Escolar Documentos

Profissional Documentos

Cultura Documentos

NSRP LLM WPQT

Enviado por

tranvando1986Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

NSRP LLM WPQT

Enviado por

tranvando1986Direitos autorais:

Formatos disponíveis

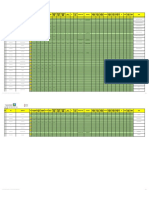

WELDING PROCEDURE QUALIFICATION FOR DEFECT PACKAGE 1/16/2018

Interpas STATUS Plan

Test Coupon Welding process Welding consumable Gas Preheat s Post Heat PWHT Qualified Ranger Test Requiement

PQR WPS Remark

Aplicat Length

No WPS PQR OD Coupon ion RMKS Line Class 1coupon Spare Total

Base Metal P-No Group No mm/inc Thick Process Pass No Thick SFA AWS F-No Trade Name Trade Name Trade Name Shilding Backing Temp°C Temp°C Temp°C Temp°C Material Tensile Bend Impact Value Impact test Hardness Macro PMI Ferrite Intergranular Chemical Base metal Date qualify Date Date Submit Code Date Submit Code Submit pWPS Make PQR Mechanical

h mm Kobelco Hyundai Lincol/Oxfordalloys Impact test B/W/H Average/Individual Max HV10 corrosion Analysis receipt PQR Mechanical PQR WPS test

I. Carbon steel (Cs)

SA106 1 1 60.3 5.54 Root: 2 1

1 NSRP-LLM-WPS-001 NSRP-LLM-PQR-001 2 GTAW ALL 5.54 5.18 ER 70S-6 6 Merit -JG56 Ar 99,99% - Min 10 Max 315 1.5-11.08 - 2 Face: 2 - 1 No No A2AW A1AP D1AA A2AS 400 2 1600

SA106 1 1 2'' 248 Submited A Submited A

NSRP-LLM-PQR-002 SA106 1 1 168.3 GTAW 2 2.5 5.18 ER 70S-6 6 Merit -JG56 Ar 99,99% 1

2 NSRP-LLM-WPS-102 10.97 1 - Min 10 Max 315 5-21.94 - 2 Side 4 - 1 No No A2AW A1AP D1AA A2AS 400 2 800

NSRP-LLM-PQR-102K SA106 1 1 6'' SMAW Other 8.47 5.1 E7016 4 LB-52 248 Submited A Submited A

SA106 1 1 60.3 605-630 Root: 2 1 N1A402 B2A704 B4AQ01

3 NSRP-LLM-WPS-004L NSRP-LLM-PQR-004L 5.54 2 GTAW ALL 5.54 5.18 ER 70S-6 6 Merit -JG56 Ar 99,99% - Min 10 Max 315 1.5-11.08 - 2 Face: 2 - 1 No No A4AQ01 A2A5 A2A501 400 2 1600 Received 26-Dec-14 17-Jan-15 24-Jan-15 24-Jan-15 26-Dec-14 2-Jan-15

SA106 1 1 2'' Min 1h 248 N1A602 A A

N1A402 B2A704 B4AQ01

SA106 1 1 168.3 GTAW 2 2.5 5.18 ER 70S-6 6 Merit -JG56 Ar 99,99% 605-630 1 A4AQ01 A2A5 A2A501

4 NSRP-LLM-WPS-005 NSRP-LLM-PQR-005 18.26 1 - Min 100 Max 315 5-36.52 - 2 Side 4 - 1 No No N2A602 P4AP02 N1A602 400 2 800 Received 26-Dec-14 17-Jan-15 24-Jan-15 24-Jan-15 26-Dec-14 2-Jan-15

SA106 1 1 6'' SMAW Other 15.76 5.1 E7016 4 LB-52 Min 1h 248 A A

N1AH02

II. Low Temp Carbon Steel ( LTCS)

A333-6 1 1 88.9 5.49 Root: 2 6/3/6 Average 10 J 1 Thickness impact

1 NSRP-LLM-WPS-026H NSRP-LLM-PQR-026H 3 GTAW ALL 5.49 5.18 ER 70S-3 6 ST-50.3 Ar 99,99% - Min 10 Max 250 - 2.74 - 10.98 2 Face: 2 1 No No test :3.33mm

A1GP01 400 2 2400 Received 12-May-14 12-Nov-14 17-Dec-14 17-Dec-14

A350 LF2 1 2 3'' STD -60 Min 7 J 248 A A

A333-6 1 1 168.28 7.11 GTAW 2 2.5 5.18 ER 70S-3 6 ST-50.3 Ar 99,99% Root: 2 6/3/6 Average 14 J 1 Thickneess impact

2 NSRP-LLM-WPS-027H NSRP-LLM-PQR-027H 2 - Min 10 Max 250 - 7.11 - 14.22 2 Face: 2 1 No No test: 5mm

A1GP01 B1GP01 400 2 1600 Received 12-May-14 12-Dec-14 17-Dec-14 17-Dec-14

A350 LF2 1 2 6'' STD SMAW Other 4.61 5.1 E7018-1 4 S-7018.1H - -57 Min 11J 248 A A

A333-6 1 1 273.05 12.7 GTAW 2 2.5 5.18 ER 70S-3 6 ST-50.3 Ar 99,99% 6/3/6 Average 27 J 1

3 NSRP-LLM-WPS-028H NSRP-LLM-PQR-028H 1 - Min 10 Max 250 - 12.7 - 25.4 2 Side 4 1 No No A1GP01 B1GP01 400 2 800 Received 18-Dec-14 2-Jan-15 14-Jan-15 14-Jan-15 24-Nov-14 17-Dec-14 1-Feb-15

A350 LF2 1 2 10'' XS SMAW Other 10.2 5.1 E7018-1 4 S-7018.1H - -50 Min 24J 248 A A

A333-6 1 1 88.9 5.49 620-630 Root: 2 6/3/6 Average 10 J 1 Thickness impact

4 NSRP-LLM-WPS-029H NSRP-LLM-PQR-029H 2 GTAW ALL 5.49 5.18 ER 70S-3 6 ST-50.3 Ar 99,99% - Min 10 Max 250 2.74 - 10.98 2 1 No No B2GQ01 B2GN04 400 2 1600 Received 23-Dec-14 3-Jan-15 24-Jan-15 24-Jan-15 24-Nov-14 23-Dec-14 1-Feb-15

A350 LF2 1 2 3'' STD Min 1h Face: 2 -60 Min 7 J 248 test :3.33mm A A

A333-6 1 1 168.28 7.11 GTAW 2 2.5 5.1 ER 70S-3 4 ST-50.3 Ar 99,99% 620-630 Root: 2 6/3/6 Average 14 J 1 Thickneess impact

5 NSRP-LLM-WPS-030H NSRP-LLM-PQR-030H 2 - Min 10 Max 250 7.11 - 14.22 2 1 No No B2GQ01 B2GN04 400 2 1600 Received 23-Dec-14 16-Jan-15 24-Jan-15 24-Jan-15 24-Nov-14 23-Dec-14 1-Feb-15

A350 LF2 1 2 6'' STD SMAW Other 4.61 5.18 E7018-1 6 S-7018.1H - Min 1h Face: 2 -57 Min 11J 248 test: 5mm A A

A333-6 1 1 273.05 12.7 GTAW 2 2.5 5.1 ER 70S-3 4 ST-50.3 Ar 99,99% 620-630 6/3/6 Average 27 J 1

6 NSRP-LLM-WPS-031H NSRP-LLM-PQR-031H 1 - Min 10 Max 250 12.7 - 25.4 2 Side 4 1 No No A4GR01 B2GQ01 400 2 800 Received 5-Feb-15 12-Jan-15 2-Mar-15 2-Mar-15 24-Nov-14 25-Dec-14 1-Feb-15

A350 LF2 1 2 10'' SMAW Other 10.2 5.18 E7018-1 6 S-7018.1H - Min 1h -50 Min 24J 248 A A

A333-6 1 1 273.05 25.4 GTAW 2 2.5 5.1 ER 70S-3 4 ST-50.3 Ar 99,99% Min 100 620-630 2 Side 4 6/3/6 Average 27 J 1 1 No No A4GR01 B2GQ01

