Escolar Documentos

Profissional Documentos

Cultura Documentos

1006 1012

Enviado por

shivaniTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1006 1012

Enviado por

shivaniDireitos autorais:

Formatos disponíveis

.

Journal of Applied Sciences 15 (7): 1006-1012, 2015

ISSN 1812-5654

© 2015 Asian Network for Scientific Information

ans net

Asian Network for Scientific Information

RESEARCH ARTICLE OPEN ACCESS

DOI: 10.3923/jas.2015.1006.1012

Application of Gypsum and Fly Ash as Additives in Stabilization of Tropical

Peat Soil

Z.A. Rahman, J.Y.Y. Lee, S.A. Rahim, T. Lihan and W.M.R. Idris

School of Environmental and Natural Resource Sciences, Faculty of Science and Technology, UKM, 43600,

Bangi Selangor, Malaysia

ARTICLE INFO ABSTRACT

Article History: The demand for land in conjunction to infrastructure development is become crucial

Received: February 25, 2015 and expensive. In the near future, a problematic soil such as peat is becoming a final

Accepted: June 12, 2015 alternative. In crucial cases, peat land cannot be avoided and has been hosted for

engineering structures (e.g., road, highway, railway and bridge). Peat soil is well

Corresponding Author:

Z.A. Rahman established of its downgraded characteristics, highly compressibility and low in

School of Environmental and Natural shear strength. This study aimed to investigate effect of fly ash and gypsum on the

Resource Sciences, mechanical properties of peat soil. Fly Ash (FA) is a by-product material that is

Faculty of Science and Technology, generated from the burning of coal in thermal power plants. In this study, gypsum

UKM, 43600, Bangi Selangor, Malaysia was prepared chemically in the laboratory to simulate residue from Neutralization

Underflow Process (NUF). For the first batch of samples, the peat samples were

initially treated with Synthetic Gypsum (SG) in the ranges between 0 and 20% of

sample dried weight (SG treated soil). In a second batch, the peat samples were

prepared with 10% FA and then mixed thoroughly with different amounts of SG

contents (0, 5, 10 and 20%) (10FA-SG treated soil). The results showed that soil

treated with mixture of 10% FA and SG indicated lower liquid limit values than the

SG treated soil. In compaction tests, the maximum dry density of both increased in

both SG treated soil and FA-SG treated soil. The permeability of SG treated soil

increased with the increases in SG contents. Similarly, occurred to permeability of

FA-SG treated soil however, its values are lower than the soil treated without FA.

Shear strength of SG treated showed decreased with increasing amount of SG

content. In contrast, the FA-SG treated soil exhibited higher strength if compared

to that of SG treated soil. The result suggested that the application of FA and SG

mixture is more effective in stabilization in mechanical strength and densification

of peat soil than the use of SG only.

Key words: Fly ash, gypsum, mechanical characteristics, compaction, shear

strength

INTRODUCTION infrastructures sites are arising (Huat et al., 2005). At present,

peat land is being gradually transformed into sites for

Tropical peat soil covers 2.7 million ha of Malaysia infrastructure developments.

(Mutalib et al., 1991). Most of the peat land areas have been Peat soil comprises of high organic and natural water

developed for agriculture purposes mainly for palm oil contents up to more than 70 and 400%, respectively. It forms

plantation. Malaysia itself contributes to 90% of world’s oil in waterlogged area, where lack of oxygen prevents natural

palm stock (Wetlands International, 2010). The coverage of microorganisms from decomposing the dead plant material

peat soil is quite extensive; utilization of marginal soil has (Badv and Sayadin, 2012). It occurs as extremely soft,

been required as population and demands for new unconsolidated surficial deposits and can be a thick layer

www.ansinet.com 1006 | Volume 15 | Issue 7 | 2015 |

J. Applied Sci., 15 (7): 1006-1012, 2015

beneath other surficial deposits (Huat, 2006). Peat soil exhibits Pandian et al., 2002; Klee, 2008). As the environmental

unique geotechnical behaviour as compared to that of regulations get tougher and more restricted, alternative

inorganic soils which made up of soil particles materials that offer economically effective should be explored.

(Deboucha et al., 2008). The amount of waste originated from daily activities,

As a result of high compressibility and low strength, production and industries continues to increase rapidly as

development of peat soils has encountered several engineering population growing (Abdul Kadir and Mohajerani, 2011).

failures associated with surface subsidence and uneven Therefore, the utilization of the industrial by-products can

settlement. This area is generally discomfort and difficult to enhance the value added of particular waste and can also

access to the sites and change chemically and biologically with minimize the cost in terms of waste disposal and management.

time (Huat et al., 2005). Jarret (1995) regarded this soft soil is In this study, fly ash and gypsum were used as additive

susceptible to massive and long term settlement as even under materials in stabilization of peat soil. The use of waste

moderate loading. Deboucha et al. (2008) reported that the materials is attractive because of their relatively cheaper,

shear strength of peat soil is very low of between 5 and compared with cement and lime as well promoting sustainable

20 kPa. Hence, peat soils are considered problematic soil and construction (Ahmed, 2014). Their effect on some mechanical

unsuitable for supporting foundation in natural state characteristic such as Atterberg limit, hydraulic conductivity,

