Escolar Documentos

Profissional Documentos

Cultura Documentos

016 - Bibliography and References

Enviado por

sharkDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

016 - Bibliography and References

Enviado por

sharkDireitos autorais:

Formatos disponíveis

PAMANTASAN NG LUNGSOD NG MAYNILA

College of Engineering and Technology

Chemical Engineering Department

REFERENCES

Adekunle, A., Orsat, V., & Raghavan, V. (2016). Lignocellulosic bioethanol: A

review and design conceptualization study of production from cassava peels.

Renewable and Sustainable Energy Reviews, 64, 518-530.

Buchanan, K. J., Hird, B., & Letcher, T. M. (1986). Crosslinked poly (sodium

acrylate) hydrogels. Polymer Bulletin, 15(4), 325-332.

Castano Pelaez, H., Reales Alfaro, J., & Zapata Montoya, J. (2013). Simultaneous

saccharification and fermentation of cassava stems. Dyna, 80(180), 97-104.

Dunn, J. B., Adom, F., Sather, N., Han, J., Snyder, S., He, C., ... & You, F. (2015).

Life-cycle analysis of bioproducts and their conventional counterparts in GREET

(No. ANL/ESD--14/9 Rev.). Argonne National Lab.(ANL), Argonne, IL (United

States).

Fujiwara, M. (2015). U.S. Patent No. 9,034,996. Washington, DC: U.S. Patent and

Trademark Office.

Gagne, P. (1986). U.S. Patent No. 4,622,425. Washington, DC: U.S. Patent and

Trademark Office.

Girisuta, B., Janssen, L. P. B. M., & Heeres, H. J. (2007). Kinetic study on the acid-

catalyzed hydrolysis of cellulose to levulinic acid. Industrial & engineering

chemistry research, 46(6), 1696-1708.

Girisuta, B., & Heeres, H. J. (2017). Levulinic Acid from Biomass: Synthesis and

Applications. In Production of Platform Chemicals from Sustainable Resources (pp.

143-169). Springer Singapore.

Holtzapple, M. T., & Davison, R. R. (1999). U.S. Patent No. 5,865,898. Washington,

DC: U.S. Patent and Trademark Office.

Kumar, P., Barrett, D. M., Delwiche, M. J., & Stroeve, P. (2009). Methods for

pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel

production. Industrial & engineering chemistry research, 48(8), 3713-3729.

Polymerization and Neutralization of Acrylic Acid derived from Cassava

Technical Study 840

(Mannihot esculenta) Peels for the Production of Sodium Polyacrylate

PAMANTASAN NG LUNGSOD NG MAYNILA

College of Engineering and Technology

Chemical Engineering Department

Lin, J., Wu, J., Yang, Z., & Pu, M. (2001). Synthesis and properties of poly (acrylic

acid)/mica superabsorbent nanocomposite. Macromolecular Rapid

Communications, 22(6), 422-424..

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y. Y., Holtzapple, M., & Ladisch,

M. (2005). Features of promising technologies for pretreatment of lignocellulosic

biomass. Bioresource technology, 96(6), 673-686.

Muenster, A., & Rohmann, M. (1981). U.S. Patent No. 4,301,266. Washington, DC:

U.S. Patent and Trademark Office.

Ofuya, C. O., & Nwajiuba, C. J. (1990). Microbial degradation and utilization of

cassava peel. World Journal of Microbiology and Biotechnology, 6(2), 144-148.

Shen, J., & Wyman, C. E. (2012). Hydrochloric acid‐catalyzed levulinic acid

formation from cellulose: data and kinetic model to maximize yields. AIChE Journal,

58(1), 236-246.

Sudaryanto, Y., Hartono, S. B., Irawaty, W., Hindarso, H., & Ismadji, S. (2006).

High surface area activated carbon prepared from cassava peel by chemical

activation. Bioresource Technology, 97(5), 734-739.