7 NSRP-LLM-WPS-032H NSRP-LLM-PQR-032H 1 - Max 250 16.00 - 50.8 400 2 800 Received 5-Feb-15 13-Jan-15 2-Mar-15 2-Mar-15

A350 LF2 1 2 10'' XXS SMAW Other 22.9 5.18 E7018-1 6 S-7018.1H - Min 1h -50 Min 24J 248 A A

A333-6 1 1 508 32.54 GTAW 2 2.5 5.1 ER 70S-3 4 ST-50.3 Ar 99,99% 620-630 - - 1

8 NSRP-LLM-WPS-032H-1 NSRP-LLM-PQR-032H-1 1 - Min 150 Max 250 16.00 - 65.08 2 Side 4 1 No No A4GR01 B2GQ01 400 2 800 Received 5-Nov-15 16-Nov-15 4-Dec-15 A 4-Dec-15 A

A350 LF2 1 2 20'' SCH 100 SMAW Other 30.04 5.18 E7018-1 6 S-7018.1H - Min 1h - - 248

III. Low Alloys (LA)

A335 P22 5A 1 88.9 5.49 5.49 Oxfordalloy 90S-B3 704-729 Root: 2 3/3/3 Average 18 J 1 Thickness impact

1 NSRP-LLM-WPS-010A NSRP-LLM-PQR-010A 2 GTAW ALL 5.28 ER90S-B3 6 Ar 99,99% Ar 99,99% Min 250 Max 315 1.5 - 10.98 2.74 - 10.98 2 Face: 2 1 Yes No Yes test :3.33mm 400 2 1600 Received 23-Nov-15 8-Dec-15 14-Dec-15 A A 20-Nov-15 27-Nov-15

A335 P22 5A 1 3'' Min 2h -39 Min 16 248

A335 P22 5A 1 168.3 10.97 GTAW 2 2.5 5.28 ER90S-B3 6 Oxfordalloy 90S-B3 Ar 99,99% 250 704-729 3/3/3 Average 54 J 1

2 NSRP-LLM-WPS-011A NSRP-LLM-PQR-011A 1 Ar 99,99% Min 250 Max 315 5-21.94 10.97 - 21.94 2 Side: 4 1 Yes No Yes 400 2 800 Received 23-Nov-15 8-Dec-15 14-Dec-15 A A 20-Nov-15 27-Nov-15

A335 P22 5A 1 6'' SMAW Other 8.47 5.5 E9018-B3 4 Oxfordalloy 9018-B3 - 1h Min 2h -29 Min 48 J 248

A335 P11 4 1 88.9 5.49 5.49 ER 80S-B2 704-729 Root: 2 3/3/3 Average 11 J 1 Thickness impact

3 NSRP-LLM-WPS-012M NSRP-LLM-PQR-012M 3 GTAW ALL 5.28 ER80S-B2 6 Ar 99,99% - Min 150 Max 315 1.5 - 10.98 2.74 - 10.98 2 Face: 2 1 Yes No Yes test :3.33mm

N3D702 N2D602 400 2 2400 Received 6-Mar-15 21-Mar-15 8-Mar-13 A 8-Mar-13 A 23-Dec-14 1-Jan-15 1-Jan-15

A335 P11 4 1 3'' Min 1h -28 Min 10 248

ER 80S-B2

A335 P11 4 1 168.28 7.11 GTAW 2 2.5 5.28 ER80S-B2 6 Chromet 1X Ar 99,99% 704-729 3/3/3 Average 16 J 1 Thickness impact

4 NSRP-LLM-WPS-013M NSRP-LLM-PQR-013M 2 - Min 150 Max 315 1.5-14.22 7.11 - 14.22 2 Side: 4 1 Yes No Yes test :5mm

N3D702 N2D602 400 2 1600 Received 6-Mar-15 21-Mar-15 8-Mar-13 A 8-Mar-13 A 23-Dec-14 1-Jan-15 1-Jan-15

A335 P11 4 1 6'' STD SMAW Other 4.61 5.5 E8018-B2 4 Chromet 1X - Min 1h -25 Min 14 J 248

ER 80S-B2

A335 P11 4 1 219.08 12.7 GTAW 2 2.5 5.28 ER80S-B2 6 Chromet 1X Ar 99,99% 150 704-729 3/3/3 Average 34 J 1

5 NSRP-LLM-WPS-014M NSRP-LLM-PQR-014M 1 - Min 150 Max 315 5 - 25.4 12.7 - 25.4 2 Side: 4 1 Yes No Yes N3D702 N2D602 400 2 800 Received 6-Mar-15 20-Mar-15 8-Mar-13 A 8-Mar-13 A 23-Dec-14 1-Jan-15 1-Jan-15

A335 P11 4 1 8'' XS SMAW Other 10.2 5.5 E8018-B2 4 Chromet 1X - 1h Min 1h -18 Min 28 J 248

A335 P11 4 1 168.28 21.95 GTAW 2 2.5 5.28 ER80S-B2 6 ER 80S-B2 Ar 99,99% 300 704-729 3/3/3 Average 34 J 1

6 NSRP-LLM-WPS-015M NSRP-LLM-PQR-015M 2 Chromet 1X - Min 150 Max 315 5 - 43.9 16.00 - 43.9 2 Side: 4 1 Yes No Yes N3D702 N2D602 400 2 1600 Received 6-Mar-15 20-Mar-15 8-Mar-13 A 8-Mar-13 A 23-Dec-14 1-Jan-15 1-Jan-15

A335 P11 4 1 6'' XXS SMAW Other 19.45 5.5 E8018-B2 4 Chromet 1X - 1h Min 1h -18 Min 28 J 248

A335 P5 5B 1 168.28 7.11 7.11 704-729 Root: 2 - 1

7 NSRP-LLM-WPS-016A NSRP-LLM-PQR-016A 1 GTAW ALL 5.28 ER80S-B6 6 Oxfordalloys 80S-B6 Ar 99,99% Ar 99,99% Min 250 Max 315 1.5 - 14.22 2 Face: 2 1 Yes No Yes A2FC01 A4FV 400 2 800 Received 26-Apr-15 15-May-15 26-Apr-15 27-Apr-15 7-May-15

A335 P5 5B 1 6'' STD Min 2h - 248 A A

A335 P5 5B 1 168.28 10.97 GTAW 2 2.5 5.28 ER80S-B6 6 Oxfordalloys 80S-B6 Ar 99,99% 250 704-729 - 1

8 NSRP-LLM-WPS-017A NSRP-LLM-PQR-017A 1 Ar 99,99% Min 250 Max 315 5 - 21.94 2 Side: 4 1 Yes No Yes A2FC01 A4FV 400 2 800 Received 26-Apr-15 15-May-15 26-Apr-15 27-Apr-15 7-May-15

A335 P5 5B 1 6'' SMAW Other 8.47 5.5 E8018-B6 4 Oxfordalloys 8018-B6 - 1h Min 2h - 248 A A

A335 P9 5B 1 60.3 5.54 5.54 704-729 Root: 2 1

9 NSRP-LLM-WPS-040A NSRP-LLM-PQR-040A 2 GTAW ALL 5.28 ER80S-B8 6 Oxfordalloys 80S-B8 Ar 99,99% Ar 99,99% Min 250 Max 315 1.5 - 11.08 2 Face: 2 1 Yes No Yes A28P 2 800 Received 27-Apr-15 16-May-15 27-Apr-15 27-Apr-15 7-May-15

A335 P9 5B 1 2'' STD Min 2h 248 A A

A335 P9 5B 1 168.28 14.28 GTAW 2 2.5 5.28 ER80S-B8 6 Oxfordalloys 80S-B8 Ar 99,99% 250 704-729 1

10 NSRP-LLM-WPS-041A NSRP-LLM-PQR-041A 1 Ar 99,99% Min 250 Max 315 5 - 28.52 2 Side: 4 1 Yes No Yes B28P 2 800 Received 27-Apr-15 16-May-15 27-Apr-15 27-Apr-15 7-May-15

A335 P9 5B 1 6'' SMAW Other 11.78 5.5 E8018-B8 4 Oxfordalloys 8018-B8 - 1h Min 2h 248 A A