(Yamaguchi et al., 1992; Duraisamy et al., 2009). It is a compaction and shear strength were examined in this study.

common practice to remove and replace peat soil with other

soil. Nevertheless, the cost will higher as the peat layers get MATERIALS AND METHODS

deeper and economically limited to shallow zone. Stabilization

technique of chemical admixture can be performed through Based soil and additive materials: Based soil used was peat

mixing of additives to allow flocculation (aggregation) and to soil that was collected from Tanjung Sepat district, Sepang

form chemical bonding between particles (Edil et al., 2006; Selangor (N 2°40’41”, E 101° 35’31”). The samples were

Huat et al., 2005). Increase in effective size in clay taken at depth below 1 m from ground surface at which water

aggregation and inter-particle bonding contribute to the level ranged between 0.5 and 0.8 m. The soil was

stability and strength of the treated soil. characterized by its high water content, spongy fabric and

Some common additives used in improving the strong odour of rotten organic matters. Based on field

mechanical strength of soil are cement, lime and fly ash. observation, the soil was dark brown in colour and very acidic

Cement is widely applied in stabilizing clay and soft soils with average pH of 3.2. The organic and natural water

(Axelsson et al., 2002; Lorenzo and Bergado, 2004). Use of contents were high of 95.6-97.4 and 77-560%, respectively.

lime can enhance the shear strength and reduce significantly The liquid limit of peat soil was between 144 and 184%. Most

the water absorption (NLA., 2004; Eren and Filiz, 2009). Fly of peat soil lacks of plastic limit characteristic. The scale of

ash with high calcium shows a significant amount of humification of peat sample was categorized as H4 according

tobermorite that leading to the formation of a denser and more to Von Post classification. This category was attributed to the

stable structure of the clay samples. It is well established that facts that peat presents with distinct plant fibres and water with

the application of chemical admixture has been successfully muddy brown colour when peat sample was squeezed. Little

improved the mechanical strength of stabilized peat soil as plant characters were identified due to its pasty in nature.

concluded by many studies (Huat et al., 2005; Kolay and Similar previous results were also stated that organic content

Romali, 2006; Deboucha et al., 2008; Islam and Hashim, of peat soil ranged between 88.6 and 99.1%. Fly ash samples

2010; Kazemian et al., 2011). Fly ash has been widely used in were collected from nearby thermal power station at Kapar,

brick and rammed earth studies (Kayali, 2005; Brooks, 2009; Selangor. It is classified as Class F, non-plastic and whitish

Cristelo et al., 2012). The usages of fly ash as additive have grey. Gypsum waste might be produced from manufacturing

also been examined by Zia and Fox (2000) and Edil et al. process, construction and demolition activities. In general, it

(2006). Kolay and Pui (2010) examined the potential usage of consists of calcium sulphate dehydrate (CaSO4C2H2O). In this

gypsum and fly ash in stabilization of peat soil. They found study, gypsum was synthetically produced in the laboratory to

that both additive industrial by products can improve the simulate waste produced from neutralization underflow

unconfined compressive strength with the increase of curing process or also known as NUF. This residue is rich in

periods. Application of recycled gypsum in the stabilized soft magnesium as a result of sulphuric acid neutralization on

clay was performed by Kamei at al. (2013) in order to improve minerals of calcium, magnesium and aluminium to produce

its shear strength. This study indicated the potential use of sulphate minerals (WorleyParson, 2008; Vaisey, 2012).

gypsum in increasing the unconfined shear strength of the Summary of the basic characteristics of peat soil, fly ash and

treated soil. synthetic gypsum used in this study is shown in Table 1. The

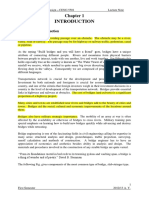

The conventional materials such as cement and lime SEM images of peat soil treated with fly ash and synthetic

become expensive, now-a-days have increased the cost of soil gypsum is shown in Fig. 1. Fly ash particles found to be filling

stabilization. In environmental aspect, the production of these the spaces between soil particles while bridging of chemical

materials has associated with high energy consumption and the bindings formed by gypsum and clay particles (Fig. 1b). The

release of attributed greenhouse gases (Worrell et al., 2001; crystal of gypsum seen as an elongate shape that interlocked

www.ansinet.com 1007 | Volume 15 | Issue 7 | 2015 |

J. Applied Sci., 15 (7): 1006-1012, 2015

(a)

3 µm EHT = 2.00 kV Signal A = SE2 Date: 29 April 2013

WD = 4.2 mm Mag = 2.50 k X

(b)

3 µm EHT = 3.00 kV Signal A = SE2 Date: 29 April 2013

WD = 4.0 mm Mag = 2.50 k X

Fig. 1(a-b): Scanning electron microscope photographs of at 2.5 K magnification (a) Peat soil treated with synthetic gypsum

(seen as elongate shapes) and (b) Peat soil treated with 10% fly ash (sphere shape) and synthetic gypsum

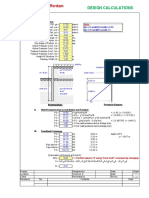

Table 1: Summary of basic characterization of peat and additive materials presented in Fig. 2. It is clearly seen that fly ash is dominated

Material properties Peat Fly ash Gypsum by silt size while, synthetic gypsum constitutes of silt and very

Natural moisture content, w (%) 77-96 0.1 39.7

Organic content (%) 95.6 - -

fine sand.