Sun, Y., & Cheng, J. (2002). Hydrolysis of lignocellulosic materials for ethanol

production: a review. Bioresource technology, 83(1), 1-11.

Wu, L., Dutta, S., & Mascal, M. (2015). Efficient, Chemical‐Catalytic Approach to

the Production of 3‐Hydroxypropanoic Acid by Oxidation of Biomass‐Derived

Levulinic Acid With Hydrogen Peroxide. ChemSusChem, 8(7), 1167-1169

Yoonan, K., & Kongkiattikajorn, J. (2005). A study of optimal conditions for

reducing sugars production from cassava peels by diluted acid and enzymes.

Kasetsart Journal of Natural Science, 38, 29-35.

Zhang, M. (2014). Size reduction of cellulosic biomass for biofuel manufacturing.

Kansas State University.

Polymerization and Neutralization of Acrylic Acid derived from Cassava

Technical Study 841

(Mannihot esculenta) Peels for the Production of Sodium Polyacrylate

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Centroid and Moment of InertiaDocumento1 páginaCentroid and Moment of InertiasharkAinda não há avaliações

- A Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Documento48 páginasA Guide To Grades, Compounding and Processing of Neoprene Rubber (Bament Guide)Neeraj BhallaAinda não há avaliações

- Process Description &: Control PhilosophyDocumento12 páginasProcess Description &: Control PhilosophyHendiko PanggabeanAinda não há avaliações

- Unit 1: Structural GenomicsDocumento4 páginasUnit 1: Structural GenomicsLavanya ReddyAinda não há avaliações

- Organic Chemistry - ChemActivity - Instructor GuideDocumento139 páginasOrganic Chemistry - ChemActivity - Instructor GuidePhamy Xaypanya100% (1)

- Reuse of Plastics Waste For The Production of Floor TilesDocumento8 páginasReuse of Plastics Waste For The Production of Floor TilesKi Tibebu MaAinda não há avaliações

- Pamantasan NG Lungsod NG MaynilaDocumento8 páginasPamantasan NG Lungsod NG MaynilasharkAinda não há avaliações

- Pamantasan NG Lungsod NG Maynila: College of Engineering and TechnologyDocumento10 páginasPamantasan NG Lungsod NG Maynila: College of Engineering and TechnologysharkAinda não há avaliações

- Clean Technologies - Recycling and RecoveryDocumento10 páginasClean Technologies - Recycling and RecoverysharkAinda não há avaliações

- Report 3 - CHE 521Documento27 páginasReport 3 - CHE 521sharkAinda não há avaliações

- Industrial Waste Management and Control Report Outline Baluyot JR., Conge, Dacaimat, RaymundoDocumento1 páginaIndustrial Waste Management and Control Report Outline Baluyot JR., Conge, Dacaimat, RaymundosharkAinda não há avaliações

- 001 - Front and TOCDocumento2 páginas001 - Front and TOCsharkAinda não há avaliações

- Agricultural and Biological Sciences, 29-34Documento1 páginaAgricultural and Biological Sciences, 29-34sharkAinda não há avaliações

- Polyisobutylene Product DescriptionDocumento2 páginasPolyisobutylene Product DescriptionsharkAinda não há avaliações

- 006 - ReferencesDocumento1 página006 - ReferencessharkAinda não há avaliações

- Name: - Check ( ) The Pictures That Represent A Circle ShapeDocumento8 páginasName: - Check ( ) The Pictures That Represent A Circle ShapesharkAinda não há avaliações

- LyricsDocumento21 páginasLyricssharkAinda não há avaliações

- Pamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentDocumento1 páginaPamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentsharkAinda não há avaliações

- Ampere Reading Versus Degree BrixDocumento4 páginasAmpere Reading Versus Degree BrixsharkAinda não há avaliações

