Escolar Documentos

Profissional Documentos

Cultura Documentos

FSA-05 EXJ Physical Data

Enviado por

pmr80_2004Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

FSA-05 EXJ Physical Data

Enviado por

pmr80_2004Direitos autorais:

Formatos disponíveis

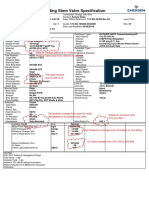

Expansion Joint Movement/Force/Spring Rate Capabilities.

(Incl

-- -- -- -- -- -- --

1/4'

3/8' 6

7/16

7/16 1/4 1/2 I :: :: I

1/2' 6 7/16I 1/4 1/2 46.0 58 43 87 .3 I 133 172 1;4 I 006

3/4'

1.

6

6

6

7/16

7/16

7/16

/16

I1fl 1/4

1/4

1/4

1/2

1/2

1/2

I 34.0

27.5

22.5

I

129

87

103

64

76

96

175

219

131 .7

1

2

199

235

294

256

304

383

262

350

438

~

.1

.02

1-1/2" 6 1/4 1/2 1 18.5 154 115 262 3 353 459 524 .15 I

2 6 7/16 1/4 1/2 14.5 185 138 350 4 423 689

552 I 700 .3 I

2-1/2 6 7/16 1/4 1/2 11.5 232 172 381 6 i 530 762 .5

3

- 7/16 1/4 1/2 10.0

8.3

278 207 412

444 --;!;--j

635 828 824

1.3

.8 1

3-112 7/16 1/4 ~! 324-1 241 742 965 888

1/2 7.5 I 1.9 I

1/4 371 476

i~ I

~

4 6 I 7/16 276 848 1104 952

I

5 6 7/16I 1/4 1/2 6.0

5.0 I 463 344 546 22 1058 1376 1092 3.7

~ I

6 6 7/16 1/4 1/2 I 556 413 617 32 1271 1652 1234 6.4

8 6 11/16 I 3/8 1/2 5.5 971 689 753 70I 1412 1837 1506 12.7

109

~

10 8 11/16 3/8 1/2 4.5 I 1214 I 861 809 1766 2296 1618 24.2

12 8 I 11/16 3/8 1/2 3.75 1456 1033 948 158 2118 2755 1896 42.1

14 11/16 3/8 1/2 3.25 1274 904 1117 160 1853 2411 234

2572

2840 19.2

16 11/16 3/8 1/2 2.75 1456 1033 1286 209 2118 2755 ! 76

18 11/16 3/8 1/2 2.5 1638 1163 1420 266 2382 3101 106

2.5

20

22

24 10

13/16

13/16

13/16

III

7/16

7/16

7/16

1/2

1/2

1/2

2.25

2.0

2152

2367

2582 1

1505

1656

1807

1588

1648

1706

T 549 I

2649

2913

3178

3440

3785

4130

3176

3296

3412

152

205

274

26 10 15/16 1/2 1/2 2.3 1990 1829 ! 659 3060 3980 3658 292

~I

2869

28 10 15/16 1/2 1/2 2.0 3090 2143 1952 765 3296 4286 3904 382

30 10 15/16 1/2 1/2 3311 2297 2075 875 3532 4594 4150 437

32 10 15/16 1/2 1/2 1.8 3531 1 2450 2438 1000 3769 4899 4876 555

34 10 15/16 1/2 1/2 1.75 3752 2603 2801 1130 4002 5602 5602 I 645

36

38

40

10

10

1U

15/16

15/16

15/16 1

1/2

1/2

1/2

1/2

1/2

1/2 ~

1.5 3973

4194

4414 I

2756

2909

3062 I

3164

3251

3338

1266

~1745

1

1563 !