Humification class H4 - -

pH 3.2 12.5 8.8 Sample preparation of treated peat soil: Prior to preparation

Specific gravity (Gs) 1.3 2.2 2.0 of treated samples, peat samples were openly air dried under

Liquid limit, wL (%) 144-184 - - room temperature and soil any aggregate form was broken

Permeability, k (×10G5) (m secG1) 4.9 - -

Compaction test

down manually by hand. The samples were sieved through

Maximum dry density, ρdmax (g cmG3) 0.54 - - 2 mm mesh size. The used additives of Fly Ash (FA) and

Optimum moisture content, wopt (%) 86.5 - - Synthetic Gypsum (SG) were oven dried for overnight before

Shear strength, Cu (kPa) 10-13 - - cold down to room temperature and kept in desiccator. The

treated samples were prepared by dry mixing between peat

with few voids (Camarini and de Milito, 2011). Particle size sample and different percentages of SG ranged between

distribution curves for fly ash and synthetic gypsum are 0 and 20% of dried weight of base soil. This first batch was

www.ansinet.com 1008 | Volume 15 | Issue 7 | 2015 |

J. Applied Sci., 15 (7): 1006-1012, 2015

100 Fly ash testing. For quick undrained tests, a set of three samples

Synthetic gypsum

of 38 mm diameter by 76 mm high sample was used. These

80 samples were subjected confining stresses of 140, 280 and

Cummulative passing (%)

420 kPa prior to shearing. The samples were sheared at strain

60 rate of 1.52 mm minG1. Shearing of the samples was performed

until the samples failed. A further explanation of the methods

40 adopted to determine the geotechnical characteristics of the

treated samples were referred to the British Standard

20 Institution 1377 (1990a-d) Part 2, 4, 5 and 7.

0 RESULTS AND DISCUSSION

1 0.1 0.01 0.001 0.0001

Diameter (mm) Effect on liquid limit: The values of liquid limit, wL for the

treated peat soil synthetic gypsum (SG treated soil) and 10%

Fig. 2: Particle size distribution of additive materials used fly ash and different amount of synthetic gypsum (10 FA-SG

treated soil) are shown in Fig. 3. For SG treated soil, the

labelled as SG treated soil. A second batch of treated samples values of wL gradually reduced from 144-123% at 20% of SG

had initially prepared between peat samples with 10% of FA content. As, 10% of FA was added to the peat soil, the value

before different amount of SG were added (10 FA-SG treated of wL generally dropped to 134% if compared to that of peat

soil). This second batch aimed to examine the effect SG soil without FA. A similar picture was seen for the liquid limit,

contents at specific amount of FA on the geotechnical wL values of the 10 FA-SG treated soil and the was located

parameters of treated peat soil. Both treated samples were kept slightly below the line of the SG treated soil (Fig. 3). It is clear

in airtight containers prior to further testing. All the treated that the addition of SG has decreased the values of liquid limit,

samples experienced a week curing period before particular wL and combination of SG and FA will further reduce the wL

parameters such as permeability and mechanical strength tests. value in treated peat soil. Several previous studies also

mentioned a similar trend of the influence of fly ash in

Geotechnical testing of treated soils: Consistency index of reducing the liquid limit value of treated soil (Geliga and

liquid limit, wL was determined by using the Casagrande cup Ismail, 2010; Yadu et al., 2011; Vukicevic et al., 2013;

techniques. This technique equipped with a cup and a grooving Saravanan et al., 2013). The influences of SG content on both

tool. This test is used to classify a particular soil and to treated soils are indicated by strong correlation values as

estimate its moisture content at which the shear strength is shown in Fig. 3.

virtually zero (Dias and Alves, 2009). A groove was cut at the

middle of the soil paste and is subjected to shallow drop of the Effect on compaction and permeability: The results of the

cup. The value of plastic limit, wP was determined from 3 mm effect of added SG contents on the maximum dry density, ρdmax

in diameter of soil thread with sign of crumbles. After of each and optimum water content, wopt are shown in Fig. 4. From

test, sample was collected to determine the moisture content. Fig. 4a, the increase in SG contents has increased the values of

Difference between wL and wP is the plasticity index, IP. maximum dry density, ρdmax of both treated SG treated and

The objective of compaction is to densify the soil mass by 10FA-SG treated soils. Meanwhile for the addition of SG has

bringing down the air voids. By compaction of the soil, decreased the optimum water content, wopt values for both

particles will re-arrange to gain more surface contact by treated soils (Fig. 4b).

reducing the inter-particle voids (Rahman et al., 2013). The results suggested that the increase in ρdmax and

Compaction tests were carried out using the standard Proctor decrease in wopt were not significantly affected by the presence

2.5 kg (or BS light) compaction effort in order to determine the of 10% fly ash. It is clearly seen that further addition of SG

values of maximum dry density, ρdmax and optimum water more than 5% has decreased the wopt. A similar result was also

content, wopt. Sample was compacted in three equal layers exhibited by 10 FA-SG treated soils up to 5% of SG content.