IV. Austenitic Steels

NSRP-LLM-PQR-105H A312 TP304/TP304L 8 1 60.3 5.54 Root: 2 - 1 A0JW B0KC01 D0JY B0JR

1 NSRP-LLM-WPS-105L (NSRP-LLM-PQR-105L) 1 GTAW ALL 7.11 5.9 ER308L 6 ST-308L Ar 99,99% Ar 99,99% Min 10 Max 175 - 1.5 - 11.08 - 2 Face: 2 1 Yes No Yes B0JY B0JR01 B0JS 400 2 800 Received 25-Dec-14 25-Dec-14

A312 TP304/TP304L 8 1 2'' 40S - 248 A A Prequalify

A312 TP304/TP304L 8 1 168.3 14.28 GTAW 2 2.5 5.9 ER308L 6 ST-308L Ar 99,99% - 1 A0JW B0KC01 D0JY B0JR

2 NSRP-LLM-WPS-019H NSRP-LLM-PQR-019H 1 - Ar 99,99% Min 10 Max 175 - 5 - 28.56 - 2 Side: 4 1 Yes No Yes B0JY B0JR01 B0JS 400 2 800 Received 19-Sep-15 26-Sep-15 6-Oct-15 6-Oct-15

A312 TP304/TP304L 8 1 6'' SCH 120 SMAW Other 11.78 5.4 E308L-16 4 S-308L.16N - - 248 A A

NSRP-LLM-PQR-107H A312 / TP316 8 1 60.3 5.54 Root: 2 - 1 A0LW A1LV04 A1LY A0LR

3 NSRP-LLM-WPS-107L (NSRP-LLM-PQR-107L) 1 GTAW ALL 7.11 5.9 ER316L 6 ST-316L Ar 99,99% Ar 99,99% Min 10 Max 175 - 1.5 - 11.08 - 2 Face: 2 1 Yes No Yes A0L501 B0L501 A0LP04 400 2 800 Received 25-Dec-14

A312 / TP316 8 1 2'' 40S - 248 A 25-Dec-14 A Prequalify

NSRP-LLM-WPS-020A NSRP-LLM-PQR-020A A312 / TP316 8 1 60.3 Root: 2 - 1 A0LW A1LV04 A1LY A0LR

4 (NSRP-LLM-PQR-20A) 5.54 1 GTAW ALL 5.9 ER316/316L 6 Oxfordalloys 316 Ar 99,99% Ar 99,99% Min 10 Max 175 - 1.5 - 11.08 - 2 Face: 2 1 Yes Yes Yes A0L501 B0L501 A0LP04 400 2 800 Received 16-Apr-15 4-May-15 Prequalify

A312 / TP316 8 1 2'' - 248 18-May-15 A A

A376 / TP347H 8 1 168.3 890-910 Root: 2 - 1

5 NSRP-LLM-WPS-042M NSRP-LLM-PQR-042M 7.11 1 GTAW ALL 7.11 5.9 ER347 6 ER347H Ar 99,99% Ar 99,99% Min 10 Max 175 1.5 - 14.22 - 2 Face: 2 1 Yes Yes Yes Yes 400 2 800 Received 24-Jan-16 4-Feb-16 24-Feb-16 A 24-Feb-16 A

A376 / TP347H 8 1 6'' Min 4h - 248

A312 / TP316 8 1 273.05 25.4 1 GTAW 2 5.9 ER316/316L Oxfordalloys 316 - 1 A0LW A1LV04 A1LY A0LR

6 NSRP-LLM-WPS-043A NSRP-LLM-PQR-043A 25.4 6 Ar 99,99% Ar 99,99% Min 10 Max 175 - 5 - 50.8 - 2 Side: 4 1 Yes Yes Yes Yes A0L501 B0L501 A0LP04 2 800 Received 16-Apr-15 4-May-15 18-May-15 A A 10-Feb-15 20-Feb-15 4-May-15

A312 / TP316 8 1 10'' XXS SMAW Other 5.4 E 316/316L-16 Oxfordalloys 316L-16 - 248

A312/TP321 8 1 88.9 Root: 2 - 1

7 NSRP-LLM-WPS-021 A NSRP-LLM-PQR-021 A 5.49 1 GTAW ALL 7.11 5.9 ER347 6 Oxfordalloys 347 Ar 99,99% Ar 99,99% Min 10 Max 175 - 1.5 - 10.98 - 2 Face: 2 1 Yes Yes Yes B0MP01 P1M602 P2M602 400 2 800 Received 9-Apr-15 24-Apr-15 18-May-15 A A 10-Feb-15 20-Feb-15 27-Feb-15

A312/TP321 8 1 3'' - 248

Root: 2

A358/TP347 8 1 355.6 23.83 GTAW 2 2 5.9 ER347 6 Oxfordalloys 347 Ar 99,99% Ar 99,99% Min 10 Max 175 - - 2 Face: 2 - 1

8 NSRP-LLM-WPS-022A NSRP-LLM-PQR-022A 1 5 - 47.66 1 Yes Yes Yes B0MP01 P1M602 P2M602 400 2 800 Received 11-Apr-15 25-Apr-15 18-May-15 A A 10-Feb-15 20-Feb-15 27-Feb-15

A358/TP347 8 1 14'' SMAW Other Other 5.4 E347-16 4 Oxfordalloys 347-16 - 2 Side: 4 - 248

A312 TP304/TP304H 8 1 88.9 5.49 1 GTAW ALL 5.54 5.9 ER308H 6 Oxfordalloys 308H Ar 99,99% Ar 99,99% Min 10 Max 175 - 1.5 - 10.98 - 2 Root: 2 - 1 1 Yes Yes Yes Yes 400 2 800

9 NSRP-LLM-WPS-044A NSRP-LLM-PQR-044A Face: 2

B0KP01 Received 19-Sep-15 26-Sep-15 6-Oct-15 A 6-Oct-15 A

A312 TP304/TP304H 8 1 3'' 40S - 248

A312 TP304/TP304H 8 1 168.3 21.97 1 GTAW 2 2.5 5.9 ER308H 6 Oxfordalloys 308H Ar 99,99% Ar 99,99% Min 10 Max 175 - 5 - 43.94 - 2 - 1 1 Yes Yes Yes Yes 400 2 800

10 NSRP-LLM-WPS-045A NSRP-LLM-PQR-045A Side: 4 B0KP01 Received 18-Nov-15 12-Dec-15 18-Dec-15 A 18-Dec-15 A 6-Nov-15 13-Nov-15

A312 TP304/TP304H 8 1 6'' XXS Other 22.9 5.4 4 - - 248

A312 TP316/TP316L 8 1 60.3 5.54 2 Ar 99,99% Ar 99,99% Min 20 Max 150 - 1.5- 11.08 - 2 - 1 1 No No No No 400 2 800

11 NSRP-LLM-WPS-069A NSRP-LLM-PQR-069A GTAW ALL 5.54 5.14 ERNiCrMo-3 43 Alloys 625 Side: 4 Received 12-Apr-16 23-Apr-16 26-Apr-16 A 26-Apr-16 A

A312 TP316/TP316L 8 1 2'' XXS - - 248

V. Ferritic stainless steel

A240 TP410S 7 1 1 - - 2 Root: 2 - 1 1 Yes No No Yes

1 NSRP-LLM-WPS-060A NSRP-LLM-PQR-060A N/A 6 GTAW ALL 6 5.14 ERNiCrMo-3 43 Alloys 625 Ar 99,99% Ar 99,99% Min 10 Max 315 1.5 - 12 Face: 2

600 2 800 Received 6-Nov-15 16-Nov-16 30-Nov-15 A 30-Nov-15 A

A240 TP410S 7 1 - 248

VI. Dupplex stainless steel

A790 10H 1 60.3 5.54 Root: 2

2 NSRP-LLM-WPS-111 NSRP-LLM-PQR-111 2 GTAW ALL 5.9 ER2209 6 ER329N Min 10 Max 150 - - 1.5 - 11.08 - 2 Face: 2 - - 1 1 - - - -

