Escolar Documentos

Profissional Documentos

Cultura Documentos

Bs 2790 Cylindrical Furnace Workmanship

Enviado por

Turbo Snail R0 notas0% acharam este documento útil (0 voto)

68 visualizações1 páginaboiler

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoboiler

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

68 visualizações1 páginaBs 2790 Cylindrical Furnace Workmanship

Enviado por

Turbo Snail Rboiler

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF ou leia online no Scribd

Você está na página 1de 1

om mae

on tes oe

co.

9.4.4 If flanges nozzles or brencher are used, the flanget

shall be machined or thermal cut by machine on the edges

{and shall be machined on the jointing and bolting surfaces,

4.9.1.5 If pads are used, the jointing wurlaces shall be

‘machined. The pads shall have sufficlent thickness to

allow ériling of the stud holes for mountings without

‘the Inner surface being pierced and the length of the

screwed portion of the stud in the pad shall be not less

‘than the diameter of the stud,

4.8.2 Screwed mountings directly connected to the boller

shell or end plates, Mountings with screwed ends shall be

used only where the Internal diameter does not exceed

‘25 mm and where the detign pressure does not exceed

1.2 Nitmm?. The screwed portion of any such mounting

shall bean integel part of it. The mountings shall be screwed

irectiy into the plete, with nue on the water side.

4.9.3 Screwed mountings fitted to semwed brancher,

‘Serewed mountings not excseding 80 mm bore shall be fitted

‘0 sultably screwed branches welded to the boiler. The

screwed portion of the mounting shall comply with BS 21,

‘The mounting shall be suitable for the operating pressure.

and temperature of the boiler.

4.8.4, Bolts and nuts, All bolt and stud holes shall be

+d. Bolts and nuts shall be machined where in contact

with flanges,

774.10 Horizontal cylindrical furnaces

4.10°1 Horizontal cylindrical furnaces thall be constructed

in one of the following ways,

"al In sections from hot more than two plates, in which

‘case the longitudinal seam shall be buttwelded i

accordance with section tiv

{tb From carbon steel pipes complying with the

requirements of the following British Standards.

Rifeart 1: HFS oF CFS, grade 430

02.4 Part 2: LAW, grade 430 and 490

"BS 9601 :S, grade 430

‘The tensile strength and minus tolerances on thickness

iven in those standards shall be taken into account,

| 1 LAW pine is used, the fongitudinal sear shell be

on-destruetivey terted in accordance with 5.8.2,2.1

4.10.2 Out-of-roundness as defined in 3.10.1.8 shall not

tected 1.0% for corrugated furnaces or 1.8 % for plain

furnaces with 2 maximum variation in diameter of any.

{085 section of 6.8 mm or half the thickness, whichever

is the greate, Any departure from citeulaety shall be

gradual.

4.10.3 The longitudinal welds thall bretk joint in,

successive sectidns by at feast 150mm,

4.10.4 At the furnace sections are flanged hot for

ircurmferemtol joints, the (langing shall be carried out at

‘one heat. Subsequently, sections shall be normalized unless

‘langing be carries out within the normalizing temperature

‘ange. ifthe furnace seetions are flanged cold, they shall be

subsequently normalized and the flanges shall be subjected

10 surface ereek detection on both sidet of the plate by the

‘Magnetic particle method. Cold spinning of furnace

fectlonsisnet permitted,

4.10.5 Edges ofall furnace flanges shall be machined or

thermabeut by machine,

88 2790: 1992

Section four

Issue 2, November 198

4.10.6 1 stlfeneis are required, they shall be attached:

bby means of continuous full penetration welding iat

accordance with figure 3.10.1.0.2,

4.10.7 The projection of turnace plates beyond eiid plates

or reversal chamber tube plates shall not exceed 3 mn,

‘The end of the furnace plate corner expoted to flame or

‘hot gas shall be ground to produce a radius of net less than,

£12, The eylinsical portion of the Hlanged end pistes

‘onnected to furnace plates shall be not fess than SO mm

tong. Typicat examples of connections are shoven in.

figures BIS), (a), (b, le) or B16).