using a rammer where each layer experienced 27 blows that An addition of 10% FA content has brought down the value

were evenly distributed over the mould area. The tests were wopt and then value levelled off up to 20% SG content.

repeated for samples with higher water contents. Compaction Therefore, as the added SG contents were increased, the

curves were delineated to achieve the values of ρdmax and wopt. amount of water to achieve the maximum dry density was

The permeability and shear strength of the treated soil apparently reduced.

samples were determined using the falling permeameter The effect of SG and 10 FA-SG content on permeability,

methods and quick undrained tests. Preparation of samples for k is shown in Fig. 5. For untreated peat soil (0% SG), the

both tests was obtained from the standard compaction k value was 4.90×10G5 m secG1. As, the contents of SG were

procedures. Each sample was equally compacted in three increased, the permeability also gradually increased up to

layers in compaction mould. The samples were extruded from 1.01×10G4 m secG1. For the 10 FA-SG treated soil, the

the mould and sealed for predetermined curing period before presence of fly ash has lowered the value of permeability to

www.ansinet.com 1009 | Volume 15 | Issue 7 | 2015 |

J. Applied Sci., 15 (7): 1006-1012, 2015

150 SG soil 12 SG soil

10 FA-SG soil 10 FA-SG soil

Liquid limit water content, wL (%)

2

R = 0.991

Permeability, kH10G (m secG )

10

1

140

8

5

130 6 2

R = 0.926

2

4

R = 0.889

120

R2 = 0.974 2

110 0

0 5 10 15 20 25 0 5 10 15 20 25

Synthetic gypsum content (%) Synthetic gypsum content (%)

Fig. 3: Atterberg limit, w values against synthetic gypsum Fig. 5: Permeability of SG and 10 FA-SG soils

contents for SG and 10 FA-SG soils

300 SG soil

0.66 10 FA-SG soil

Apparent shear strength, Cu (kPa)

(a) 2

R = 0.866 250

Maximum dry density, dmax (g cmG )

3

0.64 SG soil R2 = 0.989

10 FA-SG soil

200

0.62

150

0.60

0.58 100

0.56 50

0.54

0

0.52 0 5 10 15 20 25

Synthetic gypsum content (%)

110 (b) SG soil

10 FA-SG soil

Optimum water content, wopt (%)

100 Fig. 6: Shear strength against synthetic gypsum contents of

SG and 10 FA-SG soils

90

Flocculation may contribute to larger soil particles with bigger

80 inter-particle voids (Fig. 1). Therefore, by increasing the

amount of SG, the permeability of treated peat also increased

70

significantly as shown in Fig. 5. The higher value of k for SG

treated soil than 10 FA-SG treated soil attributable to presence

60

of fly ash that it occupies the voids hence, reduce the

0 5 10 15 20 25 permeability of 10 FA-SG treated soil. Since, the amount of

Synthetic gypsum content (%) FA was limited to 10%, further increased in SG subsequently

increase the permeability of 10 FA-SG treated soil.

Fig. 4(a-b): (a) Maximum dry density, ρdmax values and

(b) Optimum water content, wopt against synthetic Effect on shear strength: All samples were tested after a

gypsum contents for SG and 10 FA-SG soils week of curing. The effect of SG and 10% FA-SG contents on

the strength of treated peat soil is illustrated by the apparent

1.96×10G5 m secG1 for sample 10% FA with 0% SG if, shear strength, Cu is shown Fig. 6. The untreated peat soil

compared to that of SG sample without SG content. By further (SG soil) is represented by lower Cu value of 47 kPa. A low Cu

addition of the SG contents, the k values were increased value was also seen for peat soil treated with 10% of

from 2.42×10G5-5.94×10G5 m secG1 for 10 FA-SG treated soil FA (10 FA-SG soil). It seemed that presence of 10% FA in

(Fig. 5). The k values for SG treated soil were seen higher than treated peat soil did not significantly change the strength of

that of 10 FA-SG treated soil. peat soil (Cu equal 50 kPa). However, as SG content was

The increase of k values in both treated soils was possibly added up to 5% in SG soil, the Cu value climbed up from

caused by the high content of calcium (Ca2+) and magnesium 47-195 kPa. This value dropped back to 67 kPa (10% FA)

(Mg2+) in SG used in this study. These cations are responsible and 61 kPa when the SG content used in the peat soil was

in the flocculation of clay particles in the studied soil. 20%. In contrast, the Cu value for sample 10 FA-SG soil

www.ansinet.com 1010 | Volume 15 | Issue 7 | 2015 |

J. Applied Sci., 15 (7): 1006-1012, 2015

increased to 58 kPa (5% FA) and then climbed significantly to Environmental and Natural Resource Sciences, Faculty of

261 kPa as SG content of 10% before the value decreased to Science and Technology, UKM for sample preparation and

below 181 kPa at 20% of SG content. It also noticed that testing.