A790 10H 1 2'' XS

VII. Nickel Alloys

B444 N06625 43 1 88.9 5.49 Root: 2 - 1

1 NSRP-LLM-WPS-023A NSRP-LLM-PQR-023A 1 GTAW s 7.11 5.14 ERNiCrMo-3 43 Alloys 625 Ar 99,995% Ar 99,995% Min 20 Max 150 - 1.5 - 10.98 - 2 Face: 2 1 Yes No Yes Yes A1YV 400 2 800 Received 24-Jul-15 7-Aug-15 19-Aug-15 A 19-Aug-15 A

B444 N06625 43 1 3'' - 248

B423 N08825 45 1 88.9 7.62 Root: 2 - 1

2 NSRP-LLM-WPS-024A NSRP-LLM-PQR-024A 1 GTAW ALL 7.62 5.14 ERNiCrMo-3 43 Alloys 625 Ar 99,995% Ar 99,995% Min 20 Max 120 - 1.5 - 15.24 - 2 Face: 2 1 Yes No Yes Yes N1Y602 N1Y702 400 2 800 Received 3-Jul-15 18-Jul-15 13-Aug-15 A 13-Aug-15

B423 N08825 45 1 3'' XS - 248 A

B423 N08825 45 1 273.05 18.24 GTAW 2 2.5 5.14 ERNiCrMo-3 43 Alloys 625 Ar 99,995% - 1

3 NSRP-LLM-WPS-025A NSRP-LLM-PQR-025A 1 Ar 99,995% Min 20 Max 120 - 5 - 36.48 - 2 Side: 4 1 Yes No Yes Yes N1Y602 N1Y702 400 2 800 Received 3-Jul-15 18-Jul-15 13-Aug-15 A 13-Aug-15

B423 N08825 45 1 6'' SCH160 SMAW Other 15.74 5.11 ENiCrMo-3 43 ALLOY 112 - - 248 A

SB -165 UNS N04400 42 N/A 60.3 2.77 Ar 99,995% Root: 2 - 1

4 NSRP-LLM-WPS-136 NSRP-LLM-PQR-136 1 GTAW ALL 2.77 5.14 ERNiCu-7 42 ALLOY 60 Ar 99,995% Min 20 Max 120 - 1.5 - 5.54 - 2 Face: 2 1 Yes No No Yes 400 2 800 Received A

SB -165 UNS N04400 42 N/A 2'' SCH10S - - 248 A

VIII. Dissimilar

SA106 1 1 60.3 5.54 GTAW Buttering 3 5.14 ERNICr-3 43 Alloy 82 - 1

Root: 2

1 NSRP-LLM-WPS-033 NSRP-LLM-PQR-033 1 Ar 99,995% Min 20 Max 120 - 1.5-11.08 - 2 Face: 2 - 1 No No N1Y702 N2AR02 400 2 800 Received 17-Jul-15 31-Jul-15 A A

B423 N08825 45 1 2'' GTAW ALL 5.54 5.14 ERNiCrMo-3 43 Alloy 625 Ar 99,995% 248

SA106 1 1 219.08 18.26 GTAW Buttering 3 5.14 ERNICr-3 43 Alloy 82 - 1

2 NSRP-LLM-WPS-034 NSRP-LLM-PQR-034 1 GTAW ERNiCrMo-3 Alloy 625 Ar 99,995% Ar 99,995% Min 20 Max 120 - 5-36.52 - 2 Side 4 - 1 No No N1Y702 N2AR02 400 2 800 Received 17-Aug-15 29-Aug-15 9-Oct-15 A 9-Oct-15 A

B423 N08825 45 1 8'' SMAW ALL 18.26 5.14 ENiCrMo-3 43 ALLOY 112 248

A335 P11 4 1 168.28 18.24 GTAW Buttering 3 5.14 ERNICr-3 43 Alloy 82 - 1

3 NSRP-LLM-WPS-036 NSRP-LLM-PQR-036 2 GTAW ERNiCrMo-3 Alloy 625 Ar 99,995% Min 20 Max 150 - 5-36.52 - 2 Side 4 - 1 No No N1Y702 N3D702 400 2 1600 Received 17-Nov-15 23-Nov-15 14-Dec-15 A 14-Dec-15 A

B423 N08825 45 1 6'' ALL 18.24 5.14 43 Ar 99,995% 248

SMAW ENiCrMo-3 ALLOY 112

A312/TP321 8 1 60.3 5.54 GTAW - Root: 2 1

4 NSRP-LLM-WPS-037 NSRP-LLM-PQR-037 2 Alloy 625 Ar 99,995% Min 20 Max 120 - 1.5-11.08 - 2 Face: 2 - 1 No No P2M602 P2Y602 400 2 1600 Received 21-Aug-15 29-Aug-15 23-Sep-15 A 23-Sep-15 A

B423 N08825 45 1 2'' GTAW ALL 5.54 5.14 ERNiCrMo-3 43 Ar 99,995% 248

SA106 1 1 60.3 5.54 GTAW Buttering 3 5.14 ERNICr-3 43 Alloy 82 - Root: 2 1

5 NSRP-LLM-WPS-038 NSRP-LLM-PQR-038 1 Ar 99,995% Min 10 Max 175 - 1.5-11.08 - 2 Face: 2 - 1 No No N2A502 N1J502 400 2 800 Received 17-Jul-15 31-Jul-15 28-Sep-15 A 28-Sep-15 A

A312 TP316L 8 1 2'' GTAW ALL 5.54 5.14 ERNiCrMo-3 43 Alloy 625 Ar 99,995% 248

SA 106 1 1 168.3 18.26 GTAW Buttering 18.26 5.9 ERNICr-3 43 Alloy 82 - 1

6 NSRP-LLM-WPS-039 NSRP-LLM-PQR-039 1 ERNiCrMo-3 Alloy 625 Ar 99,995% Min 10 Max 175 - 5-50.8 - 2 Side 4 - 1 No No N2A502 N1J502 400 2 800 Received 2-Oct-15 9-Oct-15 26-Oct-05 A 26-Oct-05 A

A312 TP308H 8 1 6'' XXS SMAW ALL ENiCrMo-3 43 ALLOY 112 Ar 99,995% 248

SA 335 P11 4 1 168.3 10.97 GTAW Buttering 3 5.14 ERNICr-3 43 Alloy 82 - 1

WPS for Golden

7 NSRP-LLM-WPS-070 NSRP-LLM-PQR-070 1 Ar 99,995% Min 20 Max 150 - 5-21.94 - 2 Side 4 - 1 No No 400 2 800 Received 17-Nov-15 23-Nov-15 14-Dec-15 A 14-Dec-15 A Joint PCC1

A312 TP304L 8 1 6'' XS GTAW ALL 10.97 5.14 ERNiCrMo-3 43 Alloy 625 Ar 99,995% 248

SMAW ENiCrMo-3 ALLOY 112

SA 106B 1 1 273.05 10.97 GTAW Buttering 5.28 ER70S-6 6 Merit-JG56 - Ar 99,99% Min 150 Max 315 704-729 5-21.94 - 2 Side 4 - 1 1 No No N1A602 400 2 800

8 NSRP-LLM-WPS-046 NSRP-LLM-PQR-046 1 Min 2h Received 25-Dec-15 11-Jan-16 1-Feb-16 A 1-Feb-16 A

SA3365 P11 4 1 10'' SMAW ALL 5.5 E7016 4 LB-52 248

SA336 F22 5A 1 323.85 21.95 GTAW 2 5.28 ER80S-B2 6 - Metrode ER70S-B2 Ar 99,99% Ar 99,99% Min 250 Max 315 5-65.8 - 2 Side 4 - 1 1 No No N2D602 400 2 800

704-729

9 NSRP-LLM-WPS-047 NSRP-LLM-PQR-047 1 SMAW ALL 5.5 E8018-B2 4 Medtrode Chromet 1X Min 2h Received 25-Dec-15 15-Jan-16 18-Feb-16 A 18-Feb-16 A

A335 P11 P4 1 12''

248

SA336 F22 5A 1 323.85 21.85 GTAW Buttering 5.4 ENiCrMo-3 43 - Oxfordalloy112 Ar 99,99% Ar 99,99% Min 150 Max 120 5-66.64 - 2 Side 4 - 1 1 No No P1M602 400 2 800