- Myoglobin & Hemoglobin: Structure & Function of BiomoleculesDocumento17 páginasMyoglobin & Hemoglobin: Structure & Function of Biomoleculesindah46Ainda não há avaliações

- Description: Technical Data SheetDocumento4 páginasDescription: Technical Data SheetjohnAinda não há avaliações

- Hazardous Waste CPCB Schedule IDocumento13 páginasHazardous Waste CPCB Schedule IamolbhaAinda não há avaliações

- Chem 600L Experiment 7 Oral ReportDocumento64 páginasChem 600L Experiment 7 Oral ReportAudrey100% (2)

- Luteolin, A Flavonoid From Syzygium Myrtifolium Walp.Documento3 páginasLuteolin, A Flavonoid From Syzygium Myrtifolium Walp.Martinius TinAinda não há avaliações

- Gce-Biology-Teachers GuideDocumento242 páginasGce-Biology-Teachers Guideapi-170496962Ainda não há avaliações

- Chemistry in Microstructured ReactorsDocumento41 páginasChemistry in Microstructured ReactorsMatteo RizzottoAinda não há avaliações

- Earth Life and Sciences First Quarter Examination ReviewerDocumento4 páginasEarth Life and Sciences First Quarter Examination ReviewerAyeicza BautistaAinda não há avaliações

- SOM Lecture 1Documento16 páginasSOM Lecture 1Dhakshinamoorthy MaikandadevanAinda não há avaliações

- Lecture 3 - Medium Characteristics and Biochemical PathwaysDocumento15 páginasLecture 3 - Medium Characteristics and Biochemical Pathwayspalak agarwalAinda não há avaliações

- 230M Parr Safety-Lab-ReactorsDocumento8 páginas230M Parr Safety-Lab-ReactorslorenzoAinda não há avaliações

- PDF 20230712 191309 0000Documento28 páginasPDF 20230712 191309 0000Russel SalvacionAinda não há avaliações

- Biocatalyst DwiDocumento12 páginasBiocatalyst DwiKiki Pratama AizenAinda não há avaliações

- Oms A Bupivacaina FARMACOPEA INTERNACIONALDocumento3 páginasOms A Bupivacaina FARMACOPEA INTERNACIONALsociedad de servicios farmaceuticos a la comunidadAinda não há avaliações

- Biopolymer Films and Composite CoatingsDocumento33 páginasBiopolymer Films and Composite CoatingsmaryamAinda não há avaliações

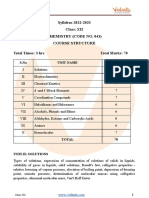

- CBSE Class 12 Chemistry SyllabusDocumento8 páginasCBSE Class 12 Chemistry SyllabusAwantika ShivhareAinda não há avaliações

- CarmegliptinDocumento12 páginasCarmegliptinQuân MinhAinda não há avaliações

- Syllabus of Tu BSC ChemistryDocumento4 páginasSyllabus of Tu BSC ChemistryraamAinda não há avaliações

- Nitrogen CycleDocumento14 páginasNitrogen CycleRafaela Eunice D CorreaAinda não há avaliações

- Pharmacology Oral Exam QuestionsDocumento8 páginasPharmacology Oral Exam Questionsjimmy50% (2)

- Product Fact Sheet: Emulsogen TS 200Documento2 páginasProduct Fact Sheet: Emulsogen TS 200Arturo Hernández100% (1)

- Environmental EngineeringDocumento5 páginasEnvironmental EngineeringLong EAinda não há avaliações

- Direct Amination of Benzene For Aniline ProductionDocumento1 páginaDirect Amination of Benzene For Aniline ProductionTrinh Quang ThanhAinda não há avaliações

- Final Pr2 Manuscript Na Pinasa 1Documento18 páginasFinal Pr2 Manuscript Na Pinasa 1KarloPangilinanAinda não há avaliações

- Must Review ThisDocumento19 páginasMust Review Thispmp123456Ainda não há avaliações