higher shear strength was achieved for the samples treated

with fly ash and gypsum. REFERENCES

The results indicated that the improvement of the Cu

values is much dependant on the amount of SG used in SG Abdul Kadir, A. and A. Mohajerani, 2011. Bricks: An

treated soil. In SG treated soil, 5% of SG was the optimum excellent building material for recycling wastes-a review.

content whereas, for samples with the presence of 10% FA Proceedings of the IASTED International Conference on

(10 FA-SG treated soil), the amount of SG should not be in Environmental Management and Engineering, July 4-6,

excess of 10%. The increase in Cu value was due to the 2011, Calgary, AB., pp: 108-115.

reaction between gypsum and soil particles that responsible in Ahmed, A., K. Ugai and T. Kamei, 2011. Investigation of

inter-particles binding and bridging. Aggregation of clay recycled gypsum in conjunction with waste plastic

particles may be attributable to increase in shear strength. trays for ground improvement. Constr. Build. Mater.,

Using of gypsum as a cementation agent can alter the 25: 208-217.

behaviour of soil to more cohesion (Hughes and Glendinning, Ahmed, A.G.A., 2014. Fly ash utilization in soil stabilization.

2004). Ahmed et al. (2011) also found that the amount of Proceedings of the International Conference on Civil,

gypsum corresponded to the increase in the shear strength of Biological and Environmental Engineering, May 27-28,

fine grain soil. However, excessive presence of gypsum has 2014, Istanbul, Turkey, pp: 76-78.

attributed to the formation of weak inter-particle binding as Axelsson, K., S.E. Johansson and R. Anderson, 2002.

stated by Kolay and Pui (2010). A combination of fly ash and Stabilization of organic soils by cement and pozzolanic

gypsum additives in treatment of peat soil (as in 10 FA-SG reactions-feasibility study. Report 3, Swedish Deep

soil) achieved higher maximum Cu value if, compared to that Stabilization Research Centre, pp: 15-16.

of SG soil. Higher shear strength was the result of blend of Badv, K. and T. Sayadin, 2012. An investigation into the

chemical bonding created from both fly ash and gypsum geotechnical characteristics of Urmia peat. Iranian J. Sci.

present in the treated soil (Moseley, 1993). However, further Technol., 36: 167-180.

addition of gypsum in 10 FA-SG soils has weaken the strength British Standard Institution 1377, 1990a. Methods of Test

of the treated peat soil possibly related to formation of weakly

for Soil for Civil Engineering Purposes-Part 2:

bonding with more porous soil as fly ash used was limited to

Classification Tests. British Standard Institution, London,

10%.

ISBN: 0580178676, Pages: 68.

British Standard Institution 1377, 1990b. Methods of Test

CONCLUSION

for Soil for Civil Engineering Purposes-Part 4:

Compaction-Related Tests. British Standard Institution,

From the results of this study, the application of fly ash

London, ISBN: 0580180700, Pages: 70.

and gypsum as additive materials can improve the geotechnical

British Standard Institution 1377, 1990c. Methods of Test for

characteristics peat soil. The consistency index of liquid limit

Soil for Civil Engineering Purposes-Part 5:

of peat soil was decreased apparently especially with the

presence of fly ash and gypsum. The compaction behaviour of Compressibility, Permeability and Durability Tests.

treated peat soil exhibited higher maximum dry density with British Standard Institution, London, ISBN: 0580180301,

lesser optimum water content as the amount of additive Pages: 42.

materials used were increased, yet the presence of fly ash did British Standard Institution 1377, 1990d. Methods of Test for

not significantly affect the value of the maximum dry density. Soil for Civil Engineering Purposes-Part 7: Shear Strength

In contrast, the permeability of treated soils increased with the Tests (Total Stress). British Standard Institution, London,

increase of SG contents. It clearly showed the fly ash can ISBN: 0580182649, Pages: 62.

lower the permeability of treated peat soil if compared to that Brooks, R.M., 2009. Soil stabilization with fly ash and rice

of samples treated solely with gypsum. In terms of shear husk ash. Int. J. Res. Rev. Applied Sci., 1: 209-217.

strength, the amount of gypsum used should be not in excess Camarini, G. and J.A. de Milito, 2011. Gypsum

as further addition has contributed to the reduction in soil hemihydrates-cement blends to improve renderings

shear strength. durability. Construction Build. Mater., 25: 4121-4125.

Cristelo, N., S. Glendinning, T. Miranda, D . Oliveira and

ACKNOWLEDGMENTS R. Silva, 2012. Soil stabilisation using alkaline activation

of fly ash for self compacting rammed earth construction.

The authors would like to thank, Universiti Kebangsaan Construction Build. Mater., 36: 727-735.

Malaysia for the financial support under the research grants Deboucha, S., R. Hashim and A. Alwi, 2008. Engineering

PIP-2013-004. The authors would also like to express properties of stabilized tropical peat soils. Elect. J.

their gratitude to the laboratory staffs at the School of Geotech. Eng., 13: 1-9.

www.ansinet.com 1011 | Volume 15 | Issue 7 | 2015 |

J. Applied Sci., 15 (7): 1006-1012, 2015

Dias, C.R. and A.M. Alves, 2009. Geotechnical properties of Lorenzo, G.A. and D.T. Bergado, 2004. Fundamental

the Cassino Beach mud. Continental Shelf Res., parameters of cement-admixed clay-new approach.