704-729

10 NSRP-LLM-WPS-048 NSRP-LLM-PQR-048 1 GTAW ALL 5.14 ERNiCrMo-3 43 Oxfordalloy625 Min2h Received 25-Dec-15 4-Feb-16 20-Feb-16 A 20-Feb-16 A

A312 TP304H 8 1 12'' 5.4 ENiCrMo-3

SCH 160 SMAW Oxfordalloy112 248

704-729

SA336 F22 5A 1 406.4 18.26 GTAW Buttering 5.4 ENiCrMo-3 43 - Oxfordalloy112 Ar 99,995% Ar 99,995% Min 150 Max 120 Min2h 5-61.92 - 2 Side 4 - 1 1 No No P1Y702 400 2 800

11 NSRP-LLM-WPS-049 NSRP-LLM-PQR-049 1 GTAW ALL 43 Received 25-Dec-15 16-Jan-16 2-Feb-16 A 2-Feb-16 A

5.14 ERNiCrMo-3 Oxfordalloy625

B423 N08825 45 1 16'' 5.4 ENiCrMo-3

SCH 120 SMAW Oxfordalloy112

704-729

A335-P9 5B 1 60.3 5.54 GTAW Buttering 5.18 ER70S-6 6 - Merit -JG56 Ar 99,995% Ar 99,995% Min 10 Max 315 Min2h 1.5-11.08 - 2 Side 4 - 1 1 No No A2AC01 400 2 800 Received

12 NSRP-LLM-WPS-068 NSRP-LLM-PQR-068 2 GTAW ALL 4-Jun-16 11-Jun-16 29-Jun-16 A 29-Jun-16 A

A106-B 1 1 2'' 5.18 ER70S-6 6 Merit -JG56

SCH XXS SMAW

IX. PIPE SUPPORT

A335 P11 4 1 168.28 10.97 GTAW 2 5.28 ER80S-B2 6 LNT 19

1 NSRP-LLM-WPS-050 NSRP-LLM-PQR-050 1 Min150 Max 315 - - 5 - 21.94 - 2 Side: 4 - - - - - - - - 22-May-15 5-Jun-15 A A

A335 P11 4 1 6'' SMAW Other 5.5 E8018-B2 4 SL-19G

A335 P5 5B 1 168.28 10.97 GTAW 2 5.28 ER80S-B6 6 Oxfordalloys 80S-B6

2 NSRP-LLM-WPS-052 NSRP-LLM-PQR-052 1 Min 177 Max 315 - - 5 - 21.94 - 2 Side: 4 - - - - - - - - 22-May-15 5-Jun-15 A A

A335 P5 5B 1 6'' SMAW Other 5.5 E8016-B6 4 Oxfordalloys 8018-B6

A335 P5 5B 1 168.28 10.97 GTAW 2 5.18 ER80S-B6 6 Oxfordalloys 80S-B6

3 NSRP-LLM-WPS-055 NSRP-LLM-PQR-055 1 Min 177 Max 315 - - 5 - 21.94 - 2 Side: 4 - - - - - - - - 24-Jul-15 7-Aug-15 19-Aug-15 A 19-Aug-15 A

A106 1 1 6'' SMAW Other 5.1 E8016-B6 4 Oxfordalloys 8018-B6

A312 TP304/TP304L 8 1 168.28 7.11 GTAW 2 5.9 ER 309 6 Oxfordalloy 309L Root: 2

4 NSRP-LLM-WPS-056 NSRP-LLM-PQR-056 1 Min 10 Max 175 - - 1.5-14.22 - 2 Face: 2 - - 1 1 - - - - 22-May-15 5-Jun-15 A A

A106 1 1 6'' SMAW Other 5.4 E309 5 Oxfordalloy 309-16

A335 P5 5B 1 168.28 10.97 GTAW 2 5.18 ER80S-B6 6 Oxfordalloys 80S-B6

5 NSRP-LLM-WPS-057 NSRP-LLM-PQR-057 1 Min 177 Max 315 - - 5 - 21.94 - 2 Side: 4 - - - - - - - - 22-May-15 5-Jun-15 A A

A335 11 4 1 6'' SMAW Other 5.1 E8016-B6 4 Oxfordalloys 8018-B6

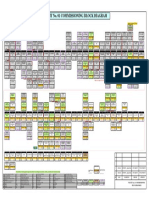

MHI WELDING PROCEDURE QUALIFICATION TEST PLAN

Remark

STATUS Plan

Test Coupon Welding Process Welding Consumable Gas

Welding

Tech WPS No, NDE Line Class PQR WPS

No,

Date Date Date Date

Group OD Thick Process Base metal qualify Mechanica Submit Code Submit Code Submit Make PQR Mechanical

Base Metal P-No Pass No, Thick SFA AWS F-No Trade Name Shilding Backing

No (mm) (mm) (Trans Mode) receipt PQR l PQR WPS pWPS test

test

N1A402, N1A602,

A333 Gr6 1 1 GTAW 2 5 5.18 ER70S-G 6 TG-S50 Ar 99.99% -

N1AH02

TECH.01 P1P1-TS-001 508 32.5 RT 8-Nov-14 3-Dec-2014 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014

N2A502, N2A602,

A350 LF2 Cl.1 1 2 SMAW other 27.5 5.1 E7016 4 NSSW-16 - -

P4AP02

N1A402, N1A602,

A333 Gr6 1 1 GTAW 2 5 5.18 ER70S-G 6 TG-S50 Ar 99.99% -

N1AH02

TECH.05 P1P1-TM-001 508 32.5 RT 1-Dec-2014 9-Jan-2015 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014

GMAW Ar 85% N2A502, N2A602,

A350 LF2 Cl.1 1 2 other 27.5 5.18 ER70S-G 6 MG-S50 -

(Spray) CO2 15% P4AP02

A335 GrP11 4 1 GTAW 1 2.5 5.28 ER80S-G 6 TG-S1CM Ar 99.99% - N2D602, N3D702 Chemical

5 Nov 2014 analisys for

TECH.06 P4P4-TS-001 168.3 21.9 RT 7-Oct-14

19 Dec 2014

4-Feb-15 A 4-Feb-15 A OK 7-Oct-14 5-Nov-14

S-000-1670-

0006V 10.1.4

A335 GrP11 4 1 SMAW other 19.4 5.5 E8016 B-2 4 CM-A96 - -

A335 GrP11 4 1 Ar 99.99% - N2D602, N3D702 Chemical

3 Dec 2014

analisys for

TECH.07 P4P4-TT-001 60.3 5.5 GTAW All 5.5 5.28 ER80S-G 6 TG-S1CM RT 3-Oct-14 15 Dec 2014 4-Feb-15 A 4-Feb-15 A OK 7-Oct-14 5-Nov-14

S-000-1670-

19 Dec 2014

A335 GrP11 4 1 Ar 99.99% - 0006V 10.1.4

A335 GrP11 4 1 GTAW 1 2.5 5.28 ER80S-G 6 TG-S1CM Ar 99.99% - N2D602, N3D702 Chemical

analisys for

TECH.08 P4P4-TM-001 168.3 21.9 RT 2-Dec-2014 9-Jan-15 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014

S-000-1670-

0006V 10.1.4

GMAW Ar 85%

A335 GrP11 4 1 other 19.4 5.28 ER80S-G 6 MG-S1CM -

(Spray) CO2 15%

Special

requirement

for S-000-

A312TP316 8 1 GTAW 1, 2, 3 6 5.9 ER347 6 WEL TIG347H Ar 99.99% Ar 99.99% P1M602, P2M602

1670-0006V

Amendments

TECH.09 P8P8-TF-001 273.1 25.4 RT 27-Nov-14 9-Jan-15 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014 10.2.3

