine Over SpeedDocumento12 páginasTurbine Over SpeedjnmanivannanAinda não há avaliações

- t32 08 PDFDocumento12 páginast32 08 PDFAlagar Samy AAinda não há avaliações

- Demonstration Excel Worksheet: ITS 135 Graphics For The WebDocumento2 páginasDemonstration Excel Worksheet: ITS 135 Graphics For The WebAlagar Samy AAinda não há avaliações

- Indian Representatives - Vibration InstituteDocumento2 páginasIndian Representatives - Vibration InstituteAlagar Samy AAinda não há avaliações

- iFIX Automation Reference Section2Documento587 páginasiFIX Automation Reference Section2megamoto02 motosAinda não há avaliações

- Newton Review AnswersDocumento35 páginasNewton Review AnswersSchlentAinda não há avaliações

- Flood Frequency Analysis 1Documento34 páginasFlood Frequency Analysis 1annashiyoAinda não há avaliações

- Franklin 1988Documento16 páginasFranklin 1988Verônica VieiraAinda não há avaliações

- Globalization and Culture The Three H Scenarios IntechOpenDocumento40 páginasGlobalization and Culture The Three H Scenarios IntechOpenRahaman KhanAinda não há avaliações

- Topic15 8p2 GalvinDocumento28 páginasTopic15 8p2 GalvinSiddharth GuptaAinda não há avaliações

- 2.0 Cegeotech2 Lec m1 (Intro)Documento19 páginas2.0 Cegeotech2 Lec m1 (Intro)Mineski Prince GarmaAinda não há avaliações

- Elitmus Elitmus Admit Card 05feb2023Documento1 páginaElitmus Elitmus Admit Card 05feb2023Dileep RajoriyaAinda não há avaliações

- Presentation On Transfomer DesignDocumento11 páginasPresentation On Transfomer Designeng.tushar598Ainda não há avaliações

- Conflict: Communication, Coaching, andDocumento16 páginasConflict: Communication, Coaching, andNemam ImeAinda não há avaliações

- Name: - AP Physics Worksheet - Mechanical Waves ReviewDocumento5 páginasName: - AP Physics Worksheet - Mechanical Waves ReviewMarcial Aguilar BarahonaAinda não há avaliações

- Physics IAS TOPIC 1 EditedDocumento23 páginasPhysics IAS TOPIC 1 Editedමේනුක සූවින්දAinda não há avaliações

- One TTS Alignment To Rule Them All - Badlani Et Al - 2022Documento5 páginasOne TTS Alignment To Rule Them All - Badlani Et Al - 2022Kyra WangAinda não há avaliações

- Escuela Nocturna Oficial de Dolega English Second Quarter 8ºgrade Teacher: Génesis L. Morales Villarreal 6701-5311 StudentDocumento22 páginasEscuela Nocturna Oficial de Dolega English Second Quarter 8ºgrade Teacher: Génesis L. Morales Villarreal 6701-5311 StudentGénesis Liriola Morales VillarrealAinda não há avaliações

- Stat 130 Module 1 B SlidesDocumento16 páginasStat 130 Module 1 B SlidesambonulanAinda não há avaliações

- BISE MCQs-I (Microsoft Forms)Documento3 páginasBISE MCQs-I (Microsoft Forms)Ghulam FaridAinda não há avaliações

- Graphic Design Thesis TopicsDocumento8 páginasGraphic Design Thesis Topicsafkololop100% (1)

- Operativa y ComsolDocumento16 páginasOperativa y ComsolAnndre RamírezAinda não há avaliações

- Delhi Public School Bangalore North ACADEMIC SESSION 2022-2023 Class - ViiiDocumento28 páginasDelhi Public School Bangalore North ACADEMIC SESSION 2022-2023 Class - Viiiharahej45Ainda não há avaliações

- Operations On StringDocumento12 páginasOperations On StringyaswanthbusireddyAinda não há avaliações

- FBXCVSDZX H AIATS For Olympiads 2024 - Class IXDocumento22 páginasFBXCVSDZX H AIATS For Olympiads 2024 - Class IXAtul KunduAinda não há avaliações

- Gyanpath 15-04-2024 Daily Current AffairsDocumento9 páginasGyanpath 15-04-2024 Daily Current AffairsABHIDEV J KAinda não há avaliações

- Ba-Dmd Sem 2 (S)Documento1 páginaBa-Dmd Sem 2 (S)dadagiri222002Ainda não há avaliações

- Module 1.2 - Architectural DraftingDocumento7 páginasModule 1.2 - Architectural DraftingJohn SantiagoAinda não há avaliações

- Environmental Groups in AlbaniaDocumento1 páginaEnvironmental Groups in AlbaniaAnonymous 6qaFbHIrOAinda não há avaliações

- Hydraulic TestDocumento3 páginasHydraulic TestSaurabh BarangeAinda não há avaliações