4.11 Fireboxes and reversal chambers

4.11.4 Plain eieular fireboxes, The cylindrical partion

shall preferably be formed from one plate in 2 similar

‘manner to the shell plates, The maximum permissible

variation in diameter at any cross section thal! not exceed

8.8mm for fireboxes up to 900 mm diameter, or 95 mm

for fireboxes over 800mm diameter, or hall the thickness

of the plate, whichever isthe greater,

Vertical ficeboxes shall preferably be tapered, a per of

Vin B on diameter being recommended. The water space

‘at the bottom between the firebox and the shell shall be

‘not less than 50 mm for boilers up to and inclu

750 mm diameter and not less than 63 mm for boilers

‘over 780 mm diameter,

‘The method of welding shall be in accordance with

station five,

Flats formed in the firebox for the insertion of water tubes

shall have an ample radius at the junetion of the flat and.

the curved surfaces and shall be free from sherp corners oF

1001 marks. The plate shall not be thinned below the

calculated thickness,

‘An og¢e flange, whether integral with the firebox or made

as a separate ring, shal preferably be formed at one heat

by suitable machinery and shall be allowed to cost

stadvatly to avoid internal stresses. Rings for frehol

‘openings or foundation rings shall be made of sett in

‘sccordance with the requirements specified in section

wo. Z sections shall not be used for foundation ring,

Methods of attachment of the'irebox to the shell shalt

be in accordance with figures 3.10.3(2}, (B) or (el,

‘Typical methods of attachment of Tirehole openings

shown in figuré (101,

4.11.2 Hemisphereal freboxes, Hemispheticalfreboxes

shall meet the requirements of 4.6.2,

4.11.3 Water-cooled reversal chambers. Where reversal

‘chamber tube plates or ehd plates are flanged for

attachment to wrapper plates the cylindeal portion shalt

be not less then 2e oF 38 mm long, whichever is greater.

Flat plates connected to wrapper plates shall have an

ernal fillet weld with a minimum leg length of 6 mm.

(see 5.3.2.4), Typical examples of connections ace shown,

in figures B(4)¢a) 10 fe).

‘Access opening frames shall be attached as shown in

figure 3.8.2.7, 7

4.17.4 Uptakes, Uptakes shall be formed trom seamless on,

longitudinally welged tube, or butt-welded plete, and shail

be Dutt-welded to the upward flange of the opening ia the

firebox top end plate,

‘The depth of the slange of the firebox top end piste

‘opening trom the commencement of the curvature of

the flange shall be not fers than twice the plate thickness

Sith 4 minimum of 25 me.

H Hot zonal Gilda ate M

Você também pode gostar

- Heat Exchangers - Shell & TubeDocumento38 páginasHeat Exchangers - Shell & TubeTurbo Snail RAinda não há avaliações

- PTS 11.32.01 CP System For Onshore Buried and Shore Approach PipelineDocumento43 páginasPTS 11.32.01 CP System For Onshore Buried and Shore Approach PipelineMohd Aizzuddin Md JanisAinda não há avaliações

- Offshore Riser Splash Zone Protection CoatingDocumento46 páginasOffshore Riser Splash Zone Protection CoatingMohamad PizulAinda não há avaliações

- Stud M27 HT HDG 200528Documento1 páginaStud M27 HT HDG 200528Turbo Snail RAinda não há avaliações

- Aramco Welding Inspector InterviewDocumento18 páginasAramco Welding Inspector InterviewTurbo Snail R100% (5)

- Peta MindaDocumento27 páginasPeta MindaTurbo Snail RAinda não há avaliações

- 11.15.03 - Design and Construction of Reinforced Concrete Foundations and StructuresDocumento23 páginas11.15.03 - Design and Construction of Reinforced Concrete Foundations and Structuresawie1982100% (2)