Special

requirement

FCAW Ar 85%

A312TP316 8 1 other 19.4 5.22 E308T0-1 6 GFW308H - for S-000-

(Spray) CO2 15%

1520-0107V

6.3.7

N1J502, P1M602,

A312TP304 8 1 Ar 99.99% Ar 99.99%

P2M602

3 Dec 2014

TECH.10 P8P8-TT-001 60.3 5.54 GTAW All 5.54 5.9 ER308L 6 WEL TIG308L RT 7-Nov-14

30 Dec 2014

4-Feb-15 A 4-Feb-15 A OK 7-Oct-14 5-Nov-14

A312TP304 8 1 Ar 99.99% -

A312TP316 8 1 GTAW 2 5 5.9 ER347 6 WEL TIG347H Ar 99.99% Ar 99.99% P1M602

5 Nov 2014

TECH.11 P8P8-TS-001 273.1 25.4 RT 8-Oct-14

30 Dec 2014

4-Feb-15 A 4-Feb-15 A OK 7-Oct-14 5-Nov-14

A312TP316 8 1 SMAW other 20.4 5.4 E347-16 5 RNY347HT - -

N1Y602, N1Y702,

UNS N08825 45 - Ar 99.995% Ar 99.995%

P1Y702

TECH.12 P45P45-TT-001 273.1 18.2 GTAW All 18.2 5.14 ERNiCrMo3 43 WEL TIG625 RT 9-Jan-2015 End Jan-2015

UNS N08825 45 - Ar 99.995% -

N1Y602, N1Y702,

UNS N08825 45 - Ar 99.995% Ar 99.995%

P1Y702

TECH.13 P45P45-TT-002 60.3 5.49 GTAW All 5.49 5.14 ERNiCrMo3 43 WEL TIG625 RT 12-Jan-2015 End Jan-2015

UNS N08825 45 - Ar 99.995% -

MHI WELDING PROCEDURE QUALIFICATION TEST PLAN

Remark

STATUS Plan

Test Coupon Welding Process Welding Consumable Gas

Welding

Tech WPS No, NDE Line Class PQR WPS

No,

Date Date Date Date

Group OD Thick Process Base metal qualify Mechanica Submit Code Submit Code Submit Make PQR Mechanical

Base Metal P-No Pass No, Thick SFA AWS F-No Trade Name Shilding Backing

No (mm) (mm) (Trans Mode) receipt PQR l PQR WPS pWPS test

test

A333 Gr6 1 1 GTAW 5.14 Ar 99.99% Ar 99.99% N1J502+N2A502

Middle of

TECH.14 P1P8-TT-001 273.1 25.4 All 25.4 ERNiCr3 43 WEL TIG82 RT End Jan-2015

Jan-2015

A312TP316 8 1 GTAW 5.14 Ar 99.99% -

A335 GrP11 4 1 30.5※1 GTAW Buttering 3 5.14 ERNiCr3 43 WEL TIG82 Ar 99.99% - N3D702+N1Y702

End Jan-

TECH.15 P4P45-TT-001 273.1 RT Mid Feb-2015

2015

UNS N08825 45 - 18.3 GTAW All 18.3 5.14 ERNiCrMo3 43 WEL TIG625 Ar 99.995% Ar 99.995%

A333 Gr6 1 1 25.4※1 GTAW Buttering 3 5.14 ERNiCr3 43 WEL TIG82 Ar 99.99% - N1Y702+N1A602

Middle of

TECH.16 P1P45-TT-001 273.1 RT Mid Feb-2015

Jan-2015

UNS N08825 45 - 18.3 GTAW All 18.3 5.14 ERNiCrMo3 43 WEL TIG625 Ar 99.995% Ar 99.995%

A312TP316 8 1 GTAW 2 5 5.9 ER308L 6 WEL TIG308L Ar 99.99% Ar 99.99% N1J502

TECH.17 P8P8-TF-002 273.1 25.4 RT 26-Nov-14 9-Jan-15 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014

FCAW Ar 85%

A312TP316 8 1 other 20.4 5.22 E308LT0-1 6 GFW308LH -

(Spray) CO2 15%

N1A602, N1AH02,

A333 Gr6 1 1 GTAW 2 5 5.18 ER70S-G 6 TG-S50 Ar 99.99% -

P4AP02

TECH.18 P1P1-TS-002 273.1 25.4 RT 8-Nov-14 3-Dec-2014 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014

A350 LF2 Cl.1 1 2 SMAW other 20.4 5.1 E7016 4 NSSW-16 - -

A312TP316 8 1 GTAW 2 5 5.9 ER347 6 WEL TIG347H Ar 99.99% - P1M602, P2M602

TECH.19 P8P8-TS-002 273.1 25.4 RT Mid Feb-2015 End Feb-2015

A312TP316 8 1 SMAW other 20.4 5.4 E308H-16 4 RNY308H - -

A312TP304 8 1

TECH.20 P8P8-TT-002 60.3 5.5 GTAW ALL 5 5.9 ER347 6 WEL TIG347H Ar 99.99% - RT P1M602, P2M002 24-Nov-14 9-Jan-15 20-Feb-15 B 20-Feb-15 B OK 8-Nov-14 3-Dec-2014

A312TP304 8 1

NOTE ※1 Thinning is required for thickness adjustment.

※2 (1) Buttering with nominal 3mm shall be done by using ERNiCr3 on A335 GrP11. (2) PWHT shall be carried out for A335 GrP11. (3) Welding shall be completed by using ERNiCrMo3 without further PWHT.

※3 (1) Buttering with nominal 3mm shall be done by using ERNiCr3 on A333 Gr6. (2) PWHT shall be carried out for A333 Gr6. (3) Welding shall be completed by using ERNiCrMo3 without further PWHT.

※4 For only Buttering

※5 A : Groove weld pressure parts

B : Fillet weld pressure parts

C : Fillet weld between pressure parts and non-pressure parts

※6 Test for each welding process is required by para.10.2.3 General Requirement for Field and Shop Fabrication of Piping

Pending

Você também pode gostar

- Instant Assessments for Data Tracking, Grade 4: MathNo EverandInstant Assessments for Data Tracking, Grade 4: MathNota: 5 de 5 estrelas5/5 (2)

- LIST WELDER YinDocumento1 páginaLIST WELDER YinNaza GavaputriAinda não há avaliações

- Company Welder & Welding Operator Register Based On Aws D1.5 2015Documento1 páginaCompany Welder & Welding Operator Register Based On Aws D1.5 2015REZKIAinda não há avaliações

- R-216G-311 - 0 Manual Valve With Limit SwitchDocumento3 páginasR-216G-311 - 0 Manual Valve With Limit SwitchFahmi HaidiAinda não há avaliações

- Rotating Equipment List: A. ProcessDocumento2 páginasRotating Equipment List: A. ProcesshungAinda não há avaliações

- Johnson Matthey CSF Line Expansion: Project Scope MatrixDocumento5 páginasJohnson Matthey CSF Line Expansion: Project Scope MatrixchanjunkaiAinda não há avaliações

- Welder Test 18 December 2018Documento1 páginaWelder Test 18 December 2018NEMO MEMBUATAinda não há avaliações

- PQR's Material & Planning 27.04.2022 - CopieDocumento2 páginasPQR's Material & Planning 27.04.2022 - Copiecsc EXPERTISEAinda não há avaliações

- Welding LOG / Dziennik SpawaniaDocumento1 páginaWelding LOG / Dziennik SpawaniaarissaAinda não há avaliações

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Documento4 páginasWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoAinda não há avaliações

- ALL WPS Rampco EthanDocumento38 páginasALL WPS Rampco EthanAli TavakoliAinda não há avaliações

- Lifting - Equipment - Matrix1 (Under Constrution)Documento1 páginaLifting - Equipment - Matrix1 (Under Constrution)PradeepAinda não há avaliações

- TS - S-000-1360-0002V - F9 - 0020 (Piping Line Class)Documento23 páginasTS - S-000-1360-0002V - F9 - 0020 (Piping Line Class)miteshAinda não há avaliações

- 6420-6000-Et-5930-4 - Ra Part-1Documento259 páginas6420-6000-Et-5930-4 - Ra Part-1MayankAinda não há avaliações

- LineClassTableF8 With Vender Piping - 20170826Documento21 páginasLineClassTableF8 With Vender Piping - 20170826miteshAinda não há avaliações

- OML 58 Phase 1 Project Welders Qualification Log: Candiate IdDocumento9 páginasOML 58 Phase 1 Project Welders Qualification Log: Candiate IdTheophilus OrupaboAinda não há avaliações