29: 589-596. J. Geotech. Geoenviron. Eng., 130: 1042-1050.

Duraisamy, Y., B.B. Huat and R. Muniandy, 2009. Moseley, M.P., 1993. Ground Improvement. Blackie

Compressibility behavior of fibrous peat reinforced with Academic and Professional, Glasgow.

cement columns. Geotechnical Geol. Eng., 27: 619-629. Mutalib, A.A., J.S. Lim, M.H. Wong and L. Koonvai, 1991.

Edil, T.B., H.A. Acosta and C.H. Benson, 2006. Stabilizing Characterization, distribution and utilization of peat in

soft fine-grained soils with fly ash. J. Mater. Civil Eng., Malaysia. Proceedings of the Symposium on Tropical

18: 283-294. Peat Land, March 8-10, 1991, Kuching, Sarawak,

Eren, S. and M. Filiz, 2009. Comparing the conventional soil pp: 7-16.

stabilization methods to the consolid system used as an NLA., 2004. Lime-treated soil construction manual: Lime

alternative admixture matter in Isparta Darıdere material. stabilization and lime modification. Bulletin 326, National

Construction Build. Mater., 23: 2473-2480. Lime Association, January 2004.

Geliga, E.A. and D.S.A. Ismail, 2010. Geotechnical properties Pandian, N.S., K.C. Krishna and B. Leelavathamma, 2002.

of fly ash and its application on soft soil stabilization. Effect of fly ash on the CBR behaviour of soils.

UNIMAS E-J. Civil. Eng., 1: 1-6. Proceedings of the Indian Geotechnical Conference,

Huat, B.B.K., S. Maail and T.A. Mohamed, 2005. Effect of October, 2002, Allahabad, pp: 183-186.

chemical admixtures on the engineering properties of Rahman, Z.A., W.Z.W. Yaacob, S.A. Rahim, T. Lihan,

tropical peat soils. Am. J. Applied Sci., 2: 1113-1120. W.M.R. Idris and W.N.F. Mohd Sani, 2013. Geotechnical

Huat, B.K., 2006. Deformation and shear strength characterisation of marine clay as potential liner material.

characteristics of some tropical peat and organic soils. Sains Malaysiana, 42: 1081-1089.

Pertanika J. Sci. Technol., 14: 61-74. Saravanan, R., R.S. Thomas and M. Joseph, 2013. A study on

Hughes, P. and S. Glendinning, 2004. Deep dry mix ground soil stabilization of clay soil using fly ash. Int. J. Res.

improvement of a soft peaty clay using blast furnace Civil Eng. Architecture Design, 1: 33-37.

slag and red gypsum. Q. J. Eng. Geol. Hydrogeol., Vaisey, M., 2012. Synthetic mineral product development.

37: 205-216. Lynas Corp, Australia.

Islam, M.S. and R. Hashim, 2010. Behaviour of stabilised Vukicevic, M., S. Maras-Dragojevic, S. Jockovic,

peat: A field study. Sci. Res. Essays, 5: 2366-2374. M. Marjanovic and V. Pujevic, 2013. Research results of

Jarret, P.M., 1995. Site investigation for organic soils and fine-grained soil stabilization using fly ash from Serbian

peat. Geogoide 6, JKR Document 20709-0341-95, electric power plant. Proceedings of the 18th International

Institut Kerja Raya, Malaysia. Conference on Soil Mechanics and Geotechnical

Kamei, T., A. Ahmed and K. Ugai, 2013. Durability of soft Engineering, September 2-6, 2013, Paris, pp: 3267-3270.

clay soil stabilized with recycled Bassanite and furnace Wetlands International, 2010. A quick scan of peatlands in

cement mixtures. Soils Foundations, 53: 155-165. Malaysia. Wetland International Malaysia, Petaling Jaya.

Kayali, O., 2005. High performance bricks from fly ash. WorleyParson, 2008. Lynas advanced materials project:

World of Coal Ash (WOCA), April 11-15, 2005, Preliminary comparison of residue disposal options.

Kentucky, USA., pp: 1-13. WorleyParsons, Kuala Lumpur.

Kazemian, S., B.B.K. Huat, A. Prasad and M. Barghci, 2011. Worrell, E., L. Prince, N. Martin, C. Hendriks and

A state of art review of peat: Geotechnical engineering L.O. Meida, 2001. Carbon dioxide emissions from the

perspective. Int. J. Phys. Sci., 6: 1974-1981. global cement industry. Ann. Rev. Energy Environ.,

Klee, H., 2008. The cement sustainability initiative. Future 26: 203-229.

Technologies and Innovations in the Cement Sector Yadu, L., R.K. Tripathi a nd D. Singh, 2011. Comparison

in China: Modeling the Future Cement Industry, of fly ash and rice husk ash stabilized black cotton soil.

November 17, 2008, Beijing, China. Int. J. Earth Sci. Eng., 4: 42-45.

Kolay, P.K. and M.P. Pui, 2010. Peat Stabilization using Yamaguchi, H., Y. Hashizume and H. Ikenaga, 1992. Change

gypsum and fly ash. UNIMAS E-J. Civil Eng., 1: 1-5. in pore size distribution of peat in shear processes.