4238

4475

4708

5512

5818

6124

-!-l6328

502

6676

, 844

943

1042

I

1.5

1I

~

42 12 I 9/16 I 1/2 4732 3253 4452 5783 6846 1163 I

11

1-1/16 3423

1.5

12 1/2 1.5 4958 3407 3571 1906 4664 6057 7142 1270

44

~

~

jJ I

46 12 1-1/16 9/16 1/2 I 1.3 5181 3562 I

3718 2090 1 I 4870 6339 7436 1680

12 1-1/16 9/16 1/2 1~5 5408 I 3717 3866 ! 5087 6608 7732 1825

12 1.25 5634 6884 8024 1968

~

52

50 12 1-1/16 9/16 1/2 1 3872 -4012] 5300

~

~~~~

1-1/16 9/16 1/2 1.25 1 5856 4027 4157 2672 5512 7166 8314 2138

n-

54 1-1/16 9/16 1/2 1.25 1 60855 4182 4303 2885 5724 7435 8606 2308

56 12 1-1/16 9/16 1/2 1.25 1 6310 4341 4448 3081 5936 7717 8896 2464

9/16 1/2 1.0 1 6532 4492I 4592 3310 6148 7992 9184, 3310

1

58I 12 1-1/16 I I

9472

60 12 I 1-1/16 9/16

/16 1/2 1.0 6761 4651 3537 I 6360 8268

5108

7361

3537

66 12 1-1/16 1/2 1.0 I 7437 i 5116 4288 6996 9095 10216 1

4288

9/16 1/2 0.9 1 5581 5477 5113 7632 9922 10954

72 12 1-1/16

I-+-., 8113

5681

78 12 1-1/16 i 9/16 I 1/2 0.9 1 8789 6046 I 5951 6022 8268 10748 11902

7022

84 12 1-1/16 9/16 I 1/2 0.66

0.7

.8 9465 6511 i 6425 6913 8904 11575 12850

8641

96 12 1-1/16 9/16 1/2 10817 7441 7375 9409 10176 13228 14750

13441

102 12 1-1/16 9/16 1/2 ; I 11488 7899 7850 11198 10812 14056 15700

16967

108 12 1-1/16 9/16 1/2 0.62 1 I 12169 8372 8325 13550 11448 14883 16652

21855

120 12 1-1/16 9/16 1/2 0.56 1 ,I 13521 93021 9275 16728 12720 16537 18550,

33547

29871

1

20288

132 12 1-1/16 I 9/16 1/2 0.51 114866

10222 1 10144 17109 13992 18190

144 12 1-1/16 1 9/16 1/2 0.47 ~ 16218 11152 11013 20164 15264 19843 22026 I,

42902

"Items are normal~ furnished with "Filled Arch" construction,

NOTES:

A, MOVEMENT CAPABIUTY

1 "Filled Arch" construction reduces above movement by 50%

2 The degree of Angular Movement is based on the maximum extension shown

3 If greater movements are desired, expansion joints in sizes of 4" IDand larger can be supplied with two, three or four arches Relatively longer "Face-to-Face" length dimensions

are incorporated into designs of Multiple Arch Type expansion joints (For Multiple Arch Type expansion joints in '/." to 3'/2" ID sizes, contact your supplier)

4 To calculate approximate movement of Multiple Arch expansion joints, take the movement shown in the above table and multiply by the number of arches

5 Movements shown above are based on proper installation practice (See Chapter IV, Section D)

B, FORCE POUNDS/SPRING RATE

1 Forces required to move expansIon foints are based on zero pressure cond~ions and room temperature in the pipe line

2 These forces should be considered only as approximates which may vary with the elastomers and fabrics used in fabrication and the specific construction design of an individual

manufacturer

3 See Chapter III, Section F for definition ot values shown

4 To calculate the approximate Force Pounds/Spring Rate tor Multiple Arch Joints, divide the single arch values by the number of arches

12

~

I

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- CENTC267 MHD Questions 2016Documento30 páginasCENTC267 MHD Questions 2016pmr80_2004Ainda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Piping Vibration AnalysisDocumento1 páginaPiping Vibration Analysispmr80_2004Ainda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- SBI MaxGainDocumento72 páginasSBI MaxGainpmr80_2004Ainda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Harmonic Analysis Tutorial CAEPIPEDocumento6 páginasHarmonic Analysis Tutorial CAEPIPEpmr80_2004Ainda não há avaliações

- ISO-14692 Allowable SetupDocumento1 páginaISO-14692 Allowable Setuppmr80_2004Ainda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Job Code: DE1: Age: Minimum 27 Years. of Which For Senior Manager & Above Minimum 5 Years in PipelinesDocumento1 páginaJob Code: DE1: Age: Minimum 27 Years. of Which For Senior Manager & Above Minimum 5 Years in Pipelinespmr80_2004Ainda não há avaliações

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Quick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016Documento44 páginasQuick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016pmr80_2004100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Velosi-Fire Test Cert - 6a DBB ValveDocumento18 páginasVelosi-Fire Test Cert - 6a DBB Valvepmr80_2004Ainda não há avaliações

- Considerations in Designing Multiphase Flow LinesDocumento7 páginasConsiderations in Designing Multiphase Flow Linespmr80_2004Ainda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Ceiling Cassette Indoor Unit Engineering ManualDocumento138 páginasCeiling Cassette Indoor Unit Engineering ManualcodefinderAinda não há avaliações