- Piping DetailsDocumento16 páginasPiping DetailsSasi MesthiriAinda não há avaliações

- QAQC Personnel Qualification Matrix - Fabrication ShopDocumento1 páginaQAQC Personnel Qualification Matrix - Fabrication ShoparnolhariAinda não há avaliações

- KH Bi-10-08643-0007 - MPSRDocumento6 páginasKH Bi-10-08643-0007 - MPSRAswin KurupAinda não há avaliações

- PIPELINERS LIMITED-Chevron Bangladesh Project Welder Register (Update On Dec, 05. 2020) Welder Test Information Qualified Welder NameDocumento1 páginaPIPELINERS LIMITED-Chevron Bangladesh Project Welder Register (Update On Dec, 05. 2020) Welder Test Information Qualified Welder NameJakir HossainAinda não há avaliações

- ITP Format - Excel GEP 1120Documento22 páginasITP Format - Excel GEP 1120raghuvarma100% (1)

- Piping UpdatedDocumento4 páginasPiping UpdatedJayanta BiswalAinda não há avaliações

- Twitter SLDDocumento1 páginaTwitter SLDMohamed ShafeyAinda não há avaliações

- Abid CJV ConstructionDocumento4 páginasAbid CJV ConstructionAliAinda não há avaliações

- SLD BudhebhaparDocumento1 páginaSLD BudhebhaparHarak DhamiAinda não há avaliações

- Diamer Basha Dam Project: Borehole No. BDL-4 Upper Left Bank, Down Stream C-Axis, Central LineDocumento4 páginasDiamer Basha Dam Project: Borehole No. BDL-4 Upper Left Bank, Down Stream C-Axis, Central LineAliAinda não há avaliações

- ALL WPS Rampco MethanolDocumento73 páginasALL WPS Rampco MethanolAli TavakoliAinda não há avaliações

- Arquitectura Rev. 7.1 OvationDocumento1 páginaArquitectura Rev. 7.1 Ovationeduard ramosAinda não há avaliações

- AS-NZS 1554.1-2014 Procedure Qualification Record (PQR)Documento1 páginaAS-NZS 1554.1-2014 Procedure Qualification Record (PQR)Bobby CurrieAinda não há avaliações

- 2544 P502a20 Iso LPS23056329 0001 - 1Documento2 páginas2544 P502a20 Iso LPS23056329 0001 - 1ahmed marieAinda não há avaliações

- Pengajuan Wps ASMEDocumento1 páginaPengajuan Wps ASMEFerdie OSAinda não há avaliações

- 2544 P502C10 Iso Amn23003003 0007 - 1Documento1 página2544 P502C10 Iso Amn23003003 0007 - 1ahmed marieAinda não há avaliações

- Product Data Sheet: 35A 440V Surface Mount Triple Pole Isolating Switch IP66Documento1 páginaProduct Data Sheet: 35A 440V Surface Mount Triple Pole Isolating Switch IP66tonielhageAinda não há avaliações

- Weekly Progress Report From 21-Oct-2023 To 26-Oct-2023 XDocumento70 páginasWeekly Progress Report From 21-Oct-2023 To 26-Oct-2023 XErickson MalicsiAinda não há avaliações

- RAN Poster 2023 20.3 One PageDocumento1 páginaRAN Poster 2023 20.3 One Pagealegarcab488Ainda não há avaliações

- QCPC - Wide Roller 35,5Documento1 páginaQCPC - Wide Roller 35,5rianAinda não há avaliações

- Equipment ListDocumento7 páginasEquipment Listyadav yadavAinda não há avaliações

- K-007 Weekly Progress Tracking - 02nov18Documento3.206 páginasK-007 Weekly Progress Tracking - 02nov18JOSEPH BASCOSAinda não há avaliações

- WPS RegDocumento1 páginaWPS RegRamzi ZoghlamiAinda não há avaliações

- P-Qac-Pro-200-38242 Welding Procedure Specification (WPS) Register Rev BDocumento1 páginaP-Qac-Pro-200-38242 Welding Procedure Specification (WPS) Register Rev BRamzi ZoghlamiAinda não há avaliações

- 036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CDocumento2 páginas036909C-2BAE02-ISO-SSC-24163-01-0F1S3-Isometric Sketch-Field Isometric - Modifications-CNguyenCanhBaoAinda não há avaliações

- Siemens: PSS®SINCAL Platform Price ListDocumento1 páginaSiemens: PSS®SINCAL Platform Price ListJohnDoeAinda não há avaliações

- Ground Floor Lighting Layout Second Floor Lighting Layout: Kitchen Lanai Master BedroomDocumento1 páginaGround Floor Lighting Layout Second Floor Lighting Layout: Kitchen Lanai Master BedroomJefferson SubilAinda não há avaliações

- Ray 3Documento7 páginasRay 3beth cincoAinda não há avaliações

- All Wps Rampco AsuDocumento33 páginasAll Wps Rampco AsuAli TavakoliAinda não há avaliações

- 2020 TCF PR StatusDocumento8 páginas2020 TCF PR Statusaaaaa dddddAinda não há avaliações

- NRG Coal Dust Monitoring - 20190731Documento123 páginasNRG Coal Dust Monitoring - 20190731Dave GreinkeAinda não há avaliações

- RCC Slab Bridge Reconstruction 1X8.0 at 14+495-GADDocumento1 páginaRCC Slab Bridge Reconstruction 1X8.0 at 14+495-GADShivam SharmaAinda não há avaliações

- Software: GeosystemDocumento1 páginaSoftware: GeosystemdjokoherususantoAinda não há avaliações

- Drilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionDocumento2 páginasDrilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final Revisionengmuhmud100% (1)

- Drilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionDocumento2 páginasDrilling and Workover - (LEM) Lifting Equipment Matrix - January 14th 2020 Final RevisionAfzaalUmairAinda não há avaliações

- Sizing CableDocumento73 páginasSizing CableM Luqman HakimAinda não há avaliações

- Quality Contol Plan Piping Erection (Above & Underground) 2542-000-QCP-1320-001 - 0 PDFDocumento33 páginasQuality Contol Plan Piping Erection (Above & Underground) 2542-000-QCP-1320-001 - 0 PDFZohrab Dadashov100% (1)

- Latst RFI ListDocumento4 páginasLatst RFI ListDeepu CAinda não há avaliações

- Pressure Test & Test Pack ManagementDocumento43 páginasPressure Test & Test Pack ManagementStanley Alex100% (4)

- Chemical Requirments: BilletDocumento3 páginasChemical Requirments: BilletRohit VishwakarmaAinda não há avaliações

- NS2 - Common and Unit #1 Commissioning Block Diagram - Matching With Adjusted Plan - REV.1Documento1 páginaNS2 - Common and Unit #1 Commissioning Block Diagram - Matching With Adjusted Plan - REV.1Do Ngoc TriuAinda não há avaliações

- 036909C 2cae18 Iso en 23251 01 0S3Documento1 página036909C 2cae18 Iso en 23251 01 0S3NguyenCanhBaoAinda não há avaliações

- Bill of Material Sketch ListDocumento8 páginasBill of Material Sketch ListNguyenCanhBaoAinda não há avaliações

- 036909C 2cae05 Iso VT 27986 04 0S2Documento1 página036909C 2cae05 Iso VT 27986 04 0S2NguyenCanhBaoAinda não há avaliações

- LLM RQ WQ 0007Documento1 páginaLLM RQ WQ 0007tranvando1986Ainda não há avaliações

- ONECNCDocumento10 páginasONECNCtranvando1986Ainda não há avaliações

- LLM RQ NDT 0002Documento1 páginaLLM RQ NDT 0002tranvando1986Ainda não há avaliações

- LLM RQ NDT 0436Documento2 páginasLLM RQ NDT 0436tranvando1986Ainda não há avaliações

- 22 October, 2012: Killed Carbon SteelDocumento1 página22 October, 2012: Killed Carbon Steeltranvando1986Ainda não há avaliações

- eta/VPG Training Manual: A LS/DYNA Based Full Vehicle Simulation Solution PackageDocumento54 páginaseta/VPG Training Manual: A LS/DYNA Based Full Vehicle Simulation Solution Packagetranvando1986Ainda não há avaliações