Kolay, P.K. and N.S.B. Romali, 2006. Highly organic soil Soils Foundations, 32: 1-16.

stabilization by different types of admixtures. Proceedings Zia, N. and P.J. Fox, 2000. Engineering properties of loess-fly

of the 2nd International Conference on Problematic Soil, ash mixtures for road base construction. Transportation

September 2006, Petaling Jaya, Selangor, Malaysia, Research Record No. 1714, TRB National Research

pp: 211-216. Council, Washington DC, USA., pp: 49-56.

www.ansinet.com 1012 | Volume 15 | Issue 7 | 2015 |

Você também pode gostar

- Bridge Construction: Balanced Cantilever MethodDocumento12 páginasBridge Construction: Balanced Cantilever MethodPankajVermaAinda não há avaliações

- Chapter 07Documento22 páginasChapter 07shivaniAinda não há avaliações

- IS 456 Amendments - 2013 PDFDocumento9 páginasIS 456 Amendments - 2013 PDFAshish JainAinda não há avaliações

- Is 456 Amendments - 2013Documento12 páginasIs 456 Amendments - 2013shivaniAinda não há avaliações

- Code: ESM-5 Subject: Civil Engineering 3: Question PaperDocumento5 páginasCode: ESM-5 Subject: Civil Engineering 3: Question PapershivaniAinda não há avaliações

- Bridge Lecture NoteDocumento128 páginasBridge Lecture NoteshivaniAinda não há avaliações

- Unit - 1 PDFDocumento24 páginasUnit - 1 PDFshivaniAinda não há avaliações

- Sub Soil Investigation Report of Construction of NewHighDocumento25 páginasSub Soil Investigation Report of Construction of NewHighshivaniAinda não há avaliações

- Siti Aimi Nadia Mohd YusoffDocumento33 páginasSiti Aimi Nadia Mohd YusoffshivaniAinda não há avaliações

- Tenax Geocomposites BrochureDocumento12 páginasTenax Geocomposites BrochureshivaniAinda não há avaliações

- AP-Foundation Concepts and FoundationDocumento40 páginasAP-Foundation Concepts and FoundationYogesh ChauhanAinda não há avaliações

- 1006 1012Documento8 páginas1006 1012shivaniAinda não há avaliações

- AP-Foundation Concepts and FoundationDocumento40 páginasAP-Foundation Concepts and FoundationYogesh ChauhanAinda não há avaliações

- Evaluating The Influence of Recycled Waste Materials On RsDocumento32 páginasEvaluating The Influence of Recycled Waste Materials On RsshivaniAinda não há avaliações

- CPT and SPT Based Liquefaction Triggering ProceduresDocumento138 páginasCPT and SPT Based Liquefaction Triggering ProceduresAndreas GiannakogiorgosAinda não há avaliações

- pdf5 PDFDocumento28 páginaspdf5 PDFshivaniAinda não há avaliações

- Soil Sequence Studies On The Tropical Buganda Catena (Masaka District Uganda)Documento12 páginasSoil Sequence Studies On The Tropical Buganda Catena (Masaka District Uganda)shivaniAinda não há avaliações

- Kioko, Chrorpher Kimali MSc. Civil Engineering-.2015Documento138 páginasKioko, Chrorpher Kimali MSc. Civil Engineering-.2015shivaniAinda não há avaliações

- Soil Sequence Studies On The Tropical Buganda Catena (Masaka District Uganda)Documento12 páginasSoil Sequence Studies On The Tropical Buganda Catena (Masaka District Uganda)shivaniAinda não há avaliações

- Exterimental Studies On Utilization of Murrum As HDocumento7 páginasExterimental Studies On Utilization of Murrum As HshivaniAinda não há avaliações

- 02 Sep 2015 171842283CUDNQ4ZVpfrDocumento18 páginas02 Sep 2015 171842283CUDNQ4ZVpfrshivaniAinda não há avaliações

- Evaluation of Low Strain Dynamic Properties Using Geophysical Method: A Case StudyDocumento17 páginasEvaluation of Low Strain Dynamic Properties Using Geophysical Method: A Case StudyshivaniAinda não há avaliações

- Smart SyncDocumento11 páginasSmart SyncshivaniAinda não há avaliações

- Full TextDocumento17 páginasFull TextshivaniAinda não há avaliações

- Critical Review of Innovative Soil Road Stabilization TechniquesDocumento9 páginasCritical Review of Innovative Soil Road Stabilization TechniquesshivaniAinda não há avaliações

- Study of Stabilization of Black Cotton Soil Usingadmixtures-14910Documento4 páginasStudy of Stabilization of Black Cotton Soil Usingadmixtures-14910shivaniAinda não há avaliações

- 2 PBDocumento5 páginas2 PBshivaniAinda não há avaliações

- Characterization and Classification of Sugarcane Growing Soils of Medak District of Telangana StateDocumento240 páginasCharacterization and Classification of Sugarcane Growing Soils of Medak District of Telangana StateshivaniAinda não há avaliações