- RH Tankless Productbrochure 101-66-10 Rev7Documento6 páginasRH Tankless Productbrochure 101-66-10 Rev7api-221502147Ainda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- FS OneDocumento1 páginaFS OneDario SantosAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- S - 11 - Concrete 04 Beam Slab Development LengthDocumento152 páginasS - 11 - Concrete 04 Beam Slab Development LengthEngr. Gazi Golam SarwarAinda não há avaliações

- Thrust Ventilation System Description: Novenco Car ParkDocumento16 páginasThrust Ventilation System Description: Novenco Car ParkOtelea StefanAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Geotechnical Characteristics of An Erodible Soil Stabilised by LiDocumento229 páginasGeotechnical Characteristics of An Erodible Soil Stabilised by LiRatan KumarAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Documento37 páginasIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedAinda não há avaliações

- Kennametal Stellite - Jet Kote BrochureDocumento16 páginasKennametal Stellite - Jet Kote BrochureAnders GrimbarkAinda não há avaliações

- Corrosion Under InsulationDocumento14 páginasCorrosion Under InsulationSethuraman Saravanakumar100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Thesis-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry InfillDocumento81 páginasThesis-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry Infillnirez14Ainda não há avaliações

- Ismael AnabalonDocumento35 páginasIsmael Anabalondnavarrete01Ainda não há avaliações

- Asdfasr 2 Q 4235Documento3 páginasAsdfasr 2 Q 4235Claire BernardAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- 01 Introduction To Theory of StructuresDocumento54 páginas01 Introduction To Theory of StructuresdharminderaroraAinda não há avaliações

- Wire Rope Lubricant PDFDocumento1 páginaWire Rope Lubricant PDFGutmonarchAinda não há avaliações

- Dokumen - Tips - Plastics Additives Handbook 2nd Edition R Gachter and H Muller Eds HanserDocumento1 páginaDokumen - Tips - Plastics Additives Handbook 2nd Edition R Gachter and H Muller Eds HanserJohn BenedictAinda não há avaliações

- Quotation For Rapicon WallDocumento2 páginasQuotation For Rapicon WallDebkumar ChowdhuryAinda não há avaliações

- A Pressuremeter's Perspective On Soil Stiffness, 2011 PDFDocumento10 páginasA Pressuremeter's Perspective On Soil Stiffness, 2011 PDFfreezefreezeAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- E DBL 018 Elastomer PDFDocumento4 páginasE DBL 018 Elastomer PDFCostas AggelidisAinda não há avaliações

- Experiment Material Science Mec424Documento12 páginasExperiment Material Science Mec424Fadhil AimanAinda não há avaliações

- Cable Data, NSSHöu, Sizes 35-95mm2, Round Form CableDocumento2 páginasCable Data, NSSHöu, Sizes 35-95mm2, Round Form CableRehan AfzalAinda não há avaliações

- Thermal Performance Analysis of Earth-Air-Pipe-Heat Exchanger System With Different Backfilling MaterialsDocumento5 páginasThermal Performance Analysis of Earth-Air-Pipe-Heat Exchanger System With Different Backfilling MaterialsKamal Kumar AgrawalAinda não há avaliações

- Data Sheet - Jindal Stainless Steelway LimitedDocumento3 páginasData Sheet - Jindal Stainless Steelway LimitedSitaram JhaAinda não há avaliações

- 2002-05-17 WTR Heat CalcsDocumento18 páginas2002-05-17 WTR Heat CalcsBruno AndradeAinda não há avaliações

- Bray Serie 20 - 21 (Ficha Tecnica)Documento4 páginasBray Serie 20 - 21 (Ficha Tecnica)Oscar Horta PolaniaAinda não há avaliações

- 5 Kiln Bearings PDFDocumento60 páginas5 Kiln Bearings PDFBülent BulutAinda não há avaliações

- 0336 338 339op0Documento46 páginas0336 338 339op0romulo110769Ainda não há avaliações

- Seismic Design of RC Structures - SaatciogluDocumento146 páginasSeismic Design of RC Structures - SaatciogluAl MamunAinda não há avaliações

- Asphalt Mixes Properties and Pavement Structure Mechanics: Silvia Cápayová, Ivan Gschwendt, Andrea ZuzulováDocumento11 páginasAsphalt Mixes Properties and Pavement Structure Mechanics: Silvia Cápayová, Ivan Gschwendt, Andrea ZuzulováRed RedAinda não há avaliações

- Superimposed, Reinforced, Built-Up Timber BeamsDocumento16 páginasSuperimposed, Reinforced, Built-Up Timber Beamsmnmusor0% (1)

- Osma Below Ground Installation Guide Od107 Revjan07Documento52 páginasOsma Below Ground Installation Guide Od107 Revjan07VCS1978Ainda não há avaliações