- ITP Blasting Painting.Documento2 páginasITP Blasting Painting.mohd as shahiddin jafri100% (4)

- PTS 31.38.01.15a - Piping Classes - Exploration and Production PDFDocumento43 páginasPTS 31.38.01.15a - Piping Classes - Exploration and Production PDFNguyễn Văn Tây91% (11)

- Astm E353Documento33 páginasAstm E353Naufal Ghifari Rahmat88% (8)

- Pickling and Passivation Procedure A380Documento3 páginasPickling and Passivation Procedure A380Suyog Gawande100% (3)

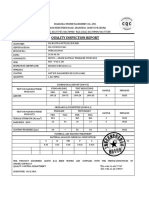

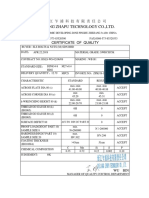

- Zhejiang Zhapu Technology Co quality certificate for SLS boltsDocumento1 páginaZhejiang Zhapu Technology Co quality certificate for SLS boltsTurbo Snail RAinda não há avaliações

- Level 2 Weld Inspection CourseDocumento18 páginasLevel 2 Weld Inspection CourseTurbo Snail RAinda não há avaliações

- Axiagearup CatalogueDocumento10 páginasAxiagearup CatalogueTurbo Snail RAinda não há avaliações

- HIT-HY 200 RV3 Injection Mortar: Technical DatasheetDocumento31 páginasHIT-HY 200 RV3 Injection Mortar: Technical DatasheetTurbo Snail RAinda não há avaliações

- Ultrasonic Testing Procedure for Structural WeldsDocumento3 páginasUltrasonic Testing Procedure for Structural WeldsTurbo Snail RAinda não há avaliações

- Aramco Welding Inspector InterviewDocumento18 páginasAramco Welding Inspector InterviewTurbo Snail R100% (5)

- CSWIP Welding Inspection Notes and QuestionsDocumento133 páginasCSWIP Welding Inspection Notes and Questionslram70100% (20)

- Ssb/Sspc-Tlo SFJT-E Structural InstallationDocumento7 páginasSsb/Sspc-Tlo SFJT-E Structural InstallationTurbo Snail RAinda não há avaliações

- What Mean Make A Good Welding InspectorDocumento4 páginasWhat Mean Make A Good Welding InspectorTurbo Snail RAinda não há avaliações

- RT Dwsi RT03 0Documento2 páginasRT Dwsi RT03 0Turbo Snail RAinda não há avaliações

- WI NotesDocumento7 páginasWI NotesPand AemonaEonAinda não há avaliações

- MT Wet MT03 0Documento2 páginasMT Wet MT03 0Turbo Snail RAinda não há avaliações

- Ssb/Sspc-Tlo SFJT-E Structural InstallationDocumento3 páginasSsb/Sspc-Tlo SFJT-E Structural InstallationTurbo Snail RAinda não há avaliações

- MT Dry MT04 0Documento2 páginasMT Dry MT04 0Turbo Snail RAinda não há avaliações

- Ssb/Sspc-Tlo SFJT-E Structural InstallationDocumento4 páginasSsb/Sspc-Tlo SFJT-E Structural InstallationTurbo Snail RAinda não há avaliações

- Ssb/Sspc-Tlo SFJT-E Structural InstallationDocumento4 páginasSsb/Sspc-Tlo SFJT-E Structural InstallationTurbo Snail RAinda não há avaliações

- Ultrasonic Testing Procedure for Structural WeldsDocumento3 páginasUltrasonic Testing Procedure for Structural WeldsTurbo Snail RAinda não há avaliações

- Ssb/Sspc-Tlo SFJT-E Structural InstallationDocumento6 páginasSsb/Sspc-Tlo SFJT-E Structural InstallationTurbo Snail RAinda não há avaliações

- Ssb/Sspc-Tlo SFJT-E Structural InstallationDocumento4 páginasSsb/Sspc-Tlo SFJT-E Structural InstallationTurbo Snail RAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)