- Hydrometer Analysis PDFDocumento4 páginasHydrometer Analysis PDFshivaniAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Telford Test HouseDocumento1 páginaTelford Test HouseUmesh MishraAinda não há avaliações

- Massive Online Open Course (Mooc) On Organic Manure Making Second Semester-Project ReportDocumento22 páginasMassive Online Open Course (Mooc) On Organic Manure Making Second Semester-Project ReportNoufal NoufiiAinda não há avaliações

- Unit 3 - Week 2: Assignment 2Documento3 páginasUnit 3 - Week 2: Assignment 2AKASH MAURYAAinda não há avaliações

- Difference Between Organic Farming and Chemical Farming - Subhashri Bio EnergiesDocumento1 páginaDifference Between Organic Farming and Chemical Farming - Subhashri Bio EnergiesŚáńtőśh MőkáśhíAinda não há avaliações

- Ae Board Exam 2017 060917Documento80 páginasAe Board Exam 2017 060917trishaAinda não há avaliações

- Skempto 1961 Effective Stress in Soils Concrete and RocksDocumento13 páginasSkempto 1961 Effective Stress in Soils Concrete and RocksSaid_Lopez_Mx100% (1)

- Sheet Pile at CofferdamDocumento2 páginasSheet Pile at CofferdamMarjun SuperalesAinda não há avaliações

- Relation Between Permability Settlement of SoilDocumento58 páginasRelation Between Permability Settlement of SoilAshok DasariAinda não há avaliações

- Aggregate Stability SQ Physical Indicator SheetDocumento2 páginasAggregate Stability SQ Physical Indicator SheetWong Jin HongAinda não há avaliações

- Stability of Earth Dam Slope PDFDocumento14 páginasStability of Earth Dam Slope PDFshubhamAinda não há avaliações

- Geotechnical ENGGDocumento10 páginasGeotechnical ENGGUjjwal GuptaAinda não há avaliações

- Choa Reclamation and Ground ImprovementDocumento359 páginasChoa Reclamation and Ground ImprovementJoko WiratmonoAinda não há avaliações

- Engineering Properties of MaterialsDocumento1 páginaEngineering Properties of Materialspapilolo2008100% (1)

- Soil Bearing Capac SPT Relationship Terzaghi & Peck ChartDocumento3 páginasSoil Bearing Capac SPT Relationship Terzaghi & Peck ChartHasnizal HashimAinda não há avaliações

- Chapter 12Documento22 páginasChapter 12muhammad yaseenAinda não há avaliações

- MoistDocumento3 páginasMoistLarra Marie PagcaliwaganAinda não há avaliações

- Compressibility of Soil: Review - Hydraulics and Geotechnical EngineeringDocumento6 páginasCompressibility of Soil: Review - Hydraulics and Geotechnical EngineeringJustine Ejay MoscosaAinda não há avaliações

- Geotechnical Assessment of Gully Erosion at Ankpa Area, North Central NigeriaDocumento13 páginasGeotechnical Assessment of Gully Erosion at Ankpa Area, North Central NigeriaIOSRjournalAinda não há avaliações

- Jeopardy Template-2Documento28 páginasJeopardy Template-2api-379960001Ainda não há avaliações

- Soil CBR - Gandhinagar-KalolDocumento6 páginasSoil CBR - Gandhinagar-KalolAlok Bhatt 'avi'Ainda não há avaliações

- CE04015 QA 1soilDocumento32 páginasCE04015 QA 1soilAdroit Writer40% (5)

- A Hill Slope Failure Analysis A Case Study of Malingoan Village Maharashtra IndiaDocumento7 páginasA Hill Slope Failure Analysis A Case Study of Malingoan Village Maharashtra IndiaMajid KhanAinda não há avaliações

- Analisis Kenaikan Tekanan Air Pori Clean Sand Menggunakan Metode Cyclic Shear-Strain ControlledDocumento10 páginasAnalisis Kenaikan Tekanan Air Pori Clean Sand Menggunakan Metode Cyclic Shear-Strain ControlledafwanrenaldoAinda não há avaliações

- New Mexico Office of The State Engineer Dam Safety BureauDocumento12 páginasNew Mexico Office of The State Engineer Dam Safety BureauYudhi Febrian100% (2)

- Soil Description: Borehole No:-1Documento3 páginasSoil Description: Borehole No:-1Binod Raj GiriAinda não há avaliações

- Application of Geosynthetics in Geotechnical EngineeringDocumento32 páginasApplication of Geosynthetics in Geotechnical EngineeringLeon FouroneAinda não há avaliações

- Schnaid Et Al (2004) in Situ Test Characterization of Unusual Geomateriais Schnaid Et Al 2004Documento25 páginasSchnaid Et Al (2004) in Situ Test Characterization of Unusual Geomateriais Schnaid Et Al 2004Marcus ViniciusAinda não há avaliações

- Total Stress Analysis: Chapter FiveDocumento4 páginasTotal Stress Analysis: Chapter FivelenanaAinda não há avaliações

- Assignment 2Documento1 páginaAssignment 2JeffLeungAinda não há avaliações

- Ist Summative Test in Sci 5 4th GradingDocumento1 páginaIst Summative Test in Sci 5 4th GradingRobbie Rose LavaAinda não há avaliações