- Practical Intelligence For Die Casting: Piq2 SRLDocumento16 páginasPractical Intelligence For Die Casting: Piq2 SRLtranvando1986Ainda não há avaliações

- 2018.01.01 NSRP 3RD RT (Film Interpretation Meeting by NSRP and JGCS)Documento4 páginas2018.01.01 NSRP 3RD RT (Film Interpretation Meeting by NSRP and JGCS)tranvando1986Ainda não há avaliações

- All SoftwareDocumento1 páginaAll Softwaretranvando1986Ainda não há avaliações

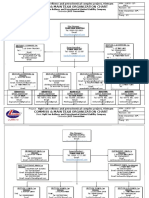

- LLM18 MAIN & COMMISS Site Organization ChartDocumento2 páginasLLM18 MAIN & COMMISS Site Organization Charttranvando1986Ainda não há avaliações

- 100% RT Line: RT Shooting Result (By JGCS)Documento9 páginas100% RT Line: RT Shooting Result (By JGCS)tranvando1986Ainda não há avaliações

- NSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)Documento9 páginasNSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)tranvando1986Ainda não há avaliações

- Applicationform Kwangjin VietnamDocumento6 páginasApplicationform Kwangjin Vietnamtranvando1986Ainda não há avaliações

- QC Data Received Status For TP Preparation - LILAMA - 20180109Documento2 páginasQC Data Received Status For TP Preparation - LILAMA - 20180109tranvando1986Ainda não há avaliações

- Welder List of JVTT - LilamaDocumento15 páginasWelder List of JVTT - Lilamatranvando1986Ainda não há avaliações

- 2018.01.04 NSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)Documento2 páginas2018.01.04 NSRP 3rd RT (Film Interpretation Meeting by NSRP and JGCS)tranvando1986Ainda não há avaliações

- 100% RT Line: RT Shooting Result (By JGCS)Documento8 páginas100% RT Line: RT Shooting Result (By JGCS)tranvando1986Ainda não há avaliações

- Isometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical ProjectDocumento3 páginasIsometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical Projecttranvando1986Ainda não há avaliações

- Department Department Code Administrative A Contract T Construction C Quality Control Q Safety S Material MDocumento1 páginaDepartment Department Code Administrative A Contract T Construction C Quality Control Q Safety S Material Mtranvando1986Ainda não há avaliações

- Isometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical ProjectDocumento3 páginasIsometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical Projecttranvando1986Ainda não há avaliações

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Documento4 páginasHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986Ainda não há avaliações

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Documento4 páginasHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986Ainda não há avaliações

- Post Weld Heat Treatment Report: °C °c/hrDocumento6 páginasPost Weld Heat Treatment Report: °C °c/hrtranvando1986Ainda não há avaliações

- Isometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical ProjectDocumento3 páginasIsometric Drawing List For Insulation Inspection: Nghi Son Refinery and Petrochemical Projecttranvando1986Ainda não há avaliações

- Dayly Report For Piping: Report No: DL-P-001 Date: 12-NOV-2011Documento18 páginasDayly Report For Piping: Report No: DL-P-001 Date: 12-NOV-2011tranvando1986Ainda não há avaliações

- Hardness Test Report: ITP For Piping Installation QCR: 6000-011Documento4 páginasHardness Test Report: ITP For Piping Installation QCR: 6000-011tranvando1986Ainda não há avaliações

- Post Weld Heat Treatment Report: °C °c/hrDocumento6 páginasPost Weld Heat Treatment Report: °C °c/hrtranvando1986Ainda não há avaliações

- QCS 2010 Section 17 Part 4 Architectural Metal Work PDFDocumento4 páginasQCS 2010 Section 17 Part 4 Architectural Metal Work PDFbryanpastor106Ainda não há avaliações

- Industry ProfileDocumento28 páginasIndustry ProfilePRIYAM XEROXAinda não há avaliações

- Underground Basement SheltersDocumento38 páginasUnderground Basement ShelterslambertAinda não há avaliações

- API 1104 SummaryDocumento7 páginasAPI 1104 Summarymohamedqc100% (1)

- Coating Application & Inspection Procedure-Rev 0Documento27 páginasCoating Application & Inspection Procedure-Rev 0tinphat100% (1)

- Architectural Specification DBI SALA Unirail SystemDocumento7 páginasArchitectural Specification DBI SALA Unirail SystemCoordinación de Proyectos Médico ArquitectónicosAinda não há avaliações

- Isye 4256 Supplemental Material: Fall, 1999Documento14 páginasIsye 4256 Supplemental Material: Fall, 1999Ram Prasad YadavAinda não há avaliações

- Balistic SeperatorDocumento36 páginasBalistic SeperatorAhmetAinda não há avaliações

- AMT 2203 Finals Learning Module 01Documento16 páginasAMT 2203 Finals Learning Module 01jose santiagoAinda não há avaliações

- HM 300 PDFDocumento1.056 páginasHM 300 PDFaugustoAinda não há avaliações

- Welding Electrodes CatalogueDocumento7 páginasWelding Electrodes CatalogueFiroj Al HasanAinda não há avaliações

- Body of Knowledge Api 510 Pressure VesseDocumento8 páginasBody of Knowledge Api 510 Pressure VesseIsaac AfricanaAinda não há avaliações

- Inspection and Test Plan For Pressure Vessel Repair, Modification, AlterationDocumento5 páginasInspection and Test Plan For Pressure Vessel Repair, Modification, AlterationMuhammed Abo-Fandood50% (2)

- Build Your Own TurbineDocumento16 páginasBuild Your Own TurbineJack D'Roca100% (5)

- New Holland Wheel Loader w230 en Service ManualDocumento20 páginasNew Holland Wheel Loader w230 en Service Manualrichard100% (41)

- SWP Plasma Cutter AS532Documento2 páginasSWP Plasma Cutter AS532Saleem Afreen67% (3)

- BOC Purging While Welding Brochure351 - 68116 PDFDocumento16 páginasBOC Purging While Welding Brochure351 - 68116 PDFAl0611981Ainda não há avaliações

- Polycarbonate (PC) : Corporate Training and PlanningDocumento54 páginasPolycarbonate (PC) : Corporate Training and Planningfaldin 1Ainda não há avaliações

- SEBM031308 Mar09) PDFDocumento837 páginasSEBM031308 Mar09) PDFQuy Le ThanhAinda não há avaliações

- Project Work 2nd ReviewDocumento18 páginasProject Work 2nd ReviewRavi AnuAinda não há avaliações

- Primacore MW 71Documento2 páginasPrimacore MW 71rjan7peAinda não há avaliações

- Analysis of Microcracks in Weld Line of ERW PipeDocumento7 páginasAnalysis of Microcracks in Weld Line of ERW PipeAyon RoyAinda não há avaliações

- Steel Construction: Today & TomorrowDocumento20 páginasSteel Construction: Today & TomorrowPvp PvpAinda não há avaliações

- 3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFDocumento11 páginas3rd Party-NDT-CCS-Post Weld Heat Treatement Procedure For SAPID Approval PDFManoj Balla100% (1)

- MANUAL 42560 A Radiator Valve - ENGDocumento4 páginasMANUAL 42560 A Radiator Valve - ENGSiniša PerčićAinda não há avaliações

- 007NANOTEC1 7weldingtypesDocumento8 páginas007NANOTEC1 7weldingtypesVikram Ramachandran SamykannuAinda não há avaliações

- E3024M-16 Standard Practice For Magnetic Particle Testing For General IndustryDocumento19 páginasE3024M-16 Standard Practice For Magnetic Particle Testing For General IndustryudomAinda não há avaliações

- Manual Drill Collar S-R-LDocumento6 páginasManual Drill Collar S-R-LJAVIER EDUARDO MANTILLA BUITRAGOAinda não há avaliações

- Curriculum - Textile Wet Processing TechnicianDocumento56 páginasCurriculum - Textile Wet Processing TechnicianFaruque SathiAinda não há avaliações

- Lecture 7 (Types of Welding)Documento22 páginasLecture 7 (Types of Welding)Syed Ahmed RazaAinda não